This automotive component, characterized by its distinctive color and design, is a type of performance exhaust silencer. It’s engineered to modify the sound produced by an internal combustion engine’s exhaust system. For example, an owner seeking a louder, more aggressive tone might install one to achieve a specific auditory profile for their vehicle.

Its use is often motivated by a desire to enhance the driving experience through sound. Performance enthusiasts sometimes choose this device to signal the power and performance capabilities of their vehicle. Historically, such modifications have been a popular way for individuals to personalize their automobiles and express their passion for motorsports. The benefits can extend to perceived power increases and a greater sense of driver engagement.

The following sections will delve into the specifics of installation, maintenance, and legal considerations surrounding aftermarket exhaust modifications, providing a detailed examination of factors relevant to individuals considering this type of enhancement.

Installation and Maintenance Guidelines

Considerations are essential for ensuring optimal performance and longevity after acquiring this exhaust component. Improper installation or neglected maintenance can lead to diminished sound quality and potential mechanical issues.

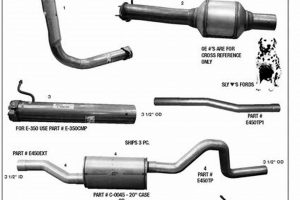

Tip 1: Verify Compatibility: Prior to installation, confirm that the selected exhaust modification is compatible with the vehicle’s make, model, and year. Consult the manufacturer’s specifications and cross-reference part numbers to prevent installation errors or performance issues.

Tip 2: Professional Installation Recommended: While DIY installation is possible, engaging a qualified mechanic is advisable. Professionals possess the necessary tools and expertise to ensure proper fitment, alignment, and secure mounting, mitigating the risk of leaks or damage.

Tip 3: Inspect Welds and Seams: Regularly examine all welds and seams for cracks or signs of corrosion. Any identified defects should be addressed promptly to prevent exhaust leaks and potential safety hazards. A visual inspection every six months is a prudent practice.

Tip 4: Monitor Exhaust Gas Temperature: If performance is a priority, monitor exhaust gas temperature (EGT) to ensure the engine is operating within safe parameters. Excessive EGT can damage exhaust components and potentially harm the engine itself.

Tip 5: Clean Regularly: Periodically clean the external surfaces to remove road debris, salt, and other contaminants that can accelerate corrosion. A simple wash with soap and water, followed by a protective coating, can extend the component’s lifespan.

Tip 6: Torque Fasteners to Specification: Ensure all fasteners are torqued to the manufacturer’s specified values. Over-tightening can damage threads, while under-tightening can lead to leaks. Use a calibrated torque wrench for accurate results.

Tip 7: Address Rattling Sounds: Investigate and resolve any rattling or unusual noises emanating from the exhaust system. Such sounds may indicate loose brackets, damaged hangers, or internal component failure. Early intervention can prevent more extensive damage.

Adhering to these guidelines will help maximize the performance and durability of the exhaust enhancement while maintaining compliance with applicable regulations. Neglecting these considerations may result in diminished sound quality, mechanical issues, and potential legal ramifications.

The subsequent sections will explore the legal and regulatory aspects associated with exhaust modifications, providing a comprehensive overview of potential implications.

1. Sound Modification

The core function of this exhaust component lies in its ability to alter the sound produced by a vehicle’s engine. The modification isn’t merely a change in volume but a reshaping of the auditory character. Its internal design, including baffling and chamber configuration, manipulates the exhaust flow, resulting in a specific tonal quality. For instance, an owner might seek to reduce high-frequency raspiness or amplify lower-frequency rumble. This sound is achieved through careful acoustic engineering and experimentation with different construction materials and configurations. This is a fundamental factor in its popularity and use.

The desired sound modification serves various purposes, ranging from aesthetic preferences to perceived performance gains. Some users prioritize a louder, more aggressive exhaust note to communicate a sense of power and sportiness. Others prefer a more refined, controlled sound that enhances the driving experience without attracting undue attention. The importance of sound modification becomes apparent in competitive motorsport. In these events, certain sound profiles are permissible, while others are not. This can influence engineering decisions. Aftermarket manufacturers cater to a wide spectrum of preferences, offering products designed to produce distinct sound signatures.

Understanding the connection between its design and the resulting sound characteristics is crucial for selecting the appropriate component for a given application. Challenges arise in accurately predicting the sonic outcome without prior experience or professional guidance. Subjective preferences further complicate the selection process. Sound modification remains a driving force behind the adoption of aftermarket exhaust components. It continues to reflect the individual’s personality and performance aspirations for their vehicle.

2. Visual Distinctiveness

The visual aspect contributes significantly to the overall appeal. The distinct color provides an immediate and recognizable identifier, differentiating it from standard, often silver or black, exhaust components. This aesthetic choice reflects a desire for personalization and a statement of individuality. The visual impact extends beyond mere color; the shape and finish of the component also play a role. Often polished or chrome-plated, these surfaces enhance the visual allure and contribute to a sense of quality and performance. For example, at automotive shows, the unique color acts as an eye-catching detail, drawing attention to customized vehicles. The selection of this particular component is driven by aesthetics. It serves as a visual cue, communicating specific attributes of the vehicle and its owner.

Consider the scenario of car customization. The visual element is often a primary factor in the decision-making process. Owners seek components that not only enhance performance but also complement the overall aesthetic of their vehicle. This exhaust part provides a readily identifiable element that contributes to the vehicle’s overall look. Its presence transforms the visual narrative, turning a functional component into a statement piece. The practical implications extend to marketing and branding. The color provides instant recognition. It enables the user to identify a brand. The visibility provides the vehicle with a sense of style.

In summary, its visual nature extends beyond mere aesthetics. It serves as a form of communication, signaling individuality, performance aspirations, and attention to detail. This design is used as a recognizable brand marker. Its unique features contribute to the value proposition. It creates an important purchase. Understanding this connection between aesthetics and functionality is crucial for appreciating its multifaceted role in the automotive landscape.

3. Performance Enhancement

Performance enhancement, in the context of this exhaust component, refers to the potential for increased engine power, improved throttle response, or enhanced fuel efficiency. It is crucial to establish a causal relationship between its installation and any tangible improvements. The stock exhaust system often presents restrictions to the free flow of exhaust gases, which can limit engine performance. This aftermarket component, designed with a larger diameter and less restrictive internal baffling, theoretically reduces backpressure and allows the engine to breathe more efficiently. For example, in certain high-performance applications, replacing the stock exhaust with a less restrictive system, incorporating this modification, might result in a measurable increase in horsepower. The extent of this increase, however, varies significantly depending on the specific engine, existing modifications, and overall tuning of the vehicle.

The importance of performance enhancement as a factor stems from the inherent desire among automotive enthusiasts to maximize the capabilities of their vehicles. However, it is essential to approach claims of performance gains with a critical and informed perspective. Dyno testing, conducted under controlled conditions, provides a reliable method for quantifying any actual improvements. Real-world examples demonstrate that while some vehicles exhibit noticeable gains, others may show negligible differences. The effectiveness of a modification depends heavily on its integration with the overall engine management system and the synergistic effect with other performance upgrades. Some owners report improved throttle response and a more immediate feeling of power delivery, even if the peak horsepower increase is minimal. A thorough understanding of these nuances is necessary to achieve the desired results.

In conclusion, while the potential for performance enhancement exists, it should not be the sole determinant in selecting this exhaust component. Factors such as sound quality, visual aesthetics, and regulatory compliance must also be considered. The practical significance lies in the ability to optimize engine performance within the constraints of applicable laws and personal preferences. Challenges arise in accurately assessing the true performance benefits and ensuring that the installation does not negatively impact other aspects of the vehicle’s operation. A balanced approach, combining objective data with subjective considerations, is essential for making informed decisions and realizing the full potential of this aftermarket modification.

4. Installation Complexity

The installation of this exhaust component is not a monolithic process; its complexity varies based on several factors including vehicle model, existing exhaust configuration, and the installer’s skill level. Understanding these variables is crucial for successful installation and optimal performance.

- Vehicle Compatibility and Modification Requirements

The primary determinant of installation complexity lies in the compatibility of the component with the vehicle. Direct bolt-on installations, where the aftermarket part fits seamlessly into the existing exhaust system without modification, represent the simplest scenario. However, modifications such as cutting, welding, or custom fabrication may be required when compatibility is not direct. For example, adapting this component to a vehicle for which it was not originally designed can entail significant fabrication work. This directly impacts the time, expertise, and tools needed for successful installation.

- Access and Existing Exhaust System Condition

The ease of access to the existing exhaust system components also influences installation complexity. Vehicles with limited undercarriage clearance or tightly packed engine bays can present challenges in removing the old exhaust and installing the new component. Furthermore, the condition of the existing exhaust system can complicate the process. Corroded or seized bolts and hangers may require specialized tools and techniques for removal, adding to the overall difficulty. For instance, removing a heavily rusted exhaust system can necessitate the use of penetrating oils, heat, or even cutting tools to dislodge stubborn components.

- Tool Requirements and Skill Level

The installation necessitates a specific set of tools, ranging from basic hand tools to specialized equipment such as exhaust pipe cutters, welders, and oxygen sensor wrenches. The installer’s skill level in using these tools is paramount. A novice installer may struggle with tasks that an experienced mechanic can complete with relative ease. Welding, in particular, requires specialized training and practice to ensure strong, leak-free joints. Improper welding can lead to exhaust leaks, reduced performance, and potential safety hazards. This highlights the importance of assessing one’s capabilities before attempting a DIY installation.

- Potential for Sensor Interference and ECU Tuning

Modifying the exhaust system can sometimes interfere with the vehicle’s oxygen sensors or other emissions control devices. In some cases, the installation of the component may necessitate recalibration of the engine control unit (ECU) to optimize performance and prevent error codes. This requires specialized diagnostic equipment and tuning software. Ignoring potential sensor interference or failing to properly tune the ECU can result in reduced fuel economy, poor engine performance, or even damage to the engine. This highlights the interconnectedness of the exhaust system with other vehicle systems and the need for a holistic approach to installation.

These factors collectively determine the installation complexity. The component ranges from simple, bolt-on procedures to elaborate tasks. Evaluating vehicle compatibility, access to existing components, tool requirements, skill level, and potential for sensor interference will optimize its performance.

5. Regulatory Compliance

The intersection of this automotive component and regulatory compliance is a critical consideration for vehicle owners and installers. Exhaust modifications, including the installation of this particular silencer, are subject to local, state, and federal regulations governing noise emissions and air quality. Failure to adhere to these regulations can result in fines, vehicle inspection failures, or legal repercussions. The primary concern from a regulatory perspective is the potential for increased noise levels beyond permissible limits. Many jurisdictions have established decibel limits for vehicle exhaust systems, and aftermarket modifications must not exceed these limits. For example, some states mandate periodic vehicle inspections, which include noise level testing. A modified exhaust system exceeding the specified decibel limit would result in a failed inspection.

The importance of regulatory compliance extends beyond avoiding penalties. Excessive noise pollution degrades the quality of life in residential areas and contributes to overall environmental concerns. Tampering with emissions control devices, which may inadvertently occur during exhaust modifications, also violates federal law and can negatively impact air quality. An example is the removal or alteration of catalytic converters, which are designed to reduce harmful emissions. Although this modification itself is not a catalytic converter, alterations to the exhaust system can impact its efficiency. Manufacturers and installers share responsibility in ensuring regulatory compliance. Manufacturers are obligated to design and market products that meet applicable standards, while installers must advise customers on the legality of modifications and perform installations in accordance with regulations. Some manufacturers produce variants of this product specifically designed to meet noise regulations in certain areas.

In summary, regulatory compliance is an indispensable aspect of the application of this exhaust component. Violations can lead to legal and environmental consequences. This has consequences for the owner, installer, and manufacturer. Owners should be aware of local regulations and ensure that any modifications comply with these standards. Manufacturers and installers must prioritize compliance. Only then can this be safely and legally applied.

Frequently Asked Questions About Aftermarket Exhaust Components

This section addresses common inquiries and misconceptions regarding aftermarket exhaust components, providing objective information to assist in informed decision-making.

Question 1: Does installing an aftermarket exhaust component automatically increase horsepower?

The presence of an aftermarket exhaust silencer does not guarantee an increase in horsepower. Performance gains are contingent upon factors such as engine type, existing modifications, and the specific design of the component. Dyno testing provides the means of reliably measuring any power increase.

Question 2: What are the legal ramifications of modifying a vehicle’s exhaust system?

Modifying a vehicle’s exhaust system may violate local, state, or federal noise and emissions regulations. Jurisdictions may enforce decibel limits, require periodic vehicle inspections, and prohibit alterations to emissions control devices such as catalytic converters. Non-compliance may result in fines or other penalties.

Question 3: Will an aftermarket exhaust component void a vehicle’s warranty?

The installation of an aftermarket exhaust component does not automatically void a vehicle’s warranty. However, if the aftermarket part directly causes a failure of a covered component, the warranty claim may be denied. Consulting with the vehicle manufacturer or a qualified mechanic is advisable prior to undertaking modifications.

Question 4: What is the typical lifespan of this aftermarket exhaust component?

The lifespan of this component is influenced by material quality, environmental conditions, and maintenance practices. Regular cleaning, inspection of welds and seams, and prompt repair of any damage can extend its operational life. Components constructed from stainless steel typically exhibit greater resistance to corrosion.

Question 5: Is professional installation required, or can it be installed as a do-it-yourself project?

The necessity of professional installation hinges on the installer’s skill level, the complexity of the installation process, and the need for specialized tools. While some installations may be straightforward bolt-on procedures, others require welding, cutting, or fabrication, necessitating the expertise of a qualified mechanic.

Question 6: How does the design affect the sound produced?

The internal design profoundly influences the sound produced. Chamber size, baffling configurations, and material choices determine the tone. Designs that minimize restrictions to exhaust flow amplify the volume. This can create a more aggressive exhaust note.

Understanding these key points is crucial for responsible vehicle modification and maintaining compliance with applicable regulations.

The subsequent sections will transition to a summary.

Conclusion

This exploration has shown the multiple facets of the “purple hornie muffler”, ranging from sound and visual modifications to performance considerations and regulatory compliance. These components serve as a focal point for automotive enthusiasts. It involves balancing personal preferences with real-world applications.

The responsible selection and installation of any aftermarket exhaust component necessitates careful research and adherence to established guidelines. This ensures optimal performance and minimizes potential legal or environmental consequences. Ongoing awareness of evolving regulations and technological advancements is important. This helps in making decisions and ensuring lasting automotive modifications.