A type of exhaust system component, commonly found in vehicles, is designed to produce a distinctive, often sporty, sound. This component achieves its unique sound profile through specific internal baffling and chamber designs that manipulate the exhaust gas flow and acoustic properties. For instance, certain car enthusiasts might install such a component to enhance the auditory experience of their vehicle, differentiating it from stock exhaust notes.

The significance of this component lies in its ability to offer a blend of aesthetics and performance. It allows vehicle owners to personalize the sound characteristics of their vehicle. Historically, modifications to exhaust systems have been a popular way to indicate vehicle performance capabilities and reflect individual style. This type of system offers a balanced approach, potentially improving exhaust flow and creating a more engaging driving experience through auditory feedback.

With a basic understanding established, the following sections will delve into specific designs, materials, installation considerations, and the potential impact on vehicle performance and regulatory compliance associated with such exhaust components. Furthermore, it will explore the nuances of sound engineering and the technologies employed to achieve desired sound characteristics without compromising vehicle functionality or violating noise regulations.

Guidance on Exhaust Modification

This section provides crucial advice concerning the selection, installation, and maintenance of an exhaust modification, emphasizing longevity, performance, and compliance.

Tip 1: Material Selection: Choose a material appropriate for the vehicle’s environment. Stainless steel is generally more resistant to corrosion compared to aluminized steel, particularly in regions with harsh weather conditions or road salt application. This choice will affect the system’s life expectancy.

Tip 2: Design Considerations: Consider the design’s impact on exhaust flow. Mandrel-bent tubing, which maintains a consistent diameter throughout bends, typically offers improved exhaust gas flow compared to crush-bent tubing, potentially resulting in modest performance improvements.

Tip 3: Professional Installation: Secure professional installation if unqualified to perform the task. Improper welding or alignment can lead to leaks, premature wear, or exhaust system damage, possibly affecting engine performance or creating safety hazards.

Tip 4: Sound Level Compliance: Ensure the modified exhaust system complies with local noise ordinances. Exceeding established decibel limits can result in fines and require system modification or replacement to meet legal requirements.

Tip 5: Compatibility Verification: Verify the compatibility of the exhaust system with the vehicle’s make, model, and year. Incompatible systems may not fit correctly, requiring extensive modifications or rendering them unusable.

Tip 6: Regular Inspections: Conduct routine inspections for signs of corrosion, damage, or leaks. Addressing these issues promptly can prevent more significant problems and extend the lifespan of the system.

Tip 7: Proper Mounting: Ensure that the exhaust system is properly mounted with appropriate hangers and insulators. This prevents excessive vibration and stress on the system, which can lead to cracking or detachment.

Adhering to these guidelines can improve the exhaust component’s performance, longevity, and legal compliance. Informed decision-making and diligent maintenance practices are key to a successful and sustainable exhaust system modification.

The final section of this article will summarize the key considerations and offer a concluding perspective on the multifaceted aspects of exhaust modification.

1. Sound wave manipulation

Sound wave manipulation is central to the design and functionality of a component intended to produce a distinctive exhaust note. This manipulation involves altering the characteristics of sound waves generated by the engine’s combustion process to achieve a desired auditory output. This alteration is achieved through a variety of methods, impacting both the volume and tonal quality of the exhaust sound.

- Reflective Baffling

Reflective baffling is a primary method of sound wave manipulation within a component designed to modify exhaust sound. Baffles strategically positioned within the exhaust system’s chambers reflect sound waves, causing interference patterns. Constructive interference amplifies certain frequencies, while destructive interference attenuates others, shaping the overall sound profile. For example, specific baffle arrangements might emphasize lower frequencies, resulting in a deeper, more resonant sound.

- Resonator Chambers

Resonator chambers act as acoustic filters, selectively dampening or amplifying specific frequencies. The size and shape of these chambers are precisely calculated to target unwanted frequencies, such as high-pitched resonances, and to enhance desirable frequencies, like a throaty rumble. The effectiveness of a resonator chamber is dependent on its ability to match and counteract specific sound frequencies, creating a cleaner and more controlled auditory experience.

- Helmholtz Resonance

Helmholtz resonance, a physical phenomenon, is often exploited in component design. A chamber with a specific neck size and volume resonates at a characteristic frequency when excited by sound waves. By incorporating Helmholtz resonators into the system, engineers can selectively eliminate or enhance specific sound frequencies, tailoring the exhaust note to a particular preference. An example is the use of this resonance to eliminate drone frequencies that can cause discomfort during highway driving.

- Wave Cancellation

Wave cancellation, a technique of destructive interference, is utilized to reduce unwanted noise levels. By introducing sound waves that are 180 degrees out of phase with the undesirable frequencies, designers can effectively neutralize those frequencies. This approach is particularly useful for mitigating high-frequency hissing or whistling sounds that can detract from the desired exhaust tone. Careful calculation and precise positioning of sound-canceling elements are crucial for this technique to be effective.

The application of these sound wave manipulation techniques enables manufacturers to craft exhaust components with highly specific and desirable auditory characteristics. These techniques, working in concert, result in a noticeable difference in the sound emitted by the vehicle, achieving the desired sonic profile through precise control over sound wave behavior within the exhaust system.

2. Exhaust gas routing

Exhaust gas routing constitutes a critical design element directly influencing the performance and auditory characteristics of a “dualtone muffler.” The path exhaust gases take through the muffler’s internal chambers directly affects sound wave propagation and interference, ultimately determining the distinct tonal qualities produced. Inefficient or poorly designed gas routing can diminish sound quality, reduce performance, or increase backpressure, negating the intended benefits of the muffler.

Consider a dual-outlet system employing separate gas pathways within the muffler. One path might direct exhaust gases through a chamber tuned for low-frequency sound, while the other promotes higher frequencies. The interaction of these distinct sound waves upon exiting the muffler creates the desired “dualtone” effect. Conversely, a poorly designed system may exhibit uneven gas flow, resulting in an unbalanced sound profile or an undesirable drone. For instance, in certain aftermarket systems, inadequate gas routing has been identified as a contributing factor to premature component failure due to localized overheating and increased stress on welds.

In conclusion, proper exhaust gas routing is paramount to the realization of the “dualtone mufflers” intended function and performance. Optimized routing not only contributes to the desired sound signature but also ensures efficient exhaust flow, mitigating potential negative impacts on engine performance and component durability. Understanding the interplay between gas dynamics and acoustic properties is essential for both the design and selection of such systems.

3. Material composition

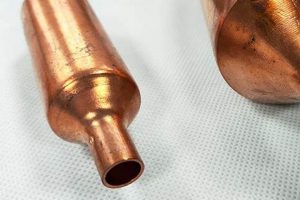

Material composition plays a crucial role in both the performance and sound characteristics of exhaust systems. The materials used in construction influence durability, thermal properties, and the acoustic properties of the muffler. A component’s material makeup is therefore integral to its longevity and ability to deliver a desired tonal quality.

- Stainless Steel Grades

The choice of stainless steel grade significantly affects corrosion resistance and sound resonance. Higher grades, such as 304 or 316 stainless steel, offer superior resistance to rust and oxidation, particularly in environments with high salt exposure. These materials also exhibit distinct acoustic properties compared to lower grades, potentially influencing the tonal quality of the muffler. An exhaust crafted from a high-grade stainless steel tends to produce a brighter, more resonant sound compared to one constructed from less corrosion-resistant alloys.

- Aluminized Steel Properties

Aluminized steel, a cost-effective alternative to stainless steel, provides moderate corrosion resistance due to its aluminum coating. However, it is generally less durable than stainless steel, particularly in regions with harsh winters and road salt application. The acoustic properties of aluminized steel differ from those of stainless steel, typically resulting in a deeper, less resonant sound. The lower cost may be attractive to some consumers, but the trade-off in longevity should be carefully considered.

- Titanium Alloys

Titanium alloys offer an exceptional strength-to-weight ratio and superior corrosion resistance. Their use in exhaust systems is typically limited to high-performance applications due to their high cost. Titanium produces a distinctive, high-pitched sound, often described as exotic or race-inspired. Systems constructed from titanium can significantly reduce vehicle weight, contributing to improved performance, but the expense often makes them prohibitive for everyday use.

- Impact of Thickness and Density

The thickness and density of the material also affect sound damping and resonance. Thicker materials generally dampen sound more effectively, reducing unwanted vibrations and drone. Higher density materials tend to produce a deeper, more solid sound. The specific choice of thickness and density requires careful engineering to balance sound characteristics, durability, and weight considerations. For example, a thinner gauge stainless steel might produce a louder, more aggressive sound, but it may also be more susceptible to damage from road debris.

The material used in its construction significantly affects the sound and longevity. Careful selection, considering factors such as corrosion resistance, acoustic properties, and cost, is crucial to achieving the desired performance and sound quality.

4. Chamber acoustics

Chamber acoustics are a core element in the functionality of a device designed to generate a distinct auditory effect. The dimensions, shape, and internal structure of these chambers directly influence the way sound waves propagate, reflect, and interact, ultimately shaping the unique tonal quality the device produces. Precise manipulation of chamber acoustics is essential for achieving the desired “dualtone” effect, distinguishing it from conventional exhaust systems.

- Resonance Frequencies

The size and shape of an internal chamber determine its resonance frequencies. Each chamber resonates most strongly at specific frequencies, amplifying those frequencies while dampening others. In a dual-tone setup, one chamber might be tuned to amplify lower frequencies, creating a deep, throaty rumble, while another amplifies higher frequencies, resulting in a sharper, more aggressive tone. The interplay between these tuned chambers generates the characteristic “dualtone” sound. An illustrative example is a system employing a Helmholtz resonator to emphasize a specific frequency range, effectively shaping the overall sound profile.

- Baffle Arrangement and Sound Reflection

The arrangement of baffles within a chamber significantly impacts sound wave reflection and interference patterns. Baffles redirect sound waves, causing them to interact constructively or destructively. Constructive interference amplifies certain frequencies, while destructive interference attenuates others. In a dual-tone muffler, baffles might be positioned to create distinct interference patterns within each chamber, emphasizing different frequency ranges. A real-world application might involve angled baffles designed to direct sound waves towards or away from the chamber outlet, influencing the perceived sound intensity and directionality.

- Sound Absorption Materials

The inclusion of sound-absorbing materials within the chambers can selectively dampen certain frequencies, further shaping the sound profile. Materials such as fiberglass or steel wool absorb sound energy, reducing the amplitude of specific frequencies. In a dual-tone setup, these materials could be strategically placed to attenuate unwanted resonances or to refine the tonal balance between the two distinct sound components. A common application involves lining the inner walls of a chamber with sound-absorbing material to reduce high-frequency harshness, resulting in a smoother, more refined sound.

- Chamber Volume and Sound Pressure

The volume of an acoustic chamber directly influences sound pressure levels and the intensity of resonance. Larger chambers generally support lower-frequency resonances, while smaller chambers favor higher frequencies. In a dual-tone muffler, the relative volumes of the two chambers can be adjusted to balance the intensity of the low and high-frequency components. For example, a larger low-frequency chamber might be paired with a smaller high-frequency chamber to create a dominant low-end rumble with a subtle high-end accent.

The interplay between these acoustic elements resonance frequencies, baffle arrangements, sound absorption, and chamber volume dictates the sonic signature. By carefully manipulating these variables, designers can create a device that produces the desired blending of high and low frequencies, ultimately achieving the desired auditory output.

5. Resonance control

Resonance control is paramount in realizing the distinct sound characteristics associated with a “dualtone muffler.” This control involves the deliberate management of acoustic resonances within the exhaust system to shape and refine the produced sound. Uncontrolled resonance can lead to undesirable droning, excessive noise levels, or a poorly defined tonal quality, undermining the intended effect. Effectively managing resonance, therefore, is not merely an aesthetic consideration but a functional imperative for delivering the desired auditory experience.

Specific design features actively contribute to resonance control. These include strategically placed baffles that disrupt standing waves, tuned resonators that cancel specific frequencies, and the use of sound-absorbing materials to dampen unwanted vibrations. For example, a Helmholtz resonator, a common component in performance exhaust systems, is precisely tuned to cancel out a specific frequency range, often targeting the droning sounds that can occur at cruising speeds. Similarly, internal chambers of varying sizes and shapes are used to shift resonant frequencies, ensuring that the desired sound components are emphasized while undesirable frequencies are suppressed. The material composition and thickness also affect resonant properties, with denser materials generally producing lower frequencies and thicker materials reducing vibration. Inadequate resonance control can result in an unbalanced sound profile, characterized by harshness, distortion, or the dominance of unwanted frequencies, effectively negating the benefits of a “dualtone” design.

In summation, resonance control is an indispensable element in the creation of a well-engineered exhaust system intended to produce a distinctive tonal quality. The effectiveness of resonance control mechanisms directly translates into the clarity, balance, and overall desirability of the final sound output. The failure to adequately address resonance issues can lead to an unsatisfactory auditory experience and may even detract from the perceived quality and performance of the vehicle. Understanding and applying resonance control techniques is thus critical for both the design and evaluation of systems intended to enhance the sound and driving experience.

6. Backpressure influence

Backpressure, the resistance to exhaust gas flow within an exhaust system, has a notable influence on the performance and sound characteristics of a “dualtone muffler.” It’s critical because it affects engine efficiency and sound modulation. Excessive backpressure can hinder exhaust gas scavenging, reducing engine power, while insufficient backpressure can diminish low-end torque. The “dualtone muffler” design manipulates backpressure to achieve the intended sound profile, often balancing performance and auditory aesthetics. Consider a scenario where a muffler designed for a specific engine displacement is installed on a smaller engine; the resulting reduced exhaust flow could increase backpressure, negatively affecting engine output and potentially altering the designed sound.

Specifically, the internal baffling and chamber design within the “dualtone muffler” are engineered to create a calculated amount of backpressure. This manipulation affects the sound waves propagating through the system, influencing the frequencies that are amplified or attenuated. A real-world example is a performance vehicle where a “dualtone muffler” is used to produce a deep, resonant sound at lower RPMs while allowing for unrestricted flow at higher RPMs, thereby minimizing backpressure-related performance losses. Incorrect backpressure can also lead to exhaust gas reversion, where exhaust gases flow back into the combustion chamber, potentially damaging engine components. Therefore, the compatibility of the “dualtone muffler” with the vehicle’s engine and intended application is crucial.

In summation, backpressure is an important consideration when evaluating the functionality and performance implications. While the primary objective might be to enhance the auditory experience, a properly designed muffler will balance backpressure to maintain engine efficiency and longevity. Understanding backpressure and its manipulation is essential for informed decisions regarding exhaust system modifications. Ignoring it can result in compromised engine performance or premature component failure, highlighting the practical significance of a balanced design philosophy.

7. Acoustic properties

Acoustic properties are fundamental in the design and performance of a “dualtone muffler”. These properties govern how sound waves propagate and interact within the muffler, directly influencing the resulting sound characteristics. An understanding of these properties is essential for creating a muffler that produces a desirable tonal quality while meeting performance requirements.

- Sound Absorption Coefficient

The sound absorption coefficient quantifies a material’s ability to absorb sound energy rather than reflect it. In a “dualtone muffler,” materials with high sound absorption coefficients, such as fiberglass or specialized damping materials, can be strategically placed to attenuate specific frequencies. This is used to reduce unwanted droning or harshness. For instance, lining the internal walls of a muffler chamber with a sound-absorbing material can effectively dampen high-frequency sounds, resulting in a smoother, deeper tone.

- Resonance Frequency

Resonance frequency refers to the frequency at which a structure vibrates with maximum amplitude. In muffler design, chambers and internal components are tuned to specific resonance frequencies to amplify or attenuate certain sound frequencies. A “dualtone muffler” may employ multiple chambers, each tuned to a different resonance frequency, to create a combination of high and low tones. An example includes using a Helmholtz resonator to cancel out a specific drone frequency, improving the overall listening experience.

- Sound Transmission Loss

Sound transmission loss (STL) measures a material’s ability to block sound transmission. Materials with high STL values are effective at reducing the overall sound level emitted by the exhaust system. The thickness and density of the muffler casing materials directly influence STL. A “dualtone muffler” designed to comply with noise regulations may incorporate materials with high STL to reduce overall exhaust noise while maintaining the desired tonal characteristics. For example, a muffler casing made of thicker steel will generally provide higher STL than a thinner casing.

- Impedance Matching

Impedance matching refers to the alignment of acoustic impedance between different components within the exhaust system. Acoustic impedance is a measure of a material’s resistance to sound wave propagation. Mismatched impedance can result in sound reflections and energy loss. In “dualtone muffler” design, attention to impedance matching between chambers and exhaust pipes is critical to ensure efficient sound transmission and minimize unwanted reflections. Proper impedance matching contributes to a clearer, more defined sound profile.

In summary, acoustic properties are central to achieving the desired performance and sound quality. By carefully manipulating sound absorption, resonance frequency, sound transmission loss, and impedance matching, manufacturers can design these systems that create a unique and desirable auditory experience while meeting regulatory requirements and performance expectations. The interplay of these properties dictates the final sound produced, emphasizing the importance of acoustic engineering in “dualtone muffler” design.

Frequently Asked Questions Regarding Dualtone Mufflers

The following section addresses common inquiries and clarifies misconceptions surrounding dualtone mufflers, their functionality, and implications for vehicle performance and regulatory compliance.

Question 1: What defines a dualtone muffler and how does it differ from a standard muffler?

A dualtone muffler is characterized by its engineered ability to produce two distinct tonal qualities simultaneously. This is achieved through specialized internal chambers and baffling designed to manipulate sound waves differently compared to a standard muffler, which typically aims for noise reduction without specific tonal shaping.

Question 2: Does the installation of a dualtone muffler invariably increase vehicle performance?

The installation of a dualtone muffler does not guarantee a performance increase. While some designs may improve exhaust flow, potentially leading to marginal gains, the primary purpose is often sound enhancement. Performance gains are dependent on the specific design and its compatibility with the vehicle’s engine.

Question 3: Are dualtone mufflers legal for street use in all jurisdictions?

The legality of dualtone mufflers for street use varies depending on local noise regulations. Many jurisdictions have specific decibel limits for vehicle exhaust systems. It is crucial to verify that the selected muffler complies with these regulations to avoid fines or legal repercussions.

Question 4: How does material composition affect the sound and longevity of a dualtone muffler?

Material composition significantly impacts both the sound characteristics and lifespan of a dualtone muffler. Stainless steel provides superior corrosion resistance and a brighter sound, while aluminized steel offers a more cost-effective option with a deeper tone but reduced durability.

Question 5: What are the potential drawbacks of installing a poorly designed dualtone muffler?

Poorly designed dualtone mufflers can lead to various issues, including increased backpressure, reduced engine performance, undesirable droning noises, and premature component failure due to inadequate construction or improper installation.

Question 6: Is professional installation required for a dualtone muffler, or can it be installed by a novice?

While some mechanically inclined individuals may attempt self-installation, professional installation is generally recommended for dualtone mufflers. Proper welding, alignment, and mounting are crucial to ensure optimal performance, longevity, and compliance with safety standards.

In summary, selecting and installing a dualtone muffler requires careful consideration of sound preferences, regulatory compliance, material quality, and potential performance implications. Informed decision-making and adherence to best practices are paramount.

The next article section will delve into specific dualtone muffler designs and their applications.

Conclusion

This exploration of the “dualtone muffler” has underscored its multifaceted nature, extending beyond mere sound enhancement. It is clear that the successful implementation of this exhaust system component hinges on a comprehensive understanding of acoustic principles, material science, and regulatory considerations. The deliberate manipulation of sound waves, achieved through strategic chamber design and material selection, dictates the resulting tonal quality. Moreover, considerations of backpressure and resonance control directly impact engine performance and overall driving experience.

The information presented should serve as a critical foundation for informed decision-making, whether one is considering the purchase, installation, or modification of a “dualtone muffler.” Continued research and adherence to industry best practices are essential to ensure optimal performance, regulatory compliance, and a responsible approach to vehicle modification. The long-term impact of these components on vehicle emissions and noise pollution warrants ongoing investigation and technological advancement.