This automotive component serves to reduce the noise emitted by an internal combustion engine. It is a crucial part of the exhaust system, designed to attenuate sound waves created by the engine’s combustion process before they are released into the atmosphere. An example would be its utilization in older model vehicles to reduce noise pollution.

Its importance lies in minimizing environmental noise and adhering to noise regulations set by various jurisdictions. Historically, these devices have evolved from simple baffles to more sophisticated designs incorporating resonance chambers and sound-absorbing materials. This evolution reflects increasing awareness of the impact of noise pollution on public health and quality of life. Benefits include quieter operation, reduced stress on vehicle occupants, and compliance with environmental standards.

The following sections will delve into the specific types available, their installation processes, performance characteristics, maintenance requirements, and selection criteria for ensuring optimal vehicle operation and noise reduction.

Maintenance and Longevity Tips

Proper care and maintenance are crucial for ensuring optimal performance and extending the lifespan of this exhaust system component. Neglecting maintenance can lead to reduced effectiveness and eventual failure, necessitating costly repairs or replacements.

Tip 1: Regular Visual Inspection: Conduct routine visual inspections for signs of rust, corrosion, or physical damage. Early detection of these issues can prevent further degradation and potential exhaust leaks. For example, examine welds and seams for cracks.

Tip 2: Avoid Short Trips: Short trips can lead to the accumulation of condensation within the exhaust system, accelerating corrosion. Prolonged idling also contributes to moisture buildup. When possible, opt for longer journeys that allow the system to fully heat up and evaporate moisture.

Tip 3: Promptly Address Exhaust Leaks: Any detected exhaust leaks should be addressed immediately. Exhaust leaks not only compromise noise reduction but also pose a safety risk by potentially allowing harmful gases to enter the vehicle cabin. Inspect exhaust manifold, exhaust pipes or exhaust components to solve the leaks problems.

Tip 4: Salt Avoidance: Exposure to road salt during winter months significantly accelerates corrosion. Regularly washing the undercarriage of the vehicle, especially after driving on salted roads, helps to remove salt deposits. Rinsing removes salt and dirt.

Tip 5: Check Mounting Hardware: Periodically inspect and tighten mounting hardware, such as brackets and hangers, to ensure secure attachment of the exhaust system. Loose hardware can lead to excessive vibrations and premature wear.

Tip 6: Professional Inspection: Schedule periodic professional inspections to check the integrity of components. An expert can evaluate the exhaust system for damages.

Following these tips will contribute significantly to maintaining optimal performance, extending its lifespan, and preventing costly repairs. Proactive maintenance is essential for ensuring continued compliance with noise regulations and a comfortable driving experience.

The subsequent sections will explore troubleshooting common issues and address frequently asked questions to provide further guidance on maintaining and repairing this essential automotive component.

1. Noise Reduction

Effective noise reduction is the primary function of an exhaust system component. The effectiveness with which this automotive component attenuates engine noise directly correlates with its design and internal structure. The component’s internal baffling and sound-absorbing materials are critical to achieving significant noise reduction. The absence or degradation of these features directly diminishes noise-dampening capabilities, resulting in increased noise pollution. For instance, a worn-out component with corroded internal baffles will fail to adequately dampen sound waves, leading to louder exhaust emissions.

The importance of noise reduction extends beyond simple comfort. Many jurisdictions have established noise regulations that vehicles must adhere to. A properly functioning noise reduction solution is, therefore, essential for legal vehicle operation. Furthermore, reduced noise pollution contributes to improved environmental quality in urban and suburban areas, minimizing disturbances to residents and wildlife. Modern designs often incorporate resonance chambers and specialized sound-absorbing materials to further enhance noise reduction capabilities, optimizing the balance between performance and environmental considerations.

In summary, noise reduction is the defining characteristic of this essential automotive component. Its effectiveness in achieving this function is crucial for both legal compliance and environmental responsibility. Maintenance of internal structure and overall integrity is vital to maintain optimal noise reduction. Ongoing advancements in design and materials continue to improve its performance, offering a quieter and more environmentally friendly driving experience.

2. Exhaust Flow

Exhaust flow is a critical parameter influencing vehicle performance, and its interaction with the exhaust system component that reduces noise is significant. Restrictions to exhaust flow can negatively impact engine efficiency and power output. Optimizing exhaust flow, while simultaneously achieving desired noise reduction, presents a design challenge for manufacturers.

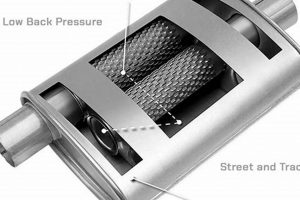

- Backpressure

Backpressure refers to the resistance encountered by exhaust gases as they move through the exhaust system. A restrictive design creates excessive backpressure, hindering the engine’s ability to expel exhaust gases efficiently. This results in reduced horsepower and torque, particularly at higher engine speeds. Performance exhaust systems seek to minimize backpressure, whereas standard systems prioritize sound attenuation, potentially creating a trade-off. Example would be in engine, a reduced horsepower can occurred when exhaust flow is restricted because of backpressure.

- Internal Design

The internal design, including the configuration of baffles, chambers, and perforations, significantly affects the flow characteristics. A well-designed component will minimize turbulence and flow restrictions while effectively dampening sound waves. Poorly designed internals can create bottlenecks, reducing flow and increasing backpressure. This element is very important for noise and exhaust flow balancing. Example would be the internal design in the component will reduce noise and keep the exhaust flow efficient.

- Pipe Diameter

The diameter of the piping within the exhaust system component impacts flow capacity. A smaller diameter pipe restricts flow, leading to increased backpressure. Conversely, an excessively large diameter pipe can reduce exhaust gas velocity, potentially impacting scavenging efficiency. Selecting the appropriate pipe diameter is crucial for optimizing performance. The pipe should be the perfect measure for the vehicle being used. For example, selecting the perfect pipe diameter for the vehicle is essential for optimizing the exhaust flow.

- Scavenging Effect

The scavenging effect leverages exhaust pulses to help draw out remaining exhaust gases from the cylinders. An optimized exhaust system design can enhance this effect, improving engine efficiency. However, overly restrictive components can negate the scavenging effect, reducing overall engine performance. For example, an optimized exhaust system design for the vehicle enhances the scavenging effect of cylinder, this results to an improved performance of the engine.

The facets discussed underscore the importance of considering exhaust flow when selecting and maintaining an effective noise reduction solution. Compromises between noise attenuation and flow optimization must be carefully evaluated to ensure that vehicle performance is not unduly sacrificed. Aftermarket exhaust systems often emphasize improved flow characteristics, but careful consideration must be given to ensure compliance with local noise regulations.

3. Material Durability

Material durability is a paramount consideration in the design and longevity of an automotive exhaust component engineered for noise reduction. The harsh operating environment, characterized by high temperatures, corrosive gases, and exposure to road debris, necessitates the selection of materials capable of withstanding degradation over extended periods.

- Corrosion Resistance

The exhaust system is continually exposed to corrosive byproducts of combustion, including water vapor, sulfur compounds, and acids. Materials lacking inherent corrosion resistance are prone to rust and perforation, leading to exhaust leaks and diminished noise reduction effectiveness. Stainless steel, aluminized steel, and ceramic coatings are employed to mitigate corrosion. An example is the use of stainless steel in performance applications, which extends component life but increases manufacturing costs.

- Thermal Stability

Exhaust gases can reach extremely high temperatures, particularly during periods of high engine load. Materials must maintain their structural integrity and mechanical properties at elevated temperatures to prevent warping, cracking, or failure. High-temperature alloys and specific grades of steel are selected based on their ability to withstand thermal stress. A practical example is the utilization of Inconel in racing exhaust systems, which offers superior thermal stability but is significantly more expensive.

- Mechanical Strength

The exhaust system is subjected to mechanical stresses from engine vibrations, road impacts, and thermal expansion/contraction cycles. Materials must possess sufficient tensile strength, yield strength, and fatigue resistance to prevent cracking or deformation under these conditions. The thickness and gauge of the material used play a crucial role in determining its ability to withstand mechanical stress. An example can be the thickness for the muffler body to prevent cracking of muffler body because of the vibration from engine and other debris from road.

- Welding Integrity

Welding is a critical process in the fabrication of exhaust components. The weld joints must be strong, durable, and resistant to corrosion and thermal fatigue. The selection of appropriate welding techniques and filler metals is essential for ensuring the long-term integrity of the exhaust system. Poorly executed welds can lead to premature failure and exhaust leaks. For example, a cracked weld on an exhaust hanger can cause the entire system to sag, leading to further stress and potential damage.

The interplay of these factors directly influences the service life and performance of an exhaust noise reduction component. Careful consideration of material properties, manufacturing processes, and operating conditions is essential for delivering a durable, reliable, and effective product. The selection of appropriate materials ultimately determines the component’s ability to withstand the harsh realities of its environment, ensuring long-term noise reduction and compliance with emissions standards.

4. Installation Ease

Installation ease directly impacts the overall cost and convenience associated with replacing or upgrading an exhaust system component designed for noise reduction. A design optimized for straightforward installation minimizes the need for specialized tools, extensive modifications, or professional assistance, thereby reducing both time and expense.

- Direct Fit Design

A direct-fit design implies that the component is engineered to precisely match the dimensions and mounting points of the original equipment manufacturer (OEM) part. This eliminates the need for cutting, welding, or bending during installation. Direct-fit components typically include all necessary hardware, such as gaskets, clamps, and hangers, further simplifying the process. For instance, a direct-fit replacement component for a specific vehicle model allows a technician to simply unbolt the old part and bolt in the new one, streamlining the replacement.

- Clear Instructions and Documentation

Comprehensive and easy-to-understand installation instructions are crucial for facilitating a smooth and successful installation process. Clear diagrams, step-by-step procedures, and torque specifications empower both professional mechanics and competent do-it-yourselfers to complete the task correctly. Conversely, vague or incomplete instructions can lead to errors, delays, and potential damage to the vehicle or the component. For example, explicit instructions indicating the correct orientation of a gasket or the proper tightening sequence for bolts can prevent leaks and ensure a secure installation.

- Accessibility of Mounting Points

The design of the vehicle’s undercarriage and the accessibility of the exhaust system mounting points significantly impact installation ease. Components positioned in hard-to-reach locations or obstructed by other vehicle components can require specialized tools or extensive disassembly to access. A well-designed system will prioritize accessibility, minimizing the time and effort required for installation. For example, if exhaust hangers are readily accessible and easily detached, the replacement process will be significantly faster and simpler.

- Modular Design and Pre-Assembled Components

Modular designs, where components are pre-assembled into larger units, can streamline the installation process. Pre-assembled sections reduce the number of individual connections and fasteners that need to be handled, saving time and minimizing the risk of errors. For example, an exhaust system that comes as a single, pre-welded unit, rather than multiple individual pipes and mufflers, simplifies the installation process considerably.

In conclusion, the ease of installation is a critical factor influencing consumer satisfaction and the overall cost of ownership for aftermarket noise reduction exhaust components. Design features that promote straightforward installation, such as direct-fit designs, clear instructions, accessible mounting points, and modular construction, enhance the appeal and practicality of these products. Conversely, complex installations can deter potential customers and lead to increased labor costs. Therefore, manufacturers must prioritize installation ease during the design phase to deliver user-friendly and cost-effective products.

5. Emission Compliance

Emission compliance represents a critical aspect of modern automotive engineering and regulatory oversight, directly impacting the design and functionality of exhaust system components, including aftermarket noise reduction solutions. Regulations governing exhaust emissions aim to minimize the release of harmful pollutants into the atmosphere, necessitating adherence to stringent standards by both vehicle manufacturers and component suppliers.

- Catalytic Converter Compatibility

The catalytic converter is a primary component in reducing harmful emissions such as hydrocarbons, carbon monoxide, and nitrogen oxides. Any alteration or modification to the exhaust system, including the installation of an aftermarket noise reduction component, must maintain compatibility with the catalytic converter to ensure continued emission control effectiveness. Incompatibility can result in increased emissions, potentially violating regulatory standards and subjecting the vehicle owner to fines or penalties. For example, certain high-flow aftermarket components can disrupt the operating temperature of the catalytic converter, reducing its efficiency and increasing emissions.

- Backpressure Effects on Combustion

Changes to the exhaust system, particularly those affecting backpressure, can influence the engine’s combustion process. Excessive backpressure can lead to incomplete combustion, resulting in increased emissions of unburned hydrocarbons and carbon monoxide. Conversely, insufficient backpressure can negatively affect engine scavenging, also leading to increased emissions. The noise reduction component must be designed to strike a balance between noise attenuation and exhaust flow to avoid compromising combustion efficiency. An example includes selecting an exhaust system design that avoids creating excessive backpressure, which could negatively affect emissions.

- Sound Level Regulations and Decibel Limits

While the primary function is noise reduction, exhaust systems are also subject to sound level regulations. Exceeding established decibel limits can result in legal penalties, and authorities may inspect vehicles suspected of violating these regulations. Noise reduction components must be designed to comply with applicable sound level regulations while still achieving effective noise attenuation. For instance, some jurisdictions require periodic noise emission testing as part of vehicle inspections to ensure compliance with local laws.

- OBD-II System Monitoring

Modern vehicles equipped with OBD-II (On-Board Diagnostics) systems continuously monitor the performance of various emission-related components. Aftermarket modifications to the exhaust system can potentially trigger fault codes or warning lights if the system detects deviations from expected parameters. Compatibility with the OBD-II system is essential to avoid false alarms and ensure accurate monitoring of emission control components. A practical example is the use of aftermarket components that are designed to not trigger OBD-II system errors, ensuring proper functionality and compliance.

The above aspects illustrate the interconnectedness of exhaust system design, noise reduction, and emission compliance. Selection and installation of exhaust noise reduction components must be carefully considered in light of applicable emission regulations to ensure legal and environmentally responsible vehicle operation. Compliance necessitates careful consideration of component compatibility, backpressure effects, sound level regulations, and OBD-II system monitoring to maintain optimal engine performance and minimize harmful emissions.

6. Cost-Effectiveness

Cost-effectiveness, in the context of aftermarket exhaust components for noise reduction, encompasses a balance between initial purchase price, long-term operating expenses, and the component’s overall lifespan. Evaluating cost-effectiveness requires careful consideration of materials, construction quality, installation requirements, and maintenance needs.

- Initial Purchase Price vs. Material Quality

A lower initial purchase price may be attractive, but often corresponds with the use of less durable materials or simplified construction techniques. Components constructed from inexpensive materials are more susceptible to corrosion, mechanical failure, and reduced noise reduction effectiveness over time. While a higher initial investment in a component constructed from premium materials, such as stainless steel, may increase the upfront cost, the extended lifespan and enhanced performance can ultimately yield greater long-term cost savings. An example is a high cost performance with the materials can give a long-term cost savings.

- Installation Costs and Complexity

The complexity of the installation process directly impacts the overall cost-effectiveness of the component. Direct-fit designs, which require minimal modification or specialized tools, typically result in lower installation costs. Conversely, universal-fit components or those requiring extensive welding or fabrication can significantly increase labor expenses. Evaluating the installation requirements and associated labor costs is crucial when assessing the total cost of ownership. Installing a muffler with universal-fit designs requires the vehicle to be more specific for it.

- Maintenance Requirements and Replacement Frequency

The frequency and cost of required maintenance also contribute to the long-term cost-effectiveness. Components prone to corrosion or mechanical failure may necessitate frequent repairs or replacements, offsetting any initial cost savings. Selecting a component with a robust design, corrosion-resistant materials, and readily available replacement parts can minimize maintenance expenses and extend the component’s service life. Components with rust must have a replacement immediately.

- Fuel Efficiency and Performance Impact

While the primary function is noise reduction, the component’s design can subtly impact fuel efficiency and engine performance. Overly restrictive designs can increase backpressure, potentially reducing fuel economy and horsepower. Conversely, a well-designed component can optimize exhaust flow, improving engine efficiency and potentially offsetting some of the initial purchase price. Considering the potential impact on fuel consumption is a relevant aspect of evaluating cost-effectiveness. A well-designed component can optimize the exhaust flow, this results to improve engine efficiency.

In summary, evaluating cost-effectiveness involves a holistic assessment that encompasses the initial purchase price, installation costs, maintenance requirements, potential performance impacts, and the component’s expected lifespan. Opting for a lower-priced component may appear economical initially, but a comprehensive analysis may reveal that a higher-quality, more durable alternative offers superior value over the long term. Careful consideration of these factors is essential for making informed decisions and maximizing the return on investment.

Frequently Asked Questions

This section addresses common inquiries and misconceptions surrounding the automotive exhaust component designed for noise reduction. The information provided aims to offer clarity and guidance for informed decision-making.

Question 1: What is the typical lifespan?

The lifespan varies depending on several factors, including material quality, environmental conditions, and driving habits. Components constructed from stainless steel in moderate climates may last 10 years or more, while those made from aluminized steel in regions with heavy road salt usage may only last 3-5 years. Regular inspections and maintenance can extend the lifespan.

Question 2: Does it improve engine performance?

Aftermarket components designed for performance enhancement may offer marginal improvements in horsepower and torque. However, standard replacement components primarily focus on noise reduction and do not typically provide significant performance gains. Any potential performance benefits should be considered in conjunction with potential impacts on emissions compliance and noise levels.

Question 3: Can it be repaired, or must it be replaced?

Minor damage, such as small rust spots or loose hangers, may be repairable. However, extensive corrosion, significant structural damage, or internal baffle failure generally necessitate replacement. Attempting to repair severely damaged components may compromise safety and noise reduction effectiveness.

Question 4: What are the signs of failure?

Common signs of failure include increased exhaust noise, rattling sounds, visible rust or corrosion, exhaust leaks, and decreased fuel efficiency. A visual inspection of the exhaust system can often reveal the source of the problem.

Question 5: Will it affect my vehicle’s warranty?

The installation of aftermarket components may void portions of the vehicle’s warranty if the component directly causes damage to other OEM parts. However, simply replacing the component with a comparable aftermarket option generally does not void the entire warranty. Consulting the vehicle’s warranty documentation and discussing potential modifications with a qualified mechanic is recommended.

Question 6: How do I choose the right replacement?

Selecting the appropriate replacement involves considering the vehicle’s make and model, the desired level of noise reduction, the component’s material quality, and the ease of installation. Consulting with a reputable auto parts supplier or a qualified mechanic can help ensure proper fit and performance.

These answers offer a starting point for understanding the nuances of this automotive component. Consult qualified professionals for specific applications.

The next section will address troubleshooting common issues and provide additional resources for further information and assistance.

Conclusion

This exploration of the crucial automotive component, sometimes referred to as a “mcdonald muffler,” has traversed its multifaceted aspects. From defining its core function in noise reduction to evaluating material durability, installation ease, emission compliance, and cost-effectiveness, a comprehensive overview has been provided. The considerations of exhaust flow dynamics and the detailed frequently asked questions further illuminate the nuances inherent in selecting, maintaining, and understanding this essential part.

Ultimately, informed decision-making regarding this exhaust component is paramount. Careful evaluation of individual needs, regulatory requirements, and long-term implications will ensure optimal performance, environmental responsibility, and overall vehicle satisfaction. Continued advancements in material science and engineering promise further refinements in design, efficiency, and longevity, underscoring its enduring significance in the automotive landscape.