An automotive service provider specializing in exhaust system maintenance, repair, and replacement focuses on components designed to reduce engine noise and emissions. These establishments typically offer services such as muffler repair, exhaust pipe replacement, catalytic converter diagnostics, and custom exhaust system fabrication. For example, a vehicle experiencing excessive exhaust noise might require a visit to one of these specialized centers.

The existence of dedicated exhaust service businesses contributes to vehicle longevity, improved air quality, and adherence to noise pollution regulations. Historically, these services evolved alongside advancements in automotive technology and increasing environmental awareness. They provide crucial services, enabling vehicles to meet performance standards and minimizing their environmental impact, ensuring compliance with evolving emissions requirements.

The following discussion will examine the specific elements of exhaust system care, including identifying signs of damage, selecting appropriate replacement parts, and understanding the implications of various service options available at these centers.

Maintenance Recommendations

Maintaining a vehicle’s exhaust system is crucial for performance, fuel efficiency, and environmental compliance. The following recommendations outline essential practices for extending the lifespan of these components.

Tip 1: Visual Inspection: Regularly examine the exhaust system for signs of corrosion, rust, or physical damage. Early detection of these issues prevents escalation into more significant and costly repairs. For example, rust spots on exhaust pipes should be addressed immediately to prevent pipe failure.

Tip 2: Listen for Unusual Noises: Pay attention to changes in exhaust sound. Hissing, rattling, or roaring noises could indicate leaks, damaged mufflers, or other component failures. A sudden increase in exhaust volume, particularly when accelerating, suggests a potential issue requiring investigation.

Tip 3: Promptly Address Warning Lights: Engine warning lights can often indicate exhaust system problems, such as catalytic converter inefficiency. Ignoring these warnings can lead to further damage and reduced vehicle performance. Diagnostic scans should be performed to identify the underlying cause of the warning light.

Tip 4: Avoid Short Trips: Frequent short trips can lead to moisture buildup within the exhaust system, accelerating corrosion. Longer drives allow the system to heat up and evaporate this moisture, prolonging the lifespan of exhaust components.

Tip 5: Regular Professional Inspections: Schedule routine exhaust system inspections with qualified technicians. These professionals can identify potential problems that may not be apparent during a visual inspection and provide preventative maintenance recommendations.

Tip 6: Catalytic Converter Protection: Protect the catalytic converter from overheating by maintaining proper engine function. Overheating can damage the converter, leading to reduced efficiency and potential failure. Ensure the engine is properly tuned and free from misfires.

Adhering to these recommendations will contribute to the optimal performance and longevity of the vehicle’s exhaust system, reducing the likelihood of unexpected repairs and ensuring compliance with emissions standards.

The subsequent sections will delve into the diagnostic procedures employed to identify exhaust system malfunctions and the options available for repair and replacement.

1. Exhaust System Diagnostics

Exhaust system diagnostics represent a critical service offered by specialized automotive centers, enabling accurate assessment and resolution of exhaust-related issues. Its relevance to facilities like these is paramount, as it forms the foundation for effective repair and maintenance strategies.

- Visual Inspection and Leak Detection

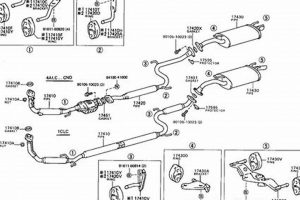

A fundamental aspect of diagnostics involves the visual inspection of exhaust components for signs of physical damage, corrosion, or leaks. Technicians may employ smoke testing equipment to identify even minute leaks undetectable by visual means alone. The identification of leaks is crucial for preventing further damage and ensuring compliance with emission standards. A cracked exhaust manifold, for instance, detected during visual inspection, necessitates either repair or replacement to restore proper functionality.

- Sensor Analysis and Diagnostic Codes

Modern vehicles incorporate sensors within the exhaust system, such as oxygen sensors and catalytic converter monitors. Analyzing the data provided by these sensors and interpreting diagnostic trouble codes (DTCs) provides valuable insights into system performance. For example, a P0420 code indicates catalytic converter inefficiency, prompting further investigation into the converter’s condition and potential causes of failure.

- Backpressure Testing

Excessive backpressure within the exhaust system can impede engine performance and fuel efficiency. Backpressure testing involves measuring the resistance to exhaust gas flow, identifying potential obstructions or blockages. A clogged catalytic converter or a collapsed muffler can create excessive backpressure, necessitating replacement of the affected component.

- Emissions Testing

In regions with stringent emissions regulations, diagnostic procedures often include emissions testing to ensure compliance. This may involve using specialized equipment to measure the levels of pollutants emitted by the vehicle. Failure to meet emissions standards necessitates further diagnostic investigation and subsequent repairs to bring the vehicle into compliance.

These diagnostic facets, when effectively employed, allow automotive centers to provide accurate and efficient exhaust system services. The ability to diagnose issues accurately translates into targeted repairs, minimized downtime, and enhanced customer satisfaction. The application of these techniques is central to the operation of a facility.

2. Muffler Repair Techniques

The proficiency in muffler repair techniques directly influences the operational success and reputation of service providers. These techniques encompass a range of procedures aimed at restoring the functionality and structural integrity of mufflers. A facility’s capability to execute these repairs effectively directly impacts its service offerings, customer satisfaction, and profitability. For instance, a specialized center equipped with skilled technicians capable of welding cracks, patching holes, or replacing damaged components can address a wider spectrum of muffler-related issues, minimizing the need for costly replacements. The expertise in identifying the most appropriate repair methodwhether welding a minor corrosion point or replacing a severely compromised mufflertranslates into both cost savings for customers and enhanced service quality.

Consider the scenario of a vehicle with a muffler exhibiting small rust perforations. A service provider equipped with advanced welding equipment and skilled welders can precisely patch these areas, extending the muffler’s lifespan at a fraction of the cost of a complete replacement. Conversely, a less-equipped facility might only offer full replacement, potentially resulting in unnecessary expense for the customer. Furthermore, the center’s ability to accurately diagnose the underlying cause of muffler damage, such as improper exhaust system alignment or excessive vibration, and address these contributing factors prevents recurrence and enhances the longevity of the repair.

In summary, the mastery of various muffler repair techniques is a critical differentiator for automotive service centers. It contributes directly to cost-effectiveness, service quality, and customer loyalty. By investing in training, equipment, and expertise in muffler repair, a center enhances its competitive advantage and establishes itself as a reliable provider of exhaust system services. The adoption of these techniques aligns with the broader theme of sustainable automotive maintenance, promoting repair over replacement whenever feasible, thereby reducing waste and minimizing environmental impact.

3. Exhaust Pipe Replacement

Exhaust pipe replacement constitutes a significant service offering directly associated with automotive service providers specializing in exhaust systems. These centers provide the necessary expertise and equipment for diagnosing exhaust pipe damage, selecting appropriate replacement parts, and executing the replacement procedure. Corrosion, physical damage from road debris, and age-related deterioration necessitate the replacement of exhaust pipes to maintain optimal exhaust flow and minimize emissions. The ability to accurately assess the condition of exhaust pipes and recommend suitable replacement solutions is crucial for ensuring vehicle performance and regulatory compliance. For instance, a severely corroded exhaust pipe can lead to exhaust leaks, reducing fuel efficiency and potentially causing harmful gases to enter the vehicle cabin. Addressing this issue through timely exhaust pipe replacement restores proper exhaust flow and mitigates these risks.

Specialized service centers possess the specialized tools and knowledge required for precise exhaust pipe replacement. This includes cutting, bending, and welding equipment to ensure a seamless fit and secure connection to other exhaust components. Furthermore, these centers offer a selection of replacement exhaust pipes, ranging from standard OEM replacements to aftermarket performance options, catering to diverse customer needs and preferences. The selection of appropriate replacement pipes is critical, as variations in pipe diameter, material, and construction can impact exhaust flow and engine performance. Correct installation ensures proper sealing and alignment, preventing leaks and maximizing the lifespan of the replacement pipe. Incorrect installation may result in rattling noises, reduced fuel efficiency, and potential damage to other exhaust system components.

The expertise in exhaust pipe replacement offered by these service providers contributes directly to vehicle longevity, environmental protection, and driver safety. By addressing exhaust pipe damage promptly and effectively, these centers play a vital role in maintaining the operational integrity of vehicles and minimizing their environmental impact. The correlation between exhaust pipe replacement and the broader context of exhaust system maintenance highlights the significance of specialized automotive service providers in upholding vehicle performance and ensuring compliance with evolving emissions standards.

4. Catalytic Converter Service

Catalytic converter service is intrinsically linked to the operational scope of businesses such as Rod’s Muffler Center. The catalytic converter, a crucial component of a vehicle’s exhaust system, reduces harmful emissions. Its malfunction directly impacts vehicle emissions compliance and overall environmental impact. Centers offering exhaust system services are therefore fundamentally involved in the diagnosis, repair, and replacement of these converters. For instance, a vehicle failing an emissions test often requires catalytic converter service, a function routinely provided by such facilities. The demand for this service stems from the converter’s susceptibility to damage from factors like overheating, contamination, and physical impact, necessitating regular inspection and potential intervention.

A key aspect of catalytic converter service involves precise diagnostics to ascertain the root cause of failure. This might include analyzing sensor data, performing backpressure tests, and conducting visual inspections to identify damage or deterioration. Based on diagnostic findings, the service may involve cleaning the converter (in certain limited cases), repairing minor damage (where feasible and permissible), or replacing the unit entirely. The replacement process necessitates selecting the appropriate converter type based on vehicle specifications and emissions regulations. Furthermore, proper installation is crucial to ensure optimal performance and prevent future issues. An example is the replacement of a converter on a vehicle exhibiting a P0420 code, indicating reduced efficiency. This replacement necessitates careful attention to ensure proper sealing and alignment to prevent exhaust leaks.

In summation, catalytic converter service constitutes a vital function within the range of services offered. The ability to accurately diagnose converter issues, perform necessary repairs or replacements, and ensure compliance with environmental regulations is essential for maintaining vehicle performance and minimizing environmental impact. Challenges associated with catalytic converter service include navigating evolving emissions standards, procuring high-quality replacement parts, and providing accurate diagnostic services. Successful execution of these services is crucial for reinforcing a facility’s reputation and ensuring long-term customer satisfaction.

5. Custom Exhaust Fabrication

Custom exhaust fabrication, a specialized service often provided by establishments such as Rod’s Muffler Center, caters to individuals seeking performance enhancements, aesthetic modifications, or unique solutions not available through standard exhaust system components. This service necessitates specialized skills, equipment, and a thorough understanding of exhaust system dynamics.

- Performance Optimization

One primary driver for custom exhaust fabrication is performance optimization. Alterations to exhaust pipe diameter, muffler design, and overall system layout can significantly influence engine horsepower and torque output. For example, fabricating a larger-diameter exhaust system for a high-performance vehicle can reduce backpressure, allowing the engine to breathe more freely and generate increased power. This application requires precise calculations and careful execution to avoid detrimental effects on engine performance.

- Aesthetic Customization

Custom exhaust fabrication also enables aesthetic customization, allowing vehicle owners to personalize the appearance of their exhaust systems. This may involve creating unique exhaust tip designs, altering the routing of exhaust pipes, or incorporating specific materials and finishes. For instance, a classic car restoration project might require fabricating an exhaust system that replicates the original design while utilizing modern materials for enhanced durability. Such projects demand meticulous attention to detail and adherence to historical accuracy.

- Specialized Applications

Certain vehicles or applications necessitate custom exhaust fabrication due to unique dimensional constraints, performance requirements, or regulatory considerations. Examples include custom-built vehicles, off-road vehicles requiring increased ground clearance, or vehicles undergoing engine swaps that necessitate modifications to the existing exhaust system. A custom-built off-road vehicle might require a high-clearance exhaust system fabricated to withstand harsh terrain, demanding specialized welding and fabrication techniques.

- Repair and Restoration

Custom exhaust fabrication can be essential for repairing or restoring damaged or obsolete exhaust systems. When replacement parts are unavailable for older vehicles or specialized equipment, custom fabrication provides a viable solution for restoring the exhaust system to its original functionality. Restoring a vintage vehicle, for example, often requires fabricating exhaust components that are no longer commercially available, calling for specialized knowledge and expertise in historical exhaust system designs.

The ability to provide custom exhaust fabrication distinguishes establishments. It positions them as capable of addressing specialized needs and offering tailored solutions beyond routine exhaust system maintenance and repair. This niche service enhances customer satisfaction and reinforces a service provider’s reputation as a comprehensive exhaust system specialist.

Frequently Asked Questions Regarding Exhaust System Services

The following addresses commonly encountered questions about exhaust system maintenance, repair, and related services.

Question 1: What are the primary indicators of exhaust system damage?

Audible changes, such as increased exhaust noise or rattling sounds, often signify exhaust system damage. Visual cues include rust, corrosion, or physical damage to exhaust pipes, mufflers, or catalytic converters. A noticeable decrease in fuel efficiency can also suggest an exhaust leak or obstruction.

Question 2: How frequently should a vehicle’s exhaust system be inspected?

Exhaust system inspection should be performed at least annually or whenever a noticeable change in exhaust sound or performance occurs. Vehicles operating in regions with harsh winter conditions or exposure to road salts may require more frequent inspections.

Question 3: What factors influence the lifespan of a catalytic converter?

The lifespan of a catalytic converter is influenced by several factors, including engine maintenance, fuel quality, and driving conditions. Overheating, contamination from oil or coolant leaks, and physical damage can significantly reduce the converter’s lifespan. Regular engine tune-ups and the use of high-quality fuel can prolong converter life.

Question 4: Is it possible to repair a muffler, or is replacement always necessary?

Muffler repair is possible in certain cases, particularly for minor rust perforations or small cracks. However, extensive corrosion, structural damage, or internal component failure often necessitates muffler replacement. The decision to repair or replace a muffler depends on the severity of the damage and the overall condition of the exhaust system.

Question 5: What are the potential consequences of driving with a damaged exhaust system?

Driving with a damaged exhaust system can result in reduced fuel efficiency, increased emissions, and potential exposure to harmful exhaust gases. It can also lead to further damage to other exhaust components and potentially trigger engine warning lights. Additionally, a damaged exhaust system may violate noise pollution regulations.

Question 6: What are the benefits of custom exhaust fabrication?

Custom exhaust fabrication offers tailored solutions for performance enhancements, aesthetic modifications, or specialized vehicle applications. It allows for optimization of exhaust flow, customization of exhaust sound, and adaptation to unique vehicle configurations. Custom fabrication provides solutions that standard exhaust components may not offer.

Proper maintenance of a vehicle’s exhaust system is paramount for optimal performance, regulatory compliance, and environmental responsibility. Consulting with qualified exhaust system specialists is recommended for addressing any concerns or issues.

The subsequent section will outline the regulatory environment governing exhaust systems and emissions control.

Conclusion

This exploration has illuminated the critical role a specialized exhaust system service provider fulfills in vehicle maintenance and environmental stewardship. From diagnostics to custom fabrication, the services offered contribute significantly to vehicle performance, regulatory compliance, and noise reduction. The multifaceted nature of exhaust system care necessitates expertise and precision, as seemingly minor issues can have cascading effects on vehicle operation and emissions output.

Therefore, the selection of a qualified and reputable center for exhaust system needs is paramount. Prioritizing preventative maintenance, adhering to recommended inspection schedules, and promptly addressing any signs of damage ensures the long-term health of the vehicle and minimizes its environmental footprint. The future of automotive service will likely emphasize stricter emissions standards and advanced diagnostic capabilities, making the expertise of specialized centers even more crucial.