A vital component within a vehicle’s exhaust system, this element plays a crucial role in mitigating noise pollution generated by the engine. For example, a faulty component can result in excessive engine noise, potentially violating local ordinances and affecting driver and passenger comfort.

Its proper function is paramount to ensuring a quieter and more pleasant driving experience. Historically, these devices have evolved significantly, from simple baffles to more complex designs that utilize sound-absorbing materials and tuned resonators. The result is decreased noise levels and improved community quality of life.

The subsequent sections will delve into the specifics of selecting, maintaining, and troubleshooting this essential component, providing a detailed overview of its operation and ensuring optimal vehicle performance.

Maintenance and Longevity Tips

Optimal performance and extended service life of the exhaust noise reduction apparatus are achievable through adherence to a few essential maintenance practices. These procedures, when diligently followed, can prevent premature failure and ensure regulatory compliance.

Tip 1: Routine Visual Inspection: Conduct regular visual checks for signs of corrosion, physical damage (dents or punctures), and loose connections. Early detection of these issues allows for timely corrective action, preventing further degradation. For instance, surface rust, if addressed promptly, can be treated with rust inhibitors, avoiding structural weakening.

Tip 2: Address Exhaust Leaks Immediately: Exhaust leaks, often indicated by increased noise or a burning smell, should be rectified without delay. Leaks can introduce corrosive gases and moisture, accelerating deterioration of exhaust system components, including the noise reduction device.

Tip 3: Proper Vehicle Operation: Avoid practices that place undue stress on the exhaust system, such as frequent short trips where the system does not reach optimal operating temperature. Incomplete combustion byproducts generated during cold starts can accumulate within the system, contributing to corrosion.

Tip 4: Regular Engine Maintenance: Ensure the engine is properly tuned and maintained. A poorly running engine can produce excessive backpressure and heat, straining the entire exhaust system, including its noise-reducing element.

Tip 5: Consider Environmental Factors: In regions with heavy road salt usage, increased frequency of washing the vehicle’s undercarriage is advisable. Salt accelerates corrosion and can significantly reduce the lifespan of exhaust components.

Tip 6: Professional Inspection: Schedule periodic inspections by a qualified technician. A trained professional can identify subtle issues that may not be apparent during a visual inspection and can provide expert advice on maintenance and potential repairs.

Consistent application of these maintenance tips will contribute significantly to the reliable operation and extended lifespan of the exhaust noise reduction apparatus, ensuring continued compliance with noise regulations and a quieter driving experience.

The subsequent sections will discuss the performance benefits and some considerations for noise reduction.

1. Noise Reduction Efficiency

Noise reduction efficiency quantifies the effectiveness of an exhaust noise reduction component in attenuating engine-generated sound. Within the context of a vehicle exhaust system, this component’s primary function is to diminish the amplitude of sound waves propagating through the exhaust stream. Greater noise reduction efficiency directly translates to lower decibel levels emitted by the vehicle, contributing to regulatory compliance and improved environmental acoustics. For instance, a component exhibiting low noise reduction efficiency may permit excessive engine noise, potentially leading to fines or necessitating vehicle modification.

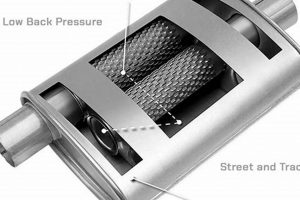

The design and materials employed significantly influence the noise reduction efficiency. Baffled designs redirect sound waves, causing them to interfere destructively, while absorption-based designs utilize sound-dampening materials like fiberglass to convert acoustic energy into heat. Consequently, variations in construction directly impact the component’s capacity to mitigate noise effectively. A real-world illustration involves comparing a standard, mass-produced component with a high-performance aftermarket alternative. The latter often incorporates advanced materials and designs optimized for superior noise attenuation, resulting in a demonstrably quieter vehicle operation.

Understanding the relationship between design, material, and noise reduction efficiency is crucial for informed selection and maintenance. Selecting an inadequate component may compromise noise control, whereas properly maintained, high-efficiency elements ensures sustained performance and minimizes environmental impact. The challenge lies in balancing noise reduction efficiency with other performance considerations, such as backpressure and exhaust flow, to achieve optimal vehicle performance and acoustic characteristics.

2. Material Durability

Material durability is a critical attribute determining the lifespan and reliable performance of exhaust noise reduction components. Exposure to extreme temperatures, corrosive elements, and physical stresses necessitates robust construction for continued functionality.

- Corrosion Resistance

The materials must withstand constant exposure to corrosive exhaust gases, moisture, and road salts. Stainless steel and aluminized steel are frequently employed for their enhanced resistance to rust and degradation. Premature corrosion failure results in exhaust leaks, increased noise, and potential replacement costs.

- Thermal Stability

Exhaust systems experience significant temperature fluctuations, requiring materials that maintain their structural integrity and mechanical properties across a wide range of temperatures. Degradation due to thermal cycling can lead to cracking, warping, and reduced noise reduction effectiveness. Examples of materials employed for the purpose of thermal stability includes ceramics and other heat resistent technologies.

- Mechanical Strength

Road debris, impacts, and vibrations impose mechanical stresses on the component. Materials possessing high tensile strength and fatigue resistance are necessary to prevent physical damage and ensure structural integrity. This includes resistance to dents, punctures, and cracking which is highly effective for noise reduction and also structural integrity.

- Abrasion Resistance

Internal abrasion from exhaust gas flow and external abrasion from road debris require materials that resist wear and erosion. Erosion of internal baffles and sound-absorbing materials compromises noise reduction performance and lifespan. Some materials are optimized by design to avoid abrasion from debris and exhaust gas.

The interplay of these factors ultimately determines the overall durability of a noise reduction device. Selection of appropriate materials, coupled with proper maintenance, is essential for ensuring long-term performance and regulatory compliance. Compromised material durability precipitates premature failure, necessitating costly replacements and potentially contributing to noise pollution.

3. Flow Restriction

Exhaust flow restriction represents a critical design parameter directly affecting engine performance. Within a noise reduction component, internal baffles and sound-absorbing materials, while effective in attenuating noise, inherently create resistance to the free flow of exhaust gases. The magnitude of this resistance, quantified as backpressure, significantly influences engine efficiency and power output. Excessive flow restriction impedes the evacuation of exhaust gases from the cylinders, leading to reduced volumetric efficiency, increased pumping losses, and diminished horsepower. In contrast, insufficient restriction can negatively impact low-end torque and fuel economy.

The design must therefore balance noise reduction with acceptable levels of flow restriction. A high-performance vehicle might tolerate a less restrictive system in exchange for increased power, whereas a standard passenger vehicle prioritizes quiet operation and fuel efficiency. For example, aftermarket components designed for performance enhancement often feature larger diameter piping and less restrictive internal designs to minimize backpressure. Conversely, original equipment manufacturers (OEMs) typically employ more restrictive designs to meet stringent noise regulations, often at the expense of marginal performance gains. The geometry of the internal passages, the density of sound-absorbing materials, and the overall size of the component contribute to the resultant flow restriction. Improperly designed or deteriorated internal components, such as collapsed baffles, can significantly increase flow restriction, leading to noticeable performance degradation and potential engine damage.

Effective management of flow restriction requires careful consideration of engine characteristics, vehicle application, and desired performance objectives. Selection of a component exhibiting appropriate flow characteristics ensures optimal engine performance, fuel efficiency, and compliance with noise regulations. Monitoring exhaust backpressure provides a valuable diagnostic tool for identifying potential restrictions within the exhaust system, enabling timely corrective action and preventing more severe engine problems. The interplay between noise reduction and flow restriction underscores the inherent trade-offs in exhaust system design, necessitating a balanced approach to achieve desired performance characteristics.

4. Corrosion Resistance

Corrosion resistance is a paramount factor in determining the longevity and performance of exhaust noise reduction apparatuses, particularly in regions characterized by frequent exposure to corrosive elements. The operational environment introduces a diverse range of challenges that demand robust material properties.

- Material Selection and Chemical Composition

The selection of materials, primarily alloys, dictates the inherent corrosion resistance of an exhaust component. Alloys with higher chromium, nickel, and molybdenum content exhibit enhanced resistance to oxidation and chloride attack. For instance, stainless steel variants like 304 and 316 are common choices, although the specific grade determines the degree of protection against pitting and crevice corrosion. In coastal regions or areas employing de-icing salts, even stainless steel can be susceptible, necessitating careful material selection based on the severity of the environment.

- Protective Coatings and Surface Treatments

Protective coatings such as aluminizing, ceramic coatings, or specialized polymer coatings can provide an additional barrier against corrosion. Aluminizing, for example, creates a sacrificial layer of aluminum oxide that passivates the steel surface, preventing the penetration of corrosive agents. Ceramic coatings offer high-temperature corrosion resistance, while polymer coatings provide a barrier against moisture and chemical attack. The effectiveness of these coatings depends on their adhesion, thickness, and resistance to abrasion and chipping.

- Weld Integrity and Joint Protection

Welded joints represent potential sites for accelerated corrosion due to localized stress and compositional changes in the weld zone. Proper welding techniques, including the use of compatible filler metals and shielding gases, are essential for minimizing corrosion susceptibility. Post-weld treatments, such as passivation or stress relieving, can further enhance corrosion resistance. Ingress of moisture and contaminants into joint crevices can initiate corrosion; therefore, sealing and protective coatings applied to welded areas are critical preventative measures.

- Environmental Factors and Operational Conditions

The operational environment plays a significant role in determining the rate of corrosion. Exposure to salt spray, road salts, acidic rain, and elevated temperatures accelerates the degradation of exhaust components. Frequent short trips, where the exhaust system does not reach optimal operating temperature, can exacerbate corrosion due to the accumulation of condensed moisture and acidic byproducts. Regular cleaning and maintenance, including rinsing the undercarriage to remove salt deposits, can mitigate the effects of environmental factors and extend the lifespan of the exhaust noise reduction apparatus.

The integration of corrosion-resistant materials, protective coatings, and proper maintenance protocols represents a multifaceted approach to ensuring the reliable and extended performance of exhaust noise reduction components. A comprehensive understanding of corrosion mechanisms and environmental factors is essential for selecting appropriate materials and implementing effective preventative measures. Neglecting corrosion resistance can lead to premature failure, increased noise levels, and costly repairs.

5. Longevity/Lifespan

The operational lifespan of a vehicle’s exhaust noise reduction component is a critical consideration influencing both vehicle maintenance costs and environmental impact. Premature failure necessitates replacement, incurring expenses and generating waste. Extended longevity translates to reduced lifecycle costs and decreased resource consumption. The following aspects directly impact the lifespan of a “great bridge muffler,” ensuring sustained performance.

- Material Composition and Manufacturing Quality

The materials employed in the construction directly determine the component’s resistance to corrosion, thermal stress, and mechanical damage. High-quality materials, such as specific grades of stainless steel, offer superior durability compared to lower-grade alternatives. Manufacturing processes influence weld integrity and overall structural soundness, further affecting the expected lifespan. For example, a poorly welded seam is prone to premature failure due to corrosion or stress cracking, significantly shortening the lifespan.

- Environmental Exposure and Operating Conditions

Exposure to road salts, extreme temperatures, and frequent short trips significantly accelerates wear and corrosion. Regions with harsh winter conditions, where de-icing salts are heavily used, present a particularly challenging environment. Frequent short trips prevent the exhaust system from reaching optimal operating temperature, leading to the accumulation of corrosive condensates. Under these conditions, a component designed for standard usage may exhibit a drastically reduced lifespan.

- Maintenance Practices and Inspection Regimen

Regular visual inspections and timely repairs of minor issues can significantly extend the component’s lifespan. Addressing exhaust leaks promptly prevents further corrosion and component degradation. Periodic cleaning of the undercarriage, especially in regions with high salt usage, removes corrosive deposits and inhibits rust formation. Consistent adherence to recommended maintenance practices contributes directly to maximizing the operational lifespan.

- Design Considerations and System Compatibility

The design of the exhaust system and its compatibility with the engine’s operating characteristics influence the stress placed on the noise reduction component. Excessive backpressure or improper mounting can accelerate wear and fatigue. A well-designed system distributes stress evenly, minimizing the risk of localized failures. Moreover, ensuring compatibility with other exhaust components prevents undue strain and contributes to extended lifespan.

The interplay of these factors ultimately determines the service life of an exhaust noise reduction component. Selection of a high-quality component, coupled with appropriate maintenance and conscientious driving habits, ensures extended longevity, reduces overall ownership costs, and minimizes environmental impact. Neglecting these considerations can lead to premature failure, necessitating frequent replacements and diminishing the economic and environmental benefits of a durable exhaust system.

Frequently Asked Questions about Great Bridge Mufflers

The following addresses common inquiries and misconceptions concerning the function, maintenance, and performance characteristics of vehicle exhaust noise reduction components.

Question 1: What constitutes a “great bridge muffler” and what specific purpose does it serve within a vehicle?

A “great bridge muffler” is an acoustic device integrated into a vehicle’s exhaust system to attenuate engine noise. Its primary function is to reduce the amplitude of sound waves generated during combustion, minimizing noise pollution and ensuring compliance with regulatory standards.

Question 2: How frequently should a vehicle’s exhaust noise reduction component be inspected, and what signs indicate potential failure?

Visual inspections should be conducted at least annually, or more frequently in regions with harsh environmental conditions. Signs of potential failure include excessive exhaust noise, visible corrosion or physical damage, and reduced engine performance.

Question 3: Does the installation of an aftermarket exhaust noise reduction apparatus affect vehicle warranty coverage?

The impact on warranty coverage depends on the specific terms outlined in the vehicle warranty agreement. Installation of an aftermarket component may void warranty coverage for related exhaust system components if the aftermarket component is determined to be the cause of the failure.

Question 4: How does the choice of materials affect the lifespan and performance of a vehicle’s exhaust noise reduction device?

Material selection significantly impacts corrosion resistance, thermal stability, and mechanical strength. High-quality materials, such as stainless steel, offer superior durability and extended lifespan compared to lower-grade alternatives. The optimal material selection depends on the vehicle’s operating environment and desired performance characteristics.

Question 5: What are the potential consequences of operating a vehicle with a malfunctioning or damaged exhaust noise reduction component?

Operating a vehicle with a malfunctioning component can result in increased noise pollution, violation of local noise ordinances, reduced engine performance, and potential damage to other exhaust system components. In some jurisdictions, it can also lead to fines or penalties.

Question 6: Are there specific maintenance procedures that can extend the lifespan of a vehicle’s exhaust noise reduction apparatus?

Yes. Regularly inspecting the component for corrosion and damage, addressing exhaust leaks promptly, avoiding practices that stress the exhaust system, and periodic cleaning of the vehicle’s undercarriage, particularly in regions with high salt usage, can significantly extend its lifespan.

In summary, understanding the function, maintenance requirements, and performance characteristics of vehicle exhaust noise reduction components is essential for ensuring optimal vehicle operation, regulatory compliance, and environmental responsibility.

The following section will explore the environmental benefits of properly functioning exhaust noise reduction systems.

Conclusion

This exploration has delineated the function, maintenance, and critical performance attributes inherent to the “great bridge muffler.” Proper execution of these tenets guarantees an effective reduction of noise pollution and promotes regulatory adherence. Careful consideration of material quality, diligent maintenance practices, and an understanding of operational influences are paramount in securing prolonged and reliable performance.

The continued emphasis on robust design and responsible vehicle maintenance remains essential. These efforts will yield tangible benefits: reduced environmental noise, improved vehicle efficiency, and ultimately, a more sustainable and responsible automotive ecosystem.