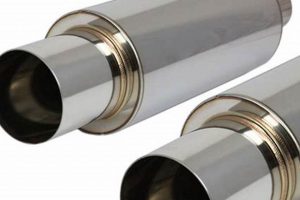

This exhaust component represents an engineered approach to managing engine noise and enhancing performance. It’s characterized by its internal design, which incorporates chambers and passages of varying sizes to selectively attenuate specific sound frequencies. This construction aims to reduce unwanted resonances while permitting optimal gas flow. The result is a noticeably quieter operation compared to systems with simpler architectures, potentially without significant restriction of exhaust expulsion.

The advantages of such a system include a refined sound profile, which can improve driving comfort and reduce noise pollution. Furthermore, the carefully calculated flow characteristics may contribute to improved engine efficiency and power output. Historically, advancements in exhaust technology have focused on achieving this balance between noise reduction, performance enhancement, and emissions control. This type of component often represents a significant step in this ongoing engineering evolution.

Understanding the principles of exhaust system design is crucial for appreciating the function and benefits described above. The following sections will delve into the specific aspects of these systems, covering topics such as materials science, acoustic engineering, and performance optimization strategies. This will provide a more in-depth look at the considerations involved in selecting and implementing these technologies.

Enhancing Performance and Sound Management

The following guidance focuses on optimizing the usage and maintenance related to advanced exhaust systems, specifically those employing progressive chambering technology for noise reduction and performance.

Tip 1: Select the Appropriate System: Compatibility with the vehicle’s make, model, and engine type is paramount. Consult manufacturer specifications and professional installers to ensure proper fitment and avoid potential performance issues.

Tip 2: Prioritize Professional Installation: Complex exhaust systems often require precise alignment and secure mounting. Improper installation can lead to leaks, vibrations, and premature component failure. Engage certified technicians for optimal results.

Tip 3: Conduct Regular Inspections: Periodically examine the exhaust system for signs of corrosion, damage, or loose connections. Address any identified issues promptly to prevent escalating problems and maintain optimal performance.

Tip 4: Monitor Exhaust Note Variations: Changes in the exhaust sound can indicate potential problems, such as leaks, internal damage, or system degradation. Investigate any unusual noises to diagnose and resolve underlying issues.

Tip 5: Ensure Proper Exhaust Flow: Avoid modifications or obstructions that could impede exhaust flow. Maintaining unrestricted gas expulsion is crucial for optimal engine performance and fuel efficiency.

Tip 6: Consider Material Quality: Exhaust system longevity is significantly influenced by the materials used in its construction. Stainless steel and other corrosion-resistant alloys offer enhanced durability and extended service life.

Implementing these recommendations can contribute to the longevity, performance, and sound quality of advanced exhaust systems, enhancing both the driving experience and vehicle efficiency.

The following sections will explore specific applications of this technology and provide further insights into maximizing its benefits.

1. Noise Reduction

The relationship between advanced muffler designs and noise reduction is intrinsic. Engineered exhaust systems, like the referenced item, prioritize the attenuation of undesirable sound frequencies generated by the engine. This is achieved through carefully designed internal chambers and strategically placed acoustic baffling. A direct cause-and-effect relationship exists: alterations to these internal structures directly influence the system’s capacity to reduce noise. Effective noise reduction is an essential component. It translates to a more comfortable driving experience and mitigation of noise pollution in surrounding environments. Consider, for instance, residential areas or prolonged highway driving, where excessive engine noise can be disruptive.

Examples of practical applications are abundant. Automotive manufacturers often incorporate sophisticated exhaust systems to meet increasingly stringent noise regulations. Aftermarket exhaust systems, which claim to enhance performance, must also address noise levels to comply with legal limits. Moreover, noise reduction contributes to a perception of vehicle quality and refinement. For example, a luxury vehicle would be expected to have a notably quieter exhaust note than a utilitarian work truck, despite both potentially using an internal combustion engine of similar size.

In summary, noise reduction is not merely a desirable feature but a critical engineering consideration in advanced muffler design. It directly impacts driver comfort, regulatory compliance, and overall vehicle experience. While achieving optimal noise reduction, balancing exhaust flow, and meeting performance requirements presents engineering challenges. Understanding these elements is crucial to appreciating the complexities of modern automotive design.

2. Performance Enhancement

The impact on engine performance constitutes a primary consideration in the design and selection of any exhaust system component. Advanced muffler designs, aim to optimize exhaust gas flow to improve power output and efficiency.

- Reduced Backpressure

Internal design reduces resistance to exhaust gases, enabling more efficient expulsion from the engine cylinders. This reduction in backpressure minimizes the energy the engine expends on exhausting waste gases. In racing applications, minimizing backpressure can lead to measurable gains in horsepower, particularly at higher engine speeds. However, excessive reduction can negatively impact low-end torque; a balanced approach is necessary.

- Improved Scavenging

This refers to the more effective removal of exhaust gases from the combustion chamber. A well-designed system can create pressure waves that actively draw out remaining exhaust. This phenomenon, known as scavenging, enhances the intake of fresh air and fuel, leading to a more complete combustion cycle. Certain designs can be tailored to exploit scavenging effects at specific engine RPM ranges, creating a performance advantage within that range.

- Optimized Flow Dynamics

The internal architecture, including chamber sizes, baffle placement, and pipe diameters, dictate the flow characteristics. Systems optimized for minimal turbulence and uniform gas velocity contribute to improved engine breathing. Computational fluid dynamics (CFD) is often employed in the design process to model and refine these flow dynamics. The goal is to achieve a balance between flow velocity and pressure drop, maximizing overall system efficiency.

- Power Band Tuning

Different designs can alter the engine’s power curve, shifting peak power and torque to higher or lower RPM ranges. This tuning capability is crucial for matching the exhaust system to specific driving styles or performance requirements. For instance, a design focused on low-end torque would be beneficial for towing applications, while a system prioritizing high-RPM power is more suited for track racing.

The interplay between these factors determines the overall impact on engine performance. While designs can yield measurable improvements in horsepower and torque, the specific gains are highly dependent on the engine’s characteristics, existing modifications, and the overall system design. Performance enhancements should be assessed through dyno testing and real-world driving evaluations to validate claims and ensure compatibility.

3. Flow Optimization

Flow optimization, as a component of this type of muffler, is centrally important to its performance characteristics. It directly influences the engine’s ability to expel exhaust gases efficiently, which subsequently impacts power output, fuel economy, and overall engine health. The design incorporates specific chamber configurations and internal pathways calculated to minimize backpressure while simultaneously promoting efficient gas scavenging. An increase in backpressure leads directly to reduced engine efficiency, due to the engine needing to spend energy expelling gases. Optimizing flow means a reduction of work required, and potentially more work done in useful applications. This design contrasts with simpler muffler designs, which often prioritize sound reduction at the expense of creating significant flow restriction. Real-world examples include aftermarket applications focused on performance gains where the original muffler design is a significant restriction point, limiting the overall power. This design is engineered to balance the trade-off between noise reduction and exhaust flow.

Achieving optimal flow requires careful consideration of several factors, including the diameter and smoothness of internal pathways, the angle of bends, and the volume of the internal chambers. Designs often employ computational fluid dynamics (CFD) modeling to visualize and optimize gas flow patterns. Further examples are evident in specialized vehicles: racing cars use meticulously designed exhaust systems to maximize engine power, even at the expense of increased noise. Conversely, passenger vehicles prioritize noise reduction, often with some compromise to maximum flow. The “progressive” aspect in the name signifies the use of graduated or staged flow management, typically with chambers of varying size and configuration, to achieve a broad range of noise attenuation and flow characteristics.

In summary, flow optimization is not merely a design consideration. But is a fundamental determinant of a system’s overall performance. Proper understanding leads to better system selection, contributing to the efficient and reliable operation of the vehicle. Design must address challenges of balancing noise reduction, pressure minimization, durability, and component cost. Future advances will continue to focus on these areas, furthering the refinement of exhaust systems. The balance between all the factors will ultimately give the product its merit.

4. Durability

Durability represents a crucial attribute of any exhaust system component, including the “carven progressive muffler.” It directly influences the lifespan, reliability, and long-term cost-effectiveness of the system. The capacity to withstand environmental stressors, operational demands, and material degradation is paramount in evaluating its overall value.

- Material Selection and Corrosion Resistance

The selection of materials constitutes a primary determinant of durability. Stainless steel alloys, for instance, offer superior resistance to corrosion compared to aluminized steel or mild steel. The muffler’s exposure to moisture, road salts, and high temperatures accelerates corrosion, potentially leading to structural failure and exhaust leaks. Material selection must align with the intended operating environment to mitigate corrosion-related degradation. Consider the differences between vehicle operation in northern climates where road salt is heavily used versus arid desert environments.

- Weld Integrity and Structural Strength

The quality of welds and the overall structural design contribute significantly to the system’s ability to withstand mechanical stresses. Vibrations, thermal expansion, and physical impacts can compromise weld integrity, leading to cracks and eventual component failure. Reinforced welds, robust mounting points, and careful design can help to mitigate these risks. Consider the stresses present in off-road applications, which necessitate even higher weld quality and structural reinforcements compared to standard on-road vehicles.

- Thermal Management and Fatigue Resistance

Exhaust systems undergo extreme temperature fluctuations during operation, which can induce thermal stress and fatigue. The ability of the materials to withstand repeated cycles of heating and cooling is crucial for preventing cracking and premature failure. Proper thermal management, including heat shields and adequate ventilation, can help to reduce thermal stress. High-performance alloys with enhanced fatigue resistance may be employed in critical areas to extend lifespan.

- Protection Against Physical Damage

The location and design of the muffler also influence its vulnerability to physical damage. Proximity to the road surface increases the risk of impacts from debris or road hazards. Skid plates, protective coatings, and strategic placement can help to safeguard against physical damage. Consider the increased risk of damage for vehicles with low ground clearance or those frequently driven on unpaved surfaces.

The interconnectedness of these facets underscores the complexity of achieving durability in exhaust system components. The effectiveness of “carven progressive muffler” depends on careful attention to material properties, manufacturing processes, and design considerations that contribute to long-term reliability and performance. Compromises in any of these areas can significantly reduce the lifespan and overall value of the system.

5. Material Composition

Material composition constitutes a foundational element in the performance and longevity of exhaust systems, and specifically impacts the value proposition of a “carven progressive muffler.” The choice of materials directly influences resistance to corrosion, thermal fatigue, and mechanical stressfactors critical to system durability and functionality. Material selection is causative, with different grades exhibiting varying susceptibilities to the harsh conditions prevalent within an exhaust environment. Stainless steel alloys, commonly employed in high-quality mufflers, offer enhanced corrosion resistance compared to aluminized steel, thereby extending the lifespan of the component. For example, in regions with heavy road salt usage, a stainless steel muffler will demonstrably outlast one constructed from a less resilient material, preventing premature failure and maintaining optimal performance. Conversely, more basic materials may suffice for cost-sensitive applications in dry climates.

The importance of material composition extends beyond mere longevity; it also impacts the acoustic properties and thermal characteristics of the muffler. Different metals exhibit varying densities and resonant frequencies, which influence the sound profile produced by the exhaust system. Moreover, materials like titanium, known for their high strength-to-weight ratio, may be employed in performance-oriented applications to reduce overall vehicle weight. Real-world applications include high-performance sports cars where lightweight exhaust systems are integral to achieving optimal handling and acceleration. In these scenarios, the enhanced material properties justify the higher cost, reflecting the practical significance of material selection in achieving specific performance objectives. The thickness of the material also plays a role, a thicker gauge being more resistive to internal abrasion.

In summary, understanding the relationship between material composition and muffler performance is critical for informed decision-making. Proper material selection optimizes resistance to corrosion, thermal stress, and mechanical damage, and contributes significantly to overall system value. Addressing design challenges, such as balancing cost, weight, and durability, necessitates a comprehensive understanding of material science and engineering principles. Advances in material technology will continue to drive improvements in exhaust system performance, underscoring the enduring relevance of this aspect. These advances can lead to more efficient designs that are lighter and perform better under varied conditions.

6. Vehicle Compatibility

The degree of compatibility between a specific vehicle and a “carven progressive muffler” dictates the success of the exhaust system upgrade or replacement. Compatibility encompasses various factors, ranging from physical fitment to electronic system integration, influencing performance, regulatory compliance, and overall user satisfaction.

- Physical Dimensions and Mounting Points

Accurate physical dimensions and proper alignment of mounting points are essential for a seamless installation. Incompatible dimensions necessitate modifications, potentially compromising structural integrity or voiding warranties. A direct-fit replacement ensures ease of installation and reduces the risk of leaks or vibrations. For example, attempting to install a muffler designed for a compact car on a full-size truck will invariably result in fitment issues. Accurate specifications are crucial for avoiding such problems.

- Engine and Exhaust System Specifications

Engine displacement, cylinder configuration, and exhaust port geometry dictate the required flow characteristics and backpressure of the muffler. An inappropriately sized muffler can negatively impact engine performance, reducing horsepower, torque, or fuel efficiency. Compatibility necessitates selecting a muffler with specifications aligned with the engine’s operating parameters. For instance, a high-flow muffler designed for a turbocharged engine may not be suitable for a naturally aspirated engine with smaller displacement.

- Emissions Control System Integration

Integration with the vehicle’s emissions control system, including catalytic converters and oxygen sensors, is crucial for regulatory compliance and environmental responsibility. An incompatible muffler can disrupt the function of these components, leading to increased emissions and potential legal ramifications. Compatibility ensures that the muffler does not impede the operation of the emissions control system and complies with applicable regulations. Tampering with or removing catalytic converters, for example, is illegal in many jurisdictions.

- Electronic Control Unit (ECU) Compatibility

Some advanced exhaust systems incorporate electronic valves or actuators controlled by the vehicle’s ECU. Compatibility with the ECU is essential for proper operation of these features and to prevent diagnostic trouble codes (DTCs). An incompatible system may trigger error messages or cause malfunctions. Compatibility ensures seamless integration with the vehicle’s electronic systems and avoids potential conflicts. Vehicles with sophisticated engine management systems may require ECU recalibration after exhaust system modifications.

These aspects of vehicle compatibility underscore the importance of thorough research and professional guidance when selecting a “carven progressive muffler.” Mismatched components can lead to performance degradation, regulatory violations, and potential safety hazards. A focus on compatibility ensures optimal performance, long-term reliability, and adherence to applicable standards.

7. Acoustic Design

Acoustic design constitutes a core principle governing the functionality and performance characteristics of a “carven progressive muffler.” It embodies the strategic manipulation of sound waves within the muffler’s internal structure to achieve specific noise reduction and sound quality objectives. Cause and effect are directly linked in this context; alterations to the muffler’s internal geometry directly influence the attenuation and transmission of sound frequencies. This control is achieved through precisely engineered chambers, baffles, and resonators that selectively absorb or reflect sound energy. A failure to adequately address acoustic design principles results in an ineffective muffler with suboptimal noise reduction. The effectiveness of acoustic design dictates the degree to which the muffler successfully attenuates undesirable engine noise.

The practical significance of acoustic design is further highlighted by the diverse range of applications. Performance-oriented vehicles often employ acoustic design to create a more aggressive and pronounced exhaust note, while luxury vehicles prioritize quiet and refined operation. These diverging objectives demonstrate the versatility of acoustic design in tailoring the sound characteristics of an exhaust system to meet specific market demands. For example, active exhaust systems utilize electronically controlled valves to adjust the acoustic properties in real-time, adapting to varying driving conditions. Such systems underscore the ability to dynamically manipulate sound through sophisticated acoustic engineering. This involves understanding Helmholtz resonance, wave interference, and other acoustic phenomena. Different exhaust designs create different pressure zones and reflection patterns, and so can produce different exhaust sounds.

In summary, acoustic design is not merely an aesthetic consideration but a fundamental engineering discipline underpinning the performance and functionality of “carven progressive mufflers.” By carefully controlling the propagation of sound waves within the muffler, engineers can achieve targeted noise reduction and sound quality objectives, enhancing the overall driving experience and satisfying diverse consumer preferences. Future developments will likely emphasize more advanced materials and computational modeling techniques to further refine acoustic design, enabling more precise control over exhaust sound characteristics.

Frequently Asked Questions

The following questions address common inquiries and misconceptions regarding “carven progressive muffler” technology, providing objective information to assist in informed decision-making.

Question 1: What distinguishes a “progressive” muffler design from conventional muffler designs?

A “progressive” design typically employs multiple chambers and strategically sized perforations or baffles to selectively attenuate sound frequencies. This approach contrasts with simpler designs that rely on a single chamber or restrictive baffling, potentially compromising exhaust flow.

Question 2: Does installation of a “carven progressive muffler” void the vehicle’s factory warranty?

The impact on the vehicle’s warranty depends on the specific terms of the warranty and applicable regulations. Installation by a qualified technician and adherence to manufacturer specifications can mitigate the risk of warranty issues. Consult the vehicle manufacturer or warranty provider for definitive guidance.

Question 3: How does “carven progressive muffler” impact fuel efficiency?

The design aims to optimize exhaust flow, potentially leading to improved fuel efficiency under certain operating conditions. However, the actual impact depends on factors such as driving style, vehicle configuration, and the engine’s tuning. A properly designed and installed system should not significantly decrease fuel efficiency.

Question 4: What is the expected lifespan of a “carven progressive muffler”?

Lifespan depends on factors such as material composition, environmental conditions, and driving habits. Mufflers constructed from high-quality materials, such as stainless steel, generally exhibit greater durability compared to those made from aluminized steel or mild steel. Regular inspection and maintenance can extend lifespan.

Question 5: Is professional installation required for a “carven progressive muffler”?

While some installations may be manageable for experienced DIY enthusiasts, professional installation is recommended to ensure proper fitment, alignment, and integration with the vehicle’s exhaust system. Improper installation can lead to leaks, vibrations, and performance issues.

Question 6: Does the installation of a “carven progressive muffler” guarantee a specific horsepower increase?

Performance gains are contingent upon various factors, including engine configuration, existing modifications, and the overall design of the exhaust system. While these types of muffler contribute to performance enhancements, guaranteed horsepower increases are not universally applicable. Dyno testing can quantify actual performance gains.

These answers provide a general overview. Consult with qualified automotive professionals for specific advice tailored to individual vehicle and performance needs.

The subsequent section will explore real-world applications and case studies related to performance muffler technology.

Conclusion

This exploration has detailed the functional aspects and benefits associated with “carven progressive muffler” technology. The analysis encompassed noise reduction, performance enhancement, flow optimization, durability considerations, material composition, vehicle compatibility, and acoustic design principles. A thorough understanding of these elements is crucial for evaluating the suitability of this technology within diverse automotive applications.

The implementation of “carven progressive muffler” systems represents a strategic approach to balancing sound attenuation and engine performance. Continued advancements in materials science and acoustic engineering will likely drive further innovation in this sector, presenting opportunities for enhanced vehicle performance and reduced environmental impact. Further research and development are necessary to optimize these systems for specific vehicle platforms and driving conditions.

![Sheldon's Custom Muffler: Performance & Sound [Shop Now] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Sheldon's Custom Muffler: Performance & Sound [Shop Now] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/02/th-208-300x200.jpg)