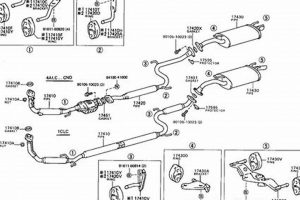

These components are integral to a vehicle’s exhaust management, designed primarily to diminish the noise produced by the engine’s combustion process. Functioning as reactive or absorptive devices, these units employ baffles, chambers, and sound-absorbing materials to mitigate the amplitude of sound waves generated within the exhaust stream. For example, a typical passenger vehicle incorporates one or more of these devices to meet regulatory noise emission standards and enhance passenger comfort.

The adoption of noise reduction technology significantly contributes to a quieter environment, both within the vehicle cabin and in the surrounding areas. This technology plays a crucial role in minimizing noise pollution, improving the overall driving experience, and adhering to governmental regulations concerning permissible sound levels. Historically, advancements in material science and acoustic engineering have led to increasingly efficient and durable designs, resulting in better performance and longevity.

The following sections will delve into the specific types, functionalities, maintenance considerations, and technological advancements associated with vehicular sound suppression, providing a detailed overview of their operation and impact on vehicle performance and environmental responsibility.

Muffler Systems

Maximizing the lifespan and effectiveness of vehicular sound suppression components requires adherence to specific maintenance practices and informed decision-making. The following tips provide guidance on ensuring proper functionality and avoiding premature failure.

Tip 1: Regular Visual Inspection: Periodically examine the unit for signs of corrosion, physical damage, or leaks. Early detection of these issues can prevent more extensive damage and costly repairs.

Tip 2: Prompt Leak Repair: Address any exhaust leaks immediately. Leaks not only increase noise levels but also compromise the engine’s efficiency and may introduce harmful gases into the vehicle cabin.

Tip 3: Proper Installation: Ensure that all components are correctly installed and securely mounted. Improper installation can lead to premature wear, increased noise, and potential safety hazards.

Tip 4: Avoid Short Trips: Minimize frequent short trips, as they prevent the complete evaporation of condensation within the exhaust system, accelerating corrosion and reducing the component’s lifespan.

Tip 5: Consider Material Upgrades: When replacing an existing unit, consider upgrading to a higher-grade material, such as stainless steel, for enhanced durability and corrosion resistance, particularly in regions with harsh weather conditions.

Tip 6: Monitor Engine Performance: A malfunctioning engine can place undue stress on the exhaust system. Address any engine-related issues promptly to prevent damage to the components.

Adhering to these recommendations will contribute to the sustained performance and longevity of the vehicle’s exhaust management, ensuring optimal noise reduction and environmental compliance.

The subsequent sections will provide a detailed analysis of various types of these systems and their specific applications, further enhancing understanding of their critical role in vehicle operation.

1. Noise Reduction Effectiveness

Noise reduction effectiveness is a paramount consideration in the design and implementation of vehicular sound suppression components. The primary objective is to mitigate the audible output generated by the internal combustion engine, aligning with both regulatory noise emission standards and occupant comfort expectations.

- Sound Absorption Materials and Chamber Design

The composition and arrangement of materials within a muffler significantly impact its ability to attenuate sound waves. Absorbent materials, such as fiberglass or mineral wool, convert sound energy into heat through friction. Chamber designs, including expansion chambers and resonators, manipulate sound waves to cause destructive interference, thereby reducing noise output. The effectiveness of these designs depends on accurate acoustic modeling and careful selection of materials.

- Frequency Targeting

Internal combustion engines produce a wide range of frequencies. Effective mufflers are designed to target specific frequencies known to be particularly intrusive or problematic. This is achieved through tuned resonators and carefully calculated chamber dimensions. Targeting specific frequencies allows for a more efficient reduction in perceived noise levels without unduly restricting exhaust flow, which could negatively impact engine performance.

- Backpressure Considerations

While noise reduction is essential, it must be balanced against the need to minimize backpressure within the exhaust system. Excessive backpressure can reduce engine power and fuel efficiency. Therefore, design of effective muffler systems necessitate an optimization of internal structures to maximize sound attenuation while minimizing the restriction of exhaust gases. This balance often involves trade-offs between noise reduction and engine performance.

- Regulatory Compliance and Testing

The design of muffler systems must adhere to stringent regulatory noise emission standards set by governmental agencies. Compliance is typically verified through rigorous testing procedures that measure the sound levels produced by the vehicle under various operating conditions. The effectiveness of a muffler system is therefore assessed not only by its subjective noise reduction capabilities but also by its ability to meet or exceed mandated standards. Certification processes often involve repeated testing and ongoing quality control measures to ensure continued compliance throughout the product lifecycle.

The interplay between these facets determines the overall noise reduction effectiveness of vehicular sound suppression components. Balancing sound absorption, frequency targeting, backpressure minimization, and regulatory compliance is essential for creating muffler systems that effectively reduce noise pollution without compromising engine performance or longevity.

2. Exhaust Flow Optimization

Exhaust flow optimization and muffler systems are intrinsically linked, representing a critical interplay between noise reduction and engine performance. Muffler systems, by their very nature, present a potential impediment to the free flow of exhaust gases. The internal structure of a muffler, designed to attenuate sound waves, inherently introduces resistance to the passage of exhaust. Therefore, achieving optimal exhaust flow is a central design challenge in muffler system engineering. If a muffler system excessively restricts exhaust flow, the resulting backpressure can diminish engine power, reduce fuel efficiency, and potentially increase engine operating temperatures. Conversely, a muffler system that prioritizes unimpeded exhaust flow may fail to adequately suppress noise, violating regulatory standards or compromising vehicle occupant comfort. The connection, therefore, hinges on achieving a delicate balance.

The design strategies employed to optimize exhaust flow within a muffler system are multifaceted. Straight-through muffler designs, for example, attempt to minimize flow restriction by directing exhaust gases along a relatively unobstructed path. However, such designs often require sophisticated internal baffling and sound-absorbing materials to achieve acceptable noise reduction levels. Chambered mufflers, while effective at noise suppression, tend to create greater backpressure due to the redirection of exhaust gases through multiple chambers. Computational fluid dynamics (CFD) modeling is frequently used to simulate exhaust gas flow within a muffler design, allowing engineers to identify and mitigate areas of excessive turbulence or flow restriction. The selection of materials, the diameter of internal pipes and chambers, and the overall configuration of the muffler system are all critical factors influencing exhaust flow characteristics.

In conclusion, exhaust flow optimization is not merely a desirable attribute of muffler systems; it is a fundamental design constraint. Successfully integrating effective noise reduction with minimal flow restriction demands a comprehensive understanding of fluid dynamics, acoustics, and materials science. The ongoing pursuit of more efficient and environmentally responsible vehicles continues to drive innovation in muffler system design, pushing engineers to develop solutions that simultaneously enhance engine performance and minimize noise pollution. The key challenges lie in balancing conflicting design objectives and in accurately predicting the complex interactions between exhaust gas flow and acoustic phenomena within the muffler system.

3. Material Durability

Material durability is a critical attribute of muffler systems, directly impacting their longevity, performance, and overall cost-effectiveness. The exhaust system, including the muffler, operates in a harsh environment characterized by high temperatures, corrosive gases (including water vapor, sulfur oxides, and nitrogen oxides), and exposure to road debris and environmental contaminants. Consequently, the materials used in muffler construction must withstand these conditions to ensure reliable operation over the intended service life of the vehicle. Premature failure of a muffler system due to material degradation can lead to increased noise levels, reduced engine efficiency, and the potential release of harmful emissions. For example, the use of low-grade steel can result in rapid corrosion and eventual structural failure, necessitating costly replacements. The selection of appropriate materials is therefore paramount in achieving a durable and reliable muffler system.

Several materials are commonly employed in muffler construction, each offering varying levels of durability and cost. Aluminized steel, for instance, provides a reasonable balance between corrosion resistance and cost-effectiveness and is frequently used in original equipment manufacturer (OEM) applications. Stainless steel, particularly grades such as 304 and 409, offers superior corrosion resistance and is often preferred for aftermarket and performance applications. Titanium, while providing excellent strength-to-weight ratio and corrosion resistance, is typically reserved for high-performance or specialized applications due to its higher cost. The thickness of the material also plays a significant role in durability, with thicker gauges generally providing greater resistance to mechanical damage and corrosion. Material coatings, such as ceramic or aluminide coatings, can further enhance corrosion resistance and extend the lifespan of the muffler system. Furthermore, internal insulation materials, such as fiberglass or mineral wool, must also exhibit thermal stability and resistance to degradation in the presence of exhaust gases to maintain their sound-absorbing properties over time.

In conclusion, the material durability of muffler systems is a key determinant of their overall performance and longevity. The selection of appropriate materials, considering factors such as corrosion resistance, thermal stability, and mechanical strength, is essential for ensuring reliable operation in the demanding environment of the exhaust system. While cost considerations are important, prioritizing material durability can lead to long-term cost savings by reducing the frequency of replacements and minimizing the potential for associated maintenance issues. The ongoing development of new materials and coatings holds the promise of further improving the durability and performance of muffler systems, contributing to both enhanced vehicle reliability and reduced environmental impact.

4. System Resonance Tuning

System resonance tuning, a critical aspect of muffler system design, directly influences the efficacy of noise reduction and the overall acoustic characteristics of a vehicle. The manipulation of sound wave interference within the muffler relies heavily on precisely engineered resonant frequencies to attenuate specific noise components.

- Helmholtz Resonators

Helmholtz resonators, a common component in muffler systems, are designed to cancel out specific frequencies through destructive interference. These resonators consist of a chamber connected to the main exhaust flow via a neck or port. The volume of the chamber and the dimensions of the neck determine the resonant frequency at which the resonator will most effectively attenuate sound. Improper tuning of Helmholtz resonators can lead to ineffective noise reduction or, in some cases, the amplification of certain frequencies.

- Quarter-Wave Resonators

Quarter-wave resonators utilize the principle of acoustic standing waves to cancel out specific frequencies. These resonators are typically designed as closed-end tubes with a length equal to one-quarter of the wavelength of the target frequency. When sound waves of the target frequency enter the resonator, they are reflected at the closed end, creating a standing wave pattern that cancels out the incoming wave. Precise tuning of quarter-wave resonators is essential to ensure effective noise cancellation at the intended frequency.

- Chamber Volume and Shape

The volume and shape of the chambers within a muffler system significantly influence the resonant frequencies and overall acoustic characteristics. Larger chambers tend to resonate at lower frequencies, while smaller chambers resonate at higher frequencies. The shape of the chambers also affects the distribution of sound waves and the effectiveness of noise cancellation. Optimization of chamber volume and shape requires careful acoustic modeling and empirical testing.

- Material Properties and Damping

The material properties of the muffler system, including its stiffness and damping characteristics, can influence the resonant frequencies and the dissipation of sound energy. Materials with higher damping coefficients tend to absorb more sound energy, reducing the overall noise output of the system. The selection of appropriate materials and the application of damping treatments are therefore important considerations in system resonance tuning.

The effective implementation of system resonance tuning within muffler systems requires a thorough understanding of acoustic principles, precise engineering calculations, and careful material selection. The integration of Helmholtz resonators, quarter-wave resonators, and optimized chamber designs allows for the targeted attenuation of specific noise frequencies, resulting in quieter and more comfortable vehicles while adhering to regulatory noise emission standards.

5. Installation Integrity

The functional performance and longevity of muffler systems are inextricably linked to the integrity of their installation. Proper installation is not merely an assembly procedure; it is a critical determinant of the system’s ability to effectively mitigate noise, manage exhaust flow, and withstand the rigors of continuous operation. Compromised installation practices introduce stress points, create opportunities for corrosion, and disrupt the intended acoustic properties of the system. For instance, improperly tightened clamps can allow exhaust leaks, negating the noise reduction capabilities of the muffler and potentially introducing harmful gases into the vehicle cabin. Similarly, misaligned connections can induce premature wear and stress cracking, reducing the lifespan of the system and requiring costly repairs or replacements. Installation integrity, therefore, represents a foundational element in realizing the full potential of any muffler system, irrespective of its design sophistication or material quality. The consequences of neglecting this aspect extend beyond mere inconvenience, impacting vehicle performance, safety, and environmental compliance.

The practical implications of installation integrity are readily apparent in real-world scenarios. A muffler system subjected to improper welding during installation, for example, may exhibit weakened joints susceptible to failure under thermal stress and vibration. This can lead to catastrophic separation of the muffler components, resulting in immediate and significant noise pollution, as well as potential damage to other vehicle components. In another instance, the failure to properly isolate the muffler system from the vehicle chassis can transmit vibrations and exacerbate noise levels within the passenger cabin. Moreover, improper support of the muffler system can lead to sagging and increased susceptibility to damage from road debris. These examples underscore the importance of adhering to manufacturer-specified installation procedures and employing qualified technicians with the necessary expertise to ensure proper fitment and secure mounting of the muffler system. Rigorous inspection of the installation process is essential to identify and rectify any potential defects before they escalate into more serious problems.

In summary, the connection between installation integrity and muffler systems is paramount. Neglecting proper installation practices undermines the designed performance characteristics of the system, reduces its lifespan, and compromises vehicle safety and environmental responsibility. Ensuring meticulous adherence to installation guidelines, coupled with thorough inspection and skilled execution, is essential for maximizing the benefits of muffler systems and avoiding the potentially severe consequences of compromised installation integrity. Addressing challenges like accessibility during installation and variations in vehicle models requires continuous refinement of installation techniques and comprehensive training for technicians. Installation integrity should be viewed not as a mere step in the process, but as a fundamental component of the system’s overall functionality and reliability.

6. Regulatory Compliance

The connection between vehicular sound suppression devices and adherence to established regulations is both direct and consequential. Government bodies at various levels mandate specific noise emission standards for vehicles operating within their jurisdictions. These standards are designed to mitigate noise pollution and safeguard public health and well-being. Sound management components serve as critical tools for vehicle manufacturers to meet these legally binding requirements. Failure to comply with noise emission regulations can result in substantial penalties, including fines, vehicle recalls, and restrictions on sales or operation. The design, manufacture, and installation of these units are therefore heavily influenced by the need to achieve and maintain regulatory compliance.

The European Union’s noise emission standards, for instance, stipulate maximum permissible sound levels for different vehicle categories. Similarly, the United States Environmental Protection Agency (EPA) sets noise standards for various types of vehicles. These regulations often specify testing procedures that manufacturers must follow to demonstrate compliance. Examples of non-compliance have led to significant repercussions for automakers, including costly recalls to retrofit vehicles with compliant sound management systems. In practical terms, this means that the internal construction of these systems, including the materials used and the configuration of chambers and baffles, must be carefully engineered to attenuate sound waves to within the legally permissible limits. Furthermore, the durability and long-term performance of these systems are also relevant, as continued compliance over the vehicle’s lifespan is typically required.

The interplay between regulatory compliance and vehicle noise control underscores the importance of rigorous engineering, quality control, and ongoing monitoring. While technological advancements may lead to more efficient and effective noise reduction solutions, the fundamental requirement to meet and exceed regulatory standards remains paramount. The challenge lies in balancing the demands of noise reduction, engine performance, and cost-effectiveness while ensuring sustained compliance throughout the vehicle’s operational life. Continuous collaboration between regulatory agencies, vehicle manufacturers, and component suppliers is essential to adapt to evolving environmental concerns and maintain a harmonious balance between transportation needs and community well-being. Furthermore, the increasing adoption of electric vehicles presents new opportunities and challenges in noise management, necessitating the development of innovative solutions to address potential acoustic issues such as tire noise and aerodynamic sounds.

Frequently Asked Questions

The following section addresses common inquiries and clarifies misconceptions regarding muffler systems, their function, maintenance, and regulatory aspects.

Question 1: What is the primary function of vehicular sound suppression systems?

The primary function of muffler systems is to attenuate the noise generated by the internal combustion engine. These systems reduce noise pollution and ensure vehicles adhere to noise emission regulations.

Question 2: How does corrosion impact the performance of exhaust noise reduction units?

Corrosion degrades the structural integrity and acoustic properties of exhaust components. Rust compromises noise attenuation capabilities and can lead to exhaust leaks, diminishing performance and potentially violating emission standards.

Question 3: What are the key indicators that a vehicular sound suppression unit requires replacement?

Key indicators include increased exhaust noise, visible rust or damage, exhaust leaks, and reduced engine performance. Any of these signs warrant inspection and potential replacement of the component.

Question 4: Do aftermarket sound management devices affect vehicle warranty?

The impact on warranty depends on the specific modification and the manufacturer’s policy. Installing an aftermarket system may void portions of the warranty if the part is deemed to cause a failure of other vehicle components.

Question 5: What role does backpressure play in sound management device design?

Backpressure is a critical design consideration. Excessive backpressure can reduce engine power and fuel efficiency. Sound suppression design balances noise reduction with optimal exhaust flow to minimize backpressure.

Question 6: How do noise emission regulations vary across different regions?

Noise emission regulations vary significantly across regions. The European Union, United States, and other countries have specific standards regarding maximum permissible sound levels for vehicles.

The information provided clarifies essential aspects of sound suppression devices. Proper maintenance, timely replacement, and adherence to regulations are critical for optimal performance and environmental responsibility.

The next section will delve into emerging technologies and future trends in sound management design, offering a glimpse into the evolving landscape of vehicle noise control.

Conclusion

The preceding discussion has illuminated the multifaceted nature of muffler systems, underscoring their critical role in vehicular noise reduction, regulatory compliance, and overall vehicle performance. From material durability to system resonance tuning and installation integrity, each element contributes significantly to the efficacy and longevity of these essential components. A comprehensive understanding of these aspects is vital for informed decision-making, whether in design, maintenance, or regulatory oversight.

Continued advancements in materials science, acoustic engineering, and regulatory frameworks will undoubtedly shape the future of vehicular noise management. The ongoing pursuit of quieter, more efficient, and environmentally responsible transportation necessitates a sustained commitment to innovation and a proactive approach to addressing the challenges posed by noise pollution. Further research and development are crucial to optimize system performance, minimize environmental impact, and ensure continued compliance with evolving regulatory standards.

![John Deere Muffler: Premium Exhaust [Cost-Effective] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades John Deere Muffler: Premium Exhaust [Cost-Effective] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/01/th-295-300x200.jpg)