A system employing two silencing devices to reduce engine exhaust noise is frequently implemented in vehicles. This setup involves dividing the exhaust flow, routing it through two separate mufflers before expulsion into the atmosphere. Such configurations are often found in performance or larger displacement engines.

The advantages of using this type of system include potentially reduced backpressure, which can lead to improved engine efficiency and power output. Furthermore, it offers opportunities for tailoring the exhaust note, providing a more aggressive or refined sound profile depending on the design. Historically, its adoption has been driven by the need to manage increased noise levels associated with high-performance engines.

The following sections will delve deeper into the specific design considerations, performance characteristics, and maintenance aspects of these exhaust systems, examining their role in optimizing vehicle performance and meeting regulatory noise standards.

Considerations for Implementing a System with Two Silencers

The integration of a system employing two silencers requires careful consideration of several factors to ensure optimal performance, longevity, and compliance with regulatory standards. These guidelines offer insight into best practices for design, installation, and maintenance.

Tip 1: Evaluate Engine Exhaust Volume and Flow Rate: Accurately assessing the engine’s exhaust characteristics is paramount. Insufficient muffler capacity may lead to pressure buildup, diminishing performance. Conversely, excessive capacity may not effectively attenuate noise.

Tip 2: Optimize Pipe Diameter and Routing: The diameter and routing of exhaust pipes preceding and following the silencers must minimize backpressure while maintaining adequate exhaust velocity. Mandrel bends are preferable to crush bends, which restrict flow.

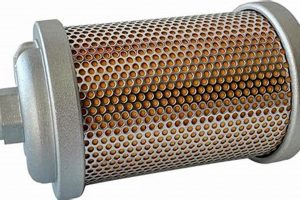

Tip 3: Select Silencers with Appropriate Acoustic Properties: Different silencer designs offer varying levels of sound attenuation and tonal qualities. Chambered, baffled, and absorption-type silencers should be considered based on the desired sound profile and performance requirements.

Tip 4: Ensure Proper Mounting and Isolation: Secure mounting hardware and vibration isolators are essential to prevent stress fractures and premature failure due to engine vibration. Rubber or polyurethane hangers are commonly used for this purpose.

Tip 5: Inspect for Leaks and Corrosion: Regularly inspect the exhaust system for leaks, particularly at joints and welds. Address any signs of corrosion promptly to prevent structural degradation and maintain optimal performance.

Tip 6: Verify Compliance with Noise Regulations: Ensure that the system complies with all applicable noise regulations in the relevant jurisdiction. Sound level testing may be required to confirm compliance.

Tip 7: Consider Material Selection for Longevity: Selecting materials like stainless steel or aluminized steel can significantly extend the system’s lifespan, especially in environments prone to corrosion.

Adhering to these considerations will result in a properly functioning exhaust system that delivers performance benefits, manages noise levels effectively, and ensures long-term reliability.

The following sections will explore detailed case studies and advanced design techniques related to these systems, providing further insight into their application and optimization.

1. Reduced Backpressure

Reduced backpressure is a significant performance objective often associated with the implementation of a system employing two silencers. The efficiency with which an engine expels exhaust gases directly influences its power output and fuel economy. This configuration aims to minimize resistance to exhaust flow, thereby enhancing engine breathing and overall efficiency.

- Enhanced Scavenging Efficiency

The division of exhaust flow into two separate paths, each leading to its own silencer, can lead to improved scavenging efficiency. This occurs when the reduced resistance allows for a more complete clearing of combustion gases from the cylinders, creating space for a more substantial intake charge. A more thorough scavenging process contributes to increased volumetric efficiency and, consequently, more power.

- Optimized Exhaust Gas Velocity

The design of the exhaust piping and silencers must balance the need for reduced backpressure with the maintenance of adequate exhaust gas velocity. Insufficient velocity can lead to the formation of exhaust gas reversion, where spent gases flow back into the cylinders, diluting the intake charge. Systems are designed to optimize both flow rate and velocity, maximizing performance gains.

- Minimization of Pumping Losses

Engine operation involves overcoming the pressure within the exhaust system to expel combustion gases. By reducing backpressure, less energy is required for this expulsion process, thereby minimizing pumping losses. This translates to increased net power output, as the engine is expending less energy on exhausting its spent gases.

- Impact on Engine Tuning

The reduction in backpressure influences the overall engine tuning. Changes to the exhaust system necessitate adjustments to fuel and ignition maps to optimize performance and prevent potential issues such as lean conditions. A properly tuned engine, in conjunction with a low-backpressure exhaust, can deliver significant performance improvements.

The cumulative effect of these factors highlights the significance of reduced backpressure within the context of systems incorporating two silencers. By optimizing exhaust flow dynamics, these systems contribute to enhanced engine efficiency, increased power output, and improved overall performance.

2. Sound Customization

The capacity to manipulate the auditory characteristics of a vehicle’s exhaust note represents a significant aspect of aftermarket exhaust system design. Utilizing a dual muffler configuration provides engineers and enthusiasts with heightened degrees of control over the sound produced, enabling them to tailor the exhaust acoustics to meet specific performance and aesthetic preferences.

- Muffler Type Variation

The selection of distinct muffler designs within a dual system provides a direct method for shaping the exhaust sound. Different internal configurations, such as chambered, baffled, or absorption-type mufflers, produce varying sound profiles. A combination of these types can achieve a unique tonal quality, blending the aggressive characteristics of one design with the smoother tones of another. This allows for intricate control over the overall sound signature.

- Resonance Chamber Integration

Integrating resonance chambers into the exhaust system, often positioned between the engine and mufflers, enables the dampening or amplification of specific frequencies. This technique is employed to eliminate undesirable drone at certain engine speeds or to accentuate desirable tones, such as a deep, throaty rumble at low RPM. The careful placement and sizing of these chambers are crucial for effective sound shaping.

- Pipe Diameter and Length Adjustments

The diameter and length of the exhaust piping leading to and from the mufflers influence the overall sound characteristics. Larger diameter pipes generally produce a deeper, louder exhaust note, while variations in pipe length can alter the resonant frequencies within the system. Strategic manipulation of these parameters offers another avenue for fine-tuning the exhaust sound profile.

- Material Selection Impact

The materials used in constructing the exhaust system, including the mufflers, contribute to the final sound quality. Stainless steel, for instance, tends to produce a brighter, more metallic sound, while aluminized steel may offer a mellower tone. The density and acoustic properties of these materials interact with the exhaust gases to shape the sound produced, further influencing customization possibilities.

The interplay of these factors underscores the complex relationship between dual muffler systems and sound customization. By carefully manipulating muffler designs, incorporating resonance chambers, adjusting pipe dimensions, and considering material properties, designers can achieve a wide range of exhaust sound profiles, catering to diverse preferences and performance objectives.

3. Exhaust Distribution

Exhaust distribution, within the context of systems employing two silencers, pertains to the manner in which exhaust gases are divided and routed through the individual mufflers. This distribution is a critical design parameter that directly influences overall system performance, sound characteristics, and thermal management. Uneven distribution can lead to imbalances in backpressure, noise attenuation, and even structural integrity of the exhaust components.

The primary cause of uneven distribution stems from asymmetries in the exhaust manifold design, variations in pipe length leading to each muffler, or inconsistencies in muffler internal construction. The effect of such imbalances can manifest as differential backpressure, where one muffler experiences a significantly higher pressure than the other. This can negatively impact engine performance, cause asymmetrical wear on the mufflers, and contribute to an undesirable exhaust note. Real-life examples include instances where one side of a system exhibits premature corrosion or failure due to prolonged exposure to higher exhaust gas temperatures resulting from a greater flow volume. Optimizing exhaust distribution involves careful consideration of pipe geometry, muffler placement, and internal muffler design to ensure an equitable division of exhaust gases.

In summary, exhaust distribution is a vital component of systems with two silencers. A balanced distribution of exhaust flow ensures optimal performance, sound quality, and longevity of the exhaust system components. Addressing challenges in achieving uniform distribution requires meticulous design and manufacturing processes. The understanding and proper management of this distribution are paramount for maximizing the benefits associated with this type of exhaust system.

4. Performance Increase

Performance enhancement represents a core objective in the implementation of dual muffler systems. The connection between these systems and improved vehicle performance lies in their ability to reduce exhaust backpressure and optimize exhaust gas flow. Backpressure, the resistance encountered by exhaust gases as they exit the engine, directly impacts volumetric efficiency. By splitting the exhaust flow and directing it through two separate mufflers, these systems inherently lower the overall restriction, allowing the engine to breathe more freely. A reduction in backpressure translates to improved scavenging efficiency, where exhaust gases are more effectively removed from the cylinders, enabling a more complete intake charge and ultimately leading to increased power output.

Real-world examples substantiate the performance benefits of dual muffler systems. In high-performance vehicles, such as sports cars and modified trucks, the installation of such a system often results in measurable gains in horsepower and torque. Dyno testing, a common method for quantifying engine performance, consistently demonstrates improvements in these metrics following the installation of a properly designed dual muffler setup. However, the degree of performance increase is contingent upon several factors, including engine displacement, existing exhaust system design, and the specific characteristics of the mufflers employed. Furthermore, the practical significance of understanding this connection extends to optimizing fuel efficiency and reducing emissions, as a more efficient engine requires less fuel to produce the same amount of power, resulting in a decrease in overall emissions output.

In summary, the connection between performance increase and dual muffler systems is rooted in the principles of exhaust gas dynamics and their impact on engine efficiency. The reduction of backpressure, facilitated by the dual muffler configuration, results in measurable improvements in horsepower, torque, and overall engine performance. These improvements, while variable depending on specific application and design parameters, underscore the value of these systems in enhancing vehicle performance and efficiency. Challenges exist in achieving optimal design and ensuring compatibility with various engine configurations, but a thorough understanding of these principles remains critical for maximizing the potential benefits.

5. Material Selection

The selection of appropriate materials for exhaust systems employing two silencers is critical for ensuring structural integrity, longevity, and optimal performance. Material properties directly influence the system’s resistance to corrosion, thermal stress, and mechanical fatigue, all of which are paramount in maintaining its functionality over time.

- Stainless Steel Grade Selection

Different grades of stainless steel offer varying levels of corrosion resistance and high-temperature strength. 304 stainless steel is commonly used due to its good balance of properties, while 316 stainless steel provides superior corrosion resistance, particularly in marine environments or where exposure to road salts is prevalent. The choice of grade directly impacts the system’s lifespan and its ability to withstand harsh conditions. Using lower-grade steel can lead to premature rust and structural failure.

- Aluminized Steel Application

Aluminized steel provides a cost-effective alternative to stainless steel in some applications. It offers a protective aluminum coating that resists corrosion; however, it is less durable and may not be suitable for high-temperature or high-stress environments. The coating can be damaged by physical impacts or prolonged exposure to extreme heat, compromising its protective properties. Its application is typically limited to less demanding sections of the exhaust system, such as piping, where cost considerations are paramount.

- Welding Material Compatibility

The selection of welding materials must be compatible with the base materials used in the exhaust system. Dissimilar metals can create galvanic corrosion, leading to premature failure at the weld joints. Using appropriate filler metals, such as stainless steel welding rods for stainless steel components, is essential for ensuring strong and durable welds that resist corrosion. Proper welding techniques, including inert gas shielding, are also crucial for preventing oxidation and contamination of the weld metal.

- Hanger and Mounting Material Durability

The materials used for hangers and mounting brackets play a critical role in the system’s ability to withstand vibration and stress. Rubber or polyurethane isolators are commonly used to dampen vibrations and prevent them from being transmitted to the chassis. These materials must be resistant to degradation from heat, oil, and other contaminants. Failure to use durable mounting materials can lead to premature wear and tear on the exhaust system and increased noise levels.

The interconnectedness of these material selection considerations directly impacts the long-term performance and reliability of systems employing two silencers. Careful evaluation of environmental factors, performance requirements, and cost constraints is necessary to optimize material selection and ensure a durable and efficient exhaust system.

6. System Longevity

The lifespan of an exhaust system incorporating two silencers is directly influenced by design, material selection, and maintenance practices. Premature failure can result from corrosion, thermal fatigue, or mechanical stress. The presence of two mufflers, while offering performance and acoustic benefits, also introduces additional points of potential failure, such as connections, welds, and mounting points. Consequently, optimizing system longevity necessitates careful consideration of these factors during design and installation. Real-world examples demonstrate that systems constructed from higher-grade stainless steel and properly installed with vibration-dampening hangers exhibit significantly extended service lives compared to those employing lower-quality materials and inadequate installation techniques. A system failure, such as a cracked weld or corroded pipe, necessitates repairs or complete replacement, incurring costs and vehicle downtime. Therefore, maximizing longevity translates to reduced life-cycle costs and improved vehicle reliability.

The connection between system configuration and durability can be seen in the routing and support of the exhaust pipes. Proper routing minimizes stress on the components, while strategically placed support hangers prevent excessive vibration and movement, mitigating fatigue. Furthermore, the internal design of the mufflers themselves plays a role in their longevity. Chambered mufflers, for instance, may be more prone to corrosion in areas where moisture can accumulate, whereas straight-through designs may be less susceptible. Regular inspections, particularly in regions with harsh weather conditions or road salt usage, can identify early signs of corrosion or damage, allowing for timely repairs and preventing more extensive failures. Coatings, such as ceramic-based paints, can provide an additional layer of protection against corrosion and thermal degradation.

In conclusion, the durability of a dual-muffler exhaust system is a function of interconnected factors, ranging from material composition to installation practices and ongoing maintenance. A focus on these aspects translates into a longer system lifespan, reduced maintenance costs, and enhanced vehicle reliability. The challenge lies in striking a balance between performance, sound characteristics, and long-term durability. However, a comprehensive understanding of material properties, design principles, and proper maintenance procedures is essential for maximizing the lifespan of these systems and ensuring their sustained performance.

Frequently Asked Questions Regarding Systems Employing Two Silencers

The following questions address common inquiries and misconceptions surrounding systems incorporating two silencers in vehicle exhaust systems. The answers provided are intended to offer clarity and insight based on engineering principles and practical experience.

Question 1: What are the primary benefits derived from utilizing an exhaust system with two silencers?

The primary benefits encompass reduced backpressure, enabling enhanced engine performance and improved fuel efficiency. Furthermore, this configuration allows for greater flexibility in customizing the exhaust sound profile to meet specific preferences or regulatory requirements.

Question 2: Does the presence of two silencers inherently guarantee a performance increase?

No, the performance increase is not guaranteed. Performance improvements are contingent upon the overall design of the exhaust system, the characteristics of the mufflers employed, and the engine’s specific requirements. A poorly designed system can, in fact, impede performance.

Question 3: How does the use of two silencers impact the overall weight of the exhaust system?

The use of two silencers typically increases the overall weight of the exhaust system compared to a single-silencer configuration. This weight increase can be a consideration, particularly in performance-oriented applications where minimizing weight is a priority. The materials used in construction will also affect the weight.

Question 4: What are the maintenance considerations specific to dual-silencer exhaust systems?

Maintenance considerations include regularly inspecting the connection points, welds, and hangers for signs of corrosion, fatigue, or damage. Given the increased complexity of the system, a more thorough inspection schedule is advisable. Pay close attention to the silencers’ shell as they can also be corroded due to exposure in weather.

Question 5: Are systems employing two silencers legal in all jurisdictions?

Legality varies significantly depending on local noise regulations and emissions standards. It is imperative to verify compliance with all applicable laws and regulations before installing or modifying an exhaust system. Sound level testing and emissions certification may be required.

Question 6: Is professional installation recommended for a system of this type?

Professional installation is highly recommended. Proper installation ensures optimal performance, prevents leaks, and guarantees compliance with safety standards. Incorrect installation can lead to reduced performance, increased noise levels, and potential damage to the vehicle.

In summary, while systems with two silencers can offer notable benefits in terms of performance and sound customization, careful consideration must be given to design, installation, and regulatory compliance. A thorough understanding of these factors is essential for realizing the full potential of this exhaust system configuration.

The following sections will provide further details and specific use cases to give a broader understanding of these systems.

Conclusion

This exploration has illuminated the multifaceted nature of the dual muffler exhaust system. Key aspects examined include the potential for reduced backpressure, the capacity for sound customization, the significance of balanced exhaust distribution, the attainable performance increases, the critical role of appropriate material selection, and factors impacting system longevity. These elements, when carefully considered and properly implemented, contribute to a functional and efficient exhaust system.

Continued advancements in exhaust system technology and a deeper understanding of acoustic and fluid dynamics will likely drive further refinements in dual muffler design. This will allow enhanced performance, durability, and regulatory compliance. Automotive engineers and enthusiasts must, therefore, maintain a diligent pursuit of knowledge in this evolving field to maximize the benefits of these systems while minimizing their potential drawbacks.