The exhaust component under discussion is specifically designed for a particular model of vehicle. It affects the sound and performance characteristics of the vehicle’s exhaust system. It is a component often sought after by enthusiasts looking to modify or upgrade their vehicle’s exhaust system for improved sound or performance.

This component’s appeal stems from its association with a higher-performance variant of a popular vehicle. It offers a potential pathway for owners of similar vehicles to achieve a similar exhaust note and potentially unlock subtle performance gains. Historically, such components have been valued for their balance of sound enhancement without excessive noise, and the promise of improved exhaust flow leading to minor improvements in engine efficiency.

The following sections will delve further into the specific attributes of this component, exploring its design features, compatibility with other vehicle models, and potential impact on overall vehicle performance.

Enhancements Through Targeted Exhaust Modification

Considerations for optimizing the vehicle’s acoustic profile and performance characteristics through exhaust modifications are presented below. These tips address key areas for potential improvement and highlight factors for informed decision-making.

Tip 1: Assess Compatibility: Prior to installation, verify exact compatibility with the target vehicle model and year. While designed for a specific variant, aftermarket applications may exist, but thorough research is necessary to avoid fitment issues.

Tip 2: Evaluate Backpressure Effects: Understand the relationship between exhaust backpressure and engine performance. Modifications that drastically reduce backpressure may not always result in increased power and can sometimes negatively impact low-end torque.

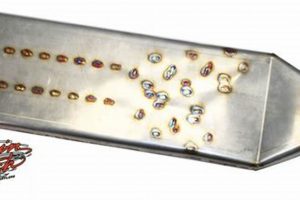

Tip 3: Consider Material Durability: Evaluate the material composition of the exhaust component. Stainless steel offers superior corrosion resistance compared to aluminized steel, extending the lifespan of the modification, particularly in regions with harsh weather conditions.

Tip 4: Inspect Welding Quality: Examine the quality of the welds. Poorly executed welds can lead to premature failure and exhaust leaks, diminishing performance and potentially creating safety hazards.

Tip 5: Research Sound Characteristics: Investigate the anticipated sound profile. While enhanced sound is often a primary objective, ensure the resulting exhaust note aligns with personal preferences and complies with local noise regulations.

Tip 6: Seek Professional Installation: Unless possessing advanced mechanical skills and access to appropriate tools, consider professional installation. Proper installation ensures secure fitment and minimizes the risk of damage to the exhaust system or vehicle.

Tip 7: Review Performance Data: Examine dyno testing data, if available, to ascertain potential performance gains. While subjective improvements in throttle response or sound are common, quantifiable power increases may be minimal.

In summary, optimizing the vehicle’s exhaust system involves careful consideration of compatibility, performance effects, material quality, and sound characteristics. Informed decision-making ensures that modifications achieve the desired improvements without compromising vehicle reliability or violating regulatory standards.

The subsequent section will discuss the implications of these modifications on warranty considerations and long-term vehicle maintenance.

1. Enhanced Sound Profile

The “enhanced sound profile” is a primary characteristic and intended outcome of the specific exhaust component. The component’s design, including internal baffling and exhaust gas routing, directly influences the resulting sound. The stock GTI muffler is engineered for a balance of performance and noise reduction, whereas this specific component prioritizes a more aggressive and audible exhaust note. This alteration is achieved through modifications that allow a greater volume of exhaust gas to exit more freely, thus generating a louder and deeper sound.

For example, owners often report a noticeable increase in the exhaust’s rumble at idle and during acceleration. This difference is a key reason many enthusiasts opt for the upgrade. Its design alters the frequencies and amplitudes of the sound waves produced by the engine, resulting in a distinct acoustic signature. In practical terms, this translates to a more engaging driving experience, especially for individuals who value the auditory feedback from their vehicle’s engine.

Understanding this connection is significant because it enables prospective buyers to make informed decisions based on their preferences. This enhancement also affects perceptions of vehicle performance, as the auditory feedback contributes to the sense of acceleration and overall driver engagement. It’s important to consider local noise regulations and personal sensitivities regarding exhaust sound levels when evaluating the suitability of this component.

2. Optimized Exhaust Flow

The design and engineering of the exhaust component aims to reduce restrictions within the exhaust system, promoting efficient evacuation of exhaust gases from the engine cylinders. Reduced backpressure enables the engine to operate more freely, potentially leading to increased power output and improved fuel efficiency. This optimization is achieved through various design features, including larger diameter piping, smoother bends, and less restrictive internal baffling within the component itself. As an integral part of the vehicle’s exhaust system, the component significantly impacts the overall exhaust flow characteristics.

For example, dyno testing often demonstrates modest horsepower gains with the installation of the component, particularly in conjunction with other performance modifications such as aftermarket air intakes and engine tuning. The improved flow helps the engine breathe more easily, especially at higher engine speeds. By reducing the energy required to expel exhaust gases, the engine can dedicate more energy to producing power. It is important to note that gains may vary depending on the vehicle’s condition, other installed modifications, and the accuracy of the testing equipment. Moreover, optimized exhaust flow can contribute to a more responsive throttle feel, enhancing the driving experience.

In summary, the component’s design emphasizes the facilitation of exhaust gas removal from the engine. This optimization can potentially translate into modest performance improvements and a more responsive driving experience. While individual results may vary, the underlying principle of reducing backpressure remains a significant factor in the component’s overall performance characteristics. Therefore, understanding the principles of exhaust flow optimization is crucial for assessing the potential benefits of this exhaust system component.

3. Model-Specific Design

The “Model-Specific Design” of the exhaust component directly correlates with its intended compatibility and performance characteristics for the specific vehicle platform. The design ensures precise fitment, proper alignment with existing exhaust system components, and optimal integration with the vehicle’s emissions control systems. Any deviation from the design standards can lead to complications, such as leaks, reduced performance, or damage to the vehicle. The design is the cause of achieving a seamless installation process and ensuring there are no performance deviations, since any deviations from the standards could lead to leakages.

For instance, the mounting points, pipe diameter, and exhaust hanger locations are designed to align precisely with the corresponding features of the vehicle. In many cases, utilizing a non-model-specific muffler would require modifications to the existing exhaust system or the muffler itself, potentially compromising the integrity of the system and affecting its overall performance. Therefore, adherence to the model-specific design ensures that the exhaust component functions as intended. It is a guarantee that this design is compatible with the emissions control systems and that the performance of the exhaust system would be optimal.

In summary, the model-specific design is a core element in ensuring proper function and performance. The component’s design ensures compatibility with the vehicle platform, which provides optimal performance, and reduces the risk of complications. A thorough understanding of the design characteristics and its significance ensures the success and effectiveness of any exhaust modification. This understanding reduces the potential installation issues and long-term durability concerns. Therefore, a complete recognition of model-specific design is crucial in optimizing the exhaust system while ensuring proper function and high-quality compatibility.

4. Performance Variant Heritage

The exhaust component derives significance from its association with a high-performance iteration of a popular vehicle. This connection to a performance-focused sub-model imbues the component with a certain pedigree, suggesting enhanced engineering and a focus on delivering a superior driving experience compared to standard components. The heritage aspect acts as a marketing advantage and provides assurance to consumers seeking a performance upgrade. It also creates an expectation of specific sound and performance characteristics, aligning with the brand identity of the performance variant. For example, the design choices were implemented for the purpose of ensuring that there is an exhaust and a louder sound, which means that the heritage aspect creates an expectation for the component.

The practical application of this understanding lies in consumer perception and aftermarket modification decisions. Owners of standard models may opt for this component as a means of achieving a similar exhaust note and potentially unlocking some of the performance benefits associated with the higher-performance variant. The implication is that, in an ideal situation, there could be an exhaust note that owners of standard models can opt for as a means to achieve. This connection can also influence resale value, with vehicles equipped with components from performance variants potentially commanding a higher price. In summary, the heritage aspect has the potential to influence perception and aftermarket modification, and even the resale value of vehicles.

The association provides a tangible link to a racing or performance-oriented lineage. It is a key consideration for enthusiasts seeking an authentic upgrade experience. This understanding assists in making informed decisions regarding aftermarket modifications. It also acknowledges the broader theme of performance enhancements and brand identity within the automotive industry. Therefore, the challenges might involve managing expectations and distinguishing between genuine performance gains and merely perceived improvements due to the sound enhancement. These implications are crucial for a thorough understanding of how heritage impacts product perception.

5. Material Durability

Material durability is a critical consideration in the design and longevity of exhaust system components, including the specified component. The capacity of the materials utilized to withstand environmental stressors, mechanical stresses, and thermal cycling directly impacts the component’s lifespan and performance.

- Corrosion Resistance

The selection of corrosion-resistant materials is paramount in exhaust system design. Exposure to moisture, road salts, and acidic combustion byproducts creates a highly corrosive environment. Stainless steel alloys, such as 304 or 409, are frequently employed due to their superior resistance to oxidation and degradation compared to aluminized steel. The specific component, when manufactured from a high-grade stainless steel, will exhibit prolonged resistance to rust and structural weakening, particularly in regions with harsh winter climates. For example, compared to a mild steel muffler that might corrode in a few years, a stainless steel version can last a decade or more.

- Thermal Stress Resistance

Exhaust systems undergo significant temperature fluctuations during operation, ranging from ambient temperatures to several hundred degrees Celsius. The repeated expansion and contraction of materials can lead to fatigue and cracking, particularly at welded joints. Materials with high thermal fatigue resistance are essential to prevent premature failure. High-quality stainless steel demonstrates good thermal stress resistance, enabling the specified exhaust component to withstand these temperature variations without significant degradation. The resistance is particularly crucial near the catalytic converter, where temperatures are highest. The implication is fewer repairs and replacements, reducing the long-term ownership cost.

- Mechanical Strength and Fatigue Life

The exhaust system is subject to mechanical stresses from vehicle vibrations, road impacts, and the weight of the components themselves. The chosen materials must possess sufficient tensile strength and fatigue life to withstand these stresses without cracking or deforming. Thicker gauge materials and robust welding techniques contribute to increased mechanical strength. The component, when constructed with appropriate thickness and reinforced welds, will exhibit increased resistance to physical damage and prolong its service life. For instance, a thinner-gauge, poorly welded muffler is more susceptible to damage from road debris or impacts, compared to a sturdier unit, which means a longer service life.

- Weld Integrity

The durability of an exhaust component is critically dependent on the quality of the welds that join its various sections. Poorly executed welds can introduce stress concentration points, making the component vulnerable to cracking under thermal or mechanical stress. High-quality welding processes, such as TIG (Tungsten Inert Gas) welding, produce stronger, more durable joints with improved resistance to corrosion. An exhaust component constructed with meticulously executed welds demonstrates greater resilience to cracking and leaks, thereby extending its lifespan. The component’s welds are what maintain its structural soundness under extreme conditions.

The facets discussed above highlight the significance of material durability in the context of the specified exhaust component. Selecting components constructed from corrosion-resistant, thermally stable, and mechanically robust materials with high-quality welds is crucial for ensuring long-term reliability and performance. The implications of material selection extend beyond the immediate performance enhancements, directly impacting the lifecycle cost and maintenance requirements of the exhaust system.

Frequently Asked Questions

The following questions and answers address common inquiries and misconceptions regarding the exhaust component specified. The information provided is intended to offer clarity and guidance to prospective purchasers and vehicle owners.

Question 1: What distinguishes this particular exhaust component from a standard exhaust system?

The component is engineered to deliver a more aggressive exhaust note and potentially improve exhaust gas flow compared to the standard equipment. Its design incorporates features that alter the sound characteristics and reduce backpressure, affecting overall vehicle performance and auditory experience. This specific performance allows the engine to work to maximum potential and reduces any restrictions of backpressure.

Question 2: Is this component compatible with all model years of the vehicle?

Compatibility is dependent on the precise model year and sub-model of the vehicle. Installation on incompatible vehicles is possible, and this may result in fitment issues, performance degradations, or damage. It is imperative to consult technical specifications and verify compatibility before purchasing this exhaust component.

Question 3: Will installation of this exhaust component void the vehicle’s warranty?

Installation of aftermarket components could affect the vehicle’s warranty coverage. Warranty implications vary and depend on the specific terms and conditions outlined by the vehicle manufacturer. Consult the warranty documentation and dealership regarding potential effects before proceeding with any modifications.

Question 4: Does this modification require any additional tuning or modifications to the vehicle’s engine control unit?

While the component can be installed without additional modifications, optimizing its performance potential often necessitates adjustments to the engine control unit. Tuning can synchronize engine parameters with the altered exhaust characteristics, potentially unlocking further power gains and refining engine operation. It is not always necessary, but it can benefit performance and engine output.

Question 5: What is the expected lifespan of this exhaust component?

The lifespan of the component hinges upon various factors, including material quality, driving conditions, and environmental exposure. A component manufactured from high-grade stainless steel, operated primarily in moderate climates, and properly maintained will generally exhibit a longer lifespan than one constructed from less durable materials and exposed to harsh conditions. If you are operating your vehicle in extreme temperatures it may reduce the lifespan of this component.

Question 6: What are the potential drawbacks of installing this exhaust component?

Potential drawbacks can include increased exhaust noise levels, which may be undesirable to some individuals or in violation of local noise regulations. There is the possibility of reduced low-end torque if the exhaust modifications excessively reduce backpressure. Improper installation may trigger exhaust leaks or negatively impact emissions control systems. Check and ensure that the exhaust is being installed properly to avoid this problem.

The preceding inquiries represent common concerns associated with the specified exhaust component. Adhering to proper installation practices and verifying compatibility significantly contributes to mitigating potential problems and optimizing the benefits.

The next section will address considerations for long-term maintenance of the exhaust system after this modification.

Conclusion

The preceding exploration has illuminated various facets of the mk7 gti clubsport muffler. Its performance implications, design considerations, and material attributes have been examined to provide a comprehensive understanding of its role within the vehicle’s exhaust system. This component, designed for a specific model, offers a balance of enhanced sound and optimized exhaust flow that appeals to performance enthusiasts.

Ultimately, the decision to integrate the mk7 gti clubsport muffler necessitates careful consideration of individual needs, regulatory constraints, and vehicle compatibility. Informed choices, predicated on a thorough understanding of its capabilities and limitations, will ensure optimal performance and long-term satisfaction.

![Loudest Flowmaster Mufflers: Find Your Sound [Guide] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Loudest Flowmaster Mufflers: Find Your Sound [Guide] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/03/th-109-300x200.jpg)

![Find The Best Muffler Tape: [Brand] Lasts Longer Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Find The Best Muffler Tape: [Brand] Lasts Longer | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/03/th-102-300x200.jpg)