The exhaust component designed for a specific model year of a compact sedan reduces engine noise and directs exhaust gases away from the vehicle. This component is located as part of the vehicle’s exhaust system and plays a crucial role in emissions control and sound dampening. For example, if this part is damaged or corroded, it can lead to increased noise levels and potential exhaust leaks.

A properly functioning exhaust component is essential for maintaining a vehicle’s compliance with noise regulations and ensuring optimal engine performance. Historically, these components were simple resonators; however, modern iterations often incorporate complex designs to achieve specific acoustic properties and minimize backpressure. Replacing a worn or damaged one restores quieter operation and helps maintain the vehicle’s value.

The subsequent sections will delve into the various aspects of this specific automotive part, including replacement procedures, common issues, available aftermarket options, and factors affecting longevity. This detailed examination will provide a comprehensive understanding of the unit and its significance in vehicle maintenance.

Maintenance & Longevity Tips

Ensuring the longevity and optimal performance of the exhaust system component designated for the 2004 Toyota Corolla requires adherence to specific maintenance practices and awareness of potential issues.

Tip 1: Inspect Regularly for Corrosion: Due to exposure to road salt and moisture, corrosion is a common issue. Routine visual inspections for rust or damage are recommended, especially in regions with harsh winters.

Tip 2: Address Exhaust Leaks Promptly: Unusual noises or a decrease in fuel efficiency may indicate an exhaust leak. These leaks can degrade performance and should be addressed by a qualified technician immediately.

Tip 3: Consider Aftermarket Options Carefully: When replacement becomes necessary, evaluating aftermarket options is crucial. Choose reputable brands known for quality and durability to ensure long-term reliability.

Tip 4: Avoid Short Trips When Possible: Short trips can cause condensation to accumulate within the exhaust system, accelerating corrosion. When feasible, opt for longer drives to allow the system to fully heat and evaporate moisture.

Tip 5: Use Quality Replacement Parts: When replacing the component, opt for parts that meet or exceed original equipment manufacturer (OEM) specifications to ensure proper fit and performance.

Tip 6: Monitor for Changes in Sound: A change in the exhaust note can indicate internal damage or deterioration. Investigating such changes promptly can prevent further damage to the system.

Tip 7: Apply Protective Coatings: Applying heat-resistant paint or other protective coatings can provide a barrier against corrosion and extend the life of the component, particularly in areas prone to road salt exposure.

Adhering to these tips will contribute to the extended lifespan and reliable operation of the vehicle’s exhaust system component, reducing the likelihood of premature failure and costly repairs.

The following section will outline the common issues and troubleshooting steps related to this critical exhaust component.

1. Sound dampening effectiveness

The sound dampening effectiveness of the exhaust silencing component for the 2004 Toyota Corolla directly correlates to occupant comfort and regulatory compliance. The components internal design, utilizing baffles and resonators, reduces the amplitude of sound waves generated by engine combustion. Inadequate sound dampening, resulting from corrosion or damage, leads to increased exhaust noise perceived inside the vehicle cabin and potentially violates local noise ordinances. For instance, a rusted through unit lacks the structural integrity to effectively dampen sound waves, resulting in a louder exhaust note.

Optimal sound dampening effectiveness not only improves the driving experience, but it also contributes to maintaining the vehicle’s resale value. Potential buyers often assess the vehicle’s overall condition, including the noise level produced by the exhaust system. A significantly louder than expected exhaust note raises concerns about the vehicle’s maintenance history and overall mechanical condition. Furthermore, achieving effective sound dampening requires precise engineering and material selection, often necessitating the use of aluminized steel or stainless steel to withstand the corrosive effects of exhaust gases and environmental factors. This, in turn, contributes to the component’s longevity and overall effectiveness.

In summary, the sound dampening effectiveness of the exhaust component is a critical performance attribute. Degradation of this performance not only impacts comfort and regulatory compliance but also influences a vehicle’s perceived value and long-term reliability. Regular inspections and timely replacements are therefore essential for maintaining the proper sound levels of a 2004 Toyota Corolla.

2. Material Corrosion Resistance

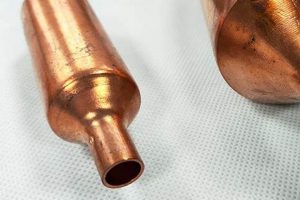

The longevity and performance of the exhaust component designed for the 2004 Toyota Corolla are intrinsically linked to its resistance to corrosion. Given its exposure to extreme temperatures, exhaust gases, and environmental factors, the material composition dictates its ability to withstand degradation over time.

- Impact of Road Salt

Regions experiencing winter conditions often utilize road salt for de-icing, which significantly accelerates the corrosion process. The chloride ions present in road salt penetrate protective coatings and promote oxidation of the metal, leading to rust and eventual structural failure of the exhaust component. This is a primary factor determining its lifespan, often necessitating replacement within a few years in such environments.

- Influence of Exhaust Gases

Exhaust gases contain corrosive byproducts of combustion, including water vapor, carbon dioxide, and sulfur dioxide. These gases react with the metal surface, particularly at elevated temperatures, leading to chemical corrosion. The choice of materials, such as aluminized steel or stainless steel, mitigates this effect by providing a protective barrier against these corrosive agents.

- Consequences of Condensation

During engine start-up and short trips, condensation forms within the exhaust system. This condensation, laden with corrosive compounds, remains in contact with the metal surface for extended periods, promoting localized corrosion. The design of the exhaust component, including drainage features, can influence the extent of condensation-induced corrosion.

- Role of Protective Coatings

Manufacturers often apply protective coatings, such as aluminizing or ceramic coatings, to enhance the corrosion resistance of exhaust components. These coatings act as a sacrificial layer, preventing direct contact between the base metal and corrosive elements. The effectiveness of these coatings depends on their composition, thickness, and application process.

In summary, material corrosion resistance is a critical factor governing the lifespan and performance of the exhaust component in the 2004 Toyota Corolla. The interplay between environmental factors, exhaust gases, condensation, and protective coatings determines the rate of degradation. Selecting components constructed from corrosion-resistant materials and implementing protective measures are crucial for ensuring long-term reliability and minimizing the need for frequent replacements.

3. Exhaust flow restriction

Exhaust flow restriction, inherent in the design and condition of the exhaust silencing component for the 2004 Toyota Corolla, significantly influences engine performance and efficiency. Understanding the factors contributing to this restriction is crucial for maintaining optimal vehicle operation.

- Internal Design and Baffle Configuration

The internal design of the component, specifically the arrangement of baffles and chambers, creates inherent resistance to exhaust gas flow. While these baffles effectively reduce noise, they simultaneously impede the free flow of gases, impacting engine performance. A balance must be struck between noise reduction and minimizing backpressure. For instance, a tightly packed baffle system effectively silences exhaust noise but can significantly restrict flow, reducing horsepower and fuel economy.

- Component Degradation and Corrosion

Over time, corrosion and the accumulation of carbon deposits within the component can further restrict exhaust flow. Rust and debris narrow the passages, increasing backpressure and hindering the efficient expulsion of exhaust gases. This degradation leads to a noticeable decline in engine performance, potentially triggering warning lights and diagnostic codes related to exhaust system efficiency. A corroded unit significantly elevates back pressure.

- Impact on Engine Performance

Increased exhaust flow restriction elevates backpressure, forcing the engine to work harder to expel exhaust gases. This reduces volumetric efficiency, diminishing the amount of fresh air and fuel drawn into the cylinders. Consequently, the engine produces less power, and fuel consumption increases. The engine’s overall responsiveness is reduced, particularly at higher engine speeds, negatively affecting acceleration and overall drivability. Replacing a restricted unit often yields a noticeable boost in performance.

- Aftermarket Performance Alternatives

Aftermarket performance-oriented alternatives for the 2004 Toyota Corolla are frequently engineered to minimize exhaust flow restriction. These designs often incorporate larger diameter piping, smoother bends, and less restrictive baffle systems. While these alternatives may offer improved engine performance, they may also result in increased exhaust noise levels, potentially exceeding legal limits or compromising driver comfort. Evaluation of both performance gains and potential noise increases is important before selecting an aftermarket alternative.

The relationship between exhaust flow restriction and the specific silencing component for the 2004 Toyota Corolla is multifaceted, encompassing design considerations, material degradation, and performance implications. Minimizing restriction while maintaining acceptable noise levels is essential for achieving optimal engine performance and fuel efficiency. Regular inspections and timely replacements are crucial for preventing performance degradation resulting from excessive backpressure.

4. OEM specification compliance

Adherence to Original Equipment Manufacturer (OEM) specifications is paramount when sourcing a replacement exhaust silencing component for a 2004 Toyota Corolla. OEM compliance ensures proper fit, performance, and emissions control, directly impacting the vehicle’s reliability and longevity.

- Dimensional Accuracy

OEM specifications dictate precise dimensions for the component, including length, diameter, and mounting point locations. Compliance guarantees seamless integration with the existing exhaust system, preventing leaks and ensuring proper alignment. A non-compliant part may require modifications or result in improper fitment, leading to exhaust leaks and potential damage to surrounding components. For example, the inlet and outlet pipe diameters must precisely match the existing exhaust piping for a secure, leak-free connection.

- Material Composition and Durability

OEM specifications prescribe the type and grade of materials used in construction, such as aluminized steel or stainless steel, to withstand the corrosive effects of exhaust gases and environmental elements. Compliance ensures the component’s resistance to rust and premature failure. A substandard material may exhibit accelerated corrosion, leading to leaks and the need for frequent replacements. For instance, using a lower-grade steel lacking sufficient corrosion resistance would shorten the component’s lifespan, particularly in regions with road salt usage.

- Acoustic Performance and Noise Levels

OEM specifications establish acceptable noise levels and acoustic characteristics for the exhaust system. Compliance ensures that the replacement component effectively dampens engine noise without exceeding legal limits or compromising passenger comfort. A non-compliant part may produce excessive noise or an undesirable exhaust tone. For example, an aftermarket component lacking the internal baffling and sound-absorbing materials specified by the OEM would likely generate a louder, more intrusive exhaust note.

- Emissions Control System Compatibility

OEM specifications ensure compatibility with the vehicle’s emissions control system, including catalytic converters and oxygen sensors. Compliance prevents interference with the proper functioning of these components, ensuring compliance with emissions regulations. A non-compliant part may alter exhaust gas flow or temperature, potentially affecting the performance and longevity of the catalytic converter or triggering diagnostic codes. The location of the oxygen sensor bung, if present on the assembly, must match the OEM specifications to ensure accurate sensor readings.

In conclusion, selecting an exhaust silencing component that adheres to OEM specifications is crucial for the 2004 Toyota Corolla. Compliance guarantees proper fitment, durability, acoustic performance, and emissions control system compatibility, ultimately contributing to the vehicle’s reliability, longevity, and compliance with environmental regulations. Deviations from OEM specifications can lead to performance degradation, increased noise levels, and potential damage to other exhaust system components.

5. Aftermarket compatibility

Aftermarket compatibility, when considering an exhaust silencing component for the 2004 Toyota Corolla, refers to the ability of non-OEM manufactured parts to integrate seamlessly and function effectively within the vehicle’s exhaust system. Evaluating aftermarket options requires careful consideration of several factors to ensure optimal performance and longevity.

- Fitment and Installation

A primary consideration is the physical fitment of the aftermarket component. Precise dimensions and mounting points are critical to ensure proper installation without modifications. Discrepancies in size or shape can lead to exhaust leaks, improper alignment, and potential damage to surrounding components. Some aftermarket components may necessitate specialized tools or expertise for installation, increasing the overall cost and complexity. Accurate cross-referencing of part numbers is essential to verify compatibility.

- Material Quality and Durability

The materials used in aftermarket exhaust components vary significantly, impacting their resistance to corrosion and overall lifespan. Lower-quality materials may exhibit accelerated degradation, particularly in regions with harsh weather conditions or heavy road salt usage. Selecting components constructed from durable materials, such as aluminized steel or stainless steel, enhances longevity and reduces the need for frequent replacements. Warranty provisions offered by the manufacturer can provide an indication of expected durability.

- Performance Characteristics

Aftermarket components may alter the performance characteristics of the exhaust system, affecting engine horsepower, torque, and fuel efficiency. Some aftermarket designs prioritize increased exhaust flow, potentially enhancing performance but also increasing noise levels. Others focus on maintaining or improving fuel economy. Evaluating the claimed performance benefits and considering potential trade-offs is crucial. Dyno testing results, if available, can provide objective data on performance changes.

- Emissions Compliance

Aftermarket exhaust components must comply with applicable emissions regulations to ensure legal operation and prevent environmental harm. Altering the exhaust system in a manner that bypasses or compromises emissions control devices is generally prohibited. Verifying that the aftermarket component is certified for use on the 2004 Toyota Corolla and meets all relevant emissions standards is essential. Some aftermarket components may require the installation of additional hardware or software to maintain emissions compliance.

In summary, aftermarket compatibility for the 2004 Toyota Corolla silencing component hinges on factors such as fitment, material quality, performance characteristics, and emissions compliance. Careful evaluation of these aspects is essential to ensure that the chosen aftermarket component provides satisfactory performance, durability, and legal operation. Consulting with qualified automotive professionals can further aid in the selection process.

6. Installation ease

Installation ease, when referring to the exhaust silencing component for the 2004 Toyota Corolla, signifies the simplicity and efficiency with which the component can be replaced or installed. This characteristic is a critical factor for both professional mechanics and vehicle owners undertaking do-it-yourself repairs.

- Direct Fit Design

The direct fit design is a key facet of installation ease. This design ensures that the replacement component matches the dimensions and mounting points of the original equipment manufacturer (OEM) part. A direct fit eliminates the need for modifications, such as cutting, welding, or bending, streamlining the installation process. For example, a component with precisely located hanger brackets allows for immediate attachment to the vehicle’s existing supports, reducing installation time and complexity.

- Accessible Mounting Locations

Accessibility of mounting locations significantly influences installation ease. Clearly accessible bolts and fasteners, free from obstructions, simplify the removal of the old component and the attachment of the new one. Conversely, difficult-to-reach mounting points require specialized tools or extensive disassembly of other vehicle components, increasing the installation’s complexity and duration. Components positioned in areas with ample clearance and unobstructed access contribute to a more straightforward installation procedure. For instance, a muffler with easily accessible mounting bolts minimizes the risk of damaging surrounding components during removal and installation.

- Comprehensive Instructions and Hardware

The availability of clear and comprehensive installation instructions enhances installation ease. Detailed step-by-step instructions, accompanied by diagrams or illustrations, guide the installer through the process, minimizing the potential for errors. Inclusion of all necessary hardware, such as gaskets, bolts, and clamps, further simplifies the installation by eliminating the need to source these components separately. A component packaged with clear instructions and all required hardware empowers the installer to complete the task efficiently and accurately. For instance, including new exhaust manifold gaskets ensures a leak-free seal, preventing the need for additional troubleshooting and repairs.

- Weight and Maneuverability

The weight and maneuverability of the component impact installation ease. A lightweight and compact component is easier to handle and position during installation, particularly in confined spaces. Conversely, a heavy or bulky component requires more effort and may necessitate the assistance of a second person, increasing the complexity and risk of injury. A muffler designed with a manageable weight and convenient lifting points contributes to a smoother and safer installation process. For example, smaller diameter resonators are much easier for one person to put in place than a large muffler.

These facets collectively determine the overall installation ease of the exhaust silencing component for the 2004 Toyota Corolla. A component incorporating direct fit design, accessible mounting locations, comprehensive instructions and hardware, and manageable weight contributes to a simpler, more efficient installation process, reducing time, effort, and the potential for errors. Prioritizing these features when selecting a replacement component ensures a smoother installation experience for both professional mechanics and do-it-yourself enthusiasts.

7. Weight considerations

The weight of the exhaust silencing component designated for the 2004 Toyota Corolla exerts a subtle yet significant influence on several aspects of vehicle performance and efficiency. Increased mass directly correlates to amplified inertia, thereby impacting acceleration and braking capabilities. A heavier component necessitates more energy to initiate motion and subsequently requires greater force to decelerate, resulting in a slight reduction in responsiveness. This effect is discernible particularly during frequent stop-and-go driving or under demanding acceleration scenarios. For example, a replacement fabricated from thicker steel, while potentially more durable, will increase the vehicles overall weight, affecting its fuel economy.

Furthermore, the weight of the exhaust component impacts fuel consumption. As vehicle mass increases, the engine must expend additional energy to maintain a given speed. This increased energy demand translates directly into elevated fuel consumption rates. While the weight difference between various exhaust component options may appear marginal, the cumulative effect over the lifespan of the vehicle can be substantial. Aftermarket “performance” units often incorporate lighter materials, such as titanium or thin-walled stainless steel, precisely to mitigate this effect. These materials reduce the weight of the car part and contribute to better fuel efficiency.

Finally, excessive weight concentrated at the rear of the vehicle, where the part is typically situated, can negatively influence handling characteristics. An imbalance in weight distribution can alter the vehicle’s center of gravity, affecting stability and responsiveness during cornering. For example, installing an excessively heavy unit may induce understeer. Therefore, weight is a factor in the overall equation. In conclusion, despite its seemingly minor contribution, the weight of the exhaust component plays a discernible role in the overall performance, fuel efficiency, and handling dynamics of the 2004 Toyota Corolla. Careful consideration of weight, alongside factors such as material durability and acoustic properties, is crucial when selecting a replacement component.

Frequently Asked Questions

This section addresses common inquiries regarding the exhaust silencing component specific to the 2004 Toyota Corolla, providing clarity on maintenance, replacement, and performance-related aspects.

Question 1: What is the expected lifespan of this exhaust component?

The typical lifespan varies depending on environmental factors and driving conditions. In regions with heavy road salt usage, corrosion accelerates, potentially necessitating replacement within 3-5 years. In milder climates, the component may last 7-10 years or longer.

Question 2: How can premature failure be prevented?

Regular inspections for corrosion and prompt attention to exhaust leaks are crucial. Applying protective coatings and avoiding short trips, which promote condensation buildup, can also extend the component’s lifespan.

Question 3: What are the symptoms of a failing exhaust component?

Common symptoms include increased exhaust noise, a decrease in fuel efficiency, a rattling sound originating from the exhaust system, and a visible rust or damage.

Question 4: Does replacing the exhaust component affect vehicle emissions?

Replacing the component with a compliant part should not negatively affect emissions. However, tampering with or removing emissions control devices is illegal and can result in failed emissions tests.

Question 5: Can aftermarket components improve engine performance?

Some aftermarket components are designed to reduce exhaust flow restriction, potentially improving engine performance. However, these components may also increase exhaust noise levels. Careful consideration of both performance gains and noise levels is advised.

Question 6: Is professional installation required for replacement?

While a mechanically inclined individual can perform the replacement, professional installation is recommended to ensure proper fitment and avoid potential complications. Improper installation can lead to exhaust leaks and damage to other components.

In essence, understanding the factors influencing the component’s lifespan, recognizing the symptoms of failure, and adhering to proper maintenance practices are essential for ensuring reliable vehicle operation.

The following section will provide an ultimate guide on how to determine your muffler replacement cost

Concluding Remarks on Exhaust System Component

This article has provided an exposition of the exhaust silencing component for the 2004 Toyota Corolla, examining its function, maintenance considerations, material properties, and aftermarket alternatives. The information presented underscores the necessity of proper maintenance and timely replacement to ensure optimal vehicle performance, regulatory compliance, and driver satisfaction. The components role in noise reduction, emissions control, and overall system efficiency has been detailed.

The lifespan of this component depends on various factors and its upkeep. Vehicle owners and technicians should use this information to identify and address these component-related issues. Prioritizing quality replacement parts and diligent upkeep contributes to prolonged vehicle life and reduced environmental impact.