This exhaust component is designed to reduce the noise produced by an internal combustion engine. It’s a crucial part of the vehicle’s exhaust system, responsible for attenuating sound waves created during the combustion process. These devices come in various shapes, sizes, and materials, tailored to different vehicle types and performance requirements.

The function of these sound-dampening components improves driving comfort by minimizing engine noise pollution. Historically, the development of these devices coincided with increasing concerns about noise pollution in urban areas. Modern iterations are designed not only to reduce noise but also to optimize exhaust flow and minimize backpressure, potentially improving engine efficiency and performance. Some performance-oriented models are constructed from materials like stainless steel for enhanced durability and resistance to corrosion.

Further sections will detail specific designs, installation procedures, performance characteristics, and common maintenance requirements related to this crucial element of automotive exhaust systems. These sections aim to provide a comprehensive understanding of their operation and optimization.

Tips for Optimal Performance

Maximizing the service life and effectiveness of the exhaust sound reduction device requires adherence to specific guidelines. Proper installation and regular maintenance are paramount.

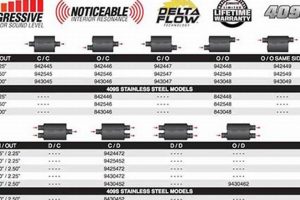

Tip 1: Select the Correct Model: Prior to installation, ensure that the replacement part is specifically designed for the vehicle’s make, model, and year. Incompatibility can lead to reduced performance and potential damage to the exhaust system.

Tip 2: Professional Installation is Recommended: Unless possessing advanced mechanical skills and appropriate tools, professional installation is strongly advised. Improper installation can compromise the device’s effectiveness and potentially damage surrounding components.

Tip 3: Inspect Mounting Hardware Regularly: Vibration and temperature fluctuations can loosen mounting hardware over time. Regularly inspect clamps, brackets, and hangers, tightening or replacing them as necessary to prevent premature wear and potential exhaust leaks.

Tip 4: Address Exhaust Leaks Promptly: Even small exhaust leaks can significantly reduce the effectiveness of the device and increase noise levels. Inspect the exhaust system regularly for signs of leaks, such as soot or unusual noises, and address them immediately.

Tip 5: Avoid Excessive Heat Exposure: Prolonged exposure to extreme heat can damage the internal components of the device. Avoid prolonged idling in hot environments and ensure proper cooling system function to minimize heat build-up in the exhaust system.

Tip 6: Consider Material Upgrades: For vehicles subjected to harsh environments or high-performance applications, upgrading to a stainless steel construction offers superior corrosion resistance and longevity.

Following these guidelines helps ensure that the exhaust sound reduction device functions optimally, providing a quieter and more efficient driving experience.

The subsequent sections will elaborate on specific performance characteristics and troubleshooting techniques related to exhaust systems.

1. Noise Reduction

Noise reduction is a primary function of exhaust systems, significantly influencing vehicle comfort and regulatory compliance. The device designed to reduce noise from the exhaust system plays a central role in achieving these goals, directly impacting the overall auditory experience associated with vehicle operation.

- Internal Acoustic Design

The internal structure incorporates chambers, baffles, and sound-absorbing materials strategically arranged to attenuate sound waves. This design disrupts the propagation of sound, reducing its intensity as it passes through the device. Variations in internal design, such as resonator placement and baffle configuration, influence the frequency and amplitude of sound reduction. This influences the characteristics of the overall sound reduction.

- Material Composition

The materials selected for construction contribute to sound absorption and damping. Materials such as fiberglass packing or specialized acoustic insulation are often incorporated to absorb sound energy and minimize resonance within the device. The density and composition of these materials directly affect their ability to dampen sound waves across different frequency ranges.

- Resonance Cancellation

Specific frequencies can be targeted for cancellation through the strategic design of resonators within the device. These resonators are tuned to specific frequencies, effectively canceling out undesirable noise components. This approach is often used to minimize drone or booming sounds that can be particularly irritating to vehicle occupants.

- Shell Construction and Vibration Damping

The outer shells construction impacts the transmission of sound and vibration. Sturdy, well-damped shells minimize the radiation of noise from the device itself. Vibration damping materials may be applied to the shell to further reduce noise emissions by minimizing resonant vibrations.

In summary, effective noise reduction relies on a combination of internal acoustic design, material selection, resonance cancellation, and shell construction. Optimizing these elements is essential for achieving a balance between performance, noise reduction, and durability in the exhaust system.

2. Exhaust Flow

Exhaust flow, the movement of spent combustion gases from an engine, is significantly influenced by the design of the device installed within the exhaust system. The design of this element affects engine performance, fuel efficiency, and emissions control. Optimizing exhaust flow is crucial for maximizing engine output while adhering to regulatory standards.

- Internal Design and Backpressure

The internal configuration dictates the degree of backpressure exerted on the engine. Excessive backpressure hinders the evacuation of exhaust gases, reducing engine power and efficiency. A device with a more direct flow path minimizes backpressure, allowing for more efficient exhaust gas removal. The specific balance between noise reduction and backpressure is a key design consideration.

- Pipe Diameter and Flow Rate

The diameter of the inlet and outlet pipes influences the exhaust flow rate. A larger diameter typically allows for greater flow, reducing backpressure. However, excessively large diameters can reduce exhaust gas velocity, potentially impacting scavenging effects and emissions control. Matching the pipe diameter to the engine’s displacement and power output is essential for optimal performance.

- Surface Smoothness and Turbulence

The smoothness of internal surfaces minimizes turbulence within the exhaust stream. Turbulence increases backpressure and reduces flow efficiency. Polished or coated internal surfaces can reduce turbulence, improving exhaust flow. The overall impact of surface smoothness depends on the overall design and operating conditions.

- Flow Distribution and Scavenging

Internal features, such as baffles or diffusers, can influence the distribution of exhaust flow and promote scavenging effects. Scavenging refers to the process of using exhaust pulses to draw out remaining exhaust gases from the cylinders. Properly designed systems enhance scavenging, improving cylinder filling and combustion efficiency.

The interplay between internal design, pipe diameter, surface smoothness, and flow distribution determines the overall impact on exhaust flow. Careful optimization of these factors is necessary to achieve the desired balance between performance, fuel economy, and emissions compliance in a given vehicle application.

3. Material Durability

Material durability is a paramount consideration in the design and selection of exhaust system components. The operational environment subjects these components to extreme conditions, including high temperatures, corrosive exhaust gases, road salts, and physical impacts. The lifespan and performance of the sound reduction device are directly correlated to the materials used in its construction.

- Corrosion Resistance

Corrosion is a primary cause of failure in exhaust systems. Exposure to moisture and acidic exhaust gases leads to oxidation and degradation of metallic components. Materials such as stainless steel offer superior corrosion resistance compared to aluminized steel or mild steel. Stainless steel alloys contain chromium, which forms a passive oxide layer that protects the underlying metal from corrosion. The grade of stainless steel used affects its corrosion resistance, with higher grades offering improved performance in harsh environments. Premature failure due to corrosion results in increased noise levels and potential exhaust leaks.

- Thermal Fatigue Resistance

Exhaust systems undergo significant temperature fluctuations during normal operation. Repeated heating and cooling cycles induce thermal stress, which can lead to fatigue cracking and material degradation. Materials with high thermal fatigue resistance, such as certain grades of stainless steel or specialized alloys, are better able to withstand these temperature variations without cracking or deforming. Thermal fatigue is accelerated by poor exhaust system design or excessive engine temperatures.

- Mechanical Strength and Impact Resistance

The exhaust system is vulnerable to physical impacts from road debris, speed bumps, and other hazards. Materials with high mechanical strength and impact resistance are better able to withstand these forces without sustaining damage. The thickness of the material also contributes to its impact resistance. Dents or punctures in the exhaust device can alter its acoustic properties and reduce its effectiveness. High-quality materials also resist deformation under the stress of clamping forces during installation.

- Weld Integrity and Joint Strength

Welds are critical points of potential failure in the exhaust system. The quality of the welds and the strength of the joints determine the overall structural integrity. Welding processes that produce strong, durable welds are essential for ensuring the longevity of the exhaust device. Proper welding techniques and filler materials are crucial for preventing weld cracking and corrosion. The design of the joints also affects their strength and resistance to stress.

In summary, the selection of durable materials and robust construction techniques are essential for maximizing the lifespan and performance of exhaust system components. Corrosion resistance, thermal fatigue resistance, mechanical strength, and weld integrity are critical factors to consider when evaluating the long-term reliability of sound reduction devices. Choosing higher-quality materials translates to reduced maintenance costs and improved overall vehicle performance.

4. Vehicle Compatibility

Vehicle compatibility represents a critical determinant of performance and longevity for automotive exhaust components. Improper fitment, resulting from mismatched specifications, can lead to diminished noise reduction, increased backpressure, and potential damage to the exhaust system or surrounding vehicle structures. The importance of vehicle-specific designs cannot be overstated; attempting to adapt an incompatible unit invariably leads to suboptimal results. As an example, installing a system designed for a V8 engine on an inline-four cylinder vehicle will likely result in insufficient backpressure, negatively impacting engine efficiency and potentially triggering diagnostic error codes. Accurate identification of vehicle make, model, and year is thus an indispensable step in the selection process.

Several real-world scenarios underscore the practical significance of understanding vehicle compatibility. In cases of performance modifications, for example, aftermarket exhaust systems are often designed with specific engine configurations in mind. A performance-oriented unit marketed for a particular sports car may offer increased exhaust flow and enhanced sound characteristics, but its effectiveness depends entirely on proper fitment. Conversely, installing a system designed for a different vehicle, even one with a similar engine displacement, could introduce unforeseen problems such as exhaust leaks, reduced ground clearance, or interference with other vehicle components. The installation process itself is greatly simplified when vehicle-specific designs are used. Direct-fit systems minimize the need for modifications or adjustments, reducing installation time and the risk of errors.

In conclusion, vehicle compatibility is not merely a desirable attribute but a fundamental requirement for the successful integration of this component into an exhaust system. Selecting a component designed specifically for the intended vehicle minimizes potential problems and ensures optimal performance. Challenges associated with incompatibility include reduced engine efficiency, increased noise levels, and potential mechanical damage. Attention to detail regarding vehicle specifications and component selection is thus crucial for ensuring the long-term reliability and effectiveness of the exhaust system.

5. Installation Method

The installation method exerts a profound influence on the performance and longevity of the exhaust system component. Adherence to recommended procedures, including proper alignment, secure fastening, and the use of appropriate sealing techniques, is paramount. Deviations from specified methods can lead to exhaust leaks, compromised noise reduction, and premature component failure. The connection between installation and system integrity is direct and quantifiable. A loosely fitted joint, for example, will almost certainly result in an exhaust leak, negating the intended sound-dampening effect and potentially introducing harmful emissions into the passenger compartment. Likewise, over-tightening fasteners can damage mounting points or distort the component itself, impacting its functionality. The effectiveness of this exhaust component is thus intrinsically linked to the precision and care employed during installation.

Practical illustrations of this connection are readily apparent in automotive service environments. Consider the scenario of a mechanic replacing a unit without properly cleaning the mating surfaces. Residual debris or corrosion can prevent a tight seal, creating a pathway for exhaust gases to escape. Or, consider the impact of using incorrect or worn-out hangers. Insufficient support can cause the system to vibrate excessively, leading to stress fractures and eventual failure of the welded joints. Furthermore, improper alignment of the exhaust system can induce strain on the connections, accelerating wear and tear. These examples emphasize the need for thoroughness and attention to detail throughout the installation process. Moreover, the correct tools are required to do the job right. Using incorrect tools can damage components during installation and introduce unintended stress.

In conclusion, the installation method is not merely a procedural formality but an integral component of the overall effectiveness of exhaust system functionality. Proper installation not only ensures optimal noise reduction and exhaust flow but also contributes significantly to the component’s lifespan and the overall health of the vehicle’s exhaust system. Challenges associated with neglecting proper installation techniques, such as exhaust leaks and premature failure, can be mitigated through adherence to established procedures and the use of qualified technicians. The investment in proper installation yields long-term benefits in terms of performance, reliability, and reduced maintenance costs.

6. Maintenance Schedule

A meticulously planned maintenance schedule is critical for maximizing the lifespan and operational efficiency of the exhaust system component. Neglecting routine inspections and preventative measures can lead to premature failure, diminished performance, and increased operational costs.

- Visual Inspection of Welds and Seams

Regular visual inspections of welds and seams detect early signs of corrosion, cracking, or separation. These areas are particularly susceptible to stress and environmental degradation. Prompt identification and repair can prevent catastrophic failure, ensuring structural integrity and preventing exhaust leaks. For example, a small crack near a weld can rapidly propagate under thermal stress, leading to a significant exhaust leak and necessitating costly repairs.

- Clamp and Hanger Assessment

Clamps and hangers secure the component to the vehicle’s chassis. Vibration and thermal expansion can loosen these fasteners over time, causing the component to shift or sag. Regular assessment ensures that clamps are properly tightened and hangers are in good condition, preventing excessive stress on the exhaust system. A loose hanger, if left unaddressed, can lead to premature failure of the exhaust system, as well as other components connected to it.

- Internal Obstruction Check

Although less frequent, internal obstructions can occur due to catalytic converter disintegration or debris accumulation. A restricted exhaust flow increases backpressure, reducing engine performance and potentially causing overheating. Periodic checks for internal obstructions, such as with an endoscope, can identify these issues before they cause significant damage. The type of driving habits and environment influence the speed with which such obstructions can develop.

- Corrosion Protection Measures

Application of corrosion-resistant coatings or sprays can extend the lifespan of the component, particularly in regions with harsh winters or coastal environments. These coatings create a protective barrier against road salts and other corrosive agents. Regular application, as part of a comprehensive maintenance schedule, minimizes the rate of corrosion and preserves the structural integrity of the component. The frequency and type of corrosion protection methods depends on the materials and environment in which they operate.

Adhering to a well-defined maintenance schedule, encompassing visual inspections, clamp and hanger assessments, obstruction checks, and corrosion protection measures, provides tangible benefits in terms of longevity, performance, and cost savings. These preventative measures help to ensure optimal functionality and reduce the likelihood of unexpected failures in the exhaust system component, contributing to overall vehicle reliability.

Frequently Asked Questions

This section addresses commonly asked questions regarding the exhaust component to ensure informed decision-making and optimal performance.

Question 1: What distinguishes one type from another?

Distinctions primarily revolve around internal design, material composition, and intended application. Some designs prioritize maximum noise reduction, while others focus on minimizing backpressure for enhanced performance. Material choices, such as aluminized steel or stainless steel, impact durability and corrosion resistance. Application-specific models cater to different vehicle types and engine configurations.

Question 2: Is professional installation necessary?

While not always mandatory, professional installation is highly recommended. Proper installation ensures correct alignment, secure connections, and leak-free performance. Incorrect installation can compromise noise reduction, exhaust flow, and structural integrity.

Question 3: How can the lifespan be extended?

The lifespan extension involves regular maintenance, including visual inspections for corrosion or damage, tightening of clamps and hangers, and application of rust-inhibiting coatings. Addressing minor issues promptly prevents them from escalating into more significant problems.

Question 4: What are the signs of a failing component?

Indicators of a failing component include increased exhaust noise, decreased fuel economy, reduced engine performance, visible corrosion, and exhaust leaks. Addressing these symptoms promptly prevents further damage to the exhaust system.

Question 5: Does it affect vehicle emissions?

While designed primarily for noise reduction, a properly functioning component contributes to efficient exhaust flow, which can indirectly impact vehicle emissions. A damaged or malfunctioning component can increase backpressure and negatively affect engine performance, potentially leading to higher emissions.

Question 6: Can the component be repaired, or must it be replaced?

The repair feasibility depends on the extent and nature of the damage. Minor issues, such as small leaks or loose connections, can sometimes be repaired. However, severe corrosion, internal damage, or structural failures typically necessitate replacement.

Understanding these aspects ensures the selection of the appropriate component, promotes proactive maintenance, and facilitates informed decision-making regarding repairs or replacements.

The following section examines troubleshooting common problems associated with it.

Conclusion

The preceding analysis has detailed the critical aspects of mufflex muffler design, function, maintenance, and compatibility. Attention to these considerations is paramount for achieving optimal performance, longevity, and compliance with noise regulations. The selection of durable materials, adherence to proper installation methods, and implementation of a regular maintenance schedule directly influence the effectiveness and reliability of these components.

Future developments in this domain will likely focus on further advancements in noise reduction technologies, improvements in material science, and enhanced vehicle-specific designs. A proactive approach to maintenance and a commitment to selecting appropriate components are essential for ensuring long-term performance and contributing to a more environmentally conscious and audibly comfortable driving experience. The ultimate responsibility lies with the vehicle owner to prioritize both performance and responsible operation.