This component is a key part of the exhaust system for a specific model of lawn tractor. It reduces the noise generated by the engine’s combustion process. Its function is to diminish the sound pressure levels emanating from the engine’s exhaust gases, thus providing a more comfortable operating environment. A failing or damaged one can lead to increased noise pollution and potentially affect the machine’s performance.

The functionality of this exhaust component is vital for operator comfort and compliance with noise regulations in many residential areas. Its design often incorporates baffles and chambers that dissipate sound waves. Historically, such components have evolved to become more efficient at noise reduction while minimizing backpressure, which can negatively impact engine performance. A well-functioning component contributes to a quieter and more pleasant lawn mowing experience.

The following sections will discuss the materials used in manufacturing this exhaust component, common issues that may arise, maintenance procedures, and replacement options to ensure continued optimal performance of the lawn tractor.

Maintenance and Longevity Tips

Proper maintenance and timely attention to potential issues can significantly extend the service life and performance of the exhaust component, ensuring a quieter and more efficient operation.

Tip 1: Regular Inspection: Examine the component periodically for signs of rust, corrosion, or physical damage. Early detection allows for timely repairs or replacement, preventing further degradation.

Tip 2: Cleanliness: Keep the area around the exhaust component free of debris, such as grass clippings and leaves. Accumulation of such material can accelerate corrosion and potentially create a fire hazard.

Tip 3: Secure Mounting: Verify that the component is securely mounted to the engine. Loose mountings can cause excessive vibration, leading to cracks and premature failure.

Tip 4: Avoid Harsh Chemicals: When cleaning the lawn tractor, avoid using harsh chemicals near the exhaust component. These chemicals can react with the metal, causing corrosion.

Tip 5: Proper Storage: During off-season storage, ensure the lawn tractor is stored in a dry environment to minimize the risk of rust and corrosion on the exhaust component.

Tip 6: Listen for Unusual Noises: Pay attention to any unusual noises emanating from the exhaust system. Rattling, hissing, or increased noise levels can indicate a problem with the component.

Tip 7: Address Issues Promptly: If any signs of damage or malfunction are detected, address the issues promptly. Ignoring minor problems can lead to more extensive and costly repairs later.

By adhering to these maintenance guidelines, the longevity and performance of this essential exhaust system component can be significantly enhanced, contributing to a quieter and more reliable operation of the lawn tractor.

The subsequent sections will delve into diagnostic procedures for identifying common issues and provide guidance on selecting appropriate replacement components.

1. Noise Reduction

The “Noise Reduction” capability intrinsically links to the function of the exhaust component, which serves as a primary means of minimizing the sound produced by the engine. Its design and condition directly impact the level of noise emitted during operation.

- Internal Baffling and Chamber Design

The internal structure, incorporating baffles and resonating chambers, disrupts and dissipates sound waves. This design directly attenuates noise levels emitted from the exhaust. Poorly designed or damaged internals compromise noise reduction effectiveness.

- Material Composition and Sound Absorption

The materials used in construction, such as specific gauges of steel and sound-absorbing packing, play a significant role in dampening noise. Deterioration or absence of these materials reduces noise reduction performance. For example, the muffler’s sound absorption capabilities can reduce noise levels by approximately 5-10 decibels compared to a straight pipe.

- Structural Integrity and Leak Prevention

A structurally sound component with airtight seals prevents the escape of exhaust gases and associated noise. Cracks, holes, or loose connections significantly increase noise pollution, reducing the effectiveness of noise reduction efforts.

- Compliance with Noise Regulations

Its design and performance are often dictated by local noise ordinances and regulations. A properly functioning component ensures compliance and prevents potential fines or restrictions. Replacing it with a non-compliant alternative can lead to legal repercussions.

These facets highlight the critical role that effective noise reduction plays in the overall performance and acceptability of the tractor’s exhaust system. The proper maintenance and timely replacement of this component ensures continued compliance with noise standards and promotes a more comfortable operating environment.

2. Exhaust System

The exhaust system, a critical assembly in combustion engine machinery, is directly linked to the function and performance of its integral components. Specifically, within the Cub Cadet XT1 lawn tractor, the exhaust component, often referred to as the muffler, is a key element within the larger system. The exhaust system is responsible for safely channeling combustion byproducts away from the engine and operator, while also playing a role in noise reduction and, in some cases, emissions control. The exhaust component contributes directly to these functions by providing a pathway for gases and dampening sound. A failure in any part of the exhaust system, including a compromised exhaust component, can lead to decreased engine efficiency, increased noise levels, and potential safety hazards due to exhaust leaks. For example, a crack in the exhaust component will result in higher than acceptable noise levels and potential exposure to hot exhaust gases.

Effective operation of the exhaust system relies on the integrity of its components and the proper sealing of connections. Any breach in the system can result in a loss of backpressure, which can negatively impact engine performance. The exhaust component also serves as a spark arrestor in some models, preventing the emission of flammable particles that could ignite dry grass or other combustible materials. Furthermore, the material composition and design of the exhaust system, including the exhaust component, influence its ability to withstand the high temperatures and corrosive nature of exhaust gases. Inferior materials or poor design can lead to premature failure and necessitate replacement.

In summary, the exhaust system and its constituent parts, including the central exhaust component, are essential for safe, efficient, and environmentally compliant operation of the Cub Cadet XT1. A well-maintained and properly functioning exhaust system is vital for ensuring operator comfort, meeting noise regulations, and preventing potential hazards associated with combustion byproducts. Understanding the relationship between the exhaust system as a whole and the individual exhaust component is crucial for effective maintenance and repair, leading to increased equipment longevity and performance.

3. Engine Performance

The exhaust component significantly influences engine performance in the Cub Cadet XT1. The component’s design directly impacts backpressure, which is the resistance to exhaust flow. Excessive backpressure reduces engine efficiency, leading to decreased power output and increased fuel consumption. Conversely, insufficient backpressure can negatively affect cylinder scavenging, reducing torque at lower RPMs. A properly functioning exhaust component maintains an optimal balance, ensuring efficient combustion and power delivery. For example, a corroded or clogged component creates excessive backpressure, noticeably diminishing the engine’s ability to perform tasks such as climbing inclines or operating with attachments.

The structural integrity of the exhaust component is also crucial. Leaks in the system, often resulting from cracks or corrosion, disrupt exhaust flow and reduce engine efficiency. Unmetered air entering the exhaust system through leaks can also interfere with the engine’s air-fuel mixture, leading to rough idling, stalling, and decreased overall performance. A real-world scenario illustrating this is an instance where a farmer notices that their lawn tractor is not running as efficiently. After checking the device, they observe cracks in the exhaust component and soot accumulation around the area. This highlights the critical importance of maintaining the exhaust system. Therefore, attention to the exhaust component and related components ensures the delivery of the intended performance.

In summary, the exhaust component plays a vital role in maintaining optimal engine performance. Proper maintenance, regular inspections, and timely replacement of damaged parts are essential for ensuring efficient combustion, power delivery, and overall equipment operation. Failing to address issues with the exhaust component can lead to a decline in engine performance, increased fuel consumption, and potential engine damage, underscoring the practical significance of understanding and maintaining this critical component.

4. Durability

The durability of the exhaust component is paramount to its functional lifespan and the operational efficiency of the lawn tractor. The exhaust component is subjected to extreme operating conditions, including high temperatures, corrosive exhaust gases, and external environmental factors. The material selection and construction methods employed in its manufacture directly influence its ability to withstand these stressors over extended periods. For instance, using thicker gauge steel and employing corrosion-resistant coatings enhance its ability to resist rust and degradation. Premature failure of a non-durable component results in increased noise pollution, reduced engine efficiency, and the need for frequent replacements, leading to increased maintenance costs.

Specific design features further contribute to enhanced durability. Reinforced welds, robust mounting brackets, and strategically placed heat shields mitigate stress concentrations and prevent premature fatigue. The internal baffling and chamber design also plays a role, ensuring that exhaust gases flow smoothly, reducing turbulence and localized hot spots. Regular inspection and cleaning can further extend the lifespan by preventing the accumulation of debris that can accelerate corrosion. A practical example is a comparison between two identical lawn tractors, one with a standard exhaust component and another with an upgraded, more durable version. After several years of use under similar conditions, the standard exhaust component exhibits significant rust and corrosion, while the upgraded version remains in good condition, demonstrating the direct correlation between material quality and longevity.

In summary, the long-term performance and reliability of the exhaust component are intrinsically linked to its inherent durability. Selecting a component constructed from high-quality materials and incorporating robust design features is crucial for minimizing maintenance requirements, reducing operational costs, and ensuring the continued efficient operation of the lawn tractor. Ignoring the importance of durability can lead to a cycle of frequent replacements and increased expenses, highlighting the practical significance of prioritizing quality and longevity in the selection process.

5. Replacement Options

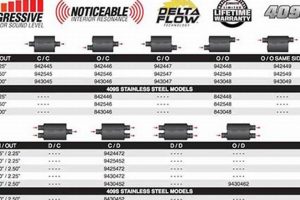

The availability and selection of replacement components are critical for maintaining the functionality and performance of mechanical equipment. For the specific exhaust component in question, a range of replacement options exists, each with distinct characteristics that influence compatibility, performance, and longevity. The decision to select a particular option often involves balancing factors such as cost, availability, and expected service life.

- Original Equipment Manufacturer (OEM) Components

OEM components are produced by the original manufacturer of the lawn tractor. These parts are designed to precisely match the original specifications and performance characteristics of the initial component. While often more expensive than aftermarket options, OEM components offer a high degree of assurance regarding fit, function, and durability. For instance, an OEM exhaust component is typically constructed from materials identical to the original, ensuring comparable resistance to corrosion and heat. Using a certified and well known brand name can make your search more easy and reliable.

- Aftermarket Components

Aftermarket components are produced by manufacturers other than the original equipment manufacturer. These alternatives often offer a cost advantage compared to OEM components. However, the quality and performance of aftermarket options can vary significantly. Some aftermarket manufacturers prioritize cost savings, potentially sacrificing material quality or design accuracy. It is important to exercise caution when selecting aftermarket options, carefully evaluating the manufacturer’s reputation and product specifications.

- Universal Fit Components

Universal fit components are designed to be adaptable to a range of equipment models. While offering flexibility, these options may require modifications to ensure proper fitment and functionality. Using a universal fit option may be necessary if specific replacements cannot be found but often requires a mechanic or someone very familiar with machine repair.

- Used or Refurbished Components

Used or refurbished components can represent a cost-effective alternative. However, the remaining service life and reliability of these options are inherently uncertain. Thorough inspection and verification of condition are essential before considering the use of a used or refurbished component. These also may not be legal in every state.

The choice among these replacement options necessitates a careful assessment of the specific requirements and constraints of the situation. Factors such as budget limitations, the desired level of performance, and the expected service life of the equipment all influence the selection process. Regardless of the chosen option, proper installation and maintenance are essential for ensuring optimal performance and longevity.

Frequently Asked Questions

The following section addresses common inquiries regarding the exhaust component of the Cub Cadet XT1 lawn tractor. These questions are intended to provide clarity on maintenance, troubleshooting, and replacement considerations.

Question 1: What are the primary indicators of a failing exhaust component?

Increased engine noise, visible rust or corrosion, exhaust leaks, and a decrease in engine performance are common indicators. A rattling sound emanating from the exhaust system may also suggest internal damage.

Question 2: How frequently should the exhaust component be inspected?

A visual inspection should be conducted at least once per season, or more frequently if the equipment is used extensively. Detailed inspections, including assessment of structural integrity, should occur annually.

Question 3: Can a damaged exhaust component affect fuel consumption?

Yes. Cracks or leaks in the exhaust system can disrupt engine backpressure, leading to inefficient combustion and increased fuel consumption.

Question 4: What materials are commonly used in the construction of these components?

Steel is the predominant material, often coated with aluminum or other corrosion-resistant substances. Some premium components utilize stainless steel for enhanced durability.

Question 5: Is it possible to repair a damaged exhaust component, or is replacement always necessary?

Minor surface rust can be addressed with rust converters and high-temperature paint. However, significant corrosion, cracks, or structural damage typically necessitate replacement to ensure safe and efficient operation.

Question 6: What factors should be considered when selecting a replacement component?

Compatibility with the specific lawn tractor model, material quality, design, and warranty are essential considerations. OEM components typically offer guaranteed compatibility and performance, while aftermarket options may provide cost savings with varying levels of quality.

Regular maintenance and prompt attention to potential issues are vital for maximizing the lifespan and performance of this critical exhaust system component.

The subsequent section will provide guidance on troubleshooting common problems and selecting the appropriate replacement parts.

Conclusion

The preceding examination of the “cub cadet xt1 muffler” underscores its significance as a critical component within the lawn tractor’s exhaust system. Its proper functioning is paramount for effective noise reduction, optimal engine performance, and long-term equipment durability. Neglecting the maintenance or timely replacement of this component can lead to a cascade of negative consequences, impacting operational efficiency and regulatory compliance.

Therefore, a thorough understanding of the exhaust component’s role, potential failure modes, and available replacement options is essential for responsible equipment ownership. Prioritizing quality, durability, and compatibility during the selection and installation process will ensure continued reliable performance and minimize the risk of costly repairs. A proactive approach to maintenance and a commitment to using appropriate replacement parts will ultimately contribute to a more efficient, quieter, and longer-lasting lawn tractor.