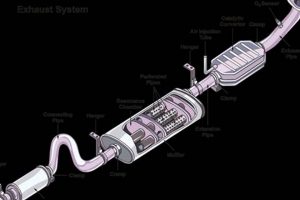

An automotive component designed to reduce the noise emitted from an internal combustion engine’s exhaust system. This device, typically located as part of the exhaust system, utilizes a series of chambers and tubes to dampen sound waves generated by the engine’s combustion process. A damaged or ineffective unit can result in significantly increased noise levels emanating from a vehicle.

This component plays a crucial role in minimizing noise pollution and ensuring compliance with local and national noise regulations. Its effectiveness contributes to a more comfortable driving experience for vehicle occupants and reduces disturbance to the surrounding environment. Historically, advancements in design and materials have led to more efficient and durable units, contributing to improved vehicle performance and longevity.

The subsequent sections will delve into the various types of these components, their operational principles, factors influencing their performance, and maintenance considerations to ensure optimal functionality and lifespan.

Maintenance & Longevity Considerations

Proper care and maintenance are essential to maximize the lifespan and effectiveness of exhaust noise reduction systems. Neglecting these aspects can lead to premature failure, increased noise levels, and potential regulatory non-compliance.

Tip 1: Regular Visual Inspection: Conduct routine visual inspections of the system for signs of rust, corrosion, or physical damage. Pay particular attention to weld points and areas exposed to road debris.

Tip 2: Prompt Repair of Damage: Address any identified damage, such as holes or cracks, immediately. Even small imperfections can significantly compromise performance and accelerate deterioration.

Tip 3: Monitor for Unusual Noises: Be alert to any changes in the exhaust system’s sound profile. Rattling, hissing, or excessively loud noises may indicate internal damage or failure.

Tip 4: Address Corrosion: Utilize rust inhibitors or protective coatings to mitigate corrosion, especially in environments with high salt exposure. Regular washing can also help remove corrosive agents.

Tip 5: Ensure Proper Mounting: Verify that the system is securely mounted and that all hangers and supports are in good condition. Loose or damaged mountings can cause excessive vibration and stress, leading to premature failure.

Tip 6: Consider Professional Inspection: Schedule periodic inspections by a qualified mechanic to assess the system’s overall condition and identify any potential problems that may not be readily apparent.

Tip 7: Be Mindful of Driving Conditions: Aggressive driving habits, such as frequent hard acceleration and braking, can subject the system to increased stress and heat. Adopting smoother driving techniques can prolong its lifespan.

By adhering to these maintenance practices, vehicle owners can ensure optimal performance, minimize noise pollution, and extend the service life of the exhaust noise reduction system.

The following sections will discuss the environmental impact and regulatory considerations associated with these systems, providing a comprehensive understanding of their role in modern automotive technology.

1. Noise attenuation

Noise attenuation, the reduction of sound intensity, constitutes a primary functional characteristic of exhaust mufflers. Its effectiveness directly correlates with the device’s ability to minimize noise pollution and adhere to regulatory standards.

- Internal Chamber Design

The configuration of internal chambers within a muffler plays a pivotal role in noise attenuation. Chambers are engineered to reflect and dissipate sound waves through interference. Complex chamber designs, incorporating multiple passages and varying volumes, often yield higher levels of sound reduction compared to simpler configurations. For instance, a resonance chamber is specifically tuned to cancel out specific frequencies common in exhaust noise.

- Sound Absorption Materials

The inclusion of sound-absorbing materials, such as fiberglass or mineral wool, further enhances noise attenuation. These materials line the internal walls of the muffler, absorbing sound energy and converting it into heat. The density and composition of these materials directly affect their sound-absorbing capabilities. High-performance mufflers often utilize advanced acoustic packing materials for superior noise reduction.

- Perforated Core Tubing

Many mufflers incorporate perforated core tubing to facilitate sound wave interaction with the absorption materials. The perforations allow sound waves to enter the surrounding absorption layer, maximizing the attenuation effect. The size, density, and pattern of the perforations influence the muffler’s overall noise reduction performance. A well-designed perforated core optimizes sound wave access to the absorption media.

- Resonance and Interference

Mufflers employ resonance and interference principles to cancel out specific frequencies within the exhaust noise spectrum. By carefully tuning the internal dimensions and chamber volumes, mufflers can create destructive interference patterns that effectively reduce noise levels. This technique is particularly effective in targeting specific frequencies that are known to be annoying or contribute significantly to overall noise pollution. Achieving optimal resonance requires precise engineering and manufacturing.

These facets of noise attenuation demonstrate the intricate engineering involved in exhaust muffler design. Effective noise reduction is achieved through a combination of internal chamber design, sound-absorbing materials, perforated core tubing, and the strategic application of resonance and interference principles. The success of a muffler in reducing noise is critical to its performance and its compliance with environmental regulations.

2. Exhaust backpressure

Exhaust backpressure, the resistance to the flow of exhaust gases in an internal combustion engine’s exhaust system, is intrinsically linked to the design and functionality of the component designed for sound reduction. This resistance significantly influences engine performance, fuel efficiency, and emissions characteristics. Understanding the interplay between these two elements is crucial for optimizing vehicle performance and maintaining regulatory compliance.

- Muffler Design and Restriction

The internal design of an exhaust noise reduction device, specifically the arrangement of chambers, baffles, and internal passages, directly influences the degree of exhaust backpressure. More restrictive designs, while potentially offering superior sound attenuation, inherently create greater backpressure. Conversely, less restrictive designs, such as those found in performance-oriented systems, minimize backpressure at the expense of noise reduction. An optimal design balances these competing factors to achieve acceptable noise levels without significantly hindering engine performance.

- Impact on Engine Performance

Excessive exhaust backpressure impedes the efficient expulsion of exhaust gases from the engine cylinders, leading to reduced volumetric efficiency and, consequently, lower power output and torque. This reduction is particularly noticeable at higher engine speeds. A properly designed component minimizes this backpressure, allowing the engine to breathe more freely and maintain optimal performance characteristics. Conversely, insufficient backpressure can also negatively impact engine performance, particularly at low RPMs.

- Fuel Efficiency Considerations

Increased exhaust backpressure forces the engine to work harder to expel exhaust gases, resulting in increased fuel consumption. The engine management system may compensate for the reduced efficiency by enriching the air-fuel mixture, further exacerbating fuel economy issues. Selecting an appropriate noise reduction device that minimizes backpressure is therefore crucial for maximizing fuel efficiency and reducing operating costs.

- Emissions Compliance

Exhaust backpressure can influence engine emissions characteristics. Excessive backpressure can lead to incomplete combustion, resulting in increased levels of harmful pollutants, such as hydrocarbons and carbon monoxide. Furthermore, it can negatively impact the performance of catalytic converters, further increasing emissions. A properly functioning noise reduction device that minimizes backpressure is essential for maintaining compliance with emissions regulations.

The relationship between exhaust backpressure and the system designed for sound reduction is a critical consideration in automotive engineering. Balancing noise attenuation with minimizing backpressure is essential for achieving optimal engine performance, fuel efficiency, and emissions compliance. The selection of an appropriate system requires careful consideration of these factors and a thorough understanding of the vehicle’s specific requirements.

3. Material durability

Material durability is a critical factor influencing the longevity, performance, and overall value of exhaust noise reduction systems. The harsh operating environment subjects these components to extreme temperatures, corrosive chemicals, and mechanical stresses, necessitating the use of robust and resilient materials.

- Corrosion Resistance

Exhaust systems are exposed to corrosive substances, including water, road salt, and acidic combustion byproducts. Materials with inherent resistance to corrosion, such as stainless steel and aluminized steel, are preferred to prevent rust and degradation. The specific grade of stainless steel, such as 304 or 409, determines its level of corrosion resistance and its suitability for different operating conditions. For instance, coastal regions with high salt concentrations demand materials with superior corrosion resistance to ensure long-term durability.

- Thermal Stability

Exhaust gases can reach extremely high temperatures, particularly near the engine manifold. Materials used in exhaust systems must maintain their structural integrity and mechanical properties at these elevated temperatures. Thermal stability is crucial to prevent warping, cracking, or weakening of the component. Alloys with high melting points and low thermal expansion coefficients are often employed to ensure dimensional stability and prevent stress-induced failures. Some systems incorporate heat shields to further protect the main component from extreme temperatures.

- Mechanical Strength

Exhaust systems are subjected to mechanical stresses from engine vibrations, road impacts, and thermal expansion and contraction. The material’s tensile strength, yield strength, and fatigue resistance are critical for withstanding these stresses and preventing mechanical failures. Thicker gauge materials and reinforced designs can enhance the mechanical strength and durability of the component. For example, heavy-duty trucks often utilize thicker-walled exhaust systems to withstand the greater stresses associated with their operation.

- Weld Integrity

Welding is a critical process in the manufacturing of exhaust systems. The quality and durability of the welds significantly impact the overall lifespan of the component. Proper welding techniques and the use of compatible filler metals are essential to ensure strong and corrosion-resistant joints. Poorly executed welds can create weak points that are susceptible to cracking or failure. Regular inspections of welds are recommended to identify and address any potential issues before they lead to catastrophic failures.

The selection of appropriate materials and manufacturing processes is paramount for ensuring the durability and longevity of exhaust noise reduction systems. Factors such as corrosion resistance, thermal stability, mechanical strength, and weld integrity must be carefully considered to withstand the harsh operating environment and provide reliable performance over the vehicle’s lifespan.

4. Internal construction

The internal construction of exhaust noise reduction systems is paramount to their effectiveness. The configuration of chambers, baffles, and resonators dictates how sound waves are manipulated to achieve desired noise reduction levels. Variations in design significantly impact performance characteristics, including sound attenuation, backpressure, and overall durability.

- Chamber Configuration

Chamber configuration refers to the arrangement and size of internal chambers within the component. Different configurations, such as straight-through, reverse-flow, and multi-chamber designs, exhibit varying degrees of sound attenuation and backpressure. Straight-through designs offer minimal backpressure but may provide limited noise reduction, while multi-chamber designs can achieve higher noise reduction levels at the expense of increased backpressure. For example, a vehicle requiring high performance may utilize a straight-through design, while a passenger vehicle may opt for a multi-chamber system to prioritize noise reduction.

- Baffle Design and Placement

Baffles are internal partitions designed to redirect and disrupt sound waves. The design and placement of baffles influence the frequency spectrum of the attenuated sound. Perforated baffles, for instance, allow some sound waves to pass through while reflecting others, effectively targeting specific frequencies. The strategic placement of baffles can create destructive interference patterns, further reducing noise levels. Racing applications often use minimal baffling to maximize exhaust flow, even at the cost of increased noise.

- Resonator Integration

Resonators are tuned chambers designed to cancel out specific frequencies. They operate by creating a sound wave that is 180 degrees out of phase with the target frequency, effectively neutralizing it. Resonators are often integrated into exhaust systems to address specific noise issues, such as drone or booming sounds at certain engine speeds. The placement and tuning of resonators are critical for their effectiveness. Aftermarket exhaust systems often incorporate resonators to fine-tune the sound characteristics of the exhaust note.

- Material Selection and Application

The materials used in internal construction directly affect the durability and performance of the noise reduction device. Stainless steel, aluminized steel, and other corrosion-resistant materials are commonly used to withstand the harsh operating environment. The thickness and gauge of the material influence its ability to withstand mechanical stresses and thermal cycling. Furthermore, the application of sound-absorbing materials, such as fiberglass or mineral wool, can enhance noise reduction capabilities. Heavy-duty applications typically require thicker materials and more robust construction to ensure long-term reliability.

In summary, the internal construction of an exhaust noise reduction system is a complex interplay of chamber configuration, baffle design, resonator integration, and material selection. These elements work in concert to achieve desired noise reduction levels while minimizing adverse effects on engine performance and durability. A thorough understanding of these design principles is essential for selecting the appropriate system for a given application.

5. Vehicle compatibility

The selection and installation of an exhaust noise reduction component are critically dependent on vehicle compatibility. This compatibility encompasses a range of factors, including engine type, exhaust system configuration, vehicle model year, and intended usage. A mismatch between the component and the vehicle can lead to performance degradation, increased noise levels, installation difficulties, and potential damage to the exhaust system or engine. For example, installing a component designed for a small displacement four-cylinder engine on a large displacement V8 engine would likely result in inadequate noise reduction and excessive backpressure, negatively impacting engine performance.

The physical dimensions and mounting points of the component must align with the vehicle’s existing exhaust system. Variations in pipe diameter, flange types, and hanger locations necessitate careful consideration during selection. Furthermore, the component’s internal design should be optimized for the specific engine’s exhaust characteristics. This includes matching the chamber volumes, baffle configurations, and resonator frequencies to the engine’s firing order and exhaust pulse characteristics. Performance-oriented vehicles often require specialized components designed to minimize backpressure and maximize exhaust flow, while maintaining acceptable noise levels. The improper selection of an exhaust noise reduction device can lead to reduced horsepower and torque.

In conclusion, ensuring vehicle compatibility is paramount for the effective and safe operation of an exhaust noise reduction component. This requires a thorough understanding of the vehicle’s specifications and the component’s design characteristics. Failure to consider these factors can result in performance degradation, increased noise pollution, and potential damage to the vehicle. Consult manufacturer specifications and professional installation services to ensure proper compatibility and optimal performance.

Frequently Asked Questions About Automotive Exhaust Noise Reduction Devices

This section addresses common inquiries and misconceptions regarding the function, maintenance, and selection of components designed to mitigate exhaust noise in vehicles. The information presented aims to provide clarity and promote informed decision-making regarding these essential automotive parts.

Question 1: What is the primary function of an automotive exhaust noise reduction device?

The primary function is to attenuate sound generated by the internal combustion engine’s exhaust system. This involves reducing the amplitude of sound waves to minimize noise pollution and comply with regulatory standards.

Question 2: How does the internal design of an exhaust noise reduction device contribute to its noise reduction capabilities?

The internal design, comprising chambers, baffles, and resonators, manipulates sound waves through reflection, absorption, and interference. These elements are carefully engineered to target specific frequencies and reduce overall noise levels.

Question 3: What factors influence the lifespan and durability of an automotive exhaust noise reduction device?

Material composition, welding quality, exposure to corrosive elements, and operating temperatures significantly impact the lifespan. Regular inspection and prompt repair of any damage are essential for maximizing longevity.

Question 4: Does the installation of an aftermarket exhaust noise reduction device void a vehicle’s warranty?

The effect on warranty coverage varies depending on the manufacturer’s policies and the nature of the aftermarket component. Modifications that directly cause damage to covered components may invalidate the warranty on those specific parts.

Question 5: How does exhaust backpressure affect engine performance and fuel efficiency?

Excessive exhaust backpressure impedes the efficient expulsion of exhaust gases, leading to reduced engine power and decreased fuel economy. A properly designed component minimizes backpressure while effectively reducing noise.

Question 6: What are the key considerations when selecting an exhaust noise reduction device for a specific vehicle?

Compatibility with the vehicle’s engine type, exhaust system configuration, and intended usage is crucial. Factors such as noise reduction requirements, performance expectations, and budget constraints should also be considered.

In summary, understanding the function, design, and maintenance of exhaust noise reduction devices is vital for ensuring optimal vehicle performance, minimizing noise pollution, and maintaining compliance with regulatory standards. Proper selection and installation are crucial for achieving desired results and avoiding potential issues.

The following sections will explore the environmental impact and regulatory considerations associated with these systems, providing a comprehensive understanding of their role in modern automotive technology.

Conclusion

This exploration has detailed the multifaceted aspects of the “beck muffler,” encompassing its functional design, maintenance requirements, and impact on both vehicle performance and environmental considerations. The effectiveness of this component hinges on a delicate balance between noise attenuation, exhaust backpressure, and material durability, each contributing to its overall utility and longevity.

Continued research and development in materials science and acoustic engineering are essential to further refine the design and performance of these systems. The ongoing pursuit of quieter, more efficient transportation solutions necessitates a deeper understanding of the complexities inherent in exhaust noise reduction technology, ensuring that future generations can benefit from both the mobility afforded by the internal combustion engine and a more peaceful environment. Therefore, further engagement with and investment in this technology are crucial for the advancement of sustainable automotive solutions.

![[Guide] Muffler Sizing: Find The Right Size Muffler For Your Car Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades [Guide] Muffler Sizing: Find The Right Size Muffler For Your Car | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/02/th-110-300x200.jpg)

![Richmond Muffler: Local Choice, Quiet Ride [Richmond, VA] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Richmond Muffler: Local Choice, Quiet Ride [Richmond, VA] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/02/th-108-300x200.jpg)