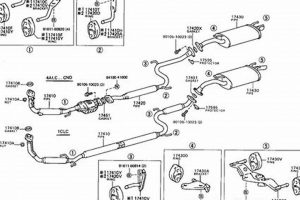

A component designed to reduce the noise generated by an internal combustion engine, featuring an intake port located on its side rather than at the center or end, is utilized in various vehicle exhaust systems. The specific location of the opening facilitates installation within constrained spaces and can influence the flow dynamics of exhaust gases. As an example, in certain motorcycle applications, this design allows the silencing device to be mounted closer to the engine, optimizing space utilization and aesthetic considerations.

Employing this particular configuration can be advantageous due to its adaptability to different chassis layouts. The positioning of the intake allows for increased design flexibility when routing exhaust piping, potentially leading to improved exhaust scavenging and engine performance. Historically, this type of configuration has emerged as a solution for vehicles where conventional muffler placement is not feasible, especially those with limited undercarriage space or unconventional frame designs.

The following sections will delve into the construction materials, performance characteristics, installation procedures, and maintenance requirements associated with noise reduction devices employing this lateral intake configuration, providing a detailed understanding of their applications and practical considerations.

Practical Considerations for Systems Utilizing a Lateral Intake Silencer

The following tips provide guidance on selecting, installing, and maintaining exhaust systems incorporating a noise reduction component featuring a side inlet.

Tip 1: Material Selection: Consider the operating environment when selecting a unit. Stainless steel offers superior corrosion resistance, particularly in regions with road salt usage, leading to increased longevity. Aluminized steel provides a more cost-effective alternative but is more susceptible to rust.

Tip 2: Dimensional Accuracy: Prior to purchase, verify the dimensions of the component and its intake port in relation to the existing exhaust system. Mismatched diameters or incorrect inlet positioning can lead to exhaust leaks and performance degradation.

Tip 3: Proper Installation: Employ appropriate mounting hardware and ensure secure connections to prevent vibration-induced failures. Exhaust hangers should be in good condition and properly aligned to support the weight of the system.

Tip 4: Regular Inspection: Routinely inspect the unit for signs of damage, such as cracks, dents, or corrosion. Early detection can prevent costly repairs and ensure continued compliance with noise regulations.

Tip 5: Leak Detection: Periodically check for exhaust leaks, particularly around the inlet connection. Leaks not only increase noise levels but can also allow harmful exhaust gases to enter the vehicle’s cabin.

Tip 6: Consider Backpressure Impact: A less restrictive internal design can improve engine performance; however, altering the original backpressure characteristics may require adjustments to the engine’s fuel management system for optimal results.

Tip 7: Professional Consultation: If uncertain about any aspect of selection, installation, or modification, consult with a qualified automotive technician. Incorrect procedures can compromise the system’s performance, safety, and longevity.

Adhering to these considerations will contribute to the reliable and effective operation of exhaust systems that incorporate a silencing component with a lateral intake port, ensuring both noise reduction and optimal engine performance.

The subsequent sections will address frequently asked questions and explore potential troubleshooting scenarios related to this specific exhaust system design.

1. Space Optimization

Space optimization is a critical design consideration in automotive engineering, particularly concerning exhaust system components. The constraints imposed by vehicle architecture often necessitate innovative solutions for accommodating noise reduction devices. The configuration with a lateral intake offers a viable approach to addressing these spatial challenges.

- Compact Vehicle Applications

In vehicles with limited undercarriage space, such as motorcycles or compact cars, the side inlet configuration allows the silencing device to be positioned closer to the engine or along unconventional exhaust routing paths. This reduces the overall length of the exhaust system and maximizes available space for other components.

- Complex Exhaust System Layouts

Vehicles with intricate exhaust manifold designs, such as those with multiple catalytic converters or resonators, benefit from the adaptability of side inlet designs. The offset inlet allows for easier integration into existing exhaust systems without requiring significant modifications to the chassis or other vehicle systems.

- Aftermarket Modifications and Custom Builds

For custom vehicle builds or aftermarket exhaust system upgrades, the design provides flexibility in positioning the silencing device. This is particularly useful when working with modified chassis or engine swaps where standard muffler configurations may not be suitable.

- Reduction of Exhaust System Footprint

By relocating the inlet to the side of the component, the overall “footprint” or area occupied by the exhaust system can be minimized. This is beneficial in situations where ground clearance is a concern or where there is limited space available within the vehicle’s undercarriage.

The inherent space-saving characteristics contribute to the widespread adoption of side inlet designs, especially in scenarios where conventional muffler placement is impractical. This configuration’s ability to navigate spatial constraints without compromising acoustic performance or engine efficiency underscores its significance in contemporary automotive engineering.

2. Flow Dynamics

The flow dynamics within a side inlet muffler critically influence its acoustic performance and overall effect on engine operation. The lateral placement of the inlet alters the way exhaust gases enter and interact with the internal baffling and resonating chambers. This contrasts with center-inlet designs where the flow is generally more direct. The side inlet creates a swirling or turbulent entry, which can affect the frequency and amplitude of sound waves being attenuated. Effective muffler design must carefully manage this turbulence to maximize sound absorption while minimizing backpressure.

The internal configuration of the muffler, including the size, shape, and positioning of baffles and perforated tubes, directly shapes the flow path. Poorly designed internals can result in excessive backpressure, hindering engine performance, or create undesirable noise characteristics. Consider, for example, a high-performance application where a straight-through design is used to minimize restriction, even at the expense of some noise reduction. Conversely, a passenger vehicle exhaust system might prioritize noise cancellation, employing more complex baffling that redirects and slows down the gas flow. Computational fluid dynamics (CFD) simulations are often employed to visualize and optimize the flow patterns within these devices.

In summary, the correlation between flow dynamics and muffler functionality is fundamental. Controlling the flow path optimizes noise reduction and minimizes adverse effects on engine performance. Challenges in design include balancing these competing factors to meet specific application requirements. A thorough understanding of these dynamics is essential for engineers involved in exhaust system design and optimization.

3. Acoustic Properties

The acoustic properties of a side inlet muffler directly dictate its effectiveness in attenuating exhaust noise. Design factors govern the degree to which sound waves are reduced, altered, or eliminated, influencing the overall sound quality and compliance with noise regulations.

- Sound Absorption Mechanisms

Side inlet mufflers employ a combination of sound absorption mechanisms, including reactive and absorptive techniques. Reactive methods utilize chambers and internal baffling to reflect and cancel out sound waves, while absorptive methods employ materials like fiberglass or steel wool to convert sound energy into heat. The ratio between these mechanisms dictates the muffler’s effectiveness at specific frequencies.

- Frequency-Specific Attenuation

The acoustic performance of a muffler is not uniform across the entire frequency spectrum. Certain muffler designs are more effective at attenuating low-frequency drone, while others excel at suppressing high-frequency rasp. The placement and geometry of internal components are tuned to target specific noise characteristics of the engine.

- Backpressure Considerations

Noise reduction and engine performance are often competing priorities. Aggressive sound attenuation can increase backpressure within the exhaust system, potentially reducing engine power output. Therefore, muffler design requires a balance between acoustic effectiveness and acceptable backpressure levels.

- Material Damping Characteristics

The materials used in muffler construction also contribute to its acoustic properties. Steel, stainless steel, and other alloys possess varying damping characteristics, influencing their ability to absorb and dissipate sound energy. Mufflers constructed with denser materials tend to exhibit superior noise reduction capabilities.

The integration of these acoustic principles within the design process leads to optimized noise reduction in exhaust systems. Design choices must consider the engines specific noise signature, desired sound characteristics, and performance requirements to achieve a muffler that meets acoustic standards without compromising engine functionality.

4. Material Durability

Material durability is a pivotal factor influencing the service life and performance of a side inlet muffler. The harsh operating environment of an exhaust system subjects the muffler to extreme temperatures, corrosive gases, road debris, and mechanical stress. Consequently, the selection of appropriate construction materials is crucial for ensuring long-term reliability.

- Corrosion Resistance

Exposure to exhaust gases containing water vapor, sulfur compounds, and other corrosive elements can rapidly degrade muffler materials. Stainless steel alloys, such as 304 or 409 stainless steel, offer superior corrosion resistance compared to carbon steel, extending the muffler’s lifespan. Aluminized steel provides an intermediate level of protection but is still vulnerable to rust in harsh environments.

- Thermal Stability

Exhaust gases can reach temperatures exceeding 1000F (538C), leading to thermal stress and material fatigue. Materials with high thermal stability, such as titanium or certain nickel-based alloys, can withstand these extreme temperatures without significant degradation. However, the high cost of these materials limits their widespread use in mass-produced mufflers.

- Mechanical Strength

Vibrations from the engine and impacts from road debris can induce mechanical stress on the muffler. Materials with high tensile strength and fatigue resistance, such as thick-gauge steel or reinforced composites, are better equipped to withstand these stresses and prevent cracking or deformation. The gauge (thickness) of the material significantly impacts durability.

- Weld Integrity

The welded joints in a side inlet muffler are often the weakest points in the structure. High-quality welding techniques and filler materials are essential for ensuring the integrity of these joints and preventing premature failure. Welding processes like TIG (Tungsten Inert Gas) welding provide stronger and more corrosion-resistant welds than MIG (Metal Inert Gas) welding.

The interplay between these factors determines the overall durability and longevity of a side inlet muffler. Selecting materials that adequately address these challenges is critical for minimizing maintenance costs and ensuring reliable exhaust system performance throughout the vehicle’s service life.

5. Installation Constraints

Installation constraints significantly impact the applicability and design of side inlet mufflers. The physical limitations of a vehicle’s chassis, available space, and existing exhaust system configuration dictate the feasibility of incorporating this muffler type. Overcoming these constraints often requires careful planning and adaptation.

- Chassis Geometry and Spatial Limitations

The layout of a vehicle’s undercarriage, including the position of suspension components, fuel tanks, and other critical systems, imposes direct constraints. Side inlet mufflers, while offering design flexibility, must still conform to the available space. This often necessitates precise measurements and custom fabrication to ensure proper fitment without compromising ground clearance or interfering with other vehicle systems. For instance, classic cars or vehicles with unconventional frame designs may present unique challenges requiring innovative mounting solutions.

- Exhaust System Routing and Connection Points

The existing exhaust system’s routing and connection points dictate the inlet and outlet orientation required for a side inlet muffler. Mismatches in pipe diameter or angle can lead to exhaust leaks and performance degradation. Adapters and custom piping may be required to seamlessly integrate the side inlet muffler into the existing system, increasing installation complexity and cost. For example, a motorcycle exhaust upgrade might require adapting the side inlet muffler to a header pipe with a different diameter and connection style.

- Mounting Points and Support Structures

Securely mounting the side inlet muffler is crucial for preventing vibration-induced failures and ensuring proper alignment. Existing mounting points may not be compatible with the side inlet design, necessitating the fabrication of new brackets or hangers. Proper support structures are essential for distributing the muffler’s weight and minimizing stress on the exhaust system. Consider the case of a truck where additional supports might be needed due to the larger size and weight of the aftermarket side inlet muffler.

- Regulatory Compliance and Clearance Requirements

Local regulations may impose restrictions on exhaust system modifications, including minimum ground clearance and permissible noise levels. The installation of a side inlet muffler must comply with these regulations to avoid legal issues. Furthermore, adequate clearance must be maintained between the muffler and heat-sensitive components, such as fuel lines or brake lines, to prevent overheating and potential hazards. Meeting these requirements often involves careful consideration of muffler placement and heat shielding.

These installation constraints collectively influence the selection, modification, and placement of side inlet mufflers. Successfully navigating these challenges ensures optimal performance, longevity, and compliance with safety and regulatory standards. The adaptability of a side inlet muffler makes it a feasible option for diverse applications, but careful assessment and planning are essential for proper integration.

6. Engine Compatibility

Engine compatibility represents a crucial determinant in the selection and integration of a side inlet muffler into a vehicle’s exhaust system. An improperly matched muffler can negatively affect engine performance, fuel efficiency, and emissions. The primary consideration centers on backpressure the resistance to exhaust gas flow created by the muffler. Excessive backpressure impedes the engine’s ability to expel exhaust gases efficiently, leading to reduced power output, increased fuel consumption, and elevated engine temperatures. Conversely, insufficient backpressure can disrupt exhaust scavenging, the process by which exhaust gases are pulled from the cylinders, also impacting performance negatively.

The engine’s displacement, power output, and intended operating range significantly influence the optimal backpressure characteristics. Smaller displacement engines typically require less backpressure than larger, high-performance engines. For example, installing a high-flow side inlet muffler, designed for a turbocharged performance engine, on a naturally aspirated economy car could result in a loss of low-end torque and decreased fuel efficiency. Conversely, a restrictive side inlet muffler designed for a small engine would severely limit the performance of a high-output engine. Therefore, muffler selection should be based on the engine’s specific requirements and operating parameters, often guided by manufacturer recommendations or aftermarket performance charts that correlate engine specifications with muffler flow rates.

In conclusion, engine compatibility constitutes a non-negotiable aspect of side inlet muffler selection. Mismatched components can yield detrimental effects on engine performance and longevity. Thorough assessment of the engine’s characteristics and careful consideration of muffler specifications are essential for achieving optimal results. Failure to prioritize engine compatibility can negate any potential benefits associated with a side inlet muffler, leading to operational inefficiencies and potential engine damage. The selection process warrants a data-driven approach, referencing engine specifications and flow-rate information to ensure proper alignment between the engine and the exhaust system.

7. Performance Impact

The integration of a side inlet muffler into an exhaust system can significantly influence a vehicle’s performance characteristics. Factors such as engine power, torque, fuel efficiency, and overall drivability are all susceptible to alteration based on the muffler’s design and compatibility with the engine.

- Backpressure Effects

The level of backpressure generated by the side inlet muffler is a primary determinant of performance impact. Excessive backpressure restricts exhaust gas flow, leading to reduced engine power, particularly at higher RPMs. Insufficient backpressure can disrupt exhaust scavenging, negatively affecting low-end torque and fuel economy. The ideal backpressure level is engine-specific and must be carefully considered during muffler selection.

- Exhaust Gas Velocity

The side inlet design affects the velocity of exhaust gases as they pass through the muffler. Changes in gas velocity can alter the scavenging efficiency of the engine, influencing cylinder filling and combustion. A well-designed side inlet muffler will maintain optimal exhaust gas velocity to maximize engine performance across the operating range.

- Sound Wave Tuning

The internal baffling and chamber design within the side inlet muffler influence the propagation of sound waves within the exhaust system. By strategically tuning these sound waves, it is possible to enhance engine performance through improved scavenging or reduced pumping losses. However, achieving the desired acoustic characteristics without negatively impacting exhaust flow is a delicate balancing act.

- Catalytic Converter Interaction

The placement and design of the side inlet muffler can influence the efficiency of the catalytic converter. If the muffler creates excessive backpressure, it can impede the flow of exhaust gases through the converter, reducing its effectiveness in converting harmful emissions. Similarly, improper muffler placement can affect the operating temperature of the converter, impacting its performance and longevity.

The performance impact of a side inlet muffler is a multifaceted consideration. The optimal design will strike a balance between noise reduction, exhaust flow efficiency, and engine compatibility. Careful selection and professional installation are essential for realizing the full performance potential of a side inlet muffler while mitigating any adverse effects on engine operation.

Frequently Asked Questions

The following section addresses common inquiries regarding the application, performance, and maintenance of side inlet mufflers.

Question 1: What are the primary advantages of utilizing a side inlet muffler compared to a center inlet design?

Side inlet designs offer increased flexibility in exhaust system routing, particularly in vehicles with limited space or unconventional chassis configurations. This configuration can facilitate easier integration with existing exhaust components and simplify installation procedures in certain applications.

Question 2: Does the placement of the inlet on the side affect the acoustic performance of the muffler?

Yes, the lateral inlet can alter the flow dynamics within the muffler, influencing its ability to attenuate specific frequencies. The internal baffling and chamber design are critical for optimizing acoustic performance regardless of inlet placement.

Question 3: How does the use of a side inlet muffler influence engine backpressure?

The impact on backpressure depends primarily on the internal design of the muffler, not solely on the inlet location. A poorly designed muffler, regardless of inlet placement, can create excessive backpressure, negatively affecting engine performance. Proper design considerations are crucial to maintaining optimal backpressure levels.

Question 4: What materials are commonly used in the construction of side inlet mufflers, and how do they affect durability?

Common materials include aluminized steel and stainless steel. Stainless steel provides superior corrosion resistance, enhancing longevity, especially in environments with road salt exposure. Aluminized steel offers a more cost-effective alternative but is more susceptible to corrosion.

Question 5: Can a side inlet muffler be installed on any vehicle, regardless of its original exhaust system design?

While side inlet designs offer adaptability, compatibility with the existing exhaust system is essential. Mismatched pipe diameters, incorrect inlet positioning, and insufficient space can hinder installation. Modifications or custom fabrication may be necessary for proper integration.

Question 6: What maintenance procedures are recommended for side inlet mufflers to ensure optimal performance and longevity?

Regular inspections for signs of corrosion, damage, or leaks are crucial. Maintaining secure connections and replacing worn exhaust hangers can prevent premature failure. Addressing any detected issues promptly will contribute to extended muffler lifespan.

In summary, understanding the specific design characteristics, material properties, and installation requirements of a side inlet muffler is crucial for its effective application and long-term performance.

The subsequent section will delve into troubleshooting common issues associated with side inlet mufflers and their integration into exhaust systems.

Conclusion

This exploration has clarified the functionality, advantages, and limitations associated with the side inlet muffler. The devices space-saving design, coupled with adaptable installation characteristics, addresses specific challenges within exhaust system design. Its acoustic performance is intricately linked to internal design elements and the management of gas flow dynamics, directly impacting its effectiveness in noise reduction. Material selection plays a crucial role in its longevity, with stainless steel offering enhanced corrosion resistance compared to aluminized steel.

The long-term performance of the side inlet muffler hinges on adherence to appropriate installation procedures and diligent maintenance practices. Vehicle owners and technicians are encouraged to thoroughly evaluate engine compatibility and spatial constraints before integration, optimizing the balance between noise reduction, engine performance, and regulatory compliance. Ongoing research and development within exhaust system technology will continue to refine the design and application of this component, contributing to improved vehicle performance and reduced environmental impact.