An exhaust component designed for cost-effectiveness reduces noise generated by an internal combustion engine. These components are often constructed from less expensive materials or engineered for simpler designs, resulting in a lower purchase price. For example, a vehicle owner seeking to minimize repair expenses might opt for this type of replacement part instead of a premium-grade option.

The appeal of such an exhaust component lies primarily in its affordability, making vehicle maintenance more accessible to budget-conscious individuals. Its availability has expanded access to vehicle repairs for individuals facing financial constraints. While premium components offer extended lifespans and enhanced performance, a cost-effective alternative fulfills the basic function of noise reduction at a lower initial investment. Historically, independent auto shops have often stocked such alternatives to cater to a diverse customer base.

Understanding the role of such a cost-effective component provides a foundation for discussing various factors, including material choices, design considerations, and impact on overall vehicle performance. Subsequent discussions will explore the specific advantages and disadvantages of selecting such an option when addressing exhaust system needs.

Guidance on Cost-Effective Exhaust Solutions

The following recommendations aim to provide insights into selecting and maintaining a vehicle exhaust system with a focus on budgetary considerations. These tips emphasize informed decision-making when pursuing affordable solutions without compromising essential functionality.

Tip 1: Research Material Options. Consider aluminized steel as an alternative to stainless steel. While less resistant to corrosion, aluminized steel offers a lower price point and a reasonable lifespan in moderate climates. Inquire about warranty coverage for each material type.

Tip 2: Evaluate Design Complexity. Simple, direct exhaust designs typically cost less to manufacture and replace than complex systems with multiple bends and chambers. Opt for a design suited to the vehicle’s primary function rather than prioritizing advanced acoustic features.

Tip 3: Compare Quotes from Multiple Sources. Obtain estimates from several repair shops and parts suppliers. Pricing can vary considerably based on overhead, brand markups, and labor rates. Request a detailed breakdown of costs for parts and labor.

Tip 4: Consider Remanufactured Components. Remanufactured exhaust components undergo a refurbishment process and are often sold at a discount compared to new parts. Ensure the remanufactured component meets original equipment specifications and carries a warranty.

Tip 5: Prioritize Essential Repairs. If a complete exhaust system replacement is financially prohibitive, address the most critical issues first, such as leaks near the engine or catalytic converter. Delaying essential repairs can lead to more significant and costly problems later.

Tip 6: Maintain Regular Inspections. Routine inspections can identify minor exhaust system issues before they escalate into major repairs. Check for rust, leaks, and loose connections during regular vehicle maintenance.

Tip 7: Evaluate DIY Installation Potential. Individuals with mechanical experience may consider self-installation to reduce labor costs. However, ensure proper safety precautions are taken, and all connections are properly sealed to avoid exhaust leaks. Consult a professional if unsure of installation procedures.

By carefully evaluating material options, design complexities, and repair alternatives, vehicle owners can make informed decisions regarding their exhaust systems, balancing cost-effectiveness with functional requirements. Proper maintenance can further extend the life of the chosen solution.

The following sections will delve into specific components of exhaust systems, examining their individual roles and relative cost considerations.

1. Affordable sound reduction

The primary function of a muffler is to mitigate engine noise, and affordable sound reduction represents the core value proposition of a cost-effective muffler. The degree to which such a component achieves this reduction while minimizing expenditure dictates its overall effectiveness. Cause and effect are directly linked: a simplified internal design and selection of less costly materials lead to a lower purchase price, which, in turn, may affect the extent of noise dampening achieved. The importance of affordable sound reduction as a component of such devices lies in making vehicle maintenance accessible to a wider range of consumers. For example, a driver of an older, high-mileage vehicle may prioritize basic functionality over premium performance, opting for a more economical option that meets minimum noise regulations. This understanding has practical significance for both consumers and manufacturers, influencing purchasing decisions and product development, respectively.

Practical applications extend beyond individual consumers. Fleet operators, responsible for maintaining numerous vehicles within a tight budget, often seek economical solutions that balance performance and cost. A business utilizing older delivery vehicles might choose such mufflers to comply with noise ordinances without incurring significant capital expenditures. Furthermore, the availability of these cost-effective solutions drives competition within the automotive parts industry, encouraging innovation in material science and manufacturing processes to enhance performance without escalating prices. The rise in popularity of online marketplaces has further amplified this effect, providing consumers with unprecedented access to a wide variety of such components at competitive prices.

In summary, affordable sound reduction defines the essence of an economical muffler. The relationship between cost, noise reduction capability, and material selection is critical. While premium components offer superior performance and longevity, cost-effective alternatives provide a viable solution for budget-conscious consumers and businesses. The challenge lies in balancing affordability with essential functionality, ensuring compliance with noise regulations and minimizing potential compromises in performance or lifespan. The continued development and accessibility of these economical exhaust parts remain essential for maintaining a diverse and accessible automotive repair market.

2. Material Cost Optimization

Material cost optimization is a primary driver in the design and manufacturing of cost-effective mufflers. The selection of materials directly impacts the component’s price point, durability, and performance characteristics. Strategic material choices are essential for achieving the target price range while meeting minimum functional requirements.

- Aluminized Steel Usage

Aluminized steel serves as a common substitute for stainless steel in economical mufflers. Its lower cost significantly reduces the overall manufacturing expense. However, aluminized steel exhibits reduced corrosion resistance, potentially shortening the lifespan of the component, particularly in regions with high road salt usage. The tradeoff represents a direct consequence of material cost optimization.

- Reduced Gauge Thickness

Decreasing the thickness of the steel used in construction represents another method of material cost optimization. Using thinner gauge steel reduces material consumption and lowers the component’s weight. This approach, however, reduces the muffler’s structural integrity and susceptibility to damage from road debris or internal pressure fluctuations. The reduced durability has the potential to influence long-term cost-effectiveness.

- Simplified Internal Baffle Design

The internal structure of a muffler, typically consisting of baffles and chambers, plays a crucial role in sound attenuation. Economical designs often employ fewer baffles or simpler baffle geometries to reduce material usage and manufacturing complexity. The simplification directly reduces material costs but could negatively affect the muffler’s ability to effectively dampen noise across a broad frequency range.

- Recycled Material Integration

Employing recycled or reclaimed materials in the muffler’s construction offers a potential cost-saving strategy. Using recycled steel, for example, reduces raw material expenses and contributes to environmentally sustainable practices. However, quality control measures must be rigorously implemented to ensure that the recycled materials meet the required performance standards, thereby maintaining the component’s reliability and durability.

Material cost optimization is a multifaceted consideration in the creation of budget-friendly mufflers. Manufacturers must carefully balance material selection, design features, and durability expectations to deliver a product that fulfills its primary function at a reduced price point. The long-term value of such components depends on the specific operating conditions and the owner’s maintenance practices.

3. Simplified design approach

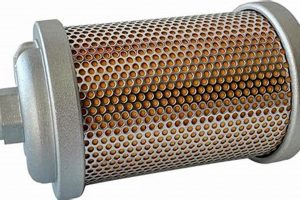

A simplified design approach directly correlates with the cost-effectiveness of an exhaust muffler. This relationship stems from reduced manufacturing complexity, lower material consumption, and streamlined assembly processes. The effect is a lower overall production cost, translating to a more affordable product for the consumer. The importance of design simplification within the context of economical mufflers lies in its capacity to provide a functional solution at a price point accessible to a broader market segment. Consider, for instance, a muffler design employing a single, straight-through perforated core encased in a cylindrical housing, foregoing intricate internal baffling systems. Such a design reduces both material usage and welding requirements, resulting in tangible cost savings. The practical significance of this understanding is that manufacturers can strategically prioritize design simplicity to cater to price-sensitive consumers without entirely compromising the core functionality of noise reduction.

Further analysis reveals practical applications in various sectors. Auto repair shops often stock simplified muffler designs as economical alternatives for customers seeking budget-friendly repairs. Fleets of older vehicles, where cost is a primary concern, frequently utilize these simpler components to maintain operational compliance with noise regulations. The automotive aftermarket also sees a significant presence of simplified designs, offering cost-effective solutions for DIY repairs and vehicle modifications. These examples highlight that a focus on design simplicity allows for widespread adoption and accessibility in diverse contexts.

In summary, a simplified design approach constitutes a fundamental element in the creation of economical mufflers. Its impact on manufacturing cost, material consumption, and overall product affordability is significant. While intricate designs may offer enhanced performance or durability, prioritizing simplicity enables manufacturers to deliver functional solutions at reduced prices, expanding market access and providing viable options for budget-conscious consumers. The challenge lies in maintaining an acceptable level of performance and lifespan while adhering to the principles of design simplification.

4. Warranty Period Length

The duration of the warranty associated with an economical muffler serves as a crucial indicator of its expected lifespan and the manufacturer’s confidence in its product. A shorter warranty period often reflects lower material quality or a simplified design, both characteristic of cost-effective options. Cause and effect are evident: reduced manufacturing costs may lead to a decreased warranty period as the manufacturer anticipates a higher likelihood of premature failure. The importance of warranty duration as a component of a frugal muffler lies in its direct correlation with long-term cost-effectiveness. For example, a muffler with a one-year warranty may appear initially appealing due to its low price, but its shorter lifespan could result in more frequent replacements compared to a slightly more expensive option with a three-year warranty. This understanding is practically significant for consumers making purchasing decisions, necessitating careful consideration of the total cost of ownership rather than solely focusing on the upfront price.

Further analysis reveals specific applications of this understanding. Auto repair shops, advising customers on muffler replacements, should emphasize the importance of comparing warranty periods alongside price. Fleet managers, responsible for maintaining numerous vehicles, must weigh the benefits of lower initial costs against potential downtime and replacement expenses associated with shorter warranties. Online retailers, providing product specifications and customer reviews, play a vital role in informing consumers about warranty details and real-world experiences with product durability. These applications underscore the need for transparency and comprehensive information regarding warranty terms to facilitate informed consumer choices.

In summary, the length of the warranty period is a significant factor in evaluating the overall value proposition of an economical muffler. It serves as a tangible metric for assessing product durability and manufacturer confidence. While low initial cost remains a primary appeal, consumers must carefully consider the potential for increased replacement frequency and associated expenses when selecting a product with a limited warranty. Addressing the challenge of balancing affordability with long-term reliability requires a comprehensive understanding of warranty terms and informed decision-making based on individual vehicle usage and maintenance needs.

5. Fuel Efficiency Impact

The link between an economical muffler and a vehicle’s fuel efficiency is indirect but present. A malfunctioning or significantly deteriorated exhaust system, including the muffler, creates backpressure that hinders optimal engine performance. This backpressure forces the engine to work harder to expel exhaust gases, resulting in increased fuel consumption. Thus, a severely damaged cost-effective muffler can negatively impact fuel efficiency. Conversely, a properly functioning, though economical, muffler that effectively facilitates exhaust flow will not significantly detract from fuel economy, compared to a higher-performance aftermarket option. The importance of fuel efficiency within the context of such mufflers lies in maintaining acceptable vehicle operating costs, preventing the initial cost savings from being negated by increased fuel consumption. For example, a delivery service opting for economical mufflers on its fleet must ensure that these components do not compromise fuel economy to the extent that the overall operating expenses increase. This highlights the practical significance of considering the potential long-term effects on fuel consumption when selecting exhaust system components.

Further analysis reveals that the design of these mufflers plays a crucial role in determining their effect on fuel efficiency. A highly restrictive design, even in a new and undamaged state, can create undue backpressure, negating any initial cost savings through increased fuel consumption. Regular inspection and timely replacement of such mufflers is thus essential to maintain optimal engine performance and fuel economy. Moreover, the material used in the muffler’s construction impacts its lifespan. A muffler constructed of lower-grade materials may corrode more rapidly, leading to increased backpressure as the internal structure degrades. Proper maintenance, including regular inspections for corrosion and leaks, can help mitigate this effect. Auto repair shops should also educate customers on the importance of maintaining their exhaust systems to preserve fuel efficiency, even when opting for economical replacement parts.

In summary, although the direct impact of an economical muffler on fuel efficiency may be less pronounced than that of other engine components, it remains a relevant consideration. A malfunctioning or poorly designed such component can indeed contribute to increased fuel consumption by creating backpressure within the exhaust system. Selecting a reasonably well-designed alternative, coupled with regular maintenance and timely replacement, enables vehicle owners to minimize any potential negative impact on fuel economy, thereby maximizing the overall cost-effectiveness of opting for an affordable muffler solution. The broader implication is that responsible vehicle maintenance involves a holistic approach, considering the interplay between different components and their combined effect on operating costs.

6. Installation Labor Cost

The expense associated with the professional fitting of an exhaust component, specifically an economically priced muffler, significantly influences the overall cost-effectiveness of the repair. The labor charge, often independent of the component’s price, can substantially alter the perceived value of selecting a more affordable part.

- Standardized Hourly Rates

Automotive repair shops typically operate on standardized hourly labor rates. These rates vary geographically and are influenced by factors such as shop overhead, technician expertise, and regional market conditions. The labor charge for muffler installation will be calculated based on the estimated time required for the job multiplied by the shop’s hourly rate. The standardization of labor rates means that the installation cost remains relatively consistent regardless of the price of the muffler itself.

- Accessibility and Complexity

The ease or difficulty of accessing and replacing the muffler directly impacts the labor time required. A vehicle with a straightforward exhaust system design, where the muffler is readily accessible, will typically incur lower labor costs. Conversely, vehicles with complex exhaust systems or those requiring the removal of other components to access the muffler will result in higher labor charges. The accessibility factor is particularly relevant when comparing labor costs across different vehicle makes and models.

- Additional Services and Components

Installation labor costs may increase if additional services are required during the muffler replacement. These services could include cutting and welding of pipes, replacement of exhaust hangers or clamps, or addressing rusted or damaged exhaust manifold bolts. The need for these additional services adds to the overall labor time and, consequently, the total cost of the repair. The presence of pre-existing issues with the exhaust system can therefore significantly impact the final installation expense.

- Warranty Implications

Some repair shops may offer a labor warranty on the installation work performed. This warranty covers potential issues arising from faulty installation, such as exhaust leaks or improperly secured components. While a labor warranty provides added peace of mind, it may also be factored into the initial labor charge. It is important to clarify the terms and coverage of any labor warranty offered to understand the full scope of protection against potential installation-related problems.

In conclusion, the installation labor cost represents a significant component of the total expense associated with replacing a muffler, even a cost-effective one. Factors such as standardized hourly rates, vehicle design complexity, the need for additional services, and the presence of a labor warranty all contribute to the final installation charge. Careful consideration of these factors is essential for accurately assessing the overall value of opting for a more affordable muffler.

7. Corrosion resistance level

The corrosion resistance level of a cost-effective muffler directly influences its lifespan and, consequently, its long-term economic value. The inverse relationship exists: a lower resistance to corrosion translates to a shorter functional life, requiring more frequent replacements. The selection of materials dictates the level of corrosion resistance. An economical muffler typically employs less expensive materials, such as aluminized steel, which provides limited protection against rust and deterioration when exposed to road salts, moisture, and exhaust gases. This susceptibility directly affects the component’s durability and the frequency of necessary replacements. The importance of this corrosion resistance is paramount, as it directly affects the long-term value proposition of a thrifty option. For instance, in regions experiencing harsh winters and extensive road salt usage, a cost-effective muffler with minimal corrosion protection might fail within a year or two, offsetting initial cost savings with recurring replacement expenses. The practical significance of this understanding lies in enabling informed consumer decisions, balancing upfront affordability against anticipated longevity and replacement costs.

Further analysis demonstrates specific practical applications. Automotive technicians, advising customers on muffler replacements, should clearly articulate the trade-offs between initial cost and expected lifespan based on material composition and environmental factors. Fleet managers, overseeing large vehicle pools, must weigh the benefits of reduced initial expenditure against the potential for increased downtime and replacement labor. Online retailers should accurately represent material specifications and warranty information, allowing consumers to assess the corrosion resistance level and make informed purchasing choices. This ensures that the trade-offs are transparent and customers can make informed decisions aligned with their specific needs and operating conditions. The availability of corrosion-resistant coatings or aftermarket treatments further complicates the decision-making process, necessitating careful evaluation of their effectiveness and cost.

In summary, the corrosion resistance level is a decisive attribute in evaluating the overall cost-effectiveness of an economical muffler. While the initial price may be attractive, the potential for accelerated corrosion and subsequent replacement expenses must be considered. Balancing upfront savings with anticipated longevity requires a comprehensive understanding of material properties, environmental factors, and individual vehicle usage patterns. Responsible decision-making involves not only assessing the initial cost but also factoring in the life-cycle expenses associated with maintaining a functional exhaust system. The challenge lies in identifying a balance between affordability and durability that minimizes overall operating costs and maximizes long-term value.

Frequently Asked Questions Regarding Economical Mufflers

The following questions and answers address common concerns and misconceptions surrounding the selection and utilization of budget-friendly exhaust components.

Question 1: How long will a cost-effective muffler typically last?

The lifespan varies significantly based on material composition, driving conditions, and geographical location. Aluminized steel variants, commonly used in these components, may exhibit a lifespan of two to five years under normal operating conditions. Exposure to road salt and harsh weather can substantially reduce this timeframe.

Question 2: Does a less expensive muffler negatively impact vehicle performance?

A properly functioning muffler, regardless of price point, should not significantly degrade vehicle performance. However, a poorly designed or severely deteriorated muffler can create excessive backpressure, which may reduce engine efficiency and horsepower. Routine maintenance is essential.

Question 3: Are economical mufflers universally compatible with all vehicle makes and models?

No. Mufflers are designed to specific vehicle specifications. Selecting a component that does not precisely match the vehicle’s requirements can lead to installation difficulties, performance issues, and potential damage to the exhaust system. Strict adherence to manufacturer guidelines is paramount.

Question 4: What are the telltale signs of muffler failure?

Common indicators include excessive exhaust noise, the presence of rust or physical damage to the muffler body, a noticeable decrease in fuel economy, and a failed emissions test. Prompt diagnosis and repair are critical to preventing further damage.

Question 5: Is self-installation of such a component advisable?

While self-installation can reduce labor costs, it requires a thorough understanding of automotive repair procedures, access to specialized tools, and adherence to safety precautions. Improper installation can lead to exhaust leaks, component damage, and potential safety hazards. Professional installation is recommended for individuals lacking the necessary expertise.

Question 6: How does a cheaper muffler affect the vehicle’s resale value?

The installation of a cost-effective muffler generally does not significantly impact resale value, provided that the component is functioning correctly and meets all applicable emissions standards. However, potential buyers may perceive a greater value in vehicles equipped with higher-quality, longer-lasting components. Full transparency is the key.

Key takeaway: While economical mufflers provide a budget-friendly option for exhaust system repair, informed decision-making necessitates careful consideration of lifespan, performance implications, and installation requirements.

The subsequent section will provide an outline of best practices to ensure you have a thrifty muffler.

Thrifty Muffler

The preceding discussion explored various facets of the “thrifty muffler,” emphasizing the delicate balance between affordability and functional requirements. Material selection, design simplification, warranty periods, fuel efficiency considerations, installation costs, and corrosion resistance levels were identified as key factors influencing the overall value proposition. Informed decision-making necessitates a thorough understanding of these trade-offs.

The pursuit of cost-effective automotive repairs should not compromise safety or environmental responsibility. Continued research and development in materials science and manufacturing processes are essential to improving the durability and performance of affordable exhaust components. Responsible consumers must prioritize comprehensive assessments, considering not only the initial purchase price but also the long-term costs associated with maintenance, repairs, and potential performance impacts.