The confluence of reduced audible output and enhanced engine efficiency represents a significant advancement in automotive exhaust technology. This engineering feat allows vehicles to operate with minimal noise pollution while simultaneously optimizing engine performance. Achieving this balance requires sophisticated internal designs that effectively attenuate sound waves without impeding exhaust flow.

The benefits of this technology are multifaceted. Owners experience a more refined driving experience due to the reduced noise level within the cabin. Furthermore, communities benefit from decreased noise pollution, contributing to a more peaceful environment. Historically, compromises had to be made between sound reduction and power output. However, modern designs circumvent this tradeoff, offering both a pleasant driving experience and improved vehicle dynamics.

Subsequent discussion will delve into the specific technologies employed to achieve this delicate equilibrium, examining the materials utilized, the internal configurations that dictate both sound suppression and flow characteristics, and the measurable impact on vehicle performance metrics.

Optimizing for Minimum Sound, Maximum Effect

The following guidance pertains to achieving a balance between reduced exhaust noise and sustained or enhanced vehicle performance.

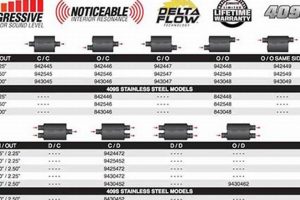

Tip 1: Select the Appropriate Size: Ensure compatibility between the chosen unit’s inlet/outlet diameter and the vehicle’s existing exhaust piping. A mismatch can create bottlenecks or turbulence, negating any potential performance gains.

Tip 2: Prioritize Internal Design: Research internal baffling and chamber designs. Straight-through designs generally offer superior flow, while multi-chamber designs are more effective at sound dampening. The optimal choice depends on the desired balance between noise reduction and exhaust velocity.

Tip 3: Consider Material Composition: Stainless steel offers durability and corrosion resistance, crucial for longevity. Aluminized steel provides a more cost-effective alternative, but may not withstand harsh environmental conditions as effectively.

Tip 4: Professional Installation is Recommended: Proper welding and sealing are essential to prevent leaks, which can compromise both noise reduction and performance. Professional installation ensures adherence to manufacturer specifications and optimal system integration.

Tip 5: Consult Vehicle-Specific Reviews: Online forums and product reviews often provide valuable insights into the real-world performance and sound characteristics of specific models when installed on comparable vehicles.

Tip 6: Verify Compliance with Local Regulations: Ensure that the chosen exhaust component adheres to local noise ordinances and emissions standards to avoid legal complications.

By carefully considering these factors, vehicle owners can make informed decisions that enhance driving comfort and maintain or improve engine performance, all while minimizing audible output.

This information sets the stage for a more in-depth exploration of specific product categories and their suitability for various automotive applications.

1. Sound attenuation technology

The efficacy of a “quietest performance muffler” is intrinsically linked to its sound attenuation technology. This technology, encompassing a range of design principles and material applications, directly governs the degree to which exhaust noise is reduced without impeding the flow of exhaust gases. In essence, sound attenuation serves as the primary determinant of a performance muffler’s ability to minimize noise pollution while simultaneously maintaining or enhancing engine performance. Without effective attenuation strategies, the device would fail to meet the critical requirement of reduced sound levels, rendering the “quietest” descriptor inaccurate.

Examples of sound attenuation techniques include the use of strategically placed baffles, resonance chambers, and sound-absorbing materials. Baffles redirect sound waves, causing them to collide and cancel each other out. Resonance chambers are designed to trap and dissipate specific frequencies, reducing overall noise levels. Sound-absorbing materials, such as fiberglass or specialized packing, convert acoustic energy into heat, further diminishing sound transmission. The selection and implementation of these techniques are paramount in achieving optimal sound reduction. For example, a straight-through design utilizing perforated tubes wrapped in sound-deadening material allows for efficient exhaust flow, but provides limited sound attenuation compared to a multi-chambered design. The proper selection relies on the targeted dB reduction and tolerable performance impact.

In conclusion, sound attenuation technology is the cornerstone of any system aiming to minimize sound output and maintaining performance metrics. Its effectiveness is the defining characteristic of a muffler’s success. Understanding the principles of sound attenuation is crucial for consumers and automotive engineers seeking to achieve a harmonious balance between noise reduction and optimal engine operation. It should be noted, that improperly implemented attenuation can have deleterious effects on both sound and performance.

2. Exhaust flow optimization

Exhaust flow optimization is a critical parameter in the design and performance of a “quietest performance muffler.” It directly impacts engine efficiency, power output, and the effectiveness of sound attenuation strategies. Balancing these factors is a complex engineering challenge.

- Backpressure Management

Excessive backpressure impedes exhaust gas expulsion from the engine cylinders, reducing volumetric efficiency and power. Optimization minimizes backpressure through strategic pipe diameter, smooth bends, and carefully designed internal baffling. A “quietest performance muffler” must mitigate sound without creating undue restriction. For example, a straight-through perforated core design offers low backpressure but requires substantial sound-deadening material to achieve the required noise reduction.

- Velocity Maintenance

Maintaining adequate exhaust gas velocity is essential for scavengingthe process of drawing out exhaust gases and facilitating fresh air intake. Insufficient velocity can lead to exhaust reversion, contaminating the intake charge and reducing engine performance. Optimization involves selecting appropriate pipe diameters and minimizing flow disruptions. A well-designed “quietest performance muffler” will balance sound attenuation with the need to maintain optimal gas velocity, potentially utilizing venturi effects or carefully shaped diffuser cones.

- Turbulence Reduction

Turbulence within the exhaust system creates resistance and generates noise. Optimization techniques include smooth transitions between pipe sections, the use of mandrel-bent tubing, and carefully designed internal components. A “quietest performance muffler” incorporates features that minimize turbulence while redirecting and attenuating sound waves. For instance, a series of strategically placed baffles, each with radiused edges, can reduce turbulence compared to sharp-edged obstructions.

- Scavenging Enhancement

Optimizing exhaust flow can enhance scavenging, improving cylinder filling and increasing engine torque, especially at lower RPMs. This requires careful consideration of exhaust manifold design, pipe length, and the overall exhaust system layout. A “quietest performance muffler,” when integrated into a well-designed system, can contribute to improved scavenging by minimizing backpressure and promoting efficient exhaust gas extraction. This may involve incorporating tuned resonators or strategically sized expansion chambers.

The interplay between these facets underscores the importance of a holistic approach to exhaust system design. A “quietest performance muffler” is not merely a noise-reduction device; it is an integral component of a carefully engineered system designed to optimize engine performance while minimizing undesirable audible output. The successful integration requires a sophisticated understanding of fluid dynamics, acoustics, and engine performance characteristics.

3. Material durability

Material durability directly impacts the longevity and consistent performance of a “quietest performance muffler.” The exhaust system operates in a harsh environment, subject to high temperatures, corrosive gases, road debris, and vibration. The selection of robust materials is therefore paramount to ensuring the muffler maintains its structural integrity and acoustic properties over time. Premature failure due to corrosion, cracking, or weld fatigue will not only necessitate replacement but also compromise the muffler’s ability to effectively reduce noise and maintain performance.

Stainless steel, particularly grades 304 and 409, is a common material choice for performance mufflers due to its corrosion resistance and high-temperature strength. Aluminized steel presents a more cost-effective alternative but offers inferior corrosion protection, particularly in regions with heavy road salt usage. The internal components, such as baffles and sound-absorbing materials, also require careful material selection. For instance, fiberglass packing, while effective at sound attenuation, can degrade over time due to heat and moisture exposure, leading to a gradual increase in exhaust noise. High-temperature ceramic packing offers improved durability in such applications. The gauge (thickness) of the metal also contributes to durability. Thicker gauge materials resist denting from road debris and are less prone to cracking under stress.

In summary, material durability is a foundational aspect of a “quietest performance muffler.” The selection of appropriate materials directly correlates with the product’s lifespan, reliability, and sustained acoustic performance. Compromising on material quality to reduce costs can lead to premature failure, increased noise levels, and the need for frequent replacements. Therefore, discerning consumers should prioritize mufflers constructed from high-quality, durable materials to ensure long-term value and satisfaction. Ultimately, considering these factors promotes informed decisions.

4. Internal chamber design

The effectiveness of a “quietest performance muffler” is fundamentally dependent upon its internal chamber design. The geometry, size, and arrangement of these chambers dictate the degree to which sound waves are attenuated before exiting the exhaust system. Various designs exist, each employing different principles of acoustic interference and absorption. The resulting sound reduction is a direct consequence of these internal configurations.

A multi-chamber design, for instance, utilizes a series of interconnected chambers of varying volumes and shapes. As exhaust gases and accompanying sound waves pass through these chambers, specific frequencies are reflected, diffracted, and absorbed. The design is such that destructive interference occurs, canceling out certain frequencies and reducing overall noise levels. In contrast, a straight-through design, while often promoting better exhaust flow, typically offers less sound attenuation unless combined with other noise-reduction techniques such as sound-absorbing packing materials. The placement and size of perforations within the core of a straight-through muffler influence both the sound characteristics and the exhaust flow dynamics. The practical significance lies in the trade-off between noise reduction and performance; an improperly designed internal chamber can restrict exhaust flow, negating any performance gains associated with the “performance” aspect of the muffler.

Understanding the nuances of internal chamber design is crucial for selecting an appropriate “quietest performance muffler.” It is important to consider the specific needs of the vehicle, the desired sound characteristics, and the potential impact on performance. Ultimately, the success of a “quietest performance muffler” hinges on a well-engineered internal design that effectively balances noise reduction with exhaust flow optimization. A system must take into account vehicle engine type, desired performance, and legal and regulatory compliance.

5. Vehicle-specific compatibility

The successful integration of a “quietest performance muffler” hinges significantly on vehicle-specific compatibility. Optimal performance and sound reduction can only be achieved when the muffler’s design characteristics align precisely with the vehicle’s exhaust system parameters. Mismatched components can lead to performance degradation and ineffective sound attenuation.

- Engine Displacement and Configuration

Muffler design must account for engine displacement and configuration (e.g., inline, V-configuration). A muffler designed for a small displacement engine may create excessive backpressure on a larger engine, hindering performance. Conversely, a muffler designed for a large engine may not provide sufficient sound attenuation on a smaller engine. Careful consideration of the manufacturer’s specifications regarding compatible engine sizes and configurations is crucial.

- Exhaust System Diameter and Routing

The inlet and outlet diameters of the muffler must match the existing exhaust piping for a seamless connection. Mismatched diameters can create turbulence and restrict exhaust flow. Furthermore, the muffler’s physical dimensions must be compatible with the vehicle’s undercarriage, ensuring proper fitment and clearance. Incorrect routing or contact with other vehicle components can cause damage and compromise performance.

- Mounting Point Compatibility

The muffler’s mounting points must align with the vehicle’s existing exhaust hangers. Modifying mounting points can be complex and may compromise the structural integrity of the exhaust system. Incompatible mounting points can lead to vibration, noise, and premature failure of the muffler or exhaust hangers. Using adapters may be acceptable but introduces additional complexity and potential points of failure.

- Emissions Control System Integration

The “quietest performance muffler” must be compatible with the vehicle’s emissions control system, including catalytic converters and oxygen sensors. Modifications that interfere with the emissions control system can result in increased emissions and potential legal repercussions. In some cases, modifications may trigger a check engine light or other diagnostic warnings.

Consideration of these elements of vehicle-specific compatibility is essential for ensuring the “quietest performance muffler” delivers intended benefits, without adverse impact to the vehicle. A detailed understanding of design elements will help maximize the benefit.

6. Regulatory compliance

The intersection of “regulatory compliance” and the implementation of a “quietest performance muffler” is paramount. Noise regulations, enforced at various levels (local, state, federal), directly dictate permissible decibel levels for vehicle exhaust systems. The selection and installation of such a muffler must adhere to these standards to avoid legal penalties, which can range from fines to vehicle impoundment. A “quietest performance muffler” that fails to meet the established noise limits is, in effect, non-compliant, negating its intended purpose and potentially rendering the vehicle illegal for operation on public roads. Therefore, before any purchase or modification, a thorough understanding of applicable noise regulations is mandatory. Furthermore, aftermarket components cannot compromise emissions standards and remain road legal.

Several examples illustrate the practical significance of this understanding. In many European countries, strict noise emission standards are enforced through vehicle inspections and roadside checks. Similarly, certain municipalities in the United States have enacted ordinances that specifically target excessively loud vehicles. The effectiveness of a “quietest performance muffler” in meeting these requirements is a key factor in determining its legality. For instance, a muffler boasting significant sound reduction capabilities may still be deemed non-compliant if it alters the vehicle’s emissions control system in a manner that violates federal or state regulations. This often is caused by an increase of the back pressure.

In conclusion, “regulatory compliance” forms a non-negotiable prerequisite for the selection and use of any “quietest performance muffler.” Failure to adhere to these regulations can have serious legal and financial consequences. Therefore, manufacturers, installers, and vehicle owners must prioritize compliance by ensuring that the chosen muffler meets all applicable noise and emissions standards. This involves verifying the muffler’s sound reduction capabilities, confirming its compatibility with the vehicle’s emissions control system, and adhering to all local, state, and federal regulations governing vehicle modifications. Neglecting regulatory compliance undermines the intended benefits of a “quietest performance muffler” and risks severe penalties.

7. Installation precision

Installation precision is a crucial determinant of the success and longevity of any “quietest performance muffler.” Even the most meticulously engineered and materially superior muffler will fail to deliver its intended benefits if improperly installed. Imprecise installation can compromise noise reduction capabilities, diminish performance enhancements, and accelerate the degradation of the exhaust system. The connection between the muffler’s design and its real-world performance hinges on the installer’s adherence to proper techniques and specifications. Real-life examples abound: a muffler with misaligned connections can create exhaust leaks, negating its noise-dampening properties and potentially allowing harmful gases to enter the passenger cabin. Improper welding can lead to premature failure due to stress concentrations and corrosion.

Further, installation impacts performance. Over-tightening clamps can distort the exhaust piping, creating flow restrictions and increasing backpressure. Conversely, insufficiently tightened clamps can lead to leaks and vibration, ultimately causing premature component failure. The correct positioning of the muffler within the exhaust system is also critical. In some applications, specific mounting orientations are required to ensure optimal sound wave attenuation and prevent contact with other vehicle components. Deviating from these specifications can result in reduced noise reduction or even damage to the vehicle. When aftermarket components are used, care should be taken to match the overall design. Some modifications, for example, should only be installed with specific engine tuning.

In summary, achieving the full potential of a “quietest performance muffler” necessitates meticulous attention to installation details. Correct welding techniques, precise alignment, proper torque specifications, and adherence to manufacturer instructions are essential. Improper install can result in diminished noise reduction, compromised performance, accelerated component wear, and potential safety hazards. The financial and operational advantages of a high-quality muffler are realized only through proper implementation. Therefore, either use a highly skilled installer or have full comprehension of the required knowledge.

Frequently Asked Questions

This section addresses common inquiries and misconceptions concerning sound-reducing performance mufflers, providing objective information to aid informed decision-making.

Question 1: Does the phrase “quietest performance muffler” imply a contradiction in terms?

No. Modern designs achieve a balance between exhaust flow optimization and sound attenuation. Sophisticated internal baffling and resonance chambers are employed to reduce noise without significantly restricting exhaust flow.

Question 2: How does the “quietest performance muffler” compare to the factory-installed muffler in terms of sound reduction?

The degree of sound reduction varies depending on the specific model and vehicle. Generally, these models aim to reduce specific frequencies known to cause road noise or in-cabin noise, while maintaining performance.

Question 3: Will installing a “quietest performance muffler” void the vehicle’s warranty?

Installation of an aftermarket part will not automatically void the warranty unless it is demonstrated that the part caused a specific failure. Consult the vehicle’s warranty documentation and relevant consumer protection laws for clarification. Installation by a certified mechanic can mitigate potential warranty concerns.

Question 4: What materials are typically used in the construction of a “quietest performance muffler,” and how do they affect durability?

Stainless steel (grades 304 and 409) and aluminized steel are common materials. Stainless steel offers superior corrosion resistance and longevity, while aluminized steel is more cost-effective but less durable. The gauge (thickness) of the material also affects resistance to damage.

Question 5: How does internal chamber design influence both sound reduction and exhaust flow?

Multi-chamber designs typically offer greater sound reduction through acoustic interference and absorption, but may introduce more flow restriction. Straight-through designs prioritize exhaust flow but require supplemental sound-deadening materials. Hybrid designs seek to balance these competing factors.

Question 6: Is professional installation recommended for a “quietest performance muffler”?

Professional installation is strongly recommended to ensure proper fitment, secure connections, and compliance with local regulations. Improper installation can compromise sound reduction, performance, and the structural integrity of the exhaust system.

These FAQs provide a baseline understanding of features, benefits and installation tips of sound-reducing performance mufflers. The product details should be considered carefully for the best results.

Subsequent sections will examine purchasing recommendations, providing insights into popular product models and purchasing considerations.

The Intersection of Quiet and Performance

This exploration has elucidated the core attributes of a “quietest performance muffler,” emphasizing the intricate interplay between noise reduction technologies, exhaust flow optimization, material science, and regulatory mandates. The analysis has underscored the importance of selecting a muffler that balances these competing demands, ensuring compliance, durability, and optimal vehicle performance.

As automotive engineering advances, expect continued refinements in exhaust technology. Future designs will likely further minimize noise pollution while maximizing engine efficiency. The informed consumer, equipped with a comprehensive understanding of these principles, stands to benefit most from these innovations, achieving a refined driving experience without compromising performance or environmental responsibility. Ongoing research into advanced materials and design configurations will inevitably lead to systems that surpass current capabilities, driving the evolution of vehicular performance and environmental harmony.