A component utilized in exhaust systems to reduce noise is identified by numerical dimensions, specifically referencing its inlet, outlet, and body size. This configuration plays a vital role in attenuating sound waves generated by the engine’s combustion process. As an example, a unit conforming to these specifications might be installed on a small engine vehicle, effectively lowering the decibel level of exhaust emissions.

The significance of this noise reduction device extends to both regulatory compliance and enhanced user experience. Governing bodies often mandate noise level restrictions, necessitating the use of such devices to meet environmental standards. Moreover, diminishing exhaust noise contributes to a more comfortable and less disruptive driving experience for vehicle occupants and surrounding areas. Historically, advancements in exhaust technology have focused on optimizing noise reduction capabilities while minimizing backpressure, thus improving engine performance and fuel efficiency.

The subsequent discussion will delve into the various types available, their construction materials, and the key factors influencing their performance and longevity. Furthermore, installation guidelines and maintenance practices will be examined to ensure optimal functionality and extended service life.

Operational Guidance

The following guidance addresses key considerations for maximizing the effectiveness and lifespan of noise reduction components characterized by specific dimensional attributes.

Tip 1: Ensure Dimensional Compatibility: Prior to installation, verify that the inlet and outlet diameters match the existing exhaust system. Dimensional mismatch can lead to leaks, reduced performance, and potential damage to connected components. For instance, employing incorrect adapters can compromise the integrity of the exhaust system.

Tip 2: Utilize Correct Installation Techniques: Secure connections are crucial. Employ appropriate clamping or welding techniques based on the manufacturer’s specifications and the materials being joined. Insufficiently secured connections may result in exhaust leaks and premature component failure.

Tip 3: Consider Material Composition: Select a material grade suitable for the operating environment. Stainless steel offers superior corrosion resistance compared to aluminized steel, particularly in regions with harsh climates or road salt exposure. Neglecting this factor can significantly reduce the component’s service life.

Tip 4: Implement Regular Inspections: Periodically inspect for signs of corrosion, damage, or leaks. Addressing minor issues promptly can prevent more significant problems and costly repairs down the line. For example, early detection of surface rust allows for timely treatment and prevention of structural degradation.

Tip 5: Minimize Exposure to Abrasive Materials: Shield the component from direct impact with road debris or other abrasive materials. Protecting it from such external factors will help to preserve its structural integrity and prevent premature wear.

Tip 6: Optimize Exhaust Flow: When selecting a design, consider its impact on exhaust flow. A design that unduly restricts exhaust flow can negatively affect engine performance and fuel efficiency. Therefore, evaluate internal design and its ability to balance noise reduction and flow optimization.

Adherence to these guidelines will contribute to the reliable operation and extended service life of this crucial component, ensuring continued compliance with noise regulations and a more refined operating experience.

The concluding section will summarize the essential aspects discussed and provide further considerations for ongoing maintenance and potential upgrades.

1. Noise Reduction Efficiency

Noise reduction efficiency represents a primary performance metric for exhaust system components. This characteristic dictates the degree to which an exhaust system device mitigates sound pressure levels generated by an internal combustion engine, directly influencing regulatory compliance and user experience. Understanding the facets contributing to this efficiency is crucial when evaluating a noise attenuation device.

- Internal Chamber Design

The internal configuration significantly impacts noise reduction. Baffled chambers, resonating cavities, and absorption materials work in concert to disrupt and attenuate sound waves. A more complex internal structure generally correlates with greater noise reduction, but also potentially increased backpressure. For example, S-shaped flow paths force sound waves to travel further, promoting cancellation, but may impede exhaust gas flow if not optimally designed.

- Sound Absorption Materials

The incorporation of sound-absorbing materials, such as fiberglass packing or specialized acoustic composites, enhances the suppression of high-frequency noise components. These materials convert sound energy into heat through friction within their fibrous structure. The density, composition, and placement of these materials directly affect the frequency range targeted for attenuation. A higher density packing often yields improved high-frequency noise reduction.

- Resonator Technology

Resonators are specifically tuned chambers designed to cancel out specific frequencies through destructive interference. By precisely calculating chamber dimensions, engineers can target dominant noise frequencies generated by the engine. Effective resonator design requires accurate engine noise profiling and precise manufacturing tolerances to ensure the intended cancellation effect is achieved. Improper tuning can result in negligible or even detrimental effects on overall noise levels.

- Backpressure Considerations

Noise reduction strategies often introduce backpressure within the exhaust system. Excessive backpressure can negatively affect engine performance, fuel efficiency, and even engine longevity. Achieving optimal noise reduction efficiency requires a careful balance between sound attenuation and minimizing backpressure. Advanced designs often incorporate features such as perforated cores and optimized flow paths to mitigate the adverse effects of noise reduction measures on exhaust gas flow.

These facets highlight the interconnected nature of noise reduction efficiency. A device achieves its intended function through a combination of internal design features, material properties, and engineering considerations. The selection and implementation of these elements must be carefully considered to balance noise reduction effectiveness with other critical performance parameters.

2. Exhaust Flow Dynamics

Exhaust flow dynamics are paramount in determining the overall performance of an internal combustion engine equipped with a noise reduction device characterized by specific dimensional attributes. The flow characteristics through this component directly influence engine power, fuel efficiency, and emissions output. Optimizing these dynamics is crucial for achieving a harmonious balance between noise attenuation and engine performance.

- Internal Volume and Diameter

The internal volume and diameter of the core affect the velocity and pressure of exhaust gases as they transit through the component. A larger internal volume generally reduces backpressure but may compromise noise reduction capabilities. Conversely, a smaller diameter core increases exhaust velocity, potentially enhancing scavenging effects but also elevating backpressure. Balancing these factors is essential for optimal engine performance.

- Baffle Design and Placement

Baffles are strategically positioned within the component to disrupt sound waves and reduce noise. However, their design and placement significantly impact exhaust flow. Baffles that are too restrictive can create excessive backpressure, impeding exhaust flow and reducing engine power. Optimized baffle designs minimize flow resistance while effectively attenuating noise. For example, louvred baffles offer a compromise between noise reduction and flow efficiency.

- Surface Roughness and Material

The internal surface roughness and material properties influence the friction experienced by exhaust gases as they flow through the component. A smoother internal surface reduces friction and promotes laminar flow, minimizing pressure drop. Materials with low thermal conductivity can help maintain exhaust gas temperature, aiding in efficient catalyst operation. For instance, ceramic coatings can reduce surface roughness and improve thermal insulation.

- Flow Path Configuration

The overall configuration of the flow path determines the residence time of exhaust gases within the component and the direction of flow. A straight-through design minimizes flow restriction but may offer limited noise reduction. S-shaped or convoluted flow paths increase residence time and enhance noise attenuation but can also increase backpressure. The optimal flow path configuration depends on the specific application and desired performance characteristics.

The interrelationship between internal volume, baffle design, surface characteristics, and flow path configuration collectively dictates exhaust flow dynamics within the designated component. By carefully considering these factors, engineers can optimize the design to minimize backpressure, maximize noise reduction, and ensure optimal engine performance across a wide range of operating conditions. Efficient exhaust flow is directly correlated with improvements in fuel economy, power output, and reduced emissions, highlighting the critical importance of understanding and managing these dynamics.

3. Material Durability

The longevity and reliable operation of a noise reduction component with specific dimensional attributes are inextricably linked to the durability of the materials used in its construction. The harsh environment within an exhaust system exposes these components to high temperatures, corrosive gases, and mechanical stresses. Material selection directly dictates the component’s ability to withstand these challenges, impacting its lifespan and overall performance. A failure in material integrity can lead to exhaust leaks, reduced noise reduction efficiency, and potential damage to other exhaust system components. For instance, a steel unit exposed to road salt without adequate corrosion protection will degrade rapidly, potentially requiring premature replacement. This connection underscores the importance of selecting materials that are specifically designed to withstand the rigorous demands of the exhaust system environment.

The choice of materials extends beyond the primary shell of the noise attenuation device. Internal components, such as baffles and sound-absorbing packing, must also exhibit comparable durability. Deterioration of these internal parts can compromise the component’s noise reduction capabilities and potentially contribute to increased backpressure. Furthermore, the welding or joining techniques employed in construction must ensure long-term structural integrity. Weak welds or poorly chosen joining materials can become points of failure, particularly under conditions of thermal cycling and vibration. A practical example is the use of high-quality stainless steel and proper welding processes in aftermarket performance applications to enhance durability and extend the life of the exhaust component.

In conclusion, the correlation between material durability and the operational lifespan of a noise reduction component with specific dimensional attributes is undeniable. Careful consideration of material selection, internal component design, and joining techniques is essential to ensure long-term reliability and optimal performance. While cost considerations often influence material choices, prioritizing durability is crucial for minimizing life-cycle costs and maximizing the value of the investment. Challenges remain in developing cost-effective materials that can withstand increasingly stringent environmental regulations and performance demands, highlighting the need for ongoing research and development in this area.

4. Dimensional Compatibility

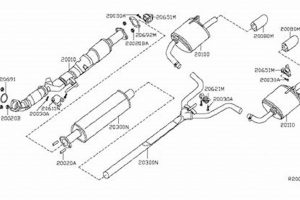

Dimensional compatibility is a critical factor governing the successful integration and performance of an exhaust component characterized by specified dimensions. Adherence to precise dimensional specifications ensures proper fitment within the existing exhaust system, preventing leaks, performance degradation, and potential damage to interconnected components. The dimensional attributes of a particular component must align with those of the exhaust piping and associated hardware for optimal functionality.

- Inlet and Outlet Diameter Matching

Correct matching of inlet and outlet diameters to the corresponding exhaust system piping is paramount. Discrepancies in diameter can result in exhaust leaks, reduced exhaust velocity, and inefficient catalytic converter operation. For example, if the inlet diameter is smaller than the exhaust pipe diameter, it can create a restriction, increasing backpressure and diminishing engine performance. Conversely, a larger inlet diameter may result in a poor seal, leading to leaks and compromising noise reduction effectiveness. Adaptors can be used to bridge small differences but are not ideal for larger mismatches.

- Overall Length and Body Size

The overall length and body size must be compatible with the available space within the vehicle’s undercarriage. Insufficient clearance can lead to physical interference with other components, potentially causing damage or creating unwanted noise and vibration. Furthermore, a component that is too long may require modifications to the exhaust system, increasing installation complexity and cost. Consideration of these spatial constraints is essential during the selection process.

- Hanger Placement and Orientation

Proper hanger placement and orientation are crucial for securing the component and preventing undue stress on the exhaust system. Misaligned hangers can lead to vibration, noise, and potential cracking of the exhaust piping. The hangers must be compatible with the existing mounting points on the vehicle’s frame or chassis. Incorrect hanger positioning can also place stress on the inlet and outlet connections, increasing the risk of leaks. Therefore, hanger compatibility is a key aspect of dimensional consideration.

- Component Body Shape and Design

The overall shape and design of the noise reduction device must be assessed for compatibility with the vehicle’s undercarriage. In some vehicles the shape of the tunnel may prevent installation of certain shapes or designs. Also, the proximity of other components such as fuel lines or suspension parts must also be factored into this design consideration. Some designs may be more susceptible to damage from road debris or require additional heat shielding if they are located near heat-sensitive components.

These dimensional considerations are intrinsically linked to the performance and longevity of the product. The proper matching of inlet and outlet diameters, suitable overall dimensions, accurate hanger placement, and consideration of the component body are vital to the functionality of the device. Overlooking these aspects can result in reduced noise attenuation efficiency, diminished engine performance, and premature component failure. As such, dimensional compatibility serves as a cornerstone for ensuring optimal performance and reliability.

5. Installation Requirements

The successful and safe integration of a noise reduction component characterized by specific dimensional attributes is directly predicated on adherence to specified installation requirements. These requirements encompass a range of factors, from the selection of appropriate tools and hardware to the proper execution of welding or clamping procedures. Failure to comply with these requirements can result in exhaust leaks, compromised performance, and, in some instances, hazardous operating conditions. The “installation requirements” serve as a critical link in the functionality chain for a device characterized by dimensional parameters, dictating its ultimate effectiveness and service life. As an example, neglecting to use properly sized and torqued clamps can lead to exhaust leaks, negating the noise reduction benefits and potentially damaging surrounding components. Conversely, employing the correct welding techniques, such as gas tungsten arc welding (GTAW) for stainless steel, ensures a strong, corrosion-resistant joint, promoting long-term reliability.

Beyond the physical aspects of installation, pre-installation checks play a crucial role. These checks include verifying dimensional compatibility, inspecting for pre-existing damage to the exhaust system, and ensuring proper alignment of the noise reduction component within the vehicle’s undercarriage. For instance, if the existing exhaust piping is corroded or misaligned, simply bolting on a new component without addressing these underlying issues can lead to premature failure and negate any performance gains. Moreover, specific torque specifications for fasteners must be strictly adhered to. Over-tightening can damage the threads or distort the component, while under-tightening can result in leaks. The correct installation procedure guarantees not only the proper fit but also the long-term stability and performance.

In conclusion, the success of this device and its installation hinges on diligent adherence to the specific installation requirements. The use of correct tools, proper techniques, and thorough pre-installation checks directly influence the performance, longevity, and safety of the component. Overlooking these requirements introduces the risk of operational deficiencies and potential hazards, ultimately undermining the value and effectiveness of the intended design. The investment in proper installation translates directly into a more refined operating experience, prolonged component life, and compliance with noise regulations.

Frequently Asked Questions Regarding Specific Exhaust Components

The following section addresses common inquiries concerning exhaust components characterized by a specific dimensional attribute, providing clear and concise answers to enhance understanding and promote informed decision-making.

Question 1: What is the typical lifespan?

The lifespan of an exhaust component is contingent upon several factors, including material composition, operating conditions, and maintenance practices. Stainless steel units generally exhibit greater longevity compared to aluminized steel counterparts, particularly in environments prone to corrosion. Regular inspections and prompt attention to any signs of damage or corrosion can significantly extend its service life.

Question 2: Does this affect vehicle performance?

The impact on vehicle performance depends on the specific design and internal configuration. Designs that unduly restrict exhaust flow can negatively affect engine power and fuel efficiency. Conversely, optimized designs that minimize backpressure can enhance engine performance while still achieving effective noise reduction. Selection of an appropriately sized component for the given engine displacement is crucial.

Question 3: How is this component installed?

Installation typically involves clamping or welding the component into the existing exhaust system. Proper alignment, secure connections, and adherence to manufacturer’s torque specifications are essential. Professional installation is recommended to ensure proper fitment and prevent leaks. The removal of any pre-existing component needs to be done carefully without damaging surrounding components.

Question 4: What maintenance does this part need?

Routine maintenance includes visual inspections for corrosion, damage, and leaks. Addressing minor issues promptly can prevent more significant problems. Periodically tightening clamps and applying rust preventative coatings can further extend the component’s lifespan.

Question 5: Is it possible to replace only this part?

Replacement of individual components within an exhaust system is generally feasible, provided that the existing system is in reasonably good condition. However, if the surrounding exhaust piping is significantly corroded or damaged, replacing the entire exhaust system may be a more prudent and cost-effective solution.

Question 6: How do I choose the correct size?

Selecting the correct size requires careful consideration of inlet and outlet diameters, overall length, and vehicle-specific fitment requirements. Consulting the vehicle manufacturer’s specifications or seeking advice from a qualified exhaust technician is recommended to ensure dimensional compatibility.

Understanding these aspects of this specific device empowers users to make informed decisions regarding selection, installation, and maintenance, ultimately contributing to enhanced vehicle performance and long-term reliability.

The following section will provide a summary of key considerations for future product development.

Conclusion

This exploration of the “1 1 4 muffler” has illuminated its multifaceted role within exhaust systems. Key aspects examined include noise reduction efficiency, exhaust flow dynamics, material durability, dimensional compatibility, and installation requirements. A thorough understanding of these elements is essential for proper selection, installation, and maintenance of this critical component, ensuring optimal performance and compliance with regulatory standards.

The continued advancement of noise reduction technology, coupled with increasingly stringent environmental regulations, necessitates ongoing research and development in this field. Prioritizing durability, optimizing exhaust flow dynamics, and ensuring dimensional compatibility will remain central to future innovations. As such, a continued focus on these principles is critical for maximizing the effectiveness and longevity of exhaust components in a constantly evolving automotive landscape.