This aftermarket automotive component is designed to modify the exhaust system of a vehicle, primarily to alter its sound characteristics. A common goal is to achieve a louder, more aggressive tone compared to the factory-installed system. For example, vehicle enthusiasts might install such a device to enhance the perceived performance of their vehicle through an altered sound profile.

The increased volume and distinctive sound often associated with these modifications can be attributed to design features that prioritize sound output over maximum noise reduction. This can appeal to drivers who value a more prominent auditory feedback from their engine. Historically, modifications of this type have been popular among those seeking to personalize their vehicles and express their automotive enthusiasm.

The following sections will delve into specific aspects related to performance characteristics, installation considerations, and potential legal implications associated with altering a vehicle’s exhaust system.

Installation and Maintenance Considerations

Proper installation and consistent maintenance are paramount for optimal performance and longevity. Ignoring these aspects can lead to diminished sound quality, potential damage, and regulatory issues.

Tip 1: Professional Installation is Recommended: While DIY installation is possible, engaging a qualified mechanic is advisable. This ensures correct fitment, proper welding (if required), and adherence to local regulations.

Tip 2: Verify Local Noise Ordinances: Prior to installation, research and understand applicable noise regulations in your area. Exceeding decibel limits can result in fines or legal action.

Tip 3: Inspect Welds Regularly: If the installation involves welding, periodically inspect the welds for cracks or corrosion. Prompt repairs prevent exhaust leaks and maintain structural integrity.

Tip 4: Check for Exhaust Leaks: Listen for unusual hissing or puffing sounds emanating from the exhaust system. Exhaust leaks can reduce engine performance and potentially introduce harmful gases into the cabin.

Tip 5: Account for Vehicle Modifications: Existing engine modifications can influence exhaust flow and sound characteristics. Adjustments may be necessary to achieve the desired sound profile and optimize performance.

Tip 6: Consider Material Compatibility: If combining with other exhaust components, ensure material compatibility to prevent galvanic corrosion. Dissimilar metals in contact can lead to accelerated degradation.

Adherence to these guidelines helps ensure the modified exhaust system operates efficiently, complies with regulations, and delivers the intended sound characteristics for an extended period.

The subsequent sections will address performance aspects and potential benefits associated with exhaust modifications.

1. Aggressive sound profile

The aggressive sound profile is a primary factor for individuals selecting an aftermarket exhaust system. This attribute is directly related to the design and construction, influencing the auditory experience of the vehicle.

- Internal Baffle Design

The internal configuration, including the arrangement and geometry of baffles, significantly impacts the sound characteristics. Designs that minimize sound wave cancellation and maximize resonance contribute to a louder, more aggressive tone. Alterations to the baffling influence the frequency and amplitude of sound waves exiting the exhaust system.

- Chamber Size and Configuration

The dimensions and layout of internal chambers within the muffler affect the sound amplification and attenuation properties. Larger chambers can facilitate lower frequency sounds, while smaller, more complex chambers may emphasize higher frequencies. Varying the chamber arrangement fine-tunes the overall sound signature.

- Material Composition

The material used in construction plays a role in sound propagation and resonance. Thicker, denser materials can dampen sound, while thinner, more resonant materials can amplify it. The selection of specific alloys influences the tonal qualities of the exhaust note.

- Exhaust Gas Flow Dynamics

The internal design affects the velocity and direction of exhaust gases. Minimal restriction to flow can enhance performance but potentially increase sound volume. Balancing flow efficiency with sound management is a key design consideration.

These design elements collectively determine the sound emitted. The integration of these features allows for a more pronounced and distinctive auditory experience, often sought by those seeking to personalize their vehicle’s sound profile.

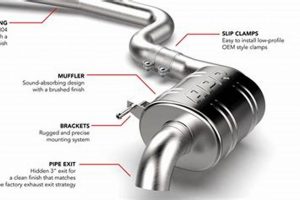

2. Welded Case Construction

The utilization of welded case construction represents a significant factor in the durability and performance of aftermarket automotive exhaust components, particularly concerning the specified product.

- Structural Integrity

Welding creates a permanent, fused joint between the individual components of the case. This enhances resistance to stress, vibration, and thermal cycling, mitigating the risk of failure under demanding operational conditions. A robust weld ensures the muffler can withstand the rigors of daily driving and high-performance applications.

- Resistance to Corrosion

Proper welding techniques, including the use of appropriate filler metals and shielding gases, minimize the potential for corrosion along the weld seams. This is critical for preserving the integrity of the muffler, especially in environments where exposure to road salts and other corrosive agents is prevalent. A well-executed weld provides a protective barrier against environmental degradation.

- Acoustic Performance

A tightly sealed, welded case is essential for maintaining consistent acoustic properties. Any leaks or imperfections in the weld seams can alter the intended sound characteristics, resulting in undesirable noise or a degradation of the desired exhaust note. A structurally sound weld ensures that the exhaust gases are channeled correctly, maximizing the intended acoustic output.

- Longevity and Reliability

The inherent strength and corrosion resistance afforded by welded case construction contribute to the overall longevity and reliability of the exhaust component. This reduces the likelihood of premature failure, minimizing the need for costly repairs or replacements. A well-built and properly welded unit offers a longer service life and increased peace of mind.

The robust nature of this construction method directly contributes to the long-term performance and durability. By providing a structurally sound and corrosion-resistant enclosure for the internal components, welded construction ensures that the muffler can effectively manage exhaust gases, maintain its intended sound characteristics, and withstand the environmental challenges encountered during vehicle operation.

3. Improved Exhaust Flow

The modification of an exhaust system to enhance its flow characteristics is a prevalent objective in automotive performance enhancement. This objective is interconnected with the design principles of aftermarket components, including the one specified. The relationship stems from the fundamental principle that reduced backpressure within the exhaust system can potentially yield gains in engine efficiency and power output.

The effectiveness of a specific component in achieving improved exhaust flow depends on several design factors. These include the internal configuration, the diameter of the exhaust piping, and the overall flow path. The removal or redesign of restrictive elements within the muffler, such as baffles or chambers, can contribute to a reduction in backpressure. For example, a straight-through design, compared to a baffled design, generally offers less resistance to exhaust gas flow. However, this reduction in backpressure must be balanced against other considerations, such as noise levels and regulatory compliance. Furthermore, the impact of improved exhaust flow is typically more pronounced when combined with other engine modifications, such as performance air intakes or engine tuning. Isolating the effect of this component alone on a stock engine may yield minimal observable gains.

In conclusion, the implementation of an aftermarket exhaust component, with the goal of improved flow, represents a multifaceted approach to vehicle modification. While the potential for increased engine efficiency exists, the actual realized gains are contingent upon design characteristics, adherence to regulatory standards, and the presence of complementary modifications. The practical significance of understanding this relationship lies in facilitating informed decisions regarding vehicle customization and performance optimization.

4. Performance Enhancement Potential

The installation of an aftermarket automotive exhaust component to realize performance enhancement potential hinges on the premise that a reduction in exhaust backpressure can positively influence engine efficiency. This influence is mediated by design characteristics that allow for less restriction of exhaust gases, theoretically allowing the engine to expel spent gases more efficiently during the exhaust stroke. The extent to which a performance gain is realized depends significantly on the specific design and internal architecture. A straighter, less obstructed path for exhaust flow generally correlates with a reduction in backpressure; however, the magnitude of this reduction, and its resulting impact on engine performance, varies among different designs.

One illustrative example of this principle can be observed in vehicles modified with a complete exhaust system upgrade, wherein both the exhaust manifold and the muffler are replaced with performance-oriented components. In such scenarios, the cumulative effect of reduced backpressure, combined with other factors such as optimized exhaust gas velocity, may contribute to a measurable increase in horsepower and torque. Conversely, the installation of a single aftermarket component on a stock engine may yield a negligible improvement in performance, as the restrictive nature of other exhaust components or the engine’s factory tuning can limit the system’s overall potential for enhancement. The specific application and complementary modifications therefore play a critical role in determining the actual performance benefits.

In summary, the connection between aftermarket exhaust components and performance enhancement is nuanced and contingent upon several factors. While the theoretical premise of reduced backpressure leading to improved engine efficiency holds merit, the practical realization of such gains requires careful consideration of design characteristics, complementary modifications, and the overall system integration. A comprehensive understanding of these factors enables informed decisions regarding vehicle customization, ensuring that the intended performance enhancements are effectively achieved.

5. Installation and compliance

The connection between installation practices and regulatory compliance is of paramount importance when considering aftermarket automotive exhaust components. Improper installation of such a system can directly lead to violations of noise ordinances, emissions regulations, or safety standards. For example, a poorly executed weld on the exhaust piping can create exhaust leaks, which not only degrades performance but also increases noise levels beyond legal limits. Similarly, incorrectly routing the exhaust system can result in damage to vehicle components or pose a fire hazard. Therefore, adherence to established installation protocols is crucial for maintaining compliance with applicable laws and regulations.

Compliance considerations extend beyond the physical installation of the exhaust system. Many jurisdictions have specific regulations regarding allowable noise levels produced by vehicles. Aftermarket exhaust systems, designed to alter the sound profile, must be carefully selected to ensure they do not exceed these limits. For example, some “super 44 muffler” designs are explicitly marketed for their aggressive sound output, potentially exceeding local noise ordinances. It is the vehicle owner’s responsibility to verify that the chosen system, once installed, meets all relevant requirements. Failure to do so can result in fines or the requirement to revert the vehicle to its original configuration.

In conclusion, the correct installation of aftermarket exhaust components is inextricably linked to compliance with applicable laws and regulations. Neglecting proper installation techniques can lead to safety hazards, performance degradation, and legal repercussions. Therefore, vehicle owners should prioritize professional installation and thoroughly research local regulations before modifying their exhaust systems. This proactive approach ensures that the aftermarket exhaust system performs as intended while remaining within the bounds of the law.

Frequently Asked Questions about Aftermarket Exhaust Systems

This section addresses common inquiries regarding the use, performance, and legal aspects of an aftermarket exhaust component designed to alter a vehicle’s sound characteristics.

Question 1: What is the expected increase in horsepower following the installation of a super 44 muffler?

The quantifiable horsepower increase is typically minimal and highly variable, depending on factors such as engine type, existing modifications, and the specific design of the component itself. Gains are often marginal and may not be readily detectable without dyno testing.

Question 2: Does the aggressive sound profile of this component violate local noise ordinances?

The likelihood of violating noise ordinances is dependent on the specific jurisdiction and the actual decibel level emitted. Researching local regulations is essential, and sound level testing may be necessary to ensure compliance.

Question 3: What are the potential long-term effects on engine performance?

Assuming proper installation and maintenance, no detrimental long-term effects are typically anticipated. Conversely, improper installation or neglect of maintenance can lead to exhaust leaks and reduced engine efficiency.

Question 4: Is professional installation required to maintain the manufacturer’s warranty?

Warranty implications vary depending on the component manufacturer and the vehicle’s original equipment manufacturer (OEM). Reviewing the warranty documentation is crucial to ascertain whether professional installation is mandated.

Question 5: Will installing a super 44 muffler affect the vehicle’s emissions control system?

If the component is installed downstream of the catalytic converter, it generally does not affect emissions control. However, any modification to the catalytic converter or upstream components may result in emissions violations.

Question 6: What are the key indicators of a malfunctioning super 44 muffler?

Indicators include excessive noise levels, exhaust leaks, reduced engine performance, and visible damage to the muffler housing.

In summary, understanding both the capabilities and limitations of altering a vehicle’s exhaust system through the installation of aftermarket components is crucial. Prioritizing compliance with local regulations and seeking professional guidance when necessary will help mitigate potential complications.

The following section will transition to a comparative analysis with other exhaust system modifications.

Super 44 Muffler

This exploration has detailed key aspects of the “super 44 muffler,” spanning its sound characteristics, construction, and potential performance implications. The analysis underscored that while the aggressive sound profile may appeal to some, it necessitates careful consideration of local noise ordinances. Furthermore, the welded case construction enhances durability, and improved exhaust flow, although typically marginal, can contribute to overall engine performance. Installation protocols and regulatory adherence were emphasized as critical elements in ensuring both the safe and legal operation of such modifications.

Ultimately, the decision to integrate a “super 44 muffler” into a vehicle’s exhaust system requires a comprehensive understanding of its benefits and limitations, along with a commitment to responsible and lawful execution. Further research and consultation with qualified automotive professionals is recommended to facilitate informed decisions tailored to specific needs and circumstances.