The selection of effective exhaust silencing devices is crucial for optimizing vehicle performance and mitigating noise pollution. Manufacturers offering these products prioritize durability, acoustic efficiency, and compatibility with various vehicle models. These components play a significant role in controlling engine exhaust emissions while ensuring compliance with noise regulations.

The adoption of high-quality silencing components yields several key advantages. Optimized exhaust flow can improve engine efficiency, leading to enhanced fuel economy. Furthermore, a properly functioning system contributes to a quieter driving experience and reduces environmental noise impact. Historically, advancements in materials science and acoustic engineering have driven the development of more sophisticated and effective systems.

The following sections will explore factors to consider when selecting a silencing system, delve into specific performance characteristics of various options, and provide guidance on maintenance best practices. This will equip readers with the knowledge to make informed decisions regarding their vehicle’s exhaust system.

Selection and Maintenance Tips for Effective Exhaust Silencing

Proper exhaust system management involves careful selection and consistent maintenance to ensure optimal performance and longevity. The following guidelines offer insights into maximizing the value of exhaust silencing devices.

Tip 1: Research Material Composition. Consider the material used in manufacturing the system. Stainless steel offers superior corrosion resistance compared to aluminized steel, extending the lifespan of the component, particularly in environments with high road salt usage.

Tip 2: Evaluate Acoustic Performance Specifications. Examine the noise reduction capabilities specified by the manufacturer. Db (decibel) ratings provide a quantitative measure of the system’s ability to dampen exhaust noise.

Tip 3: Ensure Compatibility with Vehicle Specifications. Verify that the selected exhaust component is designed for the specific vehicle make, model, and engine type. Mismatched systems can lead to performance degradation and potential damage.

Tip 4: Inspect for Structural Integrity Regularly. Periodically examine the exhaust system for signs of rust, leaks, or physical damage. Addressing minor issues promptly prevents more extensive and costly repairs.

Tip 5: Monitor Exhaust System Hangers and Mounts. Check the condition of the hangers and mounts that secure the exhaust system to the vehicle’s chassis. Damaged or deteriorated hangers can cause excessive vibration and stress, leading to premature failure.

Tip 6: Consider Professional Installation. For optimal performance and to ensure proper fitment, consider professional installation by a qualified technician. This minimizes the risk of installation errors that could compromise the system’s effectiveness.

Tip 7: Adhere to Recommended Maintenance Schedules. Follow the manufacturer’s recommended maintenance schedule for the exhaust system. This may include periodic inspections, cleaning, and component replacement.

By adhering to these guidelines, individuals can optimize the performance, extend the lifespan, and ensure the continued effectiveness of their exhaust silencing investment. This proactive approach contributes to a quieter, more efficient, and environmentally responsible vehicle operation.

The subsequent sections will summarize key considerations and offer a concluding perspective on the importance of well-maintained exhaust systems.

1. Material Durability and Superior Exhaust Systems

Material durability stands as a cornerstone in evaluating the quality of exhaust silencing devices. The composition of these components directly influences their lifespan, resistance to environmental factors, and overall performance. For systems to be considered among “good muffler brands,” the use of robust materials is non-negotiable.

- Corrosion Resistance

Exposure to moisture, road salt, and exhaust gases creates a corrosive environment for exhaust systems. Stainless steel, with its inherent resistance to oxidation, significantly extends the life of a system compared to aluminized steel or mild steel. Brands prioritizing stainless steel demonstrate a commitment to long-term product performance and reduced replacement frequency.

- Thermal Stress Mitigation

Exhaust systems undergo extreme temperature fluctuations. Materials must withstand these stresses without warping, cracking, or experiencing fatigue. High-quality alloys and manufacturing processes designed to minimize stress concentrations are critical for ensuring structural integrity. Systems from respected manufacturers typically undergo rigorous testing to validate their thermal resilience.

- Weld Integrity

The quality of welds directly impacts the durability of the system. Welds are often the points of greatest stress and are susceptible to failure if improperly executed. “Good muffler brands” employ advanced welding techniques and quality control measures to ensure robust and leak-free joints, preventing premature failure and maintaining optimal performance.

- Gauge Thickness and Density

The thickness and density of the materials used contribute to the system’s ability to withstand physical impacts and resist deformation. Thicker gauge materials provide greater protection against damage from road debris and other external factors. Brands known for durability often utilize heavier gauge materials in critical areas of their exhaust systems.

The selection of durable materials is not merely a cost consideration but a critical factor in determining the long-term value and reliability of exhaust silencing devices. Brands recognized for their commitment to material quality consistently deliver systems that withstand the rigors of daily use and provide lasting performance. The association between material durability and brands known for good mufflers is inextricably linked; it’s the foundation of reliability and customer satisfaction.

2. Acoustic Performance

Acoustic performance is a defining characteristic differentiating effective exhaust silencing solutions. For a manufacturer to be considered among “good muffler brands,” its products must demonstrably reduce exhaust noise while maintaining acceptable levels of engine performance. The correlation between acoustic effectiveness and market reputation is significant: brands that consistently deliver quiet, efficient exhaust systems garner recognition and customer loyalty. Examples of this relationship include manufacturers who invest heavily in research and development, employing advanced acoustic modeling and testing to optimize their designs. The practical significance lies in compliance with noise regulations, improved driver and passenger comfort, and reduced environmental impact.

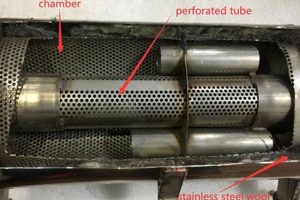

Achieving optimal acoustic performance requires a multi-faceted approach. Internal baffle design, chamber size, and the selection of sound-absorbing materials play crucial roles. Top-tier brands often utilize sophisticated internal configurations to effectively cancel out specific frequencies, resulting in a more pleasant and controlled exhaust note. Furthermore, the use of high-quality sound-deadening materials, such as fiberglass packing or specialized composite materials, contributes to noise reduction without impeding exhaust flow. Examples include brands that offer “performance” mufflers designed to minimize backpressure while still providing substantial noise attenuation.

In conclusion, acoustic performance is a critical attribute for any exhaust system manufacturer aspiring to be recognized as one of the “good muffler brands.” The ability to effectively manage exhaust noise, while preserving engine efficiency, is a hallmark of product excellence. Challenges remain in balancing these competing demands, but continuous innovation and adherence to stringent quality standards are essential for sustaining a positive reputation in this competitive market. The practical outcome is a quieter, more enjoyable driving experience and reduced noise pollution for the broader community.

3. Vehicle Compatibility

Vehicle compatibility is a fundamental criterion when evaluating exhaust silencing systems. A device’s ability to integrate seamlessly with a specific vehicle model dictates its performance, longevity, and regulatory compliance. The following elements illustrate the significance of compatibility and its role in distinguishing reputable manufacturers.

- Direct Fitment and Installation

Good muffler brands engineer their products for precise fitment with specified vehicle makes and models. This involves adhering to original equipment manufacturer (OEM) dimensions, mounting points, and exhaust routing. Products with direct fitment minimize installation complexities, reducing labor costs and the risk of improper installation that could compromise performance or safety.

- Engine Performance Optimization

Exhaust systems are integral to engine performance. Compatible devices are designed to maintain proper exhaust backpressure, which is critical for optimal combustion and fuel efficiency. Incompatible systems can disrupt exhaust flow, leading to reduced horsepower, torque, and increased fuel consumption. Manufacturers recognized for excellence prioritize maintaining or enhancing OEM performance characteristics through compatible designs.

- Emissions Compliance

Vehicle emissions are strictly regulated, and exhaust systems play a vital role in meeting these standards. Compatible devices are designed to integrate with existing emission control systems, such as catalytic converters and oxygen sensors, ensuring continued compliance with environmental regulations. Incompatible systems can interfere with these components, leading to increased emissions and potential legal penalties.

- Sensor Integration and Functionality

Modern vehicles incorporate various sensors within the exhaust system to monitor its operation and provide feedback to the engine control unit (ECU). Compatible mufflers are designed to accommodate these sensors without disrupting their functionality. This ensures that the ECU receives accurate data, allowing it to optimize engine performance and diagnose potential issues effectively.

Manufacturers achieving a high degree of vehicle compatibility demonstrate a commitment to engineering precision and quality control. Their products offer ease of installation, maintain or enhance engine performance, ensure emissions compliance, and seamlessly integrate with existing vehicle sensors. This dedication to compatibility distinguishes leading brands from those offering generic or poorly designed alternatives, ultimately contributing to superior customer satisfaction and a positive market reputation.

4. Brand Reputation

Brand reputation serves as a crucial indicator of quality and reliability within the exhaust system market. For consumers seeking effective silencing devices, a manufacturer’s standing within the industry provides valuable insight. A positive brand image, cultivated over time through consistent product performance and customer satisfaction, directly influences purchasing decisions. Conversely, brands associated with frequent defects, poor customer service, or misleading claims often face market skepticism and reduced sales. Thus, a robust reputation functions as a significant component of what constitutes a “good muffler brand.” For instance, manufacturers known for durable materials, precise fitment, and effective noise reduction typically enjoy a strong reputation, attracting a loyal customer base. Conversely, brands that prioritize cost-cutting measures at the expense of product quality often suffer reputational damage, hindering their ability to compete effectively.

The cultivation of a positive brand reputation is not a passive process. It requires consistent investment in research and development, stringent quality control measures, and responsive customer support channels. Manufacturers committed to establishing themselves as “good muffler brands” often implement comprehensive testing protocols to validate product performance under various operating conditions. Additionally, they actively solicit customer feedback and utilize that information to refine their designs and address potential issues. Real-world examples include manufacturers that offer extended warranties or satisfaction guarantees, signaling their confidence in product durability and performance. These measures contribute to building trust with consumers and reinforcing a positive brand image within the market.

In summary, brand reputation represents a critical factor in evaluating exhaust silencing devices. It reflects a manufacturer’s commitment to quality, reliability, and customer satisfaction. Consumers should consider brand reputation as a primary criterion when selecting an exhaust system, as it provides a valuable indication of expected product performance and long-term value. While challenges exist in accurately assessing reputation solely through marketing materials, researching independent reviews and customer testimonials can provide valuable insights. Ultimately, a strong reputation serves as a hallmark of a “good muffler brand,” offering consumers a measure of assurance in a complex and often opaque market.

5. Warranty Coverage

Warranty coverage serves as a tangible demonstration of a manufacturer’s confidence in the durability and reliability of its exhaust silencing products. A comprehensive warranty reduces the financial risk associated with potential defects or premature failures, thereby enhancing consumer trust and solidifying a brand’s reputation. The correlation between robust warranty offerings and what defines “good muffler brands” is significant. Manufacturers willing to stand behind their products with extended warranty periods often employ superior materials, rigorous testing procedures, and stringent quality control measures. This commitment translates to a lower likelihood of product defects and a greater peace of mind for the consumer. Real-world examples include manufacturers offering lifetime warranties on stainless steel exhaust systems, signaling a high level of confidence in the material’s resistance to corrosion and long-term performance. The practical significance of this understanding lies in the reduction of potential repair costs and the assurance of continued vehicle operation.

The specific terms and conditions of warranty coverage also warrant careful examination. A “good muffler brand” will typically offer clear and unambiguous warranty language, outlining the types of defects or failures covered, the duration of coverage, and the procedures for filing a claim. Warranties that exclude coverage for common issues, such as corrosion in regions with high road salt usage, or impose onerous claim submission requirements, may indicate a lack of confidence in the product’s long-term performance. Brands that offer straightforward warranty processes and responsive customer support are more likely to engender customer loyalty and positive word-of-mouth referrals. Furthermore, transferable warranties, which remain valid even if the vehicle is sold to a new owner, add additional value and enhance the perceived reliability of the exhaust system.

In conclusion, warranty coverage represents a crucial factor in evaluating exhaust silencing systems. It provides a concrete measure of a manufacturer’s confidence in its product’s quality and durability. Consumers should prioritize brands offering comprehensive warranty coverage with clear and accessible terms, as this offers protection against potential defects and underscores a commitment to customer satisfaction. While warranty coverage alone does not guarantee superior product performance, it serves as a valuable indicator of a “good muffler brand’s” dedication to quality and long-term product support, addressing a vital facet of product selection.

6. Price Point

The price point of exhaust silencing systems represents a critical factor in consumer purchasing decisions, but its relationship with perceived quality, specifically concerning “good muffler brands,” is not always linear. While a higher price often suggests superior materials, advanced engineering, and extended warranty coverage, it does not guarantee exceptional performance or longevity. Conversely, lower-priced options may offer adequate performance for certain applications but could compromise durability and long-term reliability. The key lies in discerning the value proposition the balance between cost and features offered by different manufacturers.

The determination of a reasonable price point for exhaust silencing devices involves considering several factors. Material composition plays a significant role, with stainless steel systems typically commanding a higher price than aluminized steel alternatives. The complexity of the internal baffle design, which influences acoustic performance, also contributes to cost. Furthermore, brand reputation, warranty terms, and the availability of installation support can affect the overall price. Reputable brands often invest in research and development to optimize their designs and utilize high-quality components, justifying a higher price point. However, consumers must exercise caution, as some brands may inflate prices based solely on brand recognition without delivering commensurate value.

In summary, price point serves as one indicator, but it should not be the sole determinant when evaluating “good muffler brands.” A comprehensive assessment requires considering material quality, acoustic performance, vehicle compatibility, brand reputation, and warranty coverage in conjunction with the cost. By carefully analyzing these factors, consumers can identify exhaust silencing systems that offer the optimal balance between performance, durability, and affordability, ultimately ensuring satisfaction with their investment. This comprehensive approach helps mitigate the risk of overpaying for a subpar product or sacrificing quality for short-term cost savings, thus leading to informed and value-driven purchasing decisions.

Frequently Asked Questions

The following questions address common inquiries regarding the selection and evaluation of effective exhaust silencing systems.

Question 1: What constitutes a “good muffler brand” beyond marketing claims?

Independent testing results, customer reviews, and verifiable performance data provide objective assessments of product efficacy and durability. Longevity within the market also suggests reliability.

Question 2: How significant is the material composition in determining the lifespan of an exhaust system?

Material composition is paramount. Stainless steel demonstrates superior corrosion resistance compared to aluminized steel, extending the system’s service life, particularly in environments with high salt exposure.

Question 3: Is professional installation necessary for all exhaust systems?

Professional installation is recommended to ensure proper fitment, alignment, and sealing, which maximizes performance and prevents potential damage. Additionally, certain systems may require specialized tools or expertise.

Question 4: How does backpressure influence engine performance and fuel efficiency?

Backpressure impacts engine efficiency. Excessive backpressure restricts exhaust flow, reducing horsepower and fuel economy. Conversely, insufficient backpressure can compromise low-end torque. The ideal balance depends on the specific engine design.

Question 5: What factors should be considered when evaluating warranty coverage for an exhaust system?

Warranty duration, covered components, claim procedures, and limitations should be carefully reviewed. A comprehensive warranty reflects the manufacturer’s confidence in product quality and provides protection against defects.

Question 6: Can an aftermarket exhaust system negatively affect vehicle emissions?

Improperly designed or installed aftermarket systems can interfere with emission control devices, leading to increased pollutant output and potential regulatory violations. Compliance with applicable emissions standards is crucial.

Selecting a high-quality exhaust system involves careful research, consideration of specific vehicle requirements, and attention to factors beyond marketing hype. A well-informed decision contributes to optimal vehicle performance, longevity, and environmental responsibility.

The subsequent section will provide a concluding perspective on the enduring importance of effective exhaust management systems in modern vehicles.

Concluding Remarks

The preceding analysis underscores the complexities inherent in selecting effective exhaust silencing solutions. Discernment requires evaluating material durability, acoustic performance, vehicle compatibility, brand reputation, warranty coverage, and price point. A holistic approach, factoring in these elements, is essential for making informed decisions. The persistent focus must remain on those manufacturers who consistently deliver systems that meet stringent performance standards, thereby earning recognition among effective exhaust silencing solutions.

The decision regarding which system to install ultimately rests with the vehicle owner, but rigorous research and a commitment to quality components will invariably yield superior results. Continued innovation in materials science and acoustic engineering will undoubtedly shape the future of exhaust system design, further emphasizing the importance of selecting components from established, reputable sources.