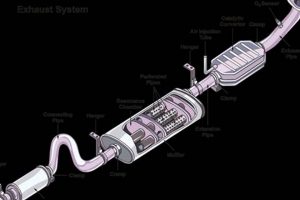

Determining the correct dimensions for an exhaust component that reduces noise involves considering several factors. This process ensures optimal performance and sound control for a vehicle’s exhaust system. For instance, selecting a component that is too small can create backpressure, negatively impacting engine efficiency, while an excessively large component might not effectively attenuate sound waves.

Proper selection is vital for balancing power, fuel economy, and noise reduction. Historically, this selection was often a trial-and-error process. However, modern engineering principles and computational fluid dynamics now provide more precise methods. The correct dimensioning can also affect compliance with local noise ordinances, contributing to environmental responsibility.

The subsequent sections will delve into the specific calculations, design considerations, and the range of available products that are relevant to achieving the optimal balance for a particular application. This will include a detailed discussion on flow rates, vehicle type considerations, and material selection for longevity.

Essential Considerations for Muffler Selection

The following guidelines provide crucial insights for achieving optimal exhaust system performance through appropriate dimensional selection.

Tip 1: Analyze Engine Displacement: The engine’s cubic capacity significantly influences exhaust flow. A larger displacement necessitates a larger exhaust component to accommodate the increased volume of exhaust gases efficiently. Ignoring this can cause detrimental backpressure.

Tip 2: Evaluate Vehicle Type and Usage: A high-performance sports car requires a different approach compared to a fuel-efficient commuter vehicle. Consider the intended use and operating conditions to match the performance characteristics accordingly. Heavy towing would also be considered.

Tip 3: Account for Existing Exhaust System Components: Compatibility with existing headers, catalytic converters, and piping is essential. Ensure that the selected component interfaces seamlessly with the rest of the system to avoid flow restrictions or leaks, and potential loss of performance.

Tip 4: Calculate Exhaust Flow Rate: Utilize formulas and online calculators to estimate the maximum exhaust flow rate. Match the component’s capacity to this calculated flow rate to prevent bottlenecks and maintain optimal engine breathing. This is the most accurate step to selecting the right muffler.

Tip 5: Consider Noise Level Requirements: Local regulations often impose limitations on vehicle noise emissions. Select a component with appropriate sound dampening characteristics to comply with these regulations, without sacrificing performance. This would mean getting a bigger or smaller muffler depending on other factors.

Tip 6: Review Material Composition: Stainless steel offers excellent corrosion resistance and durability, extending the lifespan of the component. Aluminized steel provides a more cost-effective option, but may be susceptible to rust in harsh environments. Consider the intended use of the car when choosing a material.

Tip 7: Understand Core Design: Choose between baffled or perforated cores. Baffled mufflers provide more sound reduction but can reduce performance, while perforated mufflers are quieter than straight-through designs. They are better for performance but may not provide enough sound dampening to meet regulations.

By meticulously considering these factors, one can make an informed decision, ensuring optimal exhaust system function and overall vehicle performance.

The subsequent discussion will focus on diagnostic procedures and preventative maintenance strategies to prolong the lifespan of the exhaust system.

1. Engine Displacement

Engine displacement, the total volume swept by all the pistons inside the cylinders of an engine during a single stroke, is a primary determinant in calculating the requisite dimensions for exhaust components. Larger engine displacement necessitates a larger exhaust system, including an appropriately sized muffler, to accommodate the increased volume of exhaust gases produced. The consequence of a mismatch results in increased backpressure, thereby reducing engine efficiency and overall performance. For example, a 6.0-liter V8 engine requires a significantly larger exhaust component compared to a 1.6-liter inline-4 engine to ensure unrestricted gas flow.

The correlation between engine displacement and exhaust component dimensions is not merely a linear relationship. Other factors, such as engine type (naturally aspirated vs. turbocharged) and intended application (performance vs. fuel economy), influence the optimal design. A turbocharged engine, despite having a similar displacement to a naturally aspirated engine, often requires a larger component due to increased exhaust gas volume and velocity. Moreover, a performance-oriented application prioritizes minimizing backpressure, which often necessitates a larger, less restrictive muffler, even at the expense of increased noise levels. A diesel engine, due to its higher compression ratio and combustion characteristics, necessitates larger mufflers with different acoustic properties in its exhaust system than a gasoline engine.

In summary, a thorough understanding of engine displacement and its influence on exhaust gas volume is critical for proper exhaust component selection. The correct determination of size is pivotal for realizing optimal engine performance, fuel efficiency, and compliance with noise regulations. Failure to adequately account for engine displacement can lead to a variety of performance and environmental issues, underscoring the importance of this parameter in exhaust system design.

2. Exhaust Flow Rate

Exhaust flow rate, defined as the volume of exhaust gases passing through the exhaust system per unit of time, is a critical parameter in determining appropriate component dimensions. The relationship between flow rate and these dimensions is inverse; an insufficient internal volume or restrictive design relative to the exhaust flow can cause backpressure. Elevated backpressure impedes the engine’s ability to expel exhaust gases efficiently, leading to diminished power output and reduced fuel economy. Selecting the appropriate dimension requires a thorough understanding of the engine’s characteristics and operating conditions.

Accurate calculation or measurement of exhaust flow rate is paramount. Factors influencing flow rate include engine displacement, engine speed (RPM), volumetric efficiency, and forced induction (turbocharging or supercharging). For instance, a high-performance engine operating at high RPMs will generate a significantly higher exhaust flow rate than a low-RPM engine of similar displacement. Consequently, the former requires a larger-diameter, less restrictive design to accommodate the increased flow. Incorrect component selection based on a miscalculation of flow rate can negate any potential performance gains from other engine modifications, such as improved air intake or fuel injection systems. This may lead to damaging and/or costly repairs.

In conclusion, the exhaust flow rate dictates the minimum acceptable dimensions for components intended to attenuate exhaust noise. Proper consideration of exhaust flow characteristics is essential for achieving the desired balance between noise reduction and engine performance. Neglecting this fundamental relationship can result in sub-optimal engine operation, reduced efficiency, and potential mechanical damage. The connection between the engine and the exhaust system is critical in many aspects of performance.

3. Vehicle Application

The intended use of a vehicle significantly influences the selection of appropriately dimensioned noise-reducing components in the exhaust system. A sports car, designed for high-performance driving, necessitates a system optimized for minimal backpressure, often prioritizing power output over stringent noise reduction. Conversely, a family sedan prioritizes quiet operation, typically requiring a component designed for maximum sound attenuation, even if it marginally impacts performance. This dichotomy highlights the fundamental role of vehicle application in determining the optimal dimensions.

Heavy-duty trucks and off-road vehicles provide further examples of the application-specific nature of component selection. These vehicles demand robust systems capable of withstanding harsh operating conditions and prolonged periods of high-load operation. Consequently, larger, more durable components constructed from thicker materials are often required to ensure longevity and reliability. Agricultural machinery operating in noise-sensitive environments must use specific dimension standards for these exhaust components, and often feature larger systems than similarly sized road vehicles. Failure to account for these unique requirements can lead to premature component failure and operational downtime.

Therefore, an understanding of vehicle application is paramount in the determination of correct muffler dimensions. It necessitates a careful balance of performance requirements, noise regulations, durability considerations, and operational demands. The resulting selection must reflect the specific needs of the vehicle and its intended purpose to ensure optimal performance, longevity, and compliance with applicable standards. Neglecting this aspect leads to performance degradation, increased noise pollution, and potential mechanical issues within the exhaust system.

4. Acoustic Targets

Acoustic targets, defined as the desired sound pressure levels at specific frequencies, directly dictate the selection of appropriate dimensions and internal construction of exhaust components. These targets, often established by regulatory bodies or vehicle manufacturers, represent acceptable noise emission levels. Achieving these targets requires a careful manipulation of the exhaust system’s geometry and internal baffling, all of which are intrinsically linked to the muffler dimensions. For example, meeting stringent noise regulations may necessitate a larger muffler volume or more complex internal chambers to effectively attenuate sound waves. Conversely, a less restrictive design may be permissible when acoustic targets are more lenient, allowing for a smaller muffler and potentially improved exhaust flow.

The relationship between acoustic targets and component dimensions is complex, involving wave interference, absorption, and reflection principles. A smaller muffler employing a straight-through design may be suitable for applications prioritizing performance with minimal noise reduction. Larger, multi-chamber designs, conversely, are better suited to applications needing to meet strict noise emission levels, such as residential zones. Furthermore, the material composition affects acoustic performance. Denser materials dampen sound more effectively, allowing for potentially smaller mufflers to achieve the same acoustic targets. In areas where regulations can be lenient, an exhaust cutout will allow a secondary exit point for gases, this can significantly decrease the noise reduction from the muffler.

In summary, acoustic targets serve as the foundational criteria for exhaust component determination. Precise selection and dimensioning, driven by these targets, guarantee compliance with noise regulations and maintenance of desired sound characteristics. Disregarding acoustic targets results in non-compliance, potential fines, and customer dissatisfaction. This underscores the critical role of acoustic considerations in exhaust system design and the selection of appropriately-sized components.

5. Space Constraints

Physical space limitations within a vehicle’s chassis significantly influence the selection of muffler dimensions. Space constraints represent a fundamental design parameter, often dictating a compromise between optimal acoustic performance and practical feasibility. The available space dictates the maximum permissible muffler size, directly affecting its internal volume and, consequently, its noise attenuation capabilities. A confined undercarriage, for instance, may necessitate a smaller, more compact muffler, potentially sacrificing some degree of noise reduction compared to a larger unit that would be impractical to install. Real-world examples include compact cars where limited space restricts muffler size, leading to compromises in exhaust system design. Conversely, larger vehicles such as SUVs and trucks can accommodate larger mufflers, enabling greater noise reduction. Some vehicles may need a custom exhaust fabricated due to the lack of space for a standard muffler.

The impact of space constraints extends beyond merely limiting overall muffler volume. It also influences the design of the internal baffling and chamber configurations. In constrained environments, designers must optimize the available space to maximize noise attenuation. This can involve employing complex internal geometries, such as Helmholtz resonators or multi-chamber designs, to achieve desired acoustic targets within the limited space. The necessity of effective noise reduction in smaller spaces has encouraged innovation in compact muffler technology that continues to push the boundaries of current production.

In conclusion, space constraints constitute a crucial determinant in muffler sizing. This necessitates a careful balance of performance goals, acoustic targets, and physical limitations. Engineers must strategically leverage available space to optimize muffler design, ensuring the selected component fits within the vehicle’s architecture while meeting performance and regulatory requirements. Understanding the interplay between space constraints and muffler sizing is paramount for achieving effective exhaust system design and overall vehicle performance, and to avoid costly refabrication.

Frequently Asked Questions

This section addresses common inquiries regarding the determination of appropriate dimensions for exhaust noise-reducing components. The information is intended to provide clarity on crucial aspects of the selection process.

Question 1: What are the primary consequences of selecting an undersized muffler?

An undersized muffler generates excessive backpressure, which negatively impacts engine performance by hindering exhaust gas evacuation, leading to reduced power and fuel efficiency.

Question 2: How does engine displacement influence the determination of the correct muffler size?

Engine displacement is directly proportional to the volume of exhaust gases produced. Larger displacement engines necessitate larger mufflers to accommodate the increased flow and minimize backpressure.

Question 3: Is the ideal muffler size the same for all vehicle types, assuming similar engine displacement?

No, the ideal dimensions vary based on vehicle application, intended usage, and acoustic targets. Performance vehicles prioritize minimal backpressure, while passenger vehicles prioritize noise reduction. Heavy-duty vehicles require more robust components.

Question 4: Can incorrect muffler sizing affect compliance with local noise regulations?

Yes. Mufflers that are too small or inappropriately designed might not adequately attenuate exhaust noise, potentially leading to non-compliance with noise ordinances and subsequent penalties.

Question 5: What role does exhaust flow rate play in determining optimal muffler dimensions?

Exhaust flow rate dictates the minimum acceptable dimensions for the muffler. Mufflers must be sized to accommodate the maximum expected flow rate to prevent flow restriction and maintain engine performance.

Question 6: How do physical space constraints impact the selection of the correct size?

Available space under the vehicle often limits the maximum permissible muffler dimensions. This constraint forces a compromise between optimal acoustic performance and the practicalities of installation.

Accurate selection is essential for achieving optimal engine performance, regulatory compliance, and driver satisfaction. Ignoring appropriate component choice often leads to costly repairs.

The following section will discuss diagnostic procedures and common maintenance practices to prolong the service life of the exhaust system.

Conclusion

This exploration has underscored the critical importance of precise muffler sizing. It has illustrated that correct selection is not merely a matter of choosing a part but a crucial engineering decision impacting engine performance, regulatory compliance, and vehicle operation. The interactions between engine displacement, exhaust flow rate, vehicle application, acoustic targets, and space constraints must be carefully considered. Neglecting these factors invariably leads to compromised performance or regulatory infractions.

The principles outlined within this discussion serve as a foundation for informed decision-making in exhaust system design and modification. Continued adherence to these best practices ensures optimized vehicle performance, reduced environmental impact, and the prolonged lifespan of exhaust system components. The significance of correct muffler sizing cannot be overstated; it remains a cornerstone of responsible vehicle engineering and maintenance.

![Richmond Muffler: Local Choice, Quiet Ride [Richmond, VA] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Richmond Muffler: Local Choice, Quiet Ride [Richmond, VA] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/02/th-108-300x200.jpg)