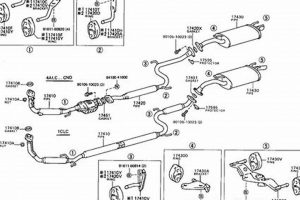

This automotive component, typically located as part of a vehicle’s exhaust system, plays a crucial role in reducing noise pollution generated by the engine’s combustion process. It achieves this through a series of internal chambers and baffles that redirect and dampen sound waves, thereby decreasing the overall decibel level emitted from the tailpipe. For example, a vehicle equipped with a functioning version of this component will produce significantly less exhaust noise compared to one where it is damaged or absent.

The proper functioning of this element contributes to a more pleasant driving experience for both the vehicle’s occupants and the surrounding environment. Historically, its development stemmed from growing concerns about noise levels in urban areas and a desire to mitigate the disturbance caused by increasingly prevalent motor vehicles. Its presence is often mandated by local and national regulations aimed at controlling noise pollution and ensuring a quieter community.

Understanding the design, materials, and maintenance of this component is essential for automotive technicians and vehicle owners alike. Subsequent sections will delve into specific aspects of its construction, common issues, and optimal strategies for preserving its operational effectiveness.

Maintenance Recommendations

Optimal performance and longevity of the noise reduction component necessitates adherence to specific maintenance guidelines.

Tip 1: Routine Visual Inspection: Conduct periodic visual inspections of the exterior casing for signs of corrosion, physical damage, or leaks. Early detection of these issues can prevent more extensive and costly repairs.

Tip 2: Exhaust System Integrity Check: Ensure the exhaust system, including this component, is securely mounted and properly aligned. Loose connections or misaligned components can lead to premature wear and reduced effectiveness.

Tip 3: Address Unusual Noises Promptly: Investigate any unusual rattling, hissing, or booming sounds emanating from the exhaust system. These sounds may indicate internal damage or component failure requiring immediate attention.

Tip 4: Preventative Rust Treatment: Apply rust-inhibiting coatings to the exterior surface, particularly in regions with high humidity or road salt exposure. This will protect the metal from corrosion and extend its lifespan.

Tip 5: Regular Engine Tune-ups: Maintain proper engine function through regular tune-ups. A poorly running engine can produce excessive exhaust gases, placing undue stress on the noise reduction component.

Tip 6: Avoid Short Trips When Possible: Frequent short trips can prevent the system from reaching optimal operating temperature, leading to moisture buildup within the component and accelerated corrosion.

Tip 7: Professional Inspection Intervals: Schedule regular inspections by a qualified automotive technician to assess the internal condition and identify potential issues not readily apparent through visual examination.

Following these maintenance recommendations will contribute to the continued efficiency and lifespan of the exhaust noise reduction component, ensuring compliance with noise regulations and a more pleasant driving experience.

The subsequent sections will provide further information regarding troubleshooting common problems and selecting appropriate replacement parts, when necessary.

1. Specific Brand Identity

The specific brand identity associated with “Wade’s Muffler” is a complex construct built upon perceived quality, historical reputation, marketing strategies, and customer experience. This identity significantly influences consumer perception and purchase decisions regarding this particular automotive exhaust component.

- Brand Recognition and Recall

Brand recognition refers to the ability of consumers to correctly identify “Wade’s Muffler” when exposed to its logo, name, or advertising materials. Brand recall, on the other hand, signifies the ability to retrieve the brand from memory when prompted by a product category or need. High brand recognition and recall translate into increased market share and customer loyalty. For example, a customer experiencing exhaust system issues may immediately consider “Wade’s Muffler” if they are familiar with the brand’s positive reputation.

- Perceived Quality and Reliability

The perceived quality of “Wade’s Muffler” is a crucial aspect of its brand identity. This perception is shaped by factors such as product durability, performance, and customer service. If “Wade’s Muffler” is consistently perceived as a reliable and long-lasting product, it will command a higher price point and attract customers seeking quality over cost. Conversely, negative reviews or perceived reliability issues can damage the brand’s identity and erode market share.

- Marketing and Advertising Strategies

The marketing and advertising strategies employed by “Wade’s Muffler” play a vital role in shaping its brand identity. These strategies may emphasize specific product features, target particular customer segments, or highlight the company’s values. For instance, a marketing campaign focusing on environmental responsibility and noise reduction could position “Wade’s Muffler” as a socially conscious brand. A strategy emphasizing performance and racing heritage may appeal to automotive enthusiasts.

- Customer Experience and Word-of-Mouth

Customer experience encompasses all interactions a customer has with “Wade’s Muffler,” from initial product inquiries to post-purchase support. Positive customer experiences foster brand loyalty and generate positive word-of-mouth referrals, strengthening the brand’s identity. Conversely, negative experiences can lead to customer dissatisfaction and negative reviews, damaging the brand’s reputation. Therefore, “Wade’s Muffler” must prioritize customer satisfaction at every touchpoint.

In conclusion, the specific brand identity of “Wade’s Muffler” is a multifaceted concept that significantly impacts its success in the automotive aftermarket. By cultivating strong brand recognition, emphasizing perceived quality, implementing effective marketing strategies, and prioritizing customer experience, “Wade’s Muffler” can establish a positive and enduring brand identity that resonates with consumers and drives sales. Comparison with competitor brands will provide valuable insights for further enhancement.

2. Sound Dampening Effectiveness

Sound dampening effectiveness is a primary performance characteristic directly associated with “Wade’s Muffler.” It quantifies the component’s ability to reduce noise generated by a vehicle’s exhaust system. The effectiveness is determined by design, materials, and internal construction, all of which contribute to the overall attenuation of sound waves.

- Internal Chamber Design

The configuration of internal chambers within “Wade’s Muffler” is critical to its sound dampening capabilities. These chambers are strategically designed to redirect and interfere with sound waves, causing them to cancel each other out through destructive interference. The size, shape, and number of chambers influence the frequency range and overall level of noise reduction achieved. For example, a design with multiple, differently sized chambers may be more effective at attenuating a broader spectrum of exhaust noise.

- Acoustic Packing Materials

Acoustic packing materials, such as fiberglass or steel wool, are often incorporated into “Wade’s Muffler” to further enhance sound absorption. These materials line the internal walls of the muffler and absorb sound energy as it passes through. The type, density, and placement of the packing material significantly affect its performance. Degradation of the packing material over time can lead to a noticeable increase in exhaust noise, indicating the need for replacement.

- Resonator Integration

Some “Wade’s Muffler” designs incorporate resonators, which are tuned chambers designed to cancel out specific frequencies. Resonators target and eliminate droning sounds or other undesirable noise characteristics that may be prominent in the exhaust system. The proper tuning of resonators is crucial for achieving optimal sound dampening effectiveness. Misaligned or damaged resonators can lead to increased noise levels or the introduction of new, undesirable frequencies.

- Material Selection and Thickness

The materials used in the construction of “Wade’s Muffler,” including the thickness of the metal casing, contribute to its sound dampening effectiveness. Thicker materials provide greater sound insulation and reduce the transmission of vibrations. Corrosion-resistant materials, such as stainless steel, are often preferred for their durability and ability to maintain sound dampening performance over extended periods. The specific alloy and gauge of the metal used influence both the muffler’s weight and its ability to withstand the harsh conditions of the exhaust system.

These interconnected facets demonstrate that sound dampening effectiveness in “Wade’s Muffler” is not a singular attribute but the result of a carefully engineered system. Maintaining the integrity of these components is crucial for preserving optimal noise reduction and ensuring compliance with local sound regulations. A degradation in any of these areas will likely diminish the overall sound dampening performance, impacting both the vehicle’s noise signature and its compliance with noise emission standards.

3. Exhaust System Integration

Exhaust system integration defines the relationship between the noise-reducing component identified as “Wade’s Muffler” and the broader exhaust system of a vehicle. This integration directly affects the performance and longevity of both “Wade’s Muffler” and the entire exhaust apparatus. A properly integrated “Wade’s Muffler” ensures optimal exhaust flow, minimizes backpressure, and effectively dampens noise across a specified frequency range. Conversely, poor integration can lead to reduced engine efficiency, increased fuel consumption, and premature failure of system components. For example, an improperly sized “Wade’s Muffler” for a particular engine displacement can create excessive backpressure, hindering the engine’s ability to expel exhaust gases efficiently. This, in turn, diminishes horsepower and torque output.

The physical connection points, including the inlet and outlet pipes of “Wade’s Muffler,” are critical areas for ensuring proper integration. These connection points must be appropriately sized and aligned to prevent exhaust leaks and minimize turbulence. The method of attachment, whether welding or mechanical fastening, must also be robust enough to withstand the high temperatures and vibrations present in the exhaust system. Moreover, the positioning of “Wade’s Muffler” within the exhaust system affects its operating temperature and exposure to environmental factors. Shielding or insulation may be necessary to protect “Wade’s Muffler” from excessive heat or road debris. The integration process should account for the vehicle’s specific make and model, as variations in exhaust system designs necessitate tailored installation procedures and component selection. A qualified technician ensures compatibility and adherence to manufacturer specifications during installation, preventing potential long-term issues.

Effective exhaust system integration hinges on a holistic understanding of the vehicle’s engine characteristics, exhaust gas dynamics, and the design parameters of the noise-reducing component. Suboptimal integration presents challenges such as increased noise levels, reduced fuel economy, and accelerated component wear. Addressing these challenges requires a comprehensive approach, encompassing proper component selection, precise installation techniques, and ongoing maintenance practices. The interdependency of the exhaust system components underscores the significance of considering “Wade’s Muffler” as an integral part of a larger system rather than a standalone element.

4. Material Durability Focus

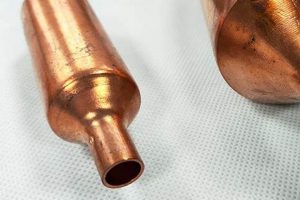

Material durability is a critical consideration in the design and manufacture of components like “Wade’s Muffler.” The operating environment of an exhaust system exposes its components to extreme temperatures, corrosive gases, and physical stresses, necessitating a deliberate focus on material selection and construction techniques to ensure longevity and reliable performance.

- Corrosion Resistance

The exhaust system environment contains moisture, acids, and salts, promoting corrosion. “Wade’s Muffler,” therefore, requires materials inherently resistant to corrosion or surface treatments that enhance corrosion protection. Stainless steel alloys, aluminized steel, and ceramic coatings are common choices to mitigate rust and degradation. For example, a “Wade’s Muffler” constructed with 304 stainless steel will offer superior corrosion resistance compared to one made from standard carbon steel, extending its lifespan, particularly in regions with high road salt usage.

- High-Temperature Stability

Exhaust gases can reach extremely high temperatures, potentially weakening or deforming muffler materials. “Wade’s Muffler” must withstand these high temperatures without significant loss of structural integrity or performance. Certain alloys, such as those containing chromium and nickel, exhibit excellent high-temperature strength and creep resistance. A “Wade’s Muffler” utilizing Inconel, though costly, demonstrates exceptional high-temperature stability in extreme performance applications.

- Vibration Fatigue Resistance

The vehicle’s engine generates vibrations transmitted through the exhaust system. These vibrations induce cyclic stresses on “Wade’s Muffler,” potentially leading to fatigue failure over time. Material selection must consider vibration damping characteristics and fatigue strength. Proper welding techniques and reinforcement strategies also mitigate vibration-induced stresses. For example, strategically placed gussets or reinforced seams on “Wade’s Muffler” reduce stress concentrations and improve fatigue life.

- Impact and Abrasion Resistance

Road debris, such as stones and gravel, can impact the exterior of “Wade’s Muffler,” causing physical damage. Material selection should consider impact and abrasion resistance, particularly for components located in vulnerable areas. Protective coatings or the use of thicker gauge materials can enhance impact resistance. A “Wade’s Muffler” designed for off-road vehicles may incorporate a skid plate or be constructed from thicker steel to withstand the rigors of rough terrain.

The interconnectedness of these material properties underscores their collective importance in determining the overall durability of “Wade’s Muffler.” A holistic approach to material selection, considering corrosion resistance, high-temperature stability, vibration fatigue resistance, and impact/abrasion resistance, results in a more robust and longer-lasting component. This, in turn, reduces maintenance costs and enhances vehicle reliability.

5. Regional Market Availability

Regional market availability represents a crucial factor influencing the accessibility and consumer adoption of “Wade’s Muffler.” This factor encompasses a variety of distribution, economic, and regulatory elements that collectively determine where and how readily consumers can purchase and utilize this specific brand of automotive exhaust component.

- Distribution Network Reach

The extent of “Wade’s Muffler’s” distribution network directly correlates with its regional market availability. A wider network, encompassing authorized retailers, independent auto parts stores, and online vendors, ensures broader consumer access. Limited distribution restricts availability, potentially driving consumers towards alternative brands. For example, if “Wade’s Muffler” primarily distributes through a single national chain that lacks a presence in certain geographic areas, consumers in those regions face increased difficulty in acquiring the product, irrespective of its quality or reputation.

- Economic Factors and Pricing Strategy

Economic conditions within a given region significantly impact the affordability and subsequent availability of “Wade’s Muffler.” Varying levels of disposable income, local tax rates, and transportation costs can influence the final price point, affecting consumer demand. If “Wade’s Muffler” adopts a uniform national pricing strategy without accounting for regional economic disparities, it may become less competitive in areas with lower income levels, effectively limiting its accessibility. Conversely, a localized pricing strategy considering regional economic factors can enhance affordability and increase market penetration.

- Regulatory Compliance and Emissions Standards

Regional variations in vehicle emissions standards and noise regulations directly impact the marketability of “Wade’s Muffler.” The component must comply with all applicable regulations within a specific region to be legally sold and installed. For instance, California’s stringent emissions standards may require a specially designed “Wade’s Muffler” variant certified to meet those requirements, limiting the availability of standard models in that market. Compliance with local regulations is thus a prerequisite for regional market entry and sustained availability.

- Brand Awareness and Marketing Investments

Regional brand awareness directly correlates with demand and subsequent market availability. Extensive marketing campaigns, targeted advertising, and local sponsorships can cultivate brand recognition and consumer preference for “Wade’s Muffler.” Regions with minimal marketing investment may experience lower brand awareness, leading to reduced demand and potentially limited product availability. A strategic approach to regional marketing investments can therefore enhance brand visibility and drive sales, supporting broader product availability.

The interplay of these facets underscores that regional market availability is not solely a function of manufacturing output or distribution logistics. Economic factors, regulatory landscapes, and marketing investments all contribute to the ease with which consumers can acquire “Wade’s Muffler” within a given geographic area. Understanding these regional dynamics is essential for “Wade’s Muffler” to optimize its distribution strategies and maximize its market penetration. Failure to consider these regional nuances can result in diminished market share and missed opportunities for growth.

6. Model-Specific Variations

The concept of model-specific variations is particularly relevant to “Wade’s Muffler” due to the broad range of vehicle makes and models on the road. These variations account for differences in engine size, exhaust system configuration, and noise emission requirements. Consequently, a universal “Wade’s Muffler” design is impractical; instead, the company offers a diverse catalog of mufflers tailored to specific vehicle applications.

- Engine Displacement and Exhaust Flow

Engine displacement directly influences the volume of exhaust gases produced. Smaller engines require mufflers with less internal volume and smaller diameter exhaust pipes to maintain optimal exhaust flow velocity. Conversely, larger engines necessitate larger mufflers and pipes to handle the increased exhaust volume without creating excessive backpressure. For instance, a “Wade’s Muffler” designed for a 2.0-liter engine will likely be too restrictive for a 5.0-liter engine, leading to reduced performance and potential engine damage. Proper matching of muffler size to engine displacement is crucial for maintaining engine efficiency and longevity.

- Exhaust System Configuration and Mounting Points

Vehicles exhibit a variety of exhaust system layouts, including single, dual, and even triple exhaust configurations. The location and orientation of mounting points on the chassis also vary significantly. “Wade’s Muffler” must offer model-specific variations to accommodate these diverse configurations, ensuring proper fitment and secure attachment. A “Wade’s Muffler” designed for a front-wheel-drive sedan will likely not fit a rear-wheel-drive truck due to differences in exhaust routing and mounting bracket locations. Precision in manufacturing and attention to model-specific dimensions are paramount for ensuring proper installation and preventing exhaust leaks or premature component failure.

- Noise Emission Regulations and Sound Tuning

Noise emission regulations vary by region, influencing the design and construction of “Wade’s Muffler.” Some regions impose strict noise limits, requiring mufflers with advanced sound-dampening technologies. Other regions may allow for more aggressive exhaust notes, permitting less restrictive muffler designs. Model-specific variations of “Wade’s Muffler” account for these regional differences, ensuring compliance with local noise regulations while catering to consumer preferences for exhaust sound characteristics. A “Wade’s Muffler” designed for the European market may incorporate additional sound-absorbing materials to meet stringent noise standards, while a version for the American market might prioritize a sportier exhaust tone.

- Vehicle-Specific Performance Characteristics

Different vehicle models have varying performance characteristics that the muffler should complement. A performance car requires a muffler that maximizes exhaust flow for increased horsepower, whereas a luxury vehicle might prioritize quietness and refinement. Model-specific variations allow “Wade’s Muffler” to tailor its products to these disparate needs. A performance-oriented “Wade’s Muffler” might feature a straight-through design for minimal backpressure, while a luxury vehicle version may incorporate baffled chambers for superior sound dampening.

In summary, the necessity for model-specific variations within the “Wade’s Muffler” product line stems from the diverse range of vehicles and their unique requirements. Engine size, exhaust system configuration, noise regulations, and performance characteristics all contribute to the need for tailored muffler designs. Proper selection and installation of the correct model-specific “Wade’s Muffler” is essential for maintaining optimal vehicle performance, ensuring regulatory compliance, and meeting individual consumer preferences.

7. Warranty Service Terms

Warranty service terms represent a legally binding agreement between the manufacturer or vendor of “Wade’s Muffler” and the consumer. These terms outline the conditions under which the manufacturer will repair or replace the muffler in the event of a defect or failure within a specified period. The scope and limitations defined within these terms directly impact the consumer’s protection and recourse in the event of product malfunction. Understanding these terms is, therefore, paramount to making an informed purchase decision.

- Coverage Period and Scope

The warranty service terms specify the duration of coverage, typically expressed in years or miles, and the types of defects or failures covered. Some warranties offer comprehensive coverage, encompassing all manufacturing defects and premature wear. Others provide limited coverage, excluding certain components or types of damage, such as corrosion due to environmental factors or damage resulting from improper installation. For instance, a “Wade’s Muffler” warranty might cover defects in materials and workmanship for three years or 36,000 miles, but exclude damage caused by road hazards or modifications to the exhaust system. Understanding the coverage period and scope allows consumers to assess the extent of protection afforded by the warranty.

- Exclusions and Limitations

Warranty service terms invariably include exclusions and limitations that define the circumstances under which the warranty is voided. Common exclusions include damage resulting from misuse, abuse, neglect, improper installation, unauthorized repairs, or modifications to the product. Limitations may restrict coverage to the original purchaser or exclude consequential damages, such as lost income or vehicle downtime. For example, a “Wade’s Muffler” warranty might be voided if the muffler is installed by an unqualified mechanic or if the vehicle is used for racing or other competitive events. Careful examination of exclusions and limitations is essential to avoid inadvertently invalidating the warranty.

- Claims Process and Procedures

The warranty service terms outline the procedures for filing a warranty claim, including required documentation, contact information, and the steps involved in obtaining warranty service. Consumers must adhere to these procedures to ensure their claim is processed efficiently and effectively. Typically, a warranty claim requires proof of purchase, a description of the defect or failure, and inspection by an authorized service center. For instance, a consumer seeking warranty service for a defective “Wade’s Muffler” may need to provide a copy of the sales receipt and allow an authorized “Wade’s Muffler” dealer to inspect the component. Familiarizing oneself with the claims process streamlines the warranty service experience.

- Remedies and Resolution Options

The warranty service terms specify the remedies available to the consumer in the event of a valid warranty claim. These remedies typically include repair, replacement, or refund of the purchase price. The manufacturer retains the right to determine the appropriate remedy based on the nature of the defect and the terms of the warranty. For example, if a “Wade’s Muffler” exhibits a manufacturing defect, the manufacturer might opt to repair the component if the defect is minor or replace it with a new one if the damage is irreparable. Understanding the available remedies allows consumers to anticipate the potential outcome of a warranty claim.

These interconnected facets of warranty service terms significantly influence the consumer’s perception of “Wade’s Muffler” and its overall value proposition. A comprehensive and transparent warranty instills confidence in the product’s quality and durability, while a restrictive or ambiguous warranty may deter potential customers. Therefore, a careful review of the warranty service terms is an essential component of the purchasing decision for “Wade’s Muffler,” empowering consumers to make informed choices and protect their investment.

Frequently Asked Questions Regarding Wade’s Muffler

This section addresses common inquiries and clarifies prevalent misconceptions regarding the functional characteristics, maintenance requirements, and operational parameters associated with Wade’s Muffler components.

Question 1: What constitutes a typical lifespan for a Wade’s Muffler under normal operating conditions?

The longevity of a Wade’s Muffler is contingent upon several factors, including driving habits, environmental exposure, and routine maintenance practices. Generally, a lifespan ranging from five to seven years is anticipated under typical usage scenarios. However, exposure to corrosive elements such as road salt, coupled with frequent short trips that fail to adequately heat the exhaust system, can significantly reduce this lifespan.

Question 2: What are the primary indicators of a failing Wade’s Muffler requiring immediate attention?

Observable symptoms indicative of a failing Wade’s Muffler encompass a marked increase in exhaust noise, the presence of rattling or hissing sounds emanating from the exhaust system, and a perceptible decrease in fuel efficiency. A visual inspection revealing rust, corrosion, or physical damage to the muffler’s exterior also suggests the need for prompt replacement.

Question 3: Does the installation of an aftermarket Wade’s Muffler void the original vehicle manufacturer’s warranty?

The installation of an aftermarket Wade’s Muffler generally does not automatically void the vehicle manufacturer’s warranty. However, if the aftermarket component is demonstrated to be the direct cause of a failure covered under the original warranty, the manufacturer may deny warranty coverage for that specific component or system affected by the aftermarket part.

Question 4: Are there specific Wade’s Muffler models designed to comply with stringent California emissions standards?

Wade’s Muffler offers certain models engineered and certified to meet the stringent emissions standards mandated by the California Air Resources Board (CARB). These models undergo rigorous testing and certification processes to ensure compliance with California’s strict air quality regulations. Verification of CARB compliance is recommended prior to purchase and installation in California.

Question 5: What constitutes proper maintenance for a Wade’s Muffler to maximize its operational lifespan?

Recommended maintenance practices for Wade’s Muffler include periodic visual inspections for signs of corrosion or damage, prompt repair of exhaust leaks, and avoidance of driving conditions that subject the exhaust system to excessive stress or vibration. Application of rust-inhibiting coatings to the exterior surface, particularly in regions with high humidity or road salt exposure, can also prolong its lifespan.

Question 6: Is professional installation recommended for a Wade’s Muffler, or can a mechanically inclined individual perform the installation?

While a mechanically inclined individual may possess the skills necessary to install a Wade’s Muffler, professional installation is generally recommended. Proper installation requires specialized tools, knowledge of exhaust system dynamics, and adherence to vehicle-specific torque specifications. Incorrect installation can lead to exhaust leaks, reduced performance, and potential damage to other components.

In summary, addressing these frequent inquiries provides a clearer understanding of Wade’s Muffler, promoting informed decision-making regarding purchase, maintenance, and potential warranty implications.

The following section will explore troubleshooting common issues associated with Wade’s Muffler and provide guidance on selecting appropriate replacement parts when necessary.

Conclusion

This exposition has presented a comprehensive overview of the automotive component referred to as “Wade’s Muffler.” The analysis has encompassed its functionality in noise reduction, maintenance protocols, the significance of brand identity, factors influencing its market availability, and critical aspects of warranty service. Emphasis has been placed on the importance of proper integration within the exhaust system and the crucial role of durable materials in ensuring longevity.

The ongoing refinement of exhaust system technology, driven by increasingly stringent environmental regulations and consumer demand for quieter vehicles, underscores the continued relevance of effective noise reduction solutions. Informed decision-making regarding the selection, installation, and maintenance of such components contributes to enhanced vehicle performance, regulatory compliance, and a more environmentally responsible transportation sector. Further research into advancements in muffler technology remains essential.