An alteration performed on the exhaust system of a specific chainsaw model, the Husqvarna 372, aims to enhance its performance characteristics. This procedure typically involves modifying or enlarging the existing openings in the muffler, the component responsible for noise reduction and exhaust gas routing. An example would be increasing the size of the muffler’s outlet to facilitate a less restrictive flow of exhaust gases.

The significance of this modification lies in its potential to increase engine power and improve throttle response. By reducing back pressure within the engine, it allows for a more efficient expulsion of exhaust gases, theoretically leading to greater combustion efficiency and subsequently, more horsepower. Historically, such modifications have been popular among chainsaw users seeking to optimize their equipment for demanding tasks like professional logging and milling operations.

The subsequent sections will delve into the practical aspects of performing this modification, potential risks and considerations, and the overall impact on the chainsaw’s performance and longevity. Detailed guidance will be provided for safe and effective execution, along with potential alternatives and performance enhancements.

Modification Guidance

The following points outline critical considerations for safely and effectively implementing a particular exhaust system alteration on the Husqvarna 372 chainsaw model.

Tip 1: Disconnect Spark Plug: Prior to commencing any work, ensure the chainsaw is rendered inoperable by disconnecting the spark plug wire. This precaution mitigates the risk of accidental engine ignition during the modification process.

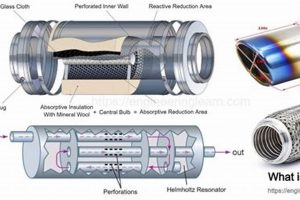

Tip 2: Assess Muffler Construction: Examine the muffler’s design to determine optimal locations for creating additional exhaust ports. Consideration should be given to structural integrity and the direction of exhaust flow.

Tip 3: Utilize Appropriate Tools: Employ precision tools, such as drill bits and rotary tools, to achieve clean and controlled material removal. Avoid using excessive force, which could damage the muffler body.

Tip 4: Control Debris: Implement measures to prevent metal shavings and debris from entering the engine cylinder. Covering the exhaust port and thoroughly cleaning the area post-modification is essential.

Tip 5: Gradual Enlargement: Initiate with smaller port sizes and incrementally increase them, testing the chainsaw’s performance after each adjustment. This iterative approach facilitates fine-tuning and prevents over-modification.

Tip 6: Deburr and Smooth Edges: After creating new ports, meticulously deburr and smooth all edges to minimize turbulence and ensure a consistent exhaust flow. This practice also prevents potential damage to internal engine components.

Tip 7: Rejet Carburetor (If Necessary): Monitor engine performance after the modification. A leaner fuel mixture might necessitate carburetor adjustments to maintain optimal air-fuel ratio and prevent engine damage.

Adhering to these points will contribute to a more successful and safer modification, potentially yielding improved engine performance while minimizing adverse effects.

The subsequent section will address potential performance outcomes and maintenance considerations following the completion of this modification.

1. Performance Enhancement

Performance enhancement, in the context of the Husqvarna 372 chainsaw exhaust alteration, refers to improvements in engine power, throttle response, and overall operational efficiency achieved through modification of the muffler system. This enhancement is a primary objective for users undertaking such alterations.

- Increased Engine Power

Engine power is directly related to the efficiency of combustion and the ability to expel exhaust gases. By reducing back pressure in the exhaust system, the engine experiences less resistance, allowing for a more complete combustion cycle. In practical terms, this translates to increased torque and horsepower, enabling the chainsaw to handle larger logs and more demanding cutting tasks. For example, a modified 372 chainsaw may exhibit faster chain speeds and improved cutting performance in hardwood applications compared to an unmodified unit.

- Improved Throttle Response

Throttle response refers to the speed at which the engine reacts to changes in throttle input. A less restrictive exhaust system allows the engine to rev more freely, resulting in quicker acceleration and improved responsiveness. This is particularly beneficial in situations requiring rapid changes in cutting speed, such as limbing or felling trees. An example would be a noticeable reduction in the time it takes for the chainsaw to reach maximum RPM after the throttle is engaged.

- Enhanced Cutting Efficiency

Improved cutting efficiency stems from the combined effects of increased engine power and throttle response. The chainsaw is able to maintain cutting speed more effectively under load, reducing the time and effort required to complete cutting tasks. In a milling application, for example, a modified chainsaw could produce planks at a faster rate with less strain on the engine. This is demonstrated by increased efficiency in converting raw lumber to usable forms.

- Optimized Heat Dissipation

While not a primary goal, modifying the exhaust system can indirectly influence engine temperature. A more efficient exhaust system can contribute to improved heat dissipation, potentially reducing the risk of overheating, especially under prolonged and demanding use. A practical example is observing lower engine temperatures after extended periods of cutting, indicating improved thermal management.

These facets of performance enhancement are interconnected and contribute to the overall effectiveness of the Husqvarna 372 chainsaw. The success of the alteration depends on a careful balance of these factors to maximize performance gains while minimizing potential adverse effects on engine reliability and longevity.

2. Exhaust Flow

Exhaust flow is a critical element directly influenced by alterations to the Husqvarna 372 chainsaw’s muffler. The stock muffler design often presents a restriction to the expulsion of exhaust gases. Modifying the muffler, typically by enlarging or adding exhaust ports, aims to reduce this restriction. This action has a direct effect on the engine’s ability to expel spent combustion gases. A more efficient exhaust flow cycle allows the engine to breathe more freely, potentially leading to increased power output. In scenarios where the chainsaw is used for milling large logs, a modified exhaust system with improved flow characteristics may reduce engine strain and increase cutting speed. The cause-and-effect relationship here is that restriction in the muffler will directly affect the expulsion of exhaust gases.

The design and execution of the muffler alteration directly dictate the extent of improvement in exhaust flow. Poorly executed modifications, such as uneven port sizes or sharp edges within the exhaust path, can create turbulence and negate potential performance gains. Precise execution is required to minimize restrictions. An example is that deburring newly created exhaust ports ensures a smooth flow, reducing back pressure. Furthermore, the modification’s impact on exhaust flow necessitates a reassessment of the engine’s air-fuel mixture. An increase in exhaust flow often requires a richer fuel mixture to maintain optimal combustion and prevent engine damage.

In conclusion, exhaust flow serves as a crucial factor determining the success and overall effectiveness of the chainsaw modification. Understanding the intricate relationship between muffler design, exhaust flow characteristics, and engine performance is paramount for achieving desired outcomes. Neglecting this understanding poses risks to engine longevity and potentially negates the intended performance enhancements. A properly modified exhaust system will allow to achieve an ideal exhaust flow. The degree of exhaust flow is important for performance enhancement.

3. Engine Protection

Engine protection, in the context of altering a Husqvarna 372 chainsaw muffler, constitutes the safeguards employed to prevent damage or premature wear to internal engine components resulting from the modification. The focus shifts from solely maximizing performance to maintaining the engine’s structural and operational integrity.

- Air-Fuel Ratio Management

Modifying the muffler alters exhaust flow, which can affect the air-fuel mixture entering the combustion chamber. A leaner mixture, characterized by a higher proportion of air, can lead to elevated engine temperatures and potentially cause piston seizure or other forms of engine damage. Adjustments to the carburetor may be necessary to maintain the correct air-fuel balance. For example, increasing the fuel flow by adjusting the carburetor jets ensures that the engine receives an adequate amount of fuel for proper combustion, preventing overheating.

- Spark Arrestor Integrity

The spark arrestor, often integrated within the muffler, prevents the emission of sparks from the exhaust, reducing the risk of fire. Modifying the muffler should not compromise the spark arrestor’s functionality. Removing or damaging the spark arrestor increases the risk of igniting dry vegetation or flammable materials in the surrounding environment. Inspections should be conducted post-modification to verify the spark arrestor remains intact and operational, adhering to safety regulations.

- Debris Ingress Prevention

Muffler modifications create an opening for debris to enter the exhaust port and, subsequently, the engine cylinder. Introduction of foreign particles can cause scoring of the cylinder walls and damage to the piston. Covering the exhaust port during modification and thoroughly cleaning the area afterward minimizes this risk. An example is using a clean cloth or tape to seal the port while drilling or grinding the muffler, preventing metal shavings from entering the engine.

- Overheating Prevention

While improved exhaust flow can potentially reduce engine temperatures, improper modifications can lead to localized hotspots or increased overall engine temperature. Monitoring engine temperature after modification is essential. If signs of overheating are detected, such as reduced power or unusual engine noise, the modification should be re-evaluated or reversed. This might involve reverting to the original muffler configuration or making further adjustments to optimize exhaust flow and cooling.

These facets of engine protection are interconnected and vital for preserving the Husqvarna 372 chainsaw’s operational lifespan after muffler modification. Prioritizing engine protection measures mitigates potential long-term damage, ensuring continued reliability and performance. For example, maintaining the correct air-fuel ratio not only prevents engine damage but also contributes to optimal combustion and fuel efficiency.

4. Noise Level

Muffler alterations on the Husqvarna 372 chainsaw directly impact noise emission levels. The stock muffler design is engineered to attenuate exhaust noise while maintaining a balance between performance and regulatory compliance. Modifying the muffler, typically by increasing exhaust port size or quantity, diminishes its sound-dampening capabilities. This invariably leads to a discernible increase in the operational noise level of the chainsaw. For instance, a chainsaw operating at a permissible noise level of 105 decibels (dB) in its original configuration could exceed 110 dB or higher after modification. This increase poses potential risks to the operator’s hearing and could violate local noise ordinances.

The increased noise level resulting from such modifications has practical implications for both professional and recreational users. Prolonged exposure to elevated noise levels can cause irreversible hearing damage, necessitating the use of appropriate hearing protection. Furthermore, the use of modified chainsaws in noise-sensitive environments, such as residential areas or national parks, may be restricted or prohibited. An example is a logging operation near a residential community facing complaints and potential legal action due to excessive noise generated by modified chainsaws. Careful consideration must be given to the trade-off between performance gains and the potential for increased noise pollution.

Ultimately, while modifying the muffler may offer performance enhancements, it is essential to acknowledge and address the accompanying rise in noise emissions. Balancing performance gains with the need to mitigate noise pollution requires informed decision-making and adherence to safety guidelines. Neglecting the noise level aspect of a muffler modification can lead to both health and legal ramifications, underscoring the importance of responsible modification practices. A proper modification can aim to make engine perform better without affecting noise level to be louder.

5. Fuel Consumption

Fuel consumption, in the context of Husqvarna 372 chainsaw muffler modifications, is directly linked to alterations in engine operating parameters. The original equipment manufacturer’s muffler design optimizes fuel efficiency while adhering to emission standards. Modifying the muffler, often to enhance engine performance, frequently disrupts this calibrated balance. An increase in exhaust flow, achieved by enlarging exhaust ports, reduces back pressure. This reduction allows the engine to expel exhaust gases more efficiently, but it also affects the scavenging process and the air-fuel mixture within the combustion chamber. For example, a chainsaw operating at a specific RPM range might experience a change in its optimal air-fuel ratio, leading to a richer mixture being required to maintain performance and prevent engine damage.

The practical consequence of this altered air-fuel ratio is a potential increase in fuel consumption. The engine demands more fuel to maintain the same power output, especially under heavy load. A logging operation might observe a decrease in the number of trees that can be felled per tank of fuel after a muffler modification. Monitoring fuel consumption is essential to understanding the modification’s overall impact. Furthermore, the type of cutting task influences fuel consumption. Milling large logs, for instance, requires sustained high-RPM operation, exacerbating the effects of a richer air-fuel mixture. It is important to re-evaluate the fuel settings in carburetor for safe and best fuel consumption after muffler mod.

In summary, while muffler modifications on the Husqvarna 372 chainsaw may improve performance, they can also lead to increased fuel consumption. The underlying cause is the altered air-fuel ratio necessitated by changes in exhaust flow. Understanding this relationship is crucial for users to make informed decisions about modifying their chainsaws, weighing the benefits of increased power against the potential cost of higher fuel consumption. Mitigation strategies include carburetor adjustments and careful monitoring of engine performance to optimize fuel efficiency without sacrificing engine health. A successful modification will improve output without drastically increasing fuel consumption.

6. Structural Integrity

Muffler modifications on the Husqvarna 372 chainsaw inherently impact the component’s structural integrity. The original muffler design is engineered to withstand specific stresses and environmental conditions. Altering this design, by adding or enlarging exhaust ports, introduces potential weak points and compromises the muffler’s ability to withstand heat, vibration, and physical impacts. For instance, creating an exhaust port too close to a mounting point can cause stress fractures over time, eventually leading to muffler failure. The cause-and-effect relationship is that material removal directly reduces the muffler’s overall strength. Maintaining structural integrity is critical for both safety and performance. A compromised muffler can leak exhaust gases, posing a burn hazard to the operator and reducing engine efficiency. In extreme cases, muffler failure can damage other engine components or create a fire hazard. Examples include melted plastic components near the exhaust outlet or vegetation ignited by escaping hot gases.

Practical considerations for preserving structural integrity during modification include careful planning of exhaust port placement and employing appropriate tools and techniques. Reinforcing modified areas with welding can mitigate stress concentrations and prevent cracking. Furthermore, periodic inspection of the muffler after modification is essential. Checking for signs of cracks, distortion, or loose mounting hardware allows for early detection of potential problems. Ignoring these signs can lead to catastrophic failure during operation. Another example is the cracking around the welds due to expansion and contraction of the metals from hot to cold.

In conclusion, structural integrity is a paramount consideration when modifying the Husqvarna 372 chainsaw muffler. While performance gains may be achieved through modification, compromising the muffler’s structural integrity presents significant risks. Careful planning, precise execution, and regular inspection are essential for minimizing these risks and ensuring the chainsaw’s safe and reliable operation. The challenge lies in balancing performance enhancement with the need to maintain the muffler’s structural integrity, underscoring the importance of a thorough understanding of both engineering principles and practical application. In balancing the needs and challenges, it is possible to modify the muffler. However, extreme care should be taken when modifying for optimum balance.

Frequently Asked Questions

This section addresses common inquiries and misconceptions concerning modifications to the Husqvarna 372 chainsaw muffler. Information presented aims to provide a clear understanding of the process and its potential implications.

Question 1: What is the primary purpose of performing a muffler modification on a Husqvarna 372 chainsaw?

The primary purpose is generally to enhance engine performance by reducing exhaust backpressure, potentially leading to increased horsepower and improved throttle response. However, this comes with other impacts to consider.

Question 2: Does modifying the muffler void the chainsaw’s warranty?

Yes, altering the muffler almost certainly voids the manufacturer’s warranty. The warranty typically covers defects in materials or workmanship, and modifications are generally not supported.

Question 3: Is specialized equipment required to modify the muffler?

The modification typically requires basic tools, including a drill, rotary tool, and potentially a welder. Precision and careful execution are more critical than specialized equipment.

Question 4: What are the potential negative consequences of modifying the muffler?

Negative consequences can include increased noise levels, potential for engine damage due to improper air-fuel mixture, and reduced structural integrity of the muffler.

Question 5: How does muffler modification affect fuel consumption?

Muffler modification can alter the engine’s air-fuel ratio, potentially leading to increased fuel consumption. Careful carburetor adjustment may be necessary to optimize fuel efficiency.

Question 6: Is it possible to revert the muffler back to its original state after modification?

Reverting to the original state may be challenging or impossible, depending on the extent of the modification. Welding may be required to restore the muffler’s original configuration, and original performance characteristics cannot be guaranteed. Buying an original one is most likely the best solution to restore.

Muffler modification presents both potential benefits and inherent risks. A thorough understanding of these aspects is crucial for responsible decision-making.

The following section will explore potential alternatives to muffler modification and consider the overall value proposition of altering the Husqvarna 372 chainsaw.

Conclusion

The preceding analysis has explored the implications of the 372 muffler mod, detailing both potential performance enhancements and inherent risks. Increased engine power and improved throttle response, core tenets of the modification, must be carefully weighed against the potential for elevated noise levels, increased fuel consumption, and compromised structural integrity. Furthermore, adherence to responsible modification practices and thorough understanding of engine operation are paramount to preserving engine longevity.

In light of the complexities outlined, a measured approach is warranted. Individuals considering the 372 muffler mod should thoroughly evaluate their specific needs and weigh the potential benefits against the associated risks and potential legal ramifications. The decision to proceed should be based on a clear understanding of the trade-offs involved, and a commitment to responsible and informed implementation. This is especially important for achieving optimum result.