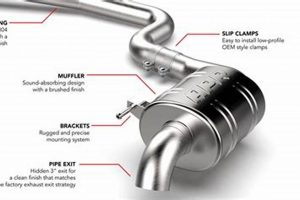

The exhaust component designed for Ford Broncos plays a crucial role in managing engine noise and emissions. This element, typically located along the vehicle’s exhaust system, utilizes baffles and chambers to dampen sound waves produced by the engine’s combustion process. An example is a performance-oriented component engineered to enhance exhaust flow, potentially improving horsepower and torque, while still adhering to legal noise regulations.

Its significance lies in its ability to regulate the sound output of the vehicle, ensuring compliance with noise pollution standards and contributing to a more comfortable driving experience. Moreover, certain aftermarket versions are engineered to optimize engine efficiency, potentially leading to improved fuel economy or increased performance. Historically, the design and materials used in this component have evolved to meet increasingly stringent environmental regulations and consumer demands for enhanced vehicle performance and sound characteristics.

This understanding of the exhaust system component is fundamental to the subsequent discussion of topics such as performance upgrades, maintenance procedures, and troubleshooting common issues related to exhaust system functionality in Ford Broncos. The following sections will delve into specific considerations for selecting, installing, and maintaining these crucial components.

Bronco Exhaust Component Considerations

This section provides critical guidance on selecting, maintaining, and upgrading the Ford Bronco’s exhaust component to ensure optimal performance and longevity.

Tip 1: Material Selection: When replacing this component, prioritize materials like stainless steel or aluminized steel for enhanced resistance to corrosion, particularly in regions with harsh winter conditions or frequent exposure to road salts. Examine the metallurgy of the product.

Tip 2: Performance Optimization: Explore aftermarket exhaust systems that are engineered to improve exhaust flow and reduce backpressure. These systems can potentially increase horsepower and torque, but ensure they comply with local noise regulations.

Tip 3: Routine Inspection: Conduct regular visual inspections of the exhaust component for signs of rust, leaks, or physical damage. Address any identified issues promptly to prevent more extensive and costly repairs.

Tip 4: Professional Installation: Consider professional installation, especially when installing complex aftermarket systems. Improper installation can lead to exhaust leaks, reduced performance, or even damage to other vehicle components.

Tip 5: Noise Level Compliance: Verify that any aftermarket exhaust component complies with local noise ordinances. Loud exhaust systems can result in fines and legal complications.

Tip 6: Heat Shield Integrity: Ensure the heat shields associated with this exhaust component are intact and properly positioned. These shields protect surrounding components from excessive heat and prevent potential damage.

Tip 7: Catalytic Converter Compatibility: When upgrading the exhaust system, ensure compatibility with the vehicle’s catalytic converter to maintain emission compliance and avoid potential issues with engine performance.

Adhering to these considerations ensures optimal performance, longevity, and legal compliance of the Ford Bronco’s exhaust system.

The following sections will further explore the specific aspects of troubleshooting and maintenance related to this critical exhaust system component.

1. Sound Attenuation

Sound attenuation, in the context of Ford Bronco exhaust systems, refers to the muffling or dampening of engine noise produced during combustion. The exhaust component achieves sound attenuation through internal baffling and resonating chambers designed to cancel out or reduce the amplitude of sound waves. This process is vital for compliance with local noise ordinances and contributes to a more comfortable driving experience for both the vehicle occupants and the surrounding environment. For example, a factory-installed exhaust component employs a specific internal design to meet regulated decibel levels, while aftermarket options may offer varying degrees of sound reduction depending on their construction and intended use. Failure to effectively attenuate sound can result in legal penalties, reduced driver comfort, and negative impacts on public perception of the vehicle.

The importance of sound attenuation directly influences the design and engineering of the exhaust component. Manufacturers must balance the need to reduce noise with considerations for exhaust flow and engine performance. Some performance-oriented exhaust components may prioritize increased flow, potentially leading to louder exhaust notes. However, these systems typically incorporate sound-dampening elements to maintain acceptable noise levels. The choice of materials, such as stainless steel or aluminized steel, can also impact sound characteristics. Thicker materials generally provide better sound insulation, while thinner materials may result in a more resonant or aggressive sound profile. As another example, when a Bronco is modified for off-road use, it is essential to select an exhaust component that meets local noise requirements for off-road areas. Choosing wrong, the vehicle can be unable to ride off-road legally.

In summary, sound attenuation is a critical aspect of any Ford Bronco exhaust system, affecting both regulatory compliance and overall driving experience. Understanding the principles of sound attenuation and the design features that contribute to noise reduction is essential for selecting the appropriate exhaust component and ensuring its proper maintenance. Challenges remain in balancing sound reduction with performance goals, requiring careful consideration of material selection, internal design, and compatibility with other vehicle systems. The importance of this balance is not only for legal compliance but it also provides a sustainable way of noise for both humans and animals surrounding the environment.

2. Exhaust Flow

Exhaust flow, concerning exhaust components designed for Ford Broncos, directly influences engine performance and efficiency. Optimized exhaust flow facilitates the swift removal of combustion gases, reducing backpressure and allowing the engine to operate more efficiently. This is critical for both stock and modified Broncos, impacting horsepower, torque, and fuel economy.

- Reduction of Backpressure

This is a core benefit of optimized exhaust flow. Backpressure inhibits the engine’s ability to expel exhaust gases effectively. This results in less power and efficiency. An exhaust component designed for improved flow minimizes this restriction, leading to tangible gains in engine output. For example, a tubular exhaust header minimizes backpressure, allowing each cylinder to exhaust its spent gases more efficiently, rather than fighting against other cylinders.

- Improved Volumetric Efficiency

Enhanced exhaust flow improves the engine’s volumetric efficiency, or its ability to draw in a fresh air/fuel mixture. By efficiently removing exhaust gases, the engine is better prepared for the next combustion cycle. For example, an increased exhaust diameter can lead to more power. But to ensure compatibility is essential.

- Thermal Management

Efficient evacuation of exhaust gases aids in managing engine temperatures. Excessive heat buildup can degrade engine components and reduce performance. An exhaust component designed to facilitate rapid exhaust flow contributes to a cooler running engine. A ceramic coated exhaust system can mitigate excessive heat.

- Impact on Turbocharging

For turbocharged Broncos, exhaust flow is paramount. The turbine, in a turbocharger, is driven by the force of exhaust gases. Reducing exhaust backpressure allows the turbine to spin more freely, improving turbocharger response and overall engine power. An exhaust system can be engineered to optimize flow to the turbo’s turbine.

These facets illustrate the profound impact of exhaust flow on the performance of Ford Broncos. Selecting a exhaust component designed to optimize exhaust flow, while considering factors such as noise levels and regulatory compliance, is crucial for maximizing engine power, efficiency, and longevity.

3. Corrosion Resistance

Corrosion resistance is a critical attribute of exhaust components designed for Ford Broncos, particularly given the vehicles’ propensity for off-road use and exposure to harsh environmental conditions. The exhaust system, including the muffler, is continually subjected to heat, moisture, road salts, and other corrosive elements, leading to degradation and eventual failure if not adequately protected. Premature failure of this component can result in increased noise pollution, reduced engine efficiency, and costly repairs. Therefore, the selection of materials and manufacturing processes that enhance corrosion resistance is of paramount importance for ensuring the longevity and reliability of the exhaust system.

The primary methods for achieving corrosion resistance in exhaust components involve the utilization of specific alloys and protective coatings. Stainless steel, particularly grades 304 and 409, is frequently employed due to its inherent resistance to oxidation and corrosion. Aluminized steel provides another viable option, offering a cost-effective alternative with enhanced corrosion protection compared to standard carbon steel. Furthermore, the application of ceramic coatings or specialized paints can provide an additional barrier against corrosive elements. For example, in regions with heavy winter salting, a stainless-steel muffler with a ceramic coating will significantly outlast a standard steel component. Similarly, off-road use exposes the exhaust system to mud, water, and abrasive materials, necessitating robust corrosion protection to prevent premature failure. Maintenance activities, such as regular washing and the application of protective sprays, can further extend the lifespan of the exhaust component.

In conclusion, corrosion resistance represents a fundamental design consideration for exhaust components in Ford Broncos, directly impacting their durability, performance, and overall cost of ownership. The use of appropriate materials, protective coatings, and diligent maintenance practices are essential for mitigating the effects of corrosion and ensuring the long-term functionality of the exhaust system. Addressing the challenges of corrosion effectively contributes to reduced maintenance requirements, improved vehicle reliability, and compliance with environmental regulations related to noise pollution and emissions. This understanding is crucial for both vehicle owners and automotive professionals involved in the maintenance and repair of Ford Broncos.

4. Emission Compliance and the Bronco Muffler

The exhaust component significantly impacts emission compliance in Ford Broncos. This part, while primarily known for sound attenuation, also plays a vital role in ensuring the exhaust system functions within regulated emission standards. It is often designed to work in conjunction with catalytic converters and other emission control devices to minimize the release of harmful pollutants into the atmosphere. Modifying or replacing the component with a non-compliant aftermarket option can negatively impact emission levels, potentially leading to vehicle failing inspection, fines, and legal ramifications. An example illustrating this interconnection involves altered exhaust system to enhance performance, inadvertently removing OEM emission-control. Resulting from this, there is a failure to meet state emission standards.

Furthermore, the catalytic converters efficiency directly influences the component’s role in emission control. A properly functioning catalytic converter reduces harmful pollutants. Subsequently, the component ensures these gases exit the system in a controlled manner, without generating excessive noise. Maintenance and inspection of the component, therefore, are crucial aspects of preserving emission compliance. Leakages or damage can affect the overall exhaust system backpressure, resulting in the catalytic converter’s reduced efficiency. In practical application, a vehicle exhibiting increased exhaust noise and reduced fuel economy could signify an exhaust component malfunction affecting emission control.

In summary, the component constitutes an integral element in achieving emission compliance for Ford Broncos. Its design, maintenance, and compatibility with other emission control devices are vital for ensuring adherence to environmental regulations. Understanding the connection is essential for responsible vehicle ownership and maintenance, ensuring the longevity of the vehicle, adherence to legal requirements, and minimization of environmental impact. A well-maintained exhaust system, inclusive of the relevant component, contributes to a sustainable vehicle operation and reduces overall environmental footprint.

5. Performance Enhancement

Performance enhancement concerning exhaust components designed for Ford Broncos involves modifications aimed at increasing engine horsepower, torque, and overall responsiveness. While the primary function of the exhaust system is to expel combustion gases, strategic alterations to the component’s design can significantly impact engine performance characteristics.

- Reduced Backpressure

Optimizing exhaust flow to minimize backpressure is a key aspect of performance enhancement. Less resistance to exhaust gas flow allows the engine to breathe more efficiently, resulting in increased power output. Example: An aftermarket component featuring larger diameter piping and mandrel bends can reduce backpressure compared to the stock system. Implication: Measurable gains in horsepower and torque across the engine’s RPM range.

- Improved Scavenging

Enhanced exhaust scavenging refers to the more effective removal of exhaust gases from the combustion chamber, further improving engine efficiency. Example: A properly designed exhaust header can create a scavenging effect, drawing exhaust gases out of the cylinder more rapidly. Implication: Increased volumetric efficiency and a reduction in residual exhaust gases, leading to a more complete combustion cycle.

- Optimized Sound Tuning

While not directly contributing to horsepower gains, a well-tuned component can enhance the perceived performance of the vehicle by producing a more aggressive and sporty exhaust note. Example: An aftermarket exhaust with a specific chamber design to create a deep, resonant tone. Implication: A more engaging driving experience and a perception of increased power, even if the actual horsepower gains are minimal.

- Material Selection and Weight Reduction

The material used in the construction of the exhaust component can impact both performance and durability. Lighter materials can reduce overall vehicle weight, improving handling and acceleration. Example: A titanium exhaust system offering significant weight savings compared to a steel system. Implication: Enhanced handling characteristics and improved acceleration due to a reduction in overall vehicle mass.

These facets illustrate how modifications to the exhaust component can contribute to tangible performance enhancements in Ford Broncos. While some modifications focus on maximizing horsepower and torque, others prioritize improvements in sound, weight, or overall driving experience. Selecting an exhaust component that aligns with specific performance goals is crucial for achieving the desired results.

6. Installation Complexity

Installation complexity, concerning exhaust components for Ford Broncos, varies significantly depending on the type of replacement or upgrade being performed. The level of technical expertise and equipment required can range from simple bolt-on replacements to intricate modifications necessitating specialized tools and professional assistance. Understanding this complexity is crucial for both DIY enthusiasts and those seeking professional installation services.

- Direct Replacement vs. Aftermarket Systems

A direct replacement component typically involves a straightforward removal and re-installation process, often requiring basic hand tools and minimal technical knowledge. An aftermarket system, however, can present greater challenges. Modifications to the exhaust hangers, cutting or welding of pipes, or adjustments to the vehicle’s undercarriage might be necessary. Implications are in time investment. A direct replacement might take less than an hour, whilst aftermarket installation can take multiple hours.

- Tool Requirements

The type of tools needed for installation directly impacts the complexity. Basic replacements might only require sockets, wrenches, and penetrating oil. More complex installations could necessitate a welder, cutting torch, pipe bender, and specialized diagnostic equipment to ensure proper fitment and functionality. Improper tool usage can cause damage to the component and the vehicle.

- Potential Modifications

Aftermarket exhausts often require modifications to the vehicle for proper installation, such as adapting to the vehicle’s frame or modifying the hangers. These alterations can increase the installation’s complexity and may require the skills of an experienced technician to prevent damage to the vehicle or exhaust system. For instance, installing high-performance headers might interfere with other engine components or require adjustments to the vehicle’s wiring or fuel lines.

- Impact on Warranty

Improper installation of an exhaust component can void the vehicle’s warranty. It is crucial to ensure the installation process aligns with the manufacturer’s recommendations and that all components are correctly fitted to avoid potential issues that could invalidate warranty coverage. For this, it is essential for the owners, or the technicians, to know the terms of the warranty to avoid losing it.

In summary, installation complexity represents a significant consideration when dealing with exhaust components for Ford Broncos. The choice between a direct replacement and an aftermarket system, the tools required, the potential for modifications, and the impact on warranty all contribute to the overall difficulty of the installation process. Prior planning and assessment of technical skills are essential for ensuring a successful and safe installation, whether performed by a DIY enthusiast or a professional mechanic.

7. Vehicle Compatibility

Vehicle compatibility is a foundational consideration when selecting an exhaust component for a Ford Bronco. Ensuring that a specific exhaust component is designed to integrate seamlessly with the intended vehicle model and year is paramount for proper fitment, optimal performance, and adherence to emission regulations. Deviations from designated compatibility can lead to installation difficulties, compromised engine operation, and potential legal ramifications.

- Engine Size and Configuration

Ford Broncos have been produced with a range of engine sizes and configurations. The exhaust component design must align with the engine specifications to ensure proper exhaust flow and backpressure characteristics. For instance, a V8 engine will require an exhaust system with a larger diameter and flow capacity compared to a six-cylinder engine. A mismatch can result in reduced power output or even engine damage.

- Model Year Variations

Even within the same Bronco generation, there can be subtle variations in the exhaust system design across different model years. These variations may involve changes to the mounting points, pipe diameters, or the location of emission control devices. Selecting an exhaust component that is specifically designed for the vehicle’s model year ensures proper fitment and prevents installation challenges.

- Trim Level and Options

Certain trim levels or optional equipment packages may influence exhaust system configuration. For example, a Bronco equipped with a factory-installed towing package might have a different exhaust routing or a heavier-duty component compared to a base model. Compatibility considerations must account for these trim-specific variations to avoid compatibility issues.

- Emissions Regulations

Emission regulations have evolved over time, leading to changes in exhaust system design and the inclusion of additional emission control devices. The exhaust component must be compatible with the vehicle’s emissions control system to ensure compliance with applicable regulations. Non-compliant components can result in failed emissions tests and legal penalties.

In conclusion, vehicle compatibility serves as the linchpin for ensuring the successful integration of an exhaust component with a Ford Bronco. A thorough understanding of engine specifications, model year variations, trim level options, and emission regulations is essential for selecting the appropriate component and avoiding potential compatibility issues. Prioritizing vehicle compatibility translates to optimized performance, regulatory compliance, and a prolonged lifespan of the exhaust system.

Frequently Asked Questions About Ford Bronco Exhaust Components

This section addresses prevalent inquiries regarding exhaust components for Ford Broncos, providing concise and informative answers to common concerns.

Question 1: What is the typical lifespan of a Ford Bronco exhaust component?

The longevity of a Ford Bronco exhaust component varies based on factors such as material, driving conditions, and maintenance practices. Typically, a stock exhaust component can last between 5 to 7 years. However, exposure to road salts, off-road conditions, and aggressive driving habits can significantly reduce its lifespan. Upgrading to a stainless-steel exhaust system can extend the lifespan to 10 years or more.

Question 2: How does a damaged Ford Bronco exhaust component affect vehicle performance?

A damaged exhaust component can negatively impact vehicle performance in several ways. Exhaust leaks can reduce engine power and fuel efficiency, while a clogged exhaust can cause backpressure, leading to reduced horsepower and increased engine temperature. Furthermore, a damaged exhaust component can increase engine noise and potentially violate noise pollution regulations.

Question 3: What are the signs that a Ford Bronco exhaust component needs replacement?

Several indicators suggest a Ford Bronco exhaust component requires replacement. These include excessive exhaust noise, noticeable rust or corrosion, a rattling sound from underneath the vehicle, a decrease in fuel efficiency, and a reduction in engine power. A visual inspection of the exhaust system can often reveal physical damage, such as holes or cracks.

Question 4: Does replacing the Ford Bronco exhaust component require professional installation?

While a direct replacement of the Ford Bronco exhaust component can be performed by a mechanically inclined individual, more complex installations, such as those involving aftermarket systems or welding, typically necessitate professional installation. Professional installation ensures proper fitment, avoids potential damage to the vehicle, and guarantees compliance with emission regulations.

Question 5: Will an aftermarket Ford Bronco exhaust component void the vehicle’s warranty?

The impact of an aftermarket exhaust component on the vehicle’s warranty depends on the specific terms of the warranty and the nature of the modification. Generally, a “cat-back” exhaust system, which replaces the exhaust component downstream of the catalytic converter, is less likely to void the warranty than modifications that alter the catalytic converter or other emission control devices. Consult the vehicle’s warranty documentation and a qualified mechanic before making any modifications.

Question 6: How can the lifespan of a Ford Bronco exhaust component be extended?

Several measures can extend the lifespan of a Ford Bronco exhaust component. These include regular washing of the undercarriage to remove road salts and debris, applying protective coatings to prevent rust, avoiding aggressive driving habits that can stress the exhaust system, and promptly addressing any signs of damage or corrosion. Routine inspections can also help identify and resolve minor issues before they escalate.

Key takeaway: The Ford Bronco exhaust component lifespan and operation are determined by materials, upkeep, damage, and quality installation.

The following section delves into the future trends in exhaust component technology and materials.

Conclusion

This exploration has underscored the multifaceted role of the bronco muffler within the vehicle’s exhaust system. From sound attenuation and emissions compliance to performance enhancement and corrosion resistance, the bronco muffler’s integrity is critical. The careful selection, proper installation, and diligent maintenance of the bronco muffler, along with all other exhaust components, are vital for preserving optimal functionality and regulatory adherence.

Ultimately, the responsible stewardship of a Ford Bronco’s exhaust system demands a commitment to quality, precision, and an informed understanding of the system’s intricate dynamics. Continued advancements in materials and design offer promising avenues for enhanced performance and longevity. The long-term performance, environmental responsibility, and driving experience rely on continued diligence and an understanding of these principles.