A component utilized in exhaust systems, primarily in automotive applications, functions to reduce noise emissions generated by the engine. Typically constructed from steel or aluminum, this device contains a series of chambers and perforated tubes designed to dampen sound waves. An example of this is a specific model designed for classic vehicles originating from a particular Los Angeles neighborhood known for its automotive culture.

The role of this element is significant for several reasons. It contributes to a quieter and more comfortable driving experience, while also playing a part in meeting noise pollution regulations. Historically, the development of these parts has mirrored advancements in engine technology and evolving environmental concerns, leading to increasingly sophisticated designs aimed at maximizing sound reduction without compromising engine performance.

The following sections will delve deeper into the various types available, the materials used in their construction, factors to consider during selection and installation, and common maintenance procedures to ensure longevity and optimal performance. Further examination will also cover performance considerations, regulatory compliance, and their impact on overall vehicle operation.

Reseda Muffler

The following guidelines provide actionable advice for maximizing the lifespan and effectiveness of your automotive exhaust sound dampening equipment. Proper maintenance and informed selection are crucial for optimal performance and regulatory compliance.

Tip 1: Regular Inspection for Corrosion: Examine the exterior regularly for signs of rust or physical damage. Corrosion compromises structural integrity and reduces noise reduction efficiency. Address minor rust spots promptly with rust inhibitors to prevent further degradation.

Tip 2: Monitor Exhaust Leaks: Listen for unusual exhaust noises indicating leaks. Escaping exhaust gases diminish noise reduction and may pose safety hazards. Repair leaks immediately by patching holes or replacing damaged sections of the exhaust system.

Tip 3: Ensure Proper Mounting and Secure Connections: Verify that all mounting points and connections are secure and properly aligned. Loose or misaligned components can cause vibrations, leading to premature wear and potential damage. Tighten or replace worn hardware as needed.

Tip 4: Consider Material Compatibility with Local Climate: Select equipment constructed from materials resistant to the corrosive effects of your local environment. In coastal regions with high salt concentrations, stainless steel variants offer superior durability compared to aluminized steel.

Tip 5: Evaluate Noise Level Requirements: Research and comply with local noise ordinances before purchasing replacement systems. Selecting a system that exceeds permissible noise levels can result in fines and legal repercussions.

Tip 6: Prioritize Quality Construction and Reputable Brands: Invest in components from established manufacturers known for quality construction and durability. Lower-cost, generic alternatives may offer short-term savings but often exhibit inferior performance and shorter lifespans.

Tip 7: Seek Professional Installation when Necessary: For complex exhaust system modifications or repairs, consult a qualified automotive technician. Incorrect installation can compromise performance, void warranties, and potentially damage other vehicle components.

By adhering to these maintenance and selection guidelines, vehicle owners can ensure the continued performance, longevity, and regulatory compliance of their exhaust sound dampening equipment.

The subsequent sections will delve into specific repair procedures, performance tuning options, and advanced diagnostic techniques for optimizing exhaust system efficiency.

1. Noise reduction efficiency

The primary function of an exhaust sound dampening device is the attenuation of engine noise, making noise reduction efficiency a paramount performance characteristic. The effectiveness with which a given device achieves this noise reduction directly correlates with its design, internal construction, and the materials employed. Higher efficiency translates to lower decibel levels emitted by the vehicle, contributing to a quieter environment and compliance with noise pollution regulations. Deficiencies in noise reduction, conversely, may result in legal penalties and diminished driving comfort.

Design features such as chamber size and configuration, perforation patterns in internal baffles, and the density and composition of sound-absorbing materials (e.g., fiberglass packing) significantly impact noise reduction efficiency. A well-designed system creates destructive interference of sound waves, canceling out a substantial portion of the engine’s exhaust noise. Consider, for instance, the development of specialized models designed to meet the stringent noise standards enforced in residential areas. These models incorporate advanced acoustic dampening techniques to minimize noise pollution in urban environments.

In summation, noise reduction efficiency is a defining characteristic impacting both environmental compliance and driver experience. Proper selection and maintenance are imperative. Factors such as a vehicle’s specific application, and environmental considerations must inform the selection process to ensure optimal performance. Failure to account for these interdependencies undermines the function and regulatory compliance, rendering the component ineffective.

2. Material durability

Material durability constitutes a critical determinant of the lifespan and performance of an exhaust sound dampening device. Premature failure due to corrosion, thermal stress, or mechanical damage compromises noise reduction efficiency and necessitates costly replacements. The selection of appropriate materials, therefore, directly impacts the long-term reliability and cost-effectiveness of this component. The operational environment, including exposure to road salts, extreme temperatures, and exhaust byproducts, exerts significant influence on material degradation rates. For example, a device constructed from low-grade steel in a region with heavy winter salting will exhibit accelerated corrosion compared to a stainless steel equivalent in a milder climate. This direct causal relationship underscores the importance of material selection.

Various materials are employed in the construction of these devices, each possessing distinct properties impacting durability. Aluminized steel offers a balance of corrosion resistance and cost-effectiveness, making it a common choice for original equipment manufacturers. However, stainless steel alloys, such as 304 or 409, provide superior resistance to corrosion and high-temperature oxidation, resulting in extended service life. Titanium represents an even more durable, albeit more expensive, option for high-performance applications. The design and manufacturing processes are likewise crucial; proper welding techniques and protective coatings enhance the inherent durability of the chosen material. Conversely, poorly executed welds or inadequate coatings create points of vulnerability, accelerating failure. The difference in operational lifespan between a properly constructed stainless steel muffler and a poorly constructed aluminized steel unit directly illustrates the tangible benefits of a focus on material durability.

In conclusion, material durability is not merely a desirable attribute but rather a fundamental requirement for the effective and economical operation of an exhaust sound dampening device. Understanding the properties of various construction materials, their resistance to specific environmental stressors, and the influence of manufacturing processes is essential for informed selection and maintenance. Addressing these factors proactively extends component lifespan, minimizes replacement costs, and maintains optimal noise reduction performance. Failing to acknowledge and address the interplay between material characteristics, environmental conditions, and operational stresses ultimately results in compromised reliability and increased expense.

3. Exhaust flow optimization

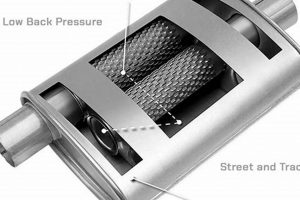

Exhaust flow optimization, in the context of an exhaust sound dampening device, relates directly to the efficiency with which exhaust gases are channeled through the system. Restriction of exhaust flow can negatively impact engine performance, fuel economy, and overall vehicle operation. An effective sound dampening device achieves a balance between noise reduction and minimal flow impedance.

- Core Design and Internal Structure

The internal configuration of a component significantly influences exhaust flow. Chambers, baffles, and perforations within the device serve to attenuate sound waves. However, poorly designed internal structures create turbulence and restrict gas passage. The design must balance acoustic requirements with the need for smooth, unimpeded flow. The optimal design for minimizing exhaust restrictions for a high performance vehicle will be very different from the optimal design to minimize noise on a passenger vehicle.

- Pipe Diameter and Flow Capacity

The diameter of the inlet and outlet pipes, as well as the internal passages, determines the device’s capacity to handle exhaust gases. Insufficient pipe diameter creates a bottleneck, increasing backpressure and reducing engine power. The proper sizing of the device to match the engine’s displacement and performance characteristics is critical for achieving optimal exhaust flow.

- Smooth Bends and Reduced Restrictions

Sharp bends and abrupt changes in pipe diameter within the device induce turbulence and increase flow resistance. The use of mandrel-bent tubing and gradual transitions minimizes these restrictions, promoting smoother and more efficient exhaust flow. Smooth transitions are critical to allow efficient transfer of exhaust gases.

- Backpressure Reduction and Engine Performance

Excessive backpressure within the exhaust system diminishes engine performance by hindering the expulsion of exhaust gases from the cylinders. Optimization of the device’s internal design and flow capacity minimizes backpressure, resulting in improved horsepower, torque, and fuel economy. However, zero backpressure can be detrimental and optimization for the individual engine in its application is critical.

The optimization of exhaust flow through an exhaust sound dampening device involves a complex interplay of design, materials, and engineering principles. Effective exhaust flow not only sustains performance but also contributes to longevity and compliance with regulatory standards.

4. Vehicle-specific compatibility

The selection of an exhaust sound dampening device requires meticulous attention to vehicle-specific compatibility, a factor directly influencing both performance and longevity. A device engineered for a different make, model, or engine configuration often results in compromised noise reduction, inefficient exhaust flow, or even physical incompatibility during installation. These discrepancies stem from variations in exhaust system geometry, engine displacement, and intended operating parameters. For instance, fitting a component designed for a four-cylinder engine onto a V8 engine will invariably lead to inadequate noise suppression and increased backpressure, negating any potential benefits. The intended application necessitates a tailored approach that acknowledges these intrinsic differences.

Practical considerations extend beyond mere fitment. A device may physically attach to an exhaust system yet still exhibit suboptimal performance due to mismatched flow characteristics. An undersized component creates a bottleneck, restricting exhaust gas expulsion and reducing engine power. Conversely, an oversized component may fail to adequately dampen noise, leading to non-compliance with local regulations. Manufacturers often provide detailed specifications outlining compatible vehicle models and engine types; adherence to these guidelines is paramount. Moreover, specialized vehicles, such as those equipped with aftermarket performance modifications, may necessitate custom-designed components to accommodate altered exhaust system layouts or increased engine output. An awareness of a vehicle’s unique characteristics is a necessity for correct component selection.

Vehicle-specific compatibility forms an indispensable element in the effective integration of an exhaust sound dampening device. The failure to prioritize compatibility introduces a spectrum of potential problems, ranging from diminished performance to legal ramifications. A comprehensive understanding of vehicle specifications, coupled with a judicious evaluation of device characteristics, ensures optimal functionality and long-term reliability. Ignoring vehicle-specific requirements results in a cascade of consequences that undermine the intended purpose and reduce overall vehicle performance.

5. Regulatory compliance

Regulatory compliance dictates the operational parameters for exhaust sound dampening devices, directly impacting design, manufacturing, and permissible noise emissions. Failure to adhere to established noise regulations can result in significant penalties, including fines, vehicle impoundment, and legal repercussions. The connection between regulatory compliance and devices specifically designed for sound reduction is thus inextricable; one serves as the defining constraint for the other.

Different jurisdictions impose varying noise limits, measured in decibels (dB), to mitigate noise pollution. These regulations often specify maximum allowable noise levels at certain distances from the vehicle or under particular operating conditions. In California, for example, strict noise laws necessitate the use of components certified to meet specific dB limits. This requirement has led to the development of specialized models designed and tested to comply with California’s stringent standards. Such examples demonstrate how regulatory requirements directly shape the design and functionality of such devices. Selecting a non-compliant component, irrespective of its individual performance characteristics, renders a vehicle in violation of local ordinances. The process of importing and registering used Japanese sports cars has been significantly complicated by California’s CARB requirements. This is an example of how the regulations have an outsized effect on the cost and availability of vehicles that were never designed with that state’s particular compliance requirements in mind.

In summation, regulatory compliance is not merely an ancillary consideration but a fundamental determinant in the selection and utilization of such sound dampening systems. Awareness of prevailing noise regulations, coupled with the implementation of certified and compliant components, ensures adherence to legal mandates and contributes to environmental well-being. Non-compliance carries tangible consequences, underscoring the critical importance of integrating regulatory considerations into every aspect of vehicle operation and maintenance. Adherence to noise standards is legally necessary and helps maintain good community relations.

6. Installation integrity

Installation integrity is a critical factor influencing the performance and longevity of an exhaust sound dampening device. Improper installation can compromise noise reduction, impede exhaust flow, and potentially damage the component or surrounding vehicle systems. Proper installation techniques are essential to realizing the intended benefits of the equipment.

- Secure Mounting and Support

The device must be securely mounted to the vehicle’s exhaust system using appropriate hangers and brackets. Insufficient support can lead to excessive vibration, stress fractures, and premature failure. Proper alignment of the device within the exhaust system is also crucial to prevent strain on connecting pipes and joints. For example, neglecting to replace worn rubber hangers during installation can result in increased vibration and noise transmission, counteracting the noise reduction benefits of the equipment.

- Proper Sealing of Joints and Connections

All joints and connections must be properly sealed to prevent exhaust leaks. Leaks not only diminish noise reduction effectiveness but also pose safety hazards due to the potential for carbon monoxide exposure. The use of high-quality gaskets and sealant compounds is essential to ensure airtight seals. For instance, failing to adequately seal the connection between the muffler and the exhaust pipe can result in an audible exhaust leak and reduced engine performance.

- Correct Orientation and Positioning

The device must be installed in the correct orientation and position as specified by the manufacturer. Incorrect positioning can alter exhaust flow dynamics, increase backpressure, and even cause physical interference with other vehicle components. Consulting the vehicle’s service manual and the device’s installation instructions is essential for ensuring proper placement. Installing a muffler backwards, although seemingly improbable, can dramatically alter its noise reduction capabilities and potentially damage the internal components.

- Torque Specifications and Fastener Selection

All fasteners used in the installation process must be tightened to the manufacturer’s specified torque values. Over-tightening can damage fasteners or mounting points, while under-tightening can lead to loosening and eventual failure. The use of appropriate fasteners, such as stainless steel bolts and nuts, is crucial for corrosion resistance and long-term reliability. For example, using incorrect torque values on exhaust manifold bolts can lead to exhaust leaks and potential damage to the cylinder head.

These facets of installation integrity directly impact the sound reduction and exhaust flow characteristics. Proper installation techniques guarantee that the device will perform as intended, contributing to both vehicle performance and regulatory compliance. Failure to adequately address these critical points undermines component effectiveness and presents potential safety concerns.

Frequently Asked Questions about Reseda Muffler Systems

This section addresses common inquiries regarding exhaust sound dampening systems, providing concise and informative answers to enhance understanding and guide decision-making.

Question 1: What is the primary function of this type of exhaust component?

The primary function is to attenuate engine noise, reducing the decibel level of exhaust emissions to comply with regulatory standards and improve driving comfort.

Question 2: How does the selection of materials impact the performance of a device?

Material durability significantly affects the lifespan and resistance to corrosion. Stainless steel provides superior protection in harsh environments compared to aluminized steel.

Question 3: What role does exhaust flow optimization play in engine performance?

Exhaust flow optimization minimizes backpressure, improving engine horsepower, torque, and fuel efficiency by facilitating the efficient expulsion of exhaust gases.

Question 4: Why is vehicle-specific compatibility essential for proper operation?

Vehicle-specific compatibility ensures the device is appropriately sized and configured for the engine and exhaust system, optimizing noise reduction and exhaust flow.

Question 5: What are the potential consequences of failing to comply with noise regulations?

Failure to comply with noise regulations can result in fines, vehicle impoundment, and legal repercussions, depending on the severity of the violation and local ordinances.

Question 6: How does installation integrity affect the performance and longevity of the component?

Proper installation, including secure mounting and sealed connections, is essential for preventing leaks, reducing vibration, and ensuring optimal noise reduction and component lifespan.

In summary, the effective utilization of these systems hinges on a thorough understanding of their function, material properties, design considerations, and regulatory implications. Informed decision-making ensures optimal performance, longevity, and compliance.

The subsequent sections will provide a detailed guide on troubleshooting common issues and performing advanced diagnostics to maintain optimal exhaust system performance.

Reseda Muffler

This exploration has elucidated the critical role of the reseda muffler within the complex system of automotive exhaust management. From the intricacies of noise reduction and material durability to the imperatives of regulatory compliance and installation integrity, the preceding sections have emphasized the multifaceted considerations that govern the selection, maintenance, and overall effectiveness of this vital component. The interplay between engineering design, environmental factors, and legal mandates underscores the significance of informed decision-making in optimizing vehicle performance and minimizing environmental impact. The careful selection, proper installation and thoughtful maintenance of a reseda muffler is of critical importance.

As automotive technology continues to evolve and environmental consciousness intensifies, the demands placed upon exhaust sound dampening devices will undoubtedly increase. Vigilance in monitoring regulatory changes, coupled with a commitment to employing best practices in component selection and maintenance, will be paramount. The continued development of innovative materials and designs will drive further advancements in noise reduction and exhaust flow efficiency, contributing to a quieter, cleaner, and more sustainable future for automotive transportation. The need for awareness of the reseda muffler will only increase in the future.