This entity represents a business specializing in the repair, replacement, and maintenance of exhaust systems. These systems are critical components of vehicles, responsible for channeling exhaust gases away from the engine, reducing noise pollution, and minimizing harmful emissions. A properly functioning system contributes to vehicle efficiency, performance, and compliance with environmental regulations.

The value of such a service lies in its ability to restore or enhance vehicle operability. Benefits include optimized engine performance, reduced fuel consumption, and compliance with emissions standards. Historically, skilled technicians providing these services have played an essential role in maintaining the functionality and longevity of vehicles, adapting to evolving automotive technologies and stricter environmental mandates.

The following sections will explore the specific services offered, diagnostic procedures employed, and the importance of utilizing quality components when addressing exhaust system issues. Further detail will be provided on the impact of a well-maintained exhaust system on overall vehicle health and environmental responsibility.

Maintenance Guidelines

The following recommendations are designed to assist in maintaining optimal exhaust system performance, thereby extending the lifespan of vehicle components and ensuring regulatory compliance.

Tip 1: Regular Inspection: Conduct routine visual examinations of the exhaust system, paying close attention to areas prone to corrosion or damage, such as joints, welds, and hangers. Early detection of issues prevents escalation and reduces repair costs.

Tip 2: Prompt Addressing of Noises: Unusual noises emanating from the exhaust system, such as rattles, hisses, or roars, often indicate underlying problems. Investigating these noises promptly can prevent further damage to the system and potential safety hazards.

Tip 3: Catalytic Converter Monitoring: The catalytic converter is a critical component for emissions control. Ensure its proper functioning through regular diagnostic tests. A malfunctioning converter can lead to reduced fuel efficiency and increased emissions.

Tip 4: Hanger Integrity: Exhaust system hangers are responsible for securing the system to the vehicle’s undercarriage. Check the condition of hangers regularly, replacing any that are damaged or corroded to prevent system sagging and potential damage to other components.

Tip 5: Avoid Short Trips: Frequent short trips can prevent the exhaust system from reaching optimal operating temperature, leading to moisture buildup and accelerated corrosion. Whenever possible, incorporate longer trips to allow the system to burn off accumulated moisture.

Tip 6: Professional Maintenance: Schedule regular maintenance appointments with qualified technicians specializing in exhaust systems. These professionals possess the expertise and equipment necessary to diagnose and address complex issues effectively.

Adherence to these guidelines promotes exhaust system longevity, enhances vehicle performance, and contributes to environmental protection through reduced emissions. Neglecting preventative maintenance can result in costly repairs and potential regulatory penalties.

The following section will delve into specific repair procedures and component replacement options to further optimize exhaust system efficiency and compliance.

1. Exhaust Diagnostics

Exhaust diagnostics form a critical component of services offered. It directly informs the subsequent repair, replacement, or modification activities undertaken. Accurate diagnostics are essential for effective and efficient vehicle maintenance.

- Sensor Analysis

This facet involves the assessment of data from oxygen sensors, mass airflow sensors, and other relevant sensors within the exhaust and engine management systems. Analyzing these signals allows technicians to identify imbalances in the air-fuel mixture, potential catalytic converter inefficiencies, and other performance-related issues. For instance, irregular oxygen sensor readings might indicate a vacuum leak or a faulty fuel injector, impacting exhaust composition and requiring targeted repairs.

- Leak Detection

Leak detection is the process of identifying breaches in the exhaust system. This can be accomplished through visual inspection, pressure testing, or the use of smoke machines. Leaks can compromise engine performance, reduce fuel efficiency, and increase noise levels. An undetected leak near a manifold gasket, for example, could lead to exhaust gases entering the passenger compartment, posing a safety hazard.

- Emissions Testing

Emissions testing involves measuring the levels of pollutants released by the vehicle. This is a crucial aspect of regulatory compliance and environmental responsibility. Elevated levels of hydrocarbons, carbon monoxide, or nitrogen oxides indicate potential problems with the engine, catalytic converter, or other components of the exhaust system. Failure to meet emissions standards can result in fines and the vehicle being deemed unfit for road use.

- Catalytic Converter Evaluation

The catalytic converter is a vital component for reducing harmful emissions. Evaluation involves assessing its efficiency in converting pollutants into less harmful substances. This can be done through diagnostic testing and visual inspection. A failing catalytic converter can lead to increased emissions, reduced fuel efficiency, and potential engine damage. Replacement or repair of the catalytic converter is often necessary to restore proper function.

These diagnostic procedures are integral to the service provided. The accuracy of these diagnostics directly affects the effectiveness of subsequent repair or maintenance operations, impacting vehicle performance, regulatory compliance, and environmental impact.

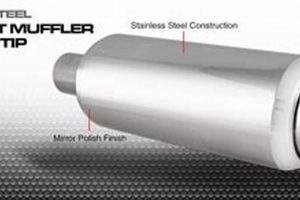

2. Muffler Replacement

Muffler replacement constitutes a core service offering for establishments specializing in exhaust system maintenance and repair. This procedure addresses issues related to noise reduction, exhaust flow, and overall system integrity, representing a significant portion of diagnostic and repair volume.

- Corrosion and Degradation

Mufflers are susceptible to corrosion due to exposure to exhaust gases, road salts, and environmental moisture. Over time, this corrosion weakens the metal, leading to leaks, reduced sound dampening, and potential structural failure. A corroded muffler necessitates replacement to maintain vehicle compliance with noise regulations and prevent exhaust leaks that could impact fuel efficiency and performance.

- Internal Baffle Damage

The internal baffles within a muffler are designed to attenuate sound waves. Physical damage to these baffles, often caused by impacts from road debris or internal corrosion, can compromise the muffler’s ability to reduce noise. Damaged baffles result in increased exhaust noise, potentially exceeding legal limits and causing driver and passenger discomfort, requiring a complete muffler replacement.

- Performance Degradation

A compromised muffler can restrict exhaust flow, leading to a reduction in engine performance. Backpressure within the exhaust system can impede the engine’s ability to expel exhaust gases efficiently. Replacing a restricted muffler with a new, properly sized unit restores optimal exhaust flow, contributing to improved horsepower and fuel economy.

- Acoustic Alteration

Muffler replacement provides an opportunity to modify the vehicle’s exhaust note. While maintaining legal noise levels is crucial, different muffler designs offer varying acoustic characteristics, ranging from quiet and subtle to more aggressive and sporty. This allows vehicle owners to personalize their vehicle’s sound while addressing the need for a functional and compliant exhaust system.

Muffler replacement is therefore a multi-faceted service, addressing not only noise reduction but also contributing to engine performance and compliance with regulatory standards. Timely and appropriate muffler replacement is essential for maintaining vehicle operability and meeting environmental requirements.

3. Pipe Repair

Pipe repair constitutes a fundamental service provided within the operations of establishments such as “peles muffler works”. Exhaust pipes, integral components of a vehicle’s exhaust system, are susceptible to damage from corrosion, impact, and thermal stress. These factors result in leaks, reduced engine performance, and increased emissions. Consequently, skilled technicians at “peles muffler works” employ various techniques, including welding, patching, and section replacement, to address pipe damage and restore system integrity. For instance, a vehicle driven frequently on salted winter roads may experience accelerated corrosion of exhaust pipes, necessitating repair or replacement services to prevent exhaust leaks and maintain proper emission control. This direct causal relationship underscores the importance of pipe repair as a key operational aspect.

The proficiency in pipe repair directly impacts the overall effectiveness of “peles muffler works”. Successful repair procedures ensure proper exhaust gas flow, minimize noise pollution, and maintain compliance with environmental regulations. Improperly repaired or neglected pipes can lead to backpressure, negatively affecting engine efficiency and potentially causing damage to other exhaust system components, such as the catalytic converter. A practical example is a vehicle failing an emissions test due to leaks in the exhaust pipes, requiring immediate attention from a qualified technician to rectify the issue and ensure regulatory compliance.

In conclusion, pipe repair represents a critical function within the spectrum of services offered. The ability to effectively diagnose and repair exhaust pipes is essential for maintaining vehicle performance, ensuring environmental compliance, and upholding the reputation of the business. Challenges in pipe repair often involve accessing difficult-to-reach areas and working with corroded materials. However, the expertise in addressing these challenges directly contributes to the overall value and effectiveness of exhaust system maintenance.

4. Welding Services

Welding services are intrinsically linked to the operational capabilities of “peles muffler works.” The ability to perform precise and durable welds is essential for fabricating, modifying, and repairing exhaust systems. Corrosion, mechanical stress, and environmental factors frequently necessitate the repair of exhaust pipes, mufflers, and catalytic converters. Welding addresses these issues by mending cracks, sealing leaks, and reinforcing weakened areas. Without competent welding services, “peles muffler works” would be unable to effectively restore damaged exhaust systems to their original functionality or fabricate custom solutions tailored to specific vehicle requirements. For instance, patching a rusted exhaust pipe section or reattaching a detached muffler hanger are typical welding applications critical for maintaining vehicle performance and safety.

The implementation of welding services extends beyond simple repairs. Fabricating custom exhaust systems, often required for modified or classic vehicles, relies heavily on the expertise of skilled welders. This involves shaping and joining metal components to achieve specific performance characteristics or aesthetic designs. Furthermore, welding is crucial for installing aftermarket performance parts, such as headers or high-flow catalytic converters, which often require modifications to the existing exhaust system. A vehicle owner seeking to improve engine performance or achieve a unique exhaust note would directly benefit from the welding proficiency of “peles muffler works.”

In summary, welding services represent a cornerstone of “peles muffler works”. The ability to execute high-quality welds enables the repair, modification, and fabrication of exhaust systems, ensuring vehicle functionality, regulatory compliance, and customer satisfaction. The challenges associated with welding, such as working with thin or corroded metals, require specialized skills and equipment. Overcoming these challenges directly contributes to the business’s ability to provide comprehensive exhaust system solutions and maintain a competitive edge in the automotive service industry.

5. Catalytic Converter

The catalytic converter is a critical component directly affecting the operational scope. It functions as an emissions control device, reducing harmful pollutants in exhaust gases. Service providers such as this entity are integral to maintaining the functionality of this component, ensuring vehicles comply with environmental regulations. A malfunctioning converter results in increased emissions, potentially leading to failed emissions tests and legal penalties. Consequently, diagnostic testing, repair, or replacement of catalytic converters constitutes a significant portion of the services provided. For example, a vehicle failing an emissions test due to a degraded converter necessitates immediate attention to rectify the issue and meet regulatory requirements.

The practical application of this relationship extends to various facets. Proper installation of catalytic converters is essential for optimal performance. Similarly, accurate diagnostics are crucial for identifying the root cause of converter failure, preventing recurring issues. Replacing a converter without addressing underlying engine problems, such as excessive oil consumption or a faulty air-fuel mixture, may result in premature failure of the new converter. Furthermore, the selection of appropriate replacement converters, compliant with specific vehicle models and emission standards, is paramount for ensuring long-term effectiveness.

In summary, the catalytic converter is a key element influencing the operations and environmental responsibility. Addressing issues relating to this crucial component requires expertise in diagnostics, repair, and replacement procedures. The ability to provide these services effectively is essential for maintaining vehicle compliance, reducing environmental impact, and upholding the reputation of the business. Challenges lie in the precise diagnosis of converter failures and ensuring adherence to stringent environmental regulations.

6. Custom Fabrication

Custom fabrication represents a specialized service offering, extending beyond routine repairs and replacements. This capability allows to address unique vehicle needs and performance goals, directly impacting the business’s ability to cater to a wider range of clientele. Such fabrication often involves modifying existing exhaust systems or creating entirely new systems tailored to specific applications.

- Performance Enhancement

Custom-fabricated exhaust systems can be designed to optimize exhaust flow, reducing backpressure and improving engine horsepower and torque. This is particularly relevant for high-performance vehicles or those undergoing engine modifications. For instance, a custom-built header can significantly improve exhaust scavenging, leading to measurable gains in engine output.

- Unique Vehicle Applications

Classic cars, modified vehicles, and off-road applications frequently require custom exhaust solutions due to non-standard configurations or the unavailability of off-the-shelf components. A custom fabrication service can create exhaust systems that fit perfectly and meet specific clearance requirements. An example includes fabricating a new exhaust system for a vintage car with a unique chassis configuration.

- Material Selection and Durability

Custom fabrication allows for the selection of specific materials, such as stainless steel or titanium, offering enhanced durability and corrosion resistance compared to standard exhaust systems. This is particularly beneficial for vehicles operating in harsh environments or those seeking long-term reliability. A custom stainless steel exhaust system is more resistant to rust and corrosion in areas with heavy salt usage on roads.

- Aesthetic Customization

Beyond performance and functionality, custom fabrication offers the opportunity to tailor the appearance of the exhaust system. This includes selecting specific tip styles, finishes, and routing configurations to achieve a desired aesthetic effect. A custom exhaust system might feature polished stainless steel tips and a unique muffler design to enhance the vehicle’s overall visual appeal.

The integration of custom fabrication elevates the services offered, allowing to cater to specialized needs and performance goals. While requiring skilled technicians and specialized equipment, this capability significantly expands the potential customer base and strengthens the business’s reputation for providing comprehensive exhaust system solutions. Examples include creating custom systems for racing applications or fabricating unique exhaust setups for show cars, both demonstrating the versatility and value of this specialized service.

7. Performance Upgrades

Performance upgrades, as related to exhaust systems, represent a specialized category of services provided. These modifications aim to enhance engine output, improve fuel efficiency, or alter the vehicle’s acoustic characteristics, all within the expertise.

- High-Flow Exhaust Systems

These systems are designed to reduce backpressure, allowing exhaust gases to exit the engine more efficiently. This improvement can translate into increased horsepower and torque, particularly at higher engine speeds. An example is replacing a restrictive stock exhaust manifold with a header designed for optimal exhaust flow, resulting in a measurable performance gain.

- Performance Mufflers

Performance mufflers are engineered to minimize exhaust restriction while maintaining an acceptable sound level. They often feature larger internal passages and less restrictive baffling compared to stock mufflers. Installing a performance muffler can improve engine responsiveness and provide a sportier exhaust note, enhancing the driving experience.

- Catalytic Converter Upgrades

High-flow catalytic converters offer reduced exhaust restriction compared to standard units, contributing to improved engine performance. These converters are often used in conjunction with other exhaust system upgrades to maximize gains. Replacing a clogged or inefficient stock converter with a high-flow unit can restore lost performance and improve emissions control.

- Custom Exhaust Tuning

Custom exhaust tuning involves modifying the exhaust system to optimize engine performance for specific driving conditions or modifications. This may include adjusting pipe diameters, adding resonators, or altering the exhaust routing. Custom tuning can fine-tune the exhaust system to maximize power output and improve overall engine efficiency.

The effective implementation of performance upgrades requires specialized knowledge and skills. Expertise in exhaust system design, welding, and engine tuning is essential for achieving the desired results without compromising vehicle reliability or emissions compliance. These services cater to enthusiasts seeking to maximize their vehicle’s potential.

Frequently Asked Questions

The following questions address common inquiries regarding services and operational procedures.

Question 1: What factors determine the cost of exhaust system repair or replacement?

The expense is dependent on variables such as the extent of the damage, the type of vehicle, the materials required, and labor costs. A comprehensive inspection is necessary to provide an accurate estimate.

Question 2: How often should a vehicle’s exhaust system be inspected?

A visual inspection should occur at least annually, or more frequently if unusual noises or performance issues are observed. Regular inspections can prevent minor problems from escalating into costly repairs.

Question 3: Is it necessary to replace the entire exhaust system if only a portion is damaged?

It is not always required. Depending on the location and severity of the damage, individual components, such as mufflers or pipes, can often be repaired or replaced independently. A qualified technician can assess the specific situation and recommend the most appropriate solution.

Question 4: What are the potential consequences of driving with a damaged exhaust system?

Operating a vehicle with a compromised exhaust system can lead to reduced fuel efficiency, increased emissions, elevated noise levels, and potential safety hazards. It may also result in legal penalties for non-compliance with emissions regulations.

Question 5: Can performance upgrades negatively affect a vehicle’s emissions?

Certain modifications can indeed impact emissions. It is crucial to ensure that any performance upgrades are compliant with local environmental regulations. Consult with a qualified technician to determine the potential effects on emissions and identify compliant options.

Question 6: What types of welding are used for exhaust system repairs?

Common welding techniques include MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding. The choice of welding method depends on the type of metal, the location of the repair, and the desired level of precision. Qualified technicians employ appropriate techniques to ensure durable and reliable welds.

Regular maintenance and timely repairs are essential for maintaining optimal vehicle performance, ensuring regulatory compliance, and promoting environmental responsibility.

The subsequent section will address preventative maintenance guidelines.

Conclusion

This exploration has elucidated the multifaceted role within vehicle maintenance and repair. The services, ranging from routine muffler replacements to intricate custom fabrications, contribute significantly to vehicle performance, regulatory adherence, and environmental stewardship. Competent diagnostics, skilled welding, and meticulous component selection are paramount for ensuring exhaust system integrity and longevity.

Properly functioning exhaust systems are vital for optimal vehicle operation and environmental protection. Continuing advancements in exhaust system technology and increasingly stringent emissions regulations necessitate ongoing vigilance and expertise. The future demands proactive maintenance and informed decisions to ensure vehicle compliance and minimize environmental impact.

![Secure Exhaust: Best Stainless Muffler Clamp [Durable] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Secure Exhaust: Best Stainless Muffler Clamp [Durable] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/02/th-113-300x200.jpg)