A device designed to significantly reduce the operational noise produced by a generator is crucial for environments where noise pollution is a concern. For instance, a generator operating at a remote campsite or in a densely populated residential area can benefit greatly from the integration of such a component, minimizing disturbance to the surrounding environment.

The advantages of diminished generator noise extend beyond mere courtesy. Reduced sound levels contribute to improved quality of life, especially in residential settings. Furthermore, in professional environments such as film sets or outdoor events, a quieter generator facilitates clearer communication and a more productive work environment. Historically, innovations in sound dampening technology have constantly strived to achieve increasingly lower decibel levels, driven by both regulatory requirements and consumer demand.

The subsequent sections will delve into specific technologies employed for noise reduction, discuss factors influencing the effectiveness of different noise reduction solutions, and offer guidance on selecting the most appropriate option for a given generator model and operational scenario.

Tips for Optimizing Generator Noise Reduction

This section provides actionable advice for maximizing noise reduction in generator operation, focusing on achieving minimal acoustic impact on the surrounding environment.

Tip 1: Implement a Multi-Layered Approach. Noise mitigation is most effective when employing a combination of strategies. This may include a specialized exhaust system, acoustic enclosures, and vibration dampening mounts. The integration of multiple layers maximizes noise reduction.

Tip 2: Ensure Proper Exhaust System Installation. The exhaust system is a primary source of generator noise. Verify that all connections are secure and free from leaks. Gaps in the exhaust system can significantly increase noise output. Regular inspection and maintenance are essential.

Tip 3: Utilize Acoustic Enclosures Strategically. Acoustic enclosures can provide significant noise reduction, but require adequate ventilation to prevent overheating. Ensure that the enclosure is properly sized for the generator and that appropriate airflow is maintained.

Tip 4: Employ Vibration Dampening Mounts. Generator operation generates significant vibration, which can transmit noise through the supporting structure. Vibration dampening mounts isolate the generator and minimize the transmission of vibrational noise.

Tip 5: Consider Generator Placement. The location of the generator can significantly impact noise levels in the surrounding area. Position the generator away from noise-sensitive areas, such as residences or offices. Utilize natural barriers, such as walls or landscaping, to further mitigate noise transmission.

Tip 6: Select the Correct Unit for the Load. Operating a generator at or near its maximum capacity increases noise output. Choose a generator with sufficient capacity to handle the load without being consistently pushed to its limit. A properly sized generator will run quieter and more efficiently.

Tip 7: Regular Maintenance is Crucial. Consistent maintenance of the generator, including oil changes, filter replacements, and spark plug inspections, contributes to quieter operation. A well-maintained generator runs more smoothly and produces less noise.

By applying these tips, significant reductions in generator noise can be achieved, resulting in a less disruptive operational environment. A proactive approach to noise mitigation enhances the usability of generators in diverse settings.

The following sections will address the selection criteria and considerations for purchasing effective noise reduction solutions, focusing on compatibility, durability, and overall performance.

1. Material Composition

The effectiveness of a generator muffler in achieving significant noise reduction is intrinsically linked to its material composition. The materials used directly influence the muffler’s ability to absorb, dampen, and reflect sound waves, directly impacting the overall noise output. A muffler constructed from materials with poor sound-dampening characteristics will inherently fail to meet the requirements of a “super quiet” designation.

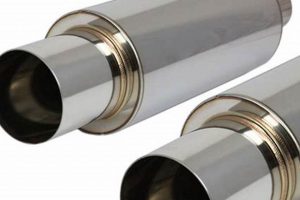

Consider, for example, a muffler constructed from thin, untreated steel. This material offers minimal sound absorption and tends to resonate, potentially amplifying certain frequencies. Conversely, a muffler utilizing thicker gauge steel, often combined with internal layers of sound-absorbing materials such as fiberglass or mineral wool, will effectively attenuate a broader range of frequencies. Stainless steel is often used for its durability and resistance to corrosion, especially in outdoor applications. The selection of specific materials directly correlates to the muffler’s acoustic performance and lifespan. The internal configuration and the density of sound-absorbing materials play a key role. A greater density of sound-absorbing material generally equates to improved sound reduction. However, it is vital to avoid restricting airflow to ensure optimal engine function.

Therefore, the proper selection and layering of materials are paramount in the design of effective sound-dampening solutions for generators. Neglecting the material’s inherent acoustic properties and durability compromises the muffler’s performance. Understanding the properties of various materials allows for informed decisions that contribute to meeting stringent noise reduction standards and ensuring customer satisfaction. Prioritizing high-quality materials contributes significantly to creating a “super quiet generator muffler.”

2. Acoustic Design

Acoustic design is a critical determinant in the effectiveness of a generator muffler intended for “super quiet” operation. The internal architecture of the muffler, including baffle placement, chamber dimensions, and exhaust flow paths, dictates the degree to which sound waves are attenuated. Poor acoustic design can lead to amplified noise levels or the generation of undesirable frequencies, effectively negating the purpose of the muffler. For instance, a muffler with insufficient baffling will allow sound waves to propagate directly through the system with minimal disruption, resulting in high noise output. The integration of Helmholtz resonators, tuned to specific frequencies, can effectively cancel out dominant noise components produced by the generator’s engine.

Sophisticated acoustic designs often incorporate multiple chambers, each optimized to dampen different frequency ranges. Perforated tubes and strategically placed sound-absorbing materials further enhance noise reduction. Computer modeling and simulation techniques are frequently employed to predict the acoustic performance of muffler designs prior to physical prototyping. This allows engineers to optimize the internal geometry and material selection for maximum noise attenuation. The choice of materials also plays a role in the acoustic design; dense, sound-absorbent materials are preferred for lining the internal chambers to minimize sound reflection and resonance. Furthermore, the shape and size of the muffler body itself can influence its acoustic properties, necessitating careful consideration of external dimensions and surface treatments.

In summary, achieving a “super quiet generator muffler” necessitates a meticulously crafted acoustic design, encompassing optimized internal geometry, strategic material placement, and careful consideration of frequency characteristics. A flawed acoustic design renders even the most robust materials ineffective. The understanding and application of acoustic principles are paramount in developing mufflers that meet stringent noise reduction requirements. The effectiveness of a generator muffler significantly relies on thoughtful and optimized acoustic design.

3. Exhaust Backpressure

The effectiveness of a “super quiet generator muffler” is inextricably linked to the management of exhaust backpressure. Exhaust backpressure is the resistance to exhaust gas flow created by the muffler. While mufflers are designed to reduce noise, they inherently introduce some level of backpressure. Excessive backpressure can negatively impact engine performance, reducing power output, increasing fuel consumption, and potentially causing engine damage over time. Therefore, the ideal design balances noise reduction with the minimization of exhaust restriction. A muffler that significantly reduces noise but creates excessive backpressure is not an optimal solution.

Consider the example of a generator used for emergency backup power. If the installed muffler creates substantial backpressure, the generator may struggle to start or may not deliver its rated power output when needed most. This compromises the reliability of the backup power system. In contrast, a muffler with a less restrictive design may reduce noise less effectively, failing to meet noise ordinances or disturbing neighbors. Thus, the design must carefully consider these competing factors. Advanced designs often use complex internal pathways and optimized chamber sizes to minimize backpressure while maximizing sound wave attenuation. Simulation software helps to model exhaust flow and pressure, allowing engineers to refine designs before physical prototypes are produced.

In conclusion, the relationship between exhaust backpressure and achieving a “super quiet generator muffler” is a critical engineering challenge. Balancing noise reduction with optimal engine performance is essential for ensuring both compliance with noise regulations and reliable generator operation. Understanding the dynamics of exhaust flow and pressure allows for the development of mufflers that achieve a harmonious balance between acoustic performance and engine efficiency.

4. Durability

Durability is a paramount consideration in the design and selection of a “super quiet generator muffler”. A muffler’s ability to maintain its noise reduction performance over an extended operational lifespan is directly linked to its construction quality and the materials used. Compromised durability can lead to increased noise output, rendering the muffler ineffective and potentially violating noise regulations. Therefore, selecting a durable muffler is essential for long-term noise control.

- Material Resistance to Corrosion

The exhaust system operates in a harsh environment, exposed to high temperatures, corrosive gases, and moisture. A muffler constructed from materials susceptible to corrosion will degrade over time, leading to leaks and reduced noise attenuation. Stainless steel and aluminized steel are commonly used for their superior corrosion resistance, ensuring prolonged muffler life and consistent noise reduction. For instance, a mild steel muffler exposed to coastal environments will rapidly corrode, negating its acoustic benefits within a short period.

- Resistance to Thermal Stress

Generators produce high exhaust gas temperatures, which can induce thermal stress in the muffler components. Repeated heating and cooling cycles can cause fatigue and cracking in materials with poor thermal resistance. High-quality mufflers are designed to withstand these thermal stresses, maintaining their structural integrity and acoustic performance. An example would be a muffler cracking around weld points due to repeated expansion and contraction.

- Abrasion and Impact Resistance

Mufflers are often exposed to external abrasion and impacts, particularly in portable generator applications. Robust construction and the use of durable outer casings protect the internal components from damage. A muffler with a thin outer shell is susceptible to punctures and dents, compromising its acoustic performance and longevity. This is crucial for generators used in demanding environments like construction sites.

- Weld Integrity

The quality of the welds used to assemble the muffler significantly impacts its overall durability. Poorly executed welds are prone to cracking and failure, leading to exhaust leaks and reduced noise attenuation. High-quality welding techniques, such as TIG welding, ensure strong and durable joints that withstand the rigors of generator operation. Consider a muffler where spot welds fail prematurely, leading to internal baffle detachment and increased noise levels.

In conclusion, the durability of a “super quiet generator muffler” is not merely a matter of longevity but a critical factor in maintaining consistent noise reduction performance. Selecting a muffler constructed from corrosion-resistant materials, designed to withstand thermal stress and abrasion, and assembled with high-quality welds ensures long-term effectiveness and compliance with noise regulations.

5. Compatibility

Compatibility constitutes a fundamental consideration in the successful implementation of any generator muffler intended to achieve substantial noise reduction. The proper alignment of muffler specifications with the generator’s operational parameters is crucial for ensuring optimal performance and avoiding adverse effects on engine function. A mismatch in compatibility can negate the potential benefits of the muffler, leading to suboptimal noise reduction and potentially causing damage to the generator.

- Engine Displacement and Exhaust Flow Rate

The muffler must be designed to accommodate the engine’s displacement and exhaust flow rate. A muffler designed for a smaller engine will create excessive backpressure on a larger engine, reducing power output and increasing fuel consumption. Conversely, a muffler designed for a larger engine may not provide sufficient noise attenuation when installed on a smaller engine. Matching the muffler’s flow capacity to the engine’s requirements is essential.

- Exhaust Port Dimensions and Threading

The muffler inlet must physically connect to the generator’s exhaust port. Incompatible port dimensions or threading will prevent proper installation, rendering the muffler useless. Verifying that the muffler’s inlet matches the generator’s exhaust port specifications is a prerequisite for successful integration. Adapters can sometimes be used to bridge minor differences, but these can introduce additional points of failure or leakage.

- Mounting Configuration and Space Constraints

The muffler must physically fit within the available space on the generator and must be securely mounted to prevent vibration and movement. Incompatible mounting configurations or excessive muffler size can prevent installation. Considering the generator’s dimensions and available mounting points is critical during muffler selection. Modifying the generator frame to accommodate an incompatible muffler is generally not advisable.

- Backpressure Limits and Engine Tuning

As previously discussed, excessive backpressure can negatively impact engine performance. The selected muffler must not exceed the generator manufacturer’s recommended backpressure limits. Exceeding these limits can require engine retuning or modifications to maintain optimal performance, adding complexity and cost to the installation. Consulting the generator’s service manual is essential for determining acceptable backpressure ranges.

In summation, compatibility is not merely a matter of physical fit but extends to ensuring the muffler’s operational characteristics align with the generator’s requirements. Careful consideration of engine displacement, exhaust flow, port dimensions, mounting constraints, and backpressure limits is essential for selecting a “super quiet generator muffler” that provides both effective noise reduction and maintains optimal engine performance. Failure to address these compatibility factors can result in suboptimal performance, engine damage, or even the inability to use the muffler at all.

Frequently Asked Questions

The following questions address common inquiries regarding specialized equipment designed to diminish noise during generator operation. These address factors concerning selection, usage, and maintenance of these devices.

Question 1: What constitutes a “super quiet” generator muffler and how does it differ from standard mufflers?

A “super quiet” generator muffler is engineered to achieve a significantly lower decibel output compared to standard models. This is typically accomplished through advanced internal baffling, specialized sound-absorbing materials, and optimized exhaust flow paths, resulting in a marked reduction in operational noise.

Question 2: Can installation of a “super quiet” generator muffler void the generator’s warranty?

The impact on the generator’s warranty depends on the manufacturer’s specific terms and conditions. Using an aftermarket muffler may void the warranty if the manufacturer determines that the muffler caused damage or malfunction. It is advisable to consult the generator’s warranty documentation and contact the manufacturer for clarification prior to installation.

Question 3: How does exhaust backpressure affect the performance of a “super quiet” generator muffler, and what measures can be taken to mitigate potential issues?

Exhaust backpressure is the resistance to exhaust gas flow caused by the muffler. Excessive backpressure can reduce engine power and fuel efficiency. Muffler designs should minimize backpressure while maximizing noise reduction. Regular maintenance, including cleaning or replacement of the muffler, can help prevent excessive backpressure buildup.

Question 4: What materials are commonly used in the construction of high-quality “super quiet” generator mufflers, and what are their respective advantages?

Common materials include stainless steel, aluminized steel, and specialized sound-absorbing composites. Stainless steel offers excellent corrosion resistance and durability. Aluminized steel provides good corrosion resistance at a lower cost. Sound-absorbing composites, such as fiberglass or mineral wool, enhance noise attenuation.

Question 5: How can the effectiveness of a “super quiet” generator muffler be assessed and maintained over time?

Effectiveness can be assessed by measuring the generator’s noise output using a sound level meter before and after muffler installation. Regular inspections for leaks, corrosion, and damage can help maintain performance. Cleaning or replacing the muffler as needed ensures consistent noise reduction.

Question 6: Are there specific regulations or standards governing the use of generator mufflers in residential or commercial settings?

Noise regulations vary by locality. Many municipalities have noise ordinances that specify maximum permissible noise levels for generators. Compliance with these regulations is essential to avoid fines or legal action. Selecting a muffler that meets applicable noise standards is crucial for responsible generator operation.

The information provided offers a basis for understanding critical facets of sound-dampening mechanisms for generators. Adherence to these guidelines promotes proper equipment usage and effective noise mitigation.

The following section discusses how to choose a suitable for a specific application.

Conclusion

The preceding analysis has explored the critical attributes of a “super quiet generator muffler,” ranging from material composition and acoustic design to exhaust backpressure management, durability, and compatibility. Each element plays a crucial role in achieving effective noise reduction without compromising generator performance. The selection of an appropriate muffler requires careful consideration of these factors to ensure optimal operation and compliance with noise regulations.

As noise pollution concerns continue to escalate, the demand for generators equipped with superior noise reduction technology will undoubtedly increase. Investing in a well-designed and properly maintained “super quiet generator muffler” is not merely an expense but a strategic decision that contributes to a quieter environment, improved community relations, and sustained operational efficiency. Ongoing research and development in acoustic engineering will likely yield even more effective noise reduction solutions in the future.