An exhaust system component designed to reduce the noise emitted by an internal combustion engine, specifically a variety typically associated with a particular brand or manufacturing standard, functions by dampening sound waves produced during the engine’s operation. These devices are integral parts of vehicles, contributing to compliance with noise regulations and enhancing the overall driving experience by minimizing auditory disturbances.

The implementation of effective noise reduction mechanisms in automotive exhaust systems offers considerable advantages. It improves vehicle comfort for both the driver and passengers. Historically, efforts to control engine noise have evolved alongside advancements in automotive technology and growing public awareness of environmental noise pollution, leading to increasingly sophisticated designs and materials optimized for sound absorption and durability.

Understanding the role and design variations of such a device is essential for comprehending vehicle performance, maintenance requirements, and compliance with local noise ordinances. The subsequent sections of this article will delve into specific aspects, including material composition, common issues, and best practices for inspection and repair, providing a comprehensive overview.

Maintenance and Longevity

The following recommendations aim to extend the operational life and maintain the performance of the noise reduction component within the vehicle’s exhaust system.

Tip 1: Routine Visual Inspection: Conduct regular visual checks for signs of physical damage, such as rust, dents, or perforations. Early detection of these issues can prevent further degradation and potential exhaust leaks.

Tip 2: Address Rust Promptly: Surface rust should be addressed immediately using appropriate rust inhibitors or converters. This will prevent corrosion from weakening the structural integrity.

Tip 3: Monitor for Unusual Noises: Pay attention to any changes in exhaust sound. Rattling, hissing, or excessive loudness may indicate internal component failure or exhaust leaks.

Tip 4: Secure Mounting Points: Verify that all mounting points and brackets are securely fastened. Loose or broken mountings can cause excessive vibration and stress, leading to premature failure.

Tip 5: Proper Exhaust System Alignment: Ensure that the exhaust system is properly aligned and not making contact with the vehicle’s chassis. Contact can cause heat transfer, vibration, and potential damage.

Tip 6: Avoid Short Trips: Frequent short trips can contribute to moisture accumulation within the exhaust system, accelerating corrosion. Extended driving allows the system to reach optimal operating temperature and evaporate moisture.

Tip 7: Seek Professional Inspection: Schedule periodic inspections with a qualified mechanic to assess the internal condition and perform necessary maintenance.

Following these preventative measures can significantly improve the lifespan, performance, and overall effectiveness of the vehicle’s noise reduction system.

The next section will address common problems encountered and solutions to ensure optimal vehicle performance.

1. Noise Reduction

The fundamental purpose of an exhaust system component is to mitigate engine noise. This noise, generated by the rapid combustion within the engine cylinders, travels through the exhaust system as pressure waves. The components internal structure, typically consisting of baffles, chambers, and sound-absorbing materials, is specifically designed to disrupt these waves. This disruption causes the sound energy to dissipate, thereby reducing the overall noise level emitted from the vehicle. The effectiveness of this noise reduction is a critical performance characteristic, impacting both driver comfort and compliance with noise pollution regulations. For example, vehicles operating in urban environments often require superior noise reduction capabilities to minimize disturbance to surrounding communities.

The physical design and materials used significantly influence the level of noise reduction achieved. Different baffle configurations create varying degrees of sound wave reflection and cancellation. Sound-absorbing materials, such as fiberglass or specialized packing, convert sound energy into heat, further diminishing noise levels. A real-world example is the difference in exhaust note between a stock vehicle and one with an aftermarket exhaust system lacking adequate noise reduction; the latter often results in a significantly louder and potentially non-compliant vehicle. Understanding these design principles enables informed decisions regarding vehicle maintenance, repair, and modification, particularly when considering replacement or upgrade options.

In summary, the relationship between noise reduction and the device is intrinsic and essential. It is the primary function, dictating the components design, materials, and overall performance. Effective noise reduction contributes directly to a quieter driving experience, regulatory compliance, and reduced environmental noise pollution. Challenges remain in balancing noise reduction with engine performance and exhaust flow efficiency, requiring ongoing research and development in exhaust system technology. Understanding this connection is crucial for automotive engineers, technicians, and vehicle owners alike.

2. Material Composition

The durability, performance, and longevity of a noise reduction device are directly influenced by the materials used in its construction. The harsh environment within an exhaust system necessitates materials that can withstand high temperatures, corrosive gases, and physical stress.

- Steel Alloys

Steel alloys, particularly those containing chromium and nickel, are commonly employed due to their inherent strength and resistance to oxidation. The presence of these elements creates a protective layer on the metal surface, inhibiting the formation of rust. The specific grade of steel affects the components overall lifespan and performance in varying climates.

- Aluminized Steel

Aluminized steel provides enhanced corrosion resistance through a thin coating of aluminum. This coating sacrifices some strength compared to stainless steel but offers a more cost-effective solution. Aluminized components are frequently used in areas where extreme corrosion resistance is not paramount, such as in milder climates.

- Stainless Steel

Stainless steel represents a premium option, delivering superior resistance to both corrosion and high temperatures. Its inherent properties ensure a prolonged lifespan even under harsh operating conditions. The higher cost of stainless steel is often justified by its extended durability and reduced maintenance requirements.

- Internal Packing Materials

Beyond the exterior shell, internal packing materials play a critical role in sound absorption. Fiberglass, steel wool, or ceramic-based materials are typically used to dampen sound waves. The composition and density of these materials directly impact the efficiency of noise reduction and their degradation over time contributes to performance decline.

The selection of appropriate materials represents a critical design consideration, balancing performance, cost, and environmental factors. Each material offers a distinct set of advantages and disadvantages, influencing the overall effectiveness and longevity of the device in various operating environments.

3. Vehicle Compatibility

Vehicle compatibility is a critical factor in the proper selection and function of any exhaust system component. Ensuring compatibility guarantees proper fitment, optimal performance, and avoidance of potential damage to the vehicle. A mismatched component can lead to inefficiencies, noise issues, and even mechanical failures.

- Model-Specific Design

Exhaust systems are often designed with specific vehicle models in mind. Factors such as engine size, chassis configuration, and emission control requirements influence the shape, size, and mounting points. A component designed for a specific model ensures proper alignment with the existing exhaust system, preventing leaks and optimizing exhaust flow.

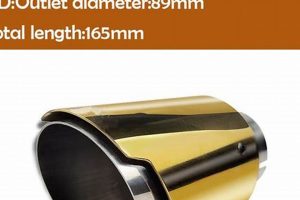

- Exhaust System Diameter

The diameter of the exhaust piping is crucial for maintaining proper backpressure and optimizing engine performance. Installing an exhaust system component with an incorrect diameter can disrupt the intended exhaust flow, leading to reduced power, increased fuel consumption, or even damage to the engine. Vehicle manufacturers specify exhaust pipe diameters to match engine characteristics.

- Mounting Points and Hangers

Proper attachment of the component to the vehicle’s chassis is essential for preventing vibration and stress on the exhaust system. Mounting points and hangers must align correctly to ensure a secure and stable installation. Mismatched mounting points can lead to excessive vibration, stress fractures, and premature failure of the exhaust system.

- Emission Control Compliance

In many regions, exhaust systems are subject to strict emission control regulations. Replacing an exhaust system component with a non-compliant aftermarket option can result in failure to meet emission standards and potential legal penalties. Ensuring compliance with local emission regulations is a crucial consideration during component selection.

These considerations highlight the importance of verifying vehicle compatibility when selecting an exhaust system component. Choosing a component specifically designed for the vehicle ensures optimal performance, avoids potential damage, and maintains compliance with applicable regulations. Failure to adhere to compatibility guidelines can have detrimental effects on the vehicle’s performance, longevity, and legality.

4. System Integration

An exhaust component, such as a noise reduction device, does not function in isolation; its performance is inextricably linked to the broader exhaust system. System integration refers to how effectively this component interacts with other parts of the exhaust, including the catalytic converter, resonators, and tailpipe. A well-integrated device contributes to optimal exhaust flow, efficient emission control, and desired sound characteristics. Conversely, poor integration can result in reduced engine performance, increased backpressure, and undesirable noise frequencies. For example, if the inner diameter of the device does not match the rest of the exhaust piping, it could create a bottleneck, hindering exhaust gas flow and negatively impacting engine power output.

Successful system integration involves careful consideration of several factors. The device’s placement within the exhaust system is crucial. Positioning it too close to the engine could expose it to excessive heat, potentially shortening its lifespan. Its internal design, including baffle configuration and sound-absorbing materials, must complement the characteristics of the other exhaust components. For instance, a resonator placed upstream of the device can help to pre-dampen certain frequencies, allowing the device to focus on reducing a narrower range of sounds more effectively. Furthermore, proper welding and sealing of connections are paramount to prevent exhaust leaks, which can compromise both noise reduction and emission control.

In conclusion, the noise reduction device’s functionality is intimately connected to its seamless integration within the complete exhaust system. Suboptimal integration leads to compromised performance, diminished noise control, and potentially adverse effects on engine health. Achieving optimal performance requires meticulous design, precise manufacturing, and careful installation, emphasizing the necessity for a holistic understanding of the exhaust system’s inter-related components and their collective influence on vehicle operation. This knowledge is indispensable for automotive technicians, engineers, and vehicle owners aiming for peak vehicle performance and regulatory compliance.

5. Flow Restriction

Flow restriction, in the context of an exhaust system noise reduction component, represents the degree to which the device impedes the free flow of exhaust gases. This impedance is an inherent consequence of the mechanisms employed to reduce noise, but excessive restriction can negatively impact engine performance.

- Internal Design

The internal design of a device, specifically the number and configuration of baffles and chambers, directly influences flow restriction. Complex internal structures are effective at attenuating sound waves but simultaneously increase resistance to gas flow. This design necessitates a balance between noise reduction and minimizing backpressure. An overabundance of baffles, or poorly designed chambers, creates turbulent airflow, which reduces engine efficiency and power output.

- Pipe Diameter

The diameter of the inlet and outlet pipes significantly impacts flow restriction. A smaller diameter pipe, relative to the rest of the exhaust system, introduces a bottleneck, increasing backpressure. While smaller diameters can enhance noise reduction by constricting exhaust gases, they also limit the engine’s ability to expel exhaust efficiently. Therefore, the pipe diameter should be appropriately sized for the engine’s displacement and performance characteristics.

- Material Buildup

Over time, the accumulation of soot, carbon deposits, and other particulate matter within the muffler contributes to flow restriction. This buildup reduces the effective cross-sectional area available for exhaust gases to flow, increasing backpressure and reducing engine performance. Regular maintenance and cleaning, or replacement of the component, are necessary to mitigate this issue.

- Backpressure Effects

Excessive flow restriction increases backpressure, which can have several negative consequences on engine performance. Increased backpressure reduces the engine’s ability to efficiently expel exhaust gases, leading to reduced horsepower and torque. It can also increase fuel consumption and elevate exhaust gas temperatures, potentially damaging other components of the exhaust system and engine. Therefore, minimizing flow restriction is critical for maintaining optimal engine performance.

The relationship between flow restriction and device performance is complex and requires careful consideration during design and maintenance. While noise reduction is the primary function, excessive flow restriction can negate its benefits by negatively impacting engine performance and longevity. Achieving an optimal balance between these competing factors is crucial for maximizing the overall effectiveness of the exhaust system.

6. Lifespan Factors

The operational lifespan of an exhaust system’s noise reduction component is significantly influenced by a confluence of factors related to its design, materials, and the conditions under which it operates. Premature failure of this component can lead to increased noise pollution, decreased vehicle performance, and the necessity for costly repairs or replacements. Therefore, understanding these lifespan determinants is crucial for automotive engineers, vehicle owners, and maintenance professionals.

Corrosion represents a primary cause of failure. Exposure to road salt, moisture, and acidic exhaust gases degrades the metal components over time, leading to rust and structural weakening. The material composition of the device directly affects its resistance to corrosion; stainless steel, for example, exhibits superior longevity compared to aluminized steel under similar conditions. Driving habits also play a role; frequent short trips do not allow the exhaust system to reach optimal operating temperature, promoting moisture accumulation and accelerating corrosion. Physical damage, such as impacts from road debris or accidents, can create points of vulnerability, further reducing the component’s lifespan. Furthermore, the quality of the manufacturing process influences its resistance to fatigue and stress cracking, particularly around welded seams and mounting points.

In conclusion, extending the operational life of a noise reduction device requires a multifaceted approach that addresses material selection, operating conditions, and preventative maintenance. Choosing components constructed from corrosion-resistant materials, minimizing exposure to harsh environmental conditions, and implementing regular inspections and maintenance can significantly prolong the device’s lifespan, reducing costs and minimizing environmental impact. Addressing these lifespan factors ensures that the vehicle meets noise emission standards while maintaining optimal performance over an extended period.

Frequently Asked Questions Regarding a Specific Exhaust System Component

The following section addresses common inquiries concerning a particular noise reduction device used in vehicle exhaust systems, providing clarity and accurate information.

Question 1: What is the primary function?

The principal role is to diminish noise generated by an internal combustion engine, achieving this through internal baffling and sound absorption techniques.

Question 2: How does the material composition affect performance?

The selection of materials, such as steel alloys, aluminized steel, or stainless steel, impacts its resistance to corrosion, heat, and physical stress, directly influencing lifespan and noise reduction efficiency.

Question 3: Why is vehicle compatibility important?

Ensuring compatibility with the specific vehicle model guarantees proper fitment, optimal exhaust flow, and avoids potential damage to the vehicle’s exhaust system or engine.

Question 4: What impact does flow restriction have on engine performance?

Excessive flow restriction can increase backpressure, reducing engine horsepower, torque, and fuel efficiency. Design considerations must balance noise reduction with minimizing flow impedance.

Question 5: How can the lifespan be extended?

The devices lifespan can be prolonged through regular visual inspections for damage or corrosion, prompt rust treatment, secure mounting, and adherence to proper driving practices.

Question 6: Are there performance differences between different brands?

Performance variations exist between different brands, primarily stemming from differences in internal design, materials, manufacturing quality, and intended vehicle applications.

This FAQ section aims to clarify fundamental aspects, empowering individuals with a better understanding of this components function, maintenance, and importance.

The subsequent portion of this discussion examines troubleshooting common issues related to the function.

Conclusion

This exploration has detailed the function, composition, compatibility, and lifespan factors associated with a specific noise reduction device. Key points addressed include the importance of material selection in resisting corrosion, the critical role of vehicle compatibility in ensuring optimal performance, and the delicate balance between noise reduction and exhaust flow restriction. Furthermore, maintenance practices were outlined as a means to extend the operational life of this integral component.

A comprehensive understanding of the deviceits design, function, and maintenanceis essential for ensuring vehicle compliance, optimizing engine performance, and minimizing environmental impact. Ongoing research and development in exhaust system technology will continue to refine these components, enhancing their efficiency and durability. Proper selection, installation, and maintenance remain paramount for maximizing the benefits and longevity of any such device.