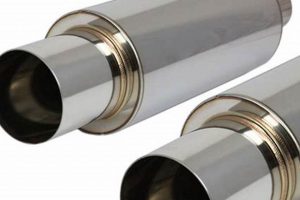

An automotive component designed to optimize engine output while mitigating exhaust noise is the central focus. This device, often a replacement for factory-installed systems, aims to improve vehicle responsiveness and overall horsepower. Its functionality relies on altering the flow of exhaust gases, reducing backpressure and increasing engine efficiency.

Such an enhancement can provide a more aggressive exhaust note and a noticeable improvement in acceleration. Historically, these systems have been popular among automotive enthusiasts seeking to personalize their vehicles and gain a competitive edge. The benefits can extend to fuel efficiency, depending on the specific design and vehicle application.

The following sections will delve into specific features, installation considerations, and expected performance gains associated with aftermarket exhaust modifications. Further analysis will consider materials, construction techniques, and the potential impact on emissions compliance.

Enhancing Vehicle Performance

The following points highlight crucial aspects of optimizing exhaust systems for improved vehicle function and output.

Tip 1: Material Selection: Opt for stainless steel construction. Stainless steel offers superior corrosion resistance compared to aluminized steel, ensuring longevity and preventing premature degradation in harsh environments. This is especially pertinent in regions with frequent exposure to road salt.

Tip 2: Diameter Optimization: Match the exhaust pipe diameter to engine specifications. An excessively large diameter can reduce exhaust velocity, negating any potential performance gains. Consult with a qualified technician to determine the optimal size for a specific vehicle and engine configuration.

Tip 3: Welding Integrity: Ensure welds are professionally executed. Weak or incomplete welds are a common failure point in exhaust systems. Prioritize systems constructed with TIG welding, known for its strength and precision.

Tip 4: Proper Installation: Employ a certified mechanic for installation. Incorrect installation can lead to exhaust leaks, reduced performance, and potential damage to other vehicle components. Professional installation ensures correct alignment and sealing.

Tip 5: Emission Compliance: Verify compliance with local emission regulations. Modifications that bypass or alter catalytic converters may be illegal and can result in fines. Confirm that the selected system is compliant with applicable environmental standards before purchase and installation.

Tip 6: Sound Level Consideration: Consider the sound output level. Aggressive systems may exceed noise restrictions in certain areas. Research and select a system that balances performance enhancement with acceptable sound levels for the intended environment.

Proper implementation of these considerations can yield tangible improvements in engine performance and overall vehicle operation.

The subsequent section will address common misconceptions and potential drawbacks associated with aftermarket exhaust modifications.

1. Flow Optimization

Flow optimization, within the context of aftermarket exhaust systems, refers to the strategic design and engineering of internal pathways to minimize backpressure and maximize exhaust gas velocity. Its implementation directly impacts engine efficiency and power output. Improved flow contributes to a more complete combustion cycle, resulting in increased horsepower and torque.

- Mandrel Bending

Mandrel bending is a technique used to create exhaust pipes with consistent diameter throughout bends. Unlike crush bending, which reduces pipe diameter at the bend, mandrel bending maintains the original size and shape. This uninterrupted flow reduces turbulence and backpressure, contributing to improved engine performance.

- Collector Design

The collector is the point where exhaust gases from multiple engine cylinders converge. Optimized collector designs prioritize smooth merging of exhaust streams. Tri-Y headers, for example, pair cylinders with firing orders that alternate, promoting scavenging and enhancing exhaust gas velocity. Effective collector design minimizes turbulence and backpressure.

- Internal Surface Finish

The smoothness of the internal surface of exhaust components directly affects flow efficiency. Rough surfaces create friction and turbulence, impeding exhaust gas velocity. Polished or coated surfaces reduce friction, allowing exhaust gases to flow more freely. This minimizes backpressure and enhances engine performance.

- Pipe Diameter Sizing

Selecting the appropriate pipe diameter is crucial for flow optimization. Oversized pipes can reduce exhaust velocity, while undersized pipes create excessive backpressure. The ideal diameter is determined by engine displacement, horsepower goals, and operating RPM range. Precise sizing ensures optimal exhaust gas velocity and efficient scavenging.

These facets of flow optimization directly influence the performance characteristics of exhaust systems. Their implementation contributes to improved engine responsiveness, increased power output, and enhanced fuel efficiency. The specific design and materials employed in each aspect play a crucial role in the overall effectiveness of the system.

2. Sound Modulation

Sound modulation within the context of performance exhaust systems denotes the deliberate shaping and control of exhaust noise characteristics. The focus is to balance performance gains with acceptable sound levels, catering to both regulatory compliance and driver preference. This manipulation encompasses frequency, amplitude, and overall tone.

- Muffler Core Design

The internal construction of the muffler core plays a critical role in determining the resulting sound profile. Straight-through designs prioritize minimal flow restriction, resulting in a louder and more aggressive tone. Chambered designs utilize strategically placed baffles to cancel out specific frequencies, producing a deeper and more controlled sound. The choice of core design is paramount in tailoring the exhaust note to desired characteristics.

- Resonator Integration

Resonators are supplementary components within the exhaust system designed to further refine the sound. These devices function as tuned acoustic chambers, effectively dampening unwanted frequencies and enhancing desirable tones. Resonator placement and size are carefully calculated to achieve the intended sound modulation. Often, resonators are paired with specific muffler designs to create a balanced acoustic profile.

- Sound Absorption Materials

The use of sound-absorbing materials, such as fiberglass packing or steel wool, within the muffler core can significantly influence the exhaust note. These materials absorb and dissipate sound waves, reducing the overall volume and softening harsh tones. The type and quantity of packing material affect the longevity of the muffler’s sound characteristics, as packing degradation can lead to increased noise levels over time.

- Valve Control Systems

Advanced exhaust systems may incorporate electronically controlled valves that allow for dynamic sound modulation. These valves can be programmed to open or close based on engine speed, throttle position, or driver input. When closed, the valves restrict exhaust flow, producing a quieter sound for cruising. When open, the valves bypass the muffler, unleashing a more aggressive and performance-oriented exhaust note. This provides versatility in sound control.

The careful consideration and implementation of these sound modulation techniques are integral to the design of a performance exhaust system. The goal is to create an exhaust note that enhances the driving experience without compromising regulatory standards or generating excessive noise pollution. The success of sound modulation is contingent on a precise understanding of acoustic principles and engineering expertise.

3. Material Durability

Material durability, when applied to performance exhaust systems, is not merely a matter of longevity but a critical determinant of sustained performance and reliability. The selection of materials and their inherent resistance to degradation directly impacts the operational lifespan and effectiveness of components, especially within the harsh environment of an exhaust system.

- Corrosion Resistance

The exhaust system is exposed to extreme temperature fluctuations and corrosive elements, including road salt, moisture, and acidic combustion byproducts. The material’s ability to resist corrosion is paramount. Stainless steel, particularly grades like 304 or 316, exhibits superior corrosion resistance compared to aluminized steel, preventing premature failure and maintaining structural integrity. The application of coatings, such as ceramic-based formulations, can further enhance corrosion protection, particularly in high-stress areas.

- Thermal Stability

Exhaust components endure significant temperature variations, ranging from ambient conditions to several hundred degrees Celsius during operation. Material stability under these thermal stresses is crucial. High-quality materials maintain their mechanical properties and resist deformation or cracking when subjected to repeated heating and cooling cycles. This prevents leaks, ensures proper fitment, and preserves the intended performance characteristics of the system.

- Weld Integrity

Welds represent critical junctures within the exhaust system, often subjected to high stress and thermal cycling. The weld material and technique must ensure robust, durable joints. TIG welding, known for its precision and strength, is commonly employed in high-performance applications. Proper weld penetration and filler metal selection are essential to prevent weld cracking or failure, ensuring the system remains structurally sound over its service life.

- Mechanical Strength

The exhaust system is vulnerable to physical impacts from road debris and vibration-induced stress. Material with high tensile strength and resistance to fatigue is necessary to withstand these forces. Thicker gauge materials and strategically placed reinforcements enhance the system’s ability to withstand mechanical stresses. This prevents dents, cracks, and other forms of damage that can compromise performance and lead to premature failure.

Therefore, material selection is inextricably linked to the overall effectiveness and longevity of an exhaust system. Employing materials with superior corrosion resistance, thermal stability, weld integrity, and mechanical strength translates directly into a system that provides sustained performance, minimizes maintenance requirements, and delivers long-term value. The choice of material directly affects performance and sound.

4. Engine Compatibility

Engine compatibility constitutes a critical determinant in the selection and performance of aftermarket exhaust systems. A mismatch between exhaust system design and engine characteristics can negate potential performance gains and, in certain cases, induce detrimental effects on engine operation. The internal dimensions, exhaust flow characteristics, and backpressure profiles of a performance muffler must align with the engine’s displacement, power output, and operating RPM range to ensure optimal functionality. A high-performance muffler engineered for a small-displacement engine, for instance, could prove restrictive on a larger, more powerful engine, limiting its ability to exhale efficiently. Conversely, an exhaust system designed for a high-output engine may create insufficient backpressure on a smaller engine, leading to reduced low-end torque.

The specific design parameters of a high-performance muffler must correlate with the engine’s exhaust gas volume and velocity. Exhaust systems that generate excessive backpressure can impede the engine’s ability to expel exhaust gases effectively, resulting in decreased horsepower and fuel efficiency. Insufficient backpressure, conversely, can compromise cylinder scavenging, reducing torque output at lower engine speeds. The precise diameter of the exhaust piping, the internal structure of the muffler, and the characteristics of any resonators incorporated within the system must be carefully matched to the engine’s specific requirements. For example, a turbocharged engine typically necessitates an exhaust system with lower backpressure than a naturally aspirated engine of similar displacement, due to the turbocharger’s inherent exhaust flow restriction. Furthermore, electronic engine management systems often rely on specific exhaust backpressure readings to optimize fuel delivery and ignition timing. An improperly matched exhaust system can disrupt these readings, leading to suboptimal engine performance and potentially triggering diagnostic trouble codes.

In summary, engine compatibility is an indispensable consideration in the selection of high-performance exhaust systems. Correctly matching the exhaust system to the engine’s specifications ensures that potential performance benefits are realized without compromising engine operation or triggering diagnostic issues. Understanding the interplay between engine characteristics and exhaust system design is essential for achieving optimal performance and maximizing the longevity of the engine and exhaust components. Failure to properly match these components can result in both immediate and long-term operational consequences.

5. Installation Precision

Installation precision is paramount to realizing the intended performance and longevity of an aftermarket exhaust system. Deviations from prescribed installation procedures can undermine the carefully engineered flow dynamics and structural integrity of the component, resulting in diminished performance and potential mechanical issues. Correct installation requires adherence to specific torque specifications, precise alignment, and proper sealing techniques.

- Flange Alignment and Sealing

Proper alignment of exhaust flanges is crucial to prevent exhaust leaks, which can diminish engine performance, compromise fuel efficiency, and introduce harmful emissions into the passenger compartment. Precise alignment ensures a uniform clamping force across the gasket, creating a leak-proof seal. Using new, high-quality gaskets and applying anti-seize compound to fastener threads are essential for achieving a reliable seal. Failure to correctly align flanges can lead to warping and premature gasket failure.

- Hanger Placement and Support

The proper placement and support of exhaust hangers are vital to prevent stress fractures and premature failure of the exhaust system. Hangers must be positioned to distribute the weight of the exhaust system evenly and minimize vibration. Using OE-style or upgraded hangers constructed from durable materials is essential. Improper hanger placement can induce stress on welds and joints, leading to cracks and leaks. Moreover, inadequate support can cause the exhaust system to contact the vehicle’s undercarriage, generating unwanted noise and potential damage.

- Torque Specification Adherence

Adhering to specified torque values for all fasteners is critical to prevent over-tightening or under-tightening, both of which can compromise the integrity of the exhaust system. Over-tightening can strip threads or distort flanges, while under-tightening can result in leaks and loosening of components over time. Using a calibrated torque wrench and following manufacturer-specified torque values are essential for ensuring proper fastener tension. Applying thread-locking compound to fasteners can further enhance their resistance to loosening under vibration.

- Clearance and Heat Shielding

Maintaining adequate clearance between the exhaust system and surrounding vehicle components, such as fuel lines, brake lines, and wiring harnesses, is necessary to prevent heat damage and potential fire hazards. Heat shields are often employed to deflect heat away from sensitive components. Ensuring proper clearance and heat shielding is particularly important in areas where the exhaust system runs close to the vehicle’s chassis or other heat-sensitive components. Failure to provide adequate clearance can lead to melting, cracking, or other forms of heat-related damage.

The interplay between installation precision and the performance and durability of an aftermarket system is undeniable. Correctly installed systems deliver the intended performance gains, minimize the risk of mechanical issues, and ensure compliance with emissions regulations. In contrast, improperly installed systems can compromise performance, introduce safety hazards, and shorten the lifespan of the component.

Frequently Asked Questions

This section addresses common inquiries regarding aftermarket performance muffler systems. The information provided aims to clarify misconceptions and offer a comprehensive understanding of these components.

Question 1: What constitutes a “performance” muffler?

A performance muffler is an aftermarket exhaust component engineered to reduce backpressure and enhance exhaust flow relative to a stock muffler. This typically translates to increased horsepower and torque, often accompanied by a modified exhaust note. Internal designs commonly prioritize straight-through flow or utilize chambered configurations optimized for performance.

Question 2: Does a performance muffler void the vehicle’s warranty?

The impact on warranty coverage depends on the specific warranty terms and applicable legislation. While installing an aftermarket muffler generally does not automatically void the entire vehicle warranty, any damage directly attributable to the muffler or its installation may not be covered. Consult the vehicle manufacturer’s warranty policy or a qualified legal professional for definitive guidance.

Question 3: What is the typical lifespan of a performance muffler?

The lifespan of a performance muffler varies based on the materials used, the operating environment, and the quality of construction. Stainless steel mufflers generally offer greater longevity than aluminized steel mufflers due to their superior corrosion resistance. Proper maintenance, such as regular inspections and cleaning, can extend the lifespan of any muffler.

Question 4: How does a performance muffler affect fuel economy?

The effect on fuel economy can be variable. In some cases, a performance muffler can improve fuel economy by reducing backpressure and enhancing engine efficiency. However, aggressive driving styles and significant modifications to the exhaust system can negate any potential fuel economy gains. Consistent driving habits and proper tuning are necessary to maximize fuel efficiency.

Question 5: Are performance mufflers street legal?

Street legality depends on local regulations regarding noise levels and emissions. Some performance mufflers are designed to comply with noise restrictions, while others produce a louder exhaust note that may violate local ordinances. Furthermore, altering or removing catalytic converters is typically illegal and can result in fines. Verify compliance with all applicable regulations before installing a performance muffler.

Question 6: Can a performance muffler be installed on any vehicle?

While universal-fit mufflers exist, optimal performance and proper fitment are best achieved with mufflers specifically designed for the vehicle’s make, model, and year. Incorrect fitment can lead to exhaust leaks, reduced performance, and potential damage to other vehicle components. Consult with a qualified technician to determine the appropriate muffler for a specific vehicle.

In essence, selecting and installing a performance muffler involves careful consideration of various factors, including warranty implications, lifespan, fuel economy effects, legal compliance, and vehicle compatibility. A well-informed decision ensures optimal performance and avoids potential complications.

The subsequent section will address the comparative advantages of various performance muffler designs and materials.

Concluding Remarks

This exploration has presented an overview of aftermarket exhaust components and specifically defined by “dan’s performance muffler”. The analysis encompassed design elements, material considerations, installation parameters, and the implications for vehicle performance, sound modulation, and legal compliance. Emphasis was placed on understanding the technical aspects that determine effectiveness and durability of such systems.

The application of this knowledge represents a crucial step for automotive professionals and vehicle owners seeking to optimize exhaust systems. Proper evaluation and implementation can yield tangible benefits in performance and driving experience, as well as regulatory and environmental responsibility.

![Sheldon's Custom Muffler: Performance & Sound [Shop Now] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Sheldon's Custom Muffler: Performance & Sound [Shop Now] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/02/th-208-300x200.jpg)