A business entity often focuses on vehicular thermal management and exhaust systems. Specifically, this type of establishment typically provides services related to cooling engines and managing exhaust gases. Examples of services include repair, replacement, and maintenance of associated components within these systems.

The importance of such a business lies in ensuring optimal engine performance, reducing emissions, and prolonging the lifespan of vehicles. Functioning cooling and exhaust systems are vital for efficient fuel consumption and preventing damage to critical engine parts. Historically, these service providers have adapted to evolving vehicle technologies and emission standards.

The following sections will explore common issues related to vehicle cooling and exhaust systems, discuss preventative maintenance strategies, and outline how to choose a reliable service provider for related needs.

Maintenance and Longevity

The following recommendations, derived from practical experience in the automotive service sector, aim to promote optimal performance and extend the lifespan of vehicle cooling and exhaust systems.

Tip 1: Regular Coolant Flushes: Maintaining clean coolant is crucial. Contaminated coolant can lead to corrosion and scaling within the radiator and engine block, reducing cooling efficiency. Scheduled coolant flushes, as specified by the vehicle manufacturer, mitigate these risks.

Tip 2: Inspect Radiator Hoses: Hoses are susceptible to degradation due to heat and pressure. Regularly examine hoses for cracks, bulges, and leaks. Replace any compromised hoses immediately to prevent coolant loss and potential engine overheating.

Tip 3: Check Exhaust System for Leaks: Exhaust leaks can lead to reduced fuel efficiency, increased emissions, and potential carbon monoxide poisoning. Inspect the exhaust manifold, catalytic converter, muffler, and tailpipe for signs of corrosion, damage, or leaks. Address any issues promptly.

Tip 4: Monitor Engine Temperature: Pay close attention to the engine temperature gauge. Overheating is a serious issue that can cause severe engine damage. If the engine temperature rises above the normal operating range, stop the vehicle immediately and investigate the cause.

Tip 5: Catalytic Converter Health: The catalytic converter plays a critical role in reducing harmful emissions. Ensure its proper functioning by addressing any engine performance issues, such as misfires or excessive oil consumption, that can damage the converter.

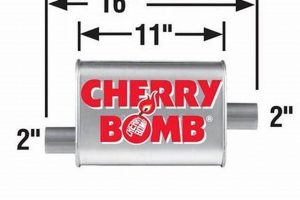

Tip 6: Muffler Condition: The muffler not only reduces exhaust noise but also contributes to overall exhaust system efficiency. Inspect the muffler for rust, corrosion, and damage. A compromised muffler can affect engine performance and fuel economy.

Implementing these preventative measures ensures reliable vehicle operation and minimizes the risk of costly repairs. Timely attention to cooling and exhaust systems can significantly extend vehicle lifespan and maintain optimal performance.

The subsequent sections will delve into the selection process for qualified service providers and address frequently asked questions regarding cooling and exhaust system maintenance.

1. Coolant Flush Intervals

Coolant flush intervals directly impact the operational effectiveness and lifespan of cooling systems serviced by businesses specializing in radiator and muffler maintenance. Infrequent or neglected coolant flushes lead to the accumulation of contaminants within the cooling system, accelerating corrosion and scaling. This, in turn, reduces the radiator’s heat transfer efficiency and can cause blockages, leading to engine overheating. For instance, vehicles operating in regions with hard water are particularly susceptible to mineral buildup, necessitating more frequent coolant flushes than vehicles in areas with softer water. A failure to adhere to recommended coolant flush intervals can result in premature radiator failure and increased repair costs.

Regular coolant flushes, performed according to the vehicle manufacturer’s specifications, mitigate these risks. A coolant flush involves draining the old coolant, flushing the system with a cleaning solution, and refilling it with fresh coolant of the appropriate type. This process removes contaminants and restores the coolant’s ability to effectively transfer heat. An example of the benefits includes observed improvements in engine temperature regulation following a coolant flush in vehicles with a history of overheating. Furthermore, specific coolants are formulated for different engine types and materials; selecting the correct coolant is crucial for preventing corrosion and ensuring compatibility with the cooling system components.

In summary, the regularity of coolant flushes is a critical preventative maintenance practice directly related to the longevity and efficiency of vehicular cooling systems. Ignoring recommended coolant flush intervals can lead to significant damage and increased repair expenses. Therefore, understanding and adhering to these intervals is essential for vehicle owners and technicians alike in maintaining optimal engine performance and preventing costly cooling system failures.

2. Hose Integrity Checks

Hose integrity checks are an integral aspect of cooling and exhaust system maintenance, impacting the functionality and reliability of vehicles serviced by providers such as establishments focusing on radiator and muffler repair. These checks are crucial for preventing leaks, overheating, and other issues that can compromise vehicle performance.

- Visual Inspection for Cracks and Swelling

Visual inspection is a primary method for assessing hose integrity. Technicians examine hoses for visible cracks, swelling, or signs of deterioration. Cracks indicate material fatigue and potential points of failure, while swelling suggests internal degradation due to exposure to incompatible fluids or excessive pressure. For example, a hose exhibiting numerous surface cracks requires immediate replacement to prevent a coolant leak and subsequent engine overheating. The implications of neglected visual inspections include unexpected breakdowns and potential engine damage.

- Physical Flexibility and Hardness Assessment

Hose flexibility and hardness are indicators of material degradation. Over time, hoses can become brittle or excessively soft due to heat, age, and chemical exposure. A hose that feels unusually hard or lacks flexibility is prone to cracking or splitting under pressure. Conversely, an excessively soft hose may collapse, restricting coolant flow. A case in point is a radiator hose that becomes significantly harder than normal, indicating a need for replacement to ensure proper coolant circulation. The inability to properly assess the physical properties of hoses leads to diminished cooling efficiency and possible engine damage.

- Clamp Integrity and Connection Security

Hose clamps are essential for maintaining secure connections between hoses and other components, such as the radiator, engine block, and thermostat housing. Checks involve ensuring clamps are properly tightened, free from corrosion, and correctly positioned. Loose or corroded clamps can lead to coolant leaks, while improperly positioned clamps can damage the hose. For example, a loose hose clamp on a radiator hose can result in a gradual coolant leak, leading to eventual engine overheating. Routine clamp inspection and tightening are thus paramount.

- Pressure Testing for Leak Detection

Pressure testing is a more advanced method for identifying leaks that may not be visible during a visual inspection. The cooling system is pressurized to a level above its normal operating pressure, and the hoses are then inspected for leaks. This method can reveal pinhole leaks or areas of weakness that are not otherwise apparent. For instance, a small leak detected during a pressure test can prevent a more significant failure and potential engine damage. Periodic pressure testing provides valuable insights regarding hose integrity.

These hose integrity checks, conducted by specialists in radiator and muffler services, are crucial for maintaining reliable vehicle operation. By identifying and addressing potential hose failures early, these services prevent costly repairs and ensure optimal engine performance and longevity. Therefore, prioritizing regular hose inspections is a vital component of preventative vehicle maintenance.

3. Exhaust Leak Detection

Exhaust leak detection is a critical service provided by automotive maintenance specialists. The presence of exhaust leaks can significantly impact vehicle performance, fuel efficiency, and passenger safety. Therefore, accurate and timely detection is paramount.

- Auditory Inspection and Localization

Auditory inspection involves listening for unusual noises emanating from the exhaust system. Hissing, popping, or roaring sounds can indicate the presence of leaks, often localized at joints, flanges, or damaged components. An example includes a distinct hissing sound heard near the exhaust manifold upon engine start, suggesting a gasket leak. This method, while basic, provides an initial indication of potential exhaust system breaches. Neglecting auditory inspection can result in prolonged exposure to hazardous exhaust gases and decreased engine performance.

- Visual Examination for Soot and Corrosion

Visual examination entails inspecting exhaust system components for telltale signs of leaks, such as soot deposits, rust, or corrosion. Soot accumulates near leak points due to escaping exhaust gases. Corrosion weakens exhaust components, making them susceptible to failure and leaks. An instance of this is the presence of black soot around a muffler weld, signaling a compromised joint. Visual assessment is essential for identifying both current and potential leak locations. Failure to perform visual checks leads to missed leak indicators and escalating exhaust system damage.

- Pressure Testing and Smoke Testing

Pressure testing involves sealing the exhaust system and introducing pressurized air to identify leaks through audible hissing or visual observation of escaping air. Smoke testing utilizes a smoke machine to introduce a visible smoke into the exhaust system, revealing leak points as smoke exits through breaches. An example includes detecting a pinhole leak in an exhaust pipe using smoke emanating from the compromised area. These methods provide more precise leak localization. The disregard of pressure and smoke testing can mean overlooking minor leaks that progressively worsen.

- Gas Analyzers and Emission Monitoring

Gas analyzers measure the composition of exhaust gases to detect anomalies indicative of leaks. High levels of hydrocarbons (HC) or carbon monoxide (CO) can suggest incomplete combustion or exhaust leaks before the catalytic converter. Emission monitoring during vehicle inspections also identifies excessive emissions resulting from exhaust system breaches. For example, failing an emissions test due to elevated HC levels can point to an exhaust manifold leak. This facet relates directly to environmental compliance. Lack of emission monitoring can result in undetected environmental pollution and legal repercussions.

The ability to accurately detect and address exhaust leaks is vital for maintaining vehicle safety, performance, and environmental compliance. The services offered, incorporating these detection methods, play a critical role in identifying and resolving exhaust system issues, ensuring vehicles operate efficiently and safely.

4. Catalytic Converter Efficiency

Catalytic converter efficiency is a critical factor in vehicular emission control, directly impacting the services and expertise required of establishments focusing on radiator and muffler maintenance. The converter’s ability to effectively reduce harmful pollutants from exhaust gases determines a vehicle’s compliance with environmental regulations and its overall operational performance.

- Role of Precious Metals in Catalytic Conversion

Catalytic converters utilize precious metals, such as platinum, palladium, and rhodium, as catalysts to facilitate chemical reactions that convert harmful pollutants into less harmful substances. Platinum and palladium oxidize hydrocarbons (HC) and carbon monoxide (CO) into carbon dioxide (CO2) and water (H2O), while rhodium reduces nitrogen oxides (NOx) into nitrogen (N2) and oxygen (O2). An example of this process is the oxidation of CO into CO2, reducing its toxicity. The efficiency of these reactions is contingent upon the integrity and surface area of the precious metals within the converter. If a converter is not functioning to OEM-specified efficiency, harmful substances are expelled into the atmosphere and cause for vehicles failing emission tests.

- Impact of Engine Performance on Converter Function

Engine performance directly influences catalytic converter efficiency. Issues such as misfires, excessive oil consumption, or incorrect air-fuel ratios can overload the converter, leading to overheating, damage, and reduced efficiency. For instance, a misfiring engine introduces unburned fuel into the exhaust stream, which can ignite within the converter, causing it to overheat and melt. Similarly, vehicles with excessive oil consumption experience increased levels of hydrocarbons entering the converter, which decreases precious metal catalyst effectiveness over time. Addressing engine performance issues is paramount to ensuring optimal converter function and prolonging its lifespan, directly relating to the diagnostic services offered.

- Thermal Management and Cooling System Influence

The cooling system plays an indirect but significant role in catalytic converter efficiency. Overheating can severely damage the converter, reducing its effectiveness and lifespan. An efficiently functioning cooling system maintains optimal engine operating temperatures, preventing excessive heat from reaching the exhaust system and the converter. For example, a malfunctioning radiator fan or a clogged coolant passage can lead to engine overheating, subsequently damaging the catalytic converter. Therefore, ensuring proper cooling system operation is vital for protecting the catalytic converter and maintaining its efficiency, necessitating integrated diagnostic and maintenance services.

- Diagnostic Testing and Monitoring Technologies

Diagnostic testing and monitoring technologies are employed to assess catalytic converter efficiency and identify potential issues. Oxygen sensors placed before and after the converter measure the oxygen content of the exhaust gases, providing an indication of the converter’s ability to reduce pollutants. Scan tools read fault codes related to catalytic converter performance, alerting technicians to potential problems. An example includes observing a P0420 code (Catalyst System Efficiency Below Threshold), indicating the converter’s reduced effectiveness. Proper diagnosis and repair rely on advanced technologies to ensure regulatory compliance.

These interconnected facets highlight the complex relationship between catalytic converter efficiency and the expertise provided by automotive service providers specializing in radiator and muffler systems. Maintaining engine health, thermal management, and employing advanced diagnostic tools are essential components of ensuring efficient catalytic converter function, contributing to reduced emissions and improved air quality. By addressing these factors, service providers contribute to environmental sustainability and regulatory compliance.

5. Muffler Structural Soundness

Muffler structural soundness is intrinsically linked to the operational effectiveness and overall service quality of an establishment specializing in radiator and muffler systems. The muffler’s primary function is to attenuate exhaust noise, contributing to reduced noise pollution and a more comfortable driving experience. However, its structural integrity also impacts exhaust system efficiency and engine performance. A compromised muffler, exhibiting corrosion, damage, or internal deterioration, leads to increased exhaust backpressure, potentially reducing engine power and fuel economy. For example, a heavily rusted muffler with internal baffles collapsing causes significant exhaust restriction, measurably impacting engine output. Therefore, assessing and maintaining muffler structural soundness are crucial for comprehensive vehicle service.

The cause-and-effect relationship between muffler condition and vehicle performance necessitates thorough inspection protocols within relevant service providers. Regular visual examinations for rust, holes, and compromised welds are fundamental. Internal inspection, using specialized tools, can reveal baffle degradation not visible externally. Furthermore, pressure testing identifies leaks indicative of structural weakness. Consider a scenario where a seemingly intact muffler exhibits subtle weld corrosion detected only via pressure testing; early intervention prevents catastrophic failure and potential exhaust system damage. The practical significance of this understanding lies in optimizing vehicle performance, ensuring environmental compliance (through reduced noise pollution), and preventing costly repairs associated with exhaust system failures stemming from neglected muffler maintenance.

In summary, muffler structural soundness is not merely an aesthetic consideration but a critical factor influencing vehicle performance, environmental impact, and overall operational safety. Establishments focusing on radiator and muffler maintenance must prioritize structural assessments as a core component of their service offerings. Challenges include accurately diagnosing internal damage and addressing corrosion in harsh environments. However, the benefits of proactive maintenance improved fuel economy, reduced emissions, and enhanced driving experience far outweigh the challenges. By integrating rigorous inspection protocols and employing skilled technicians, businesses contribute to sustainable transportation and customer satisfaction.

Frequently Asked Questions

The following section addresses common inquiries regarding cooling and exhaust systems, offering information to assist in informed decision-making about vehicle maintenance.

Question 1: What factors determine the lifespan of a radiator?

Radiator lifespan is influenced by several factors, including coolant quality, operating environment, and vehicle usage. Neglecting regular coolant flushes, operating in corrosive environments (e.g., areas with road salt), and frequent heavy towing can significantly shorten radiator lifespan. The type of metals used in the radiator construction will also affect lifespan.

Question 2: What are the signs of a failing catalytic converter?

Symptoms of a failing catalytic converter include reduced engine performance, decreased fuel efficiency, a rattling noise from under the vehicle, and a sulfur-like smell. A diagnostic scan may also reveal codes related to catalytic converter inefficiency. A visual inspection might show a glowing-red converter after driving. Note that some converters have shields that make this difficult to see. If these symptoms are exhibited, expert evaluation is required.

Question 3: How often should a muffler be replaced?

Muffler replacement frequency varies based on environmental conditions and driving habits. In regions with high humidity or road salt usage, mufflers may corrode more rapidly. Frequent short trips can also accelerate corrosion due to moisture buildup within the exhaust system. Inspect the muffler at least annually for rust, holes, or damage, and replace it as needed.

Question 4: Can an exhaust leak affect engine performance?

Yes, exhaust leaks can negatively impact engine performance. Leaks near the exhaust manifold can disrupt the engine’s air-fuel ratio, leading to reduced power and fuel efficiency. Leaks further down the exhaust system may not directly affect engine performance but can still cause increased noise and potentially hazardous fumes.

Question 5: What type of coolant is recommended for my vehicle?

The appropriate coolant type varies depending on the vehicle make and model. Consult the vehicle’s owner’s manual or a qualified technician to determine the correct coolant specification. Using the wrong type of coolant can lead to corrosion and damage to the cooling system components.

Question 6: What are the benefits of a high-performance radiator?

High-performance radiators offer improved cooling capacity compared to stock radiators. These radiators are often constructed with larger cores and more efficient fin designs. Benefits include enhanced engine cooling, particularly in high-performance applications or during heavy towing, and increased engine longevity.

Regular maintenance and timely repairs are crucial for maintaining optimal cooling and exhaust system performance. Ignoring these systems could lead to safety concerns as well as significant expense.

The subsequent section provides guidance on selecting a reliable service provider.

Conclusion

The preceding analysis has underscored the vital role played by establishments specializing in vehicular cooling and exhaust systems. Key points include the importance of preventative maintenance such as regular coolant flushes and hose integrity checks; the critical need for accurate exhaust leak detection methodologies; and the interconnectedness of catalytic converter efficiency with overall engine health. These factors, when properly addressed, contribute to enhanced vehicle performance, reduced emissions, and extended vehicle lifespan.

Given the complexities of modern vehicular technology and the increasingly stringent environmental regulations, diligent maintenance of cooling and exhaust systems is not merely an option, but a necessity. Therefore, prioritize proactive vehicle care, seek qualified and reputable service providers, and remain informed about the specific needs of the vehicle’s cooling and exhaust systems. Such actions ensure continued optimal performance, environmental responsibility, and safe operation.