An aftermarket automotive component, frequently constructed from materials like stainless steel or titanium, is engineered to modify a vehicle’s exhaust sound and appearance. These components offer alternatives to factory-installed exhaust systems, often prioritizing aesthetics and performance enhancement. For instance, a component might be crafted to produce a deeper, more aggressive exhaust note, while simultaneously presenting a visually appealing, polished finish.

The significance of these modified components lies in their capacity to personalize a vehicle, reflecting the owner’s individual style and potentially increasing horsepower. Historically, vehicle owners have sought to customize their automobiles, and upgraded exhaust systems represent a common avenue for achieving this. These components can contribute to a vehicle’s overall performance by reducing backpressure in the exhaust system, leading to improved engine efficiency.

The subsequent sections will delve into the specifics of performance gains achieved through modified exhaust systems, the diverse range of materials employed in their construction, and the considerations for selecting the most suitable system for a particular vehicle and driving style. We will also discuss the legal and regulatory aspects of aftermarket exhaust modifications.

Guidance on Aftermarket Automotive Exhaust Components

The following points provide essential information for individuals considering the installation of a performance-oriented exhaust component. Prudent decision-making is crucial for optimizing both vehicle aesthetics and functional performance.

Tip 1: Conduct Thorough Research: Before purchasing any component, investigate various manufacturers and models. Read independent reviews and consult automotive forums to gain insights into product quality, performance claims, and potential installation challenges.

Tip 2: Consider Material Composition: Exhaust systems are typically manufactured from stainless steel, aluminized steel, or titanium. Stainless steel offers a balance of durability and corrosion resistance, while titanium provides superior weight reduction and heat dissipation, albeit at a higher cost.

Tip 3: Evaluate Exhaust System Design: Different exhaust designs, such as cat-back or axle-back systems, offer varying levels of performance enhancement and installation complexity. A cat-back system replaces the exhaust components from the catalytic converter rearward, potentially offering more significant performance gains than an axle-back system.

Tip 4: Assess Sound Characteristics: Exhaust systems significantly alter a vehicle’s sound profile. Listen to audio samples or, if possible, experience the exhaust system in person to ensure the resulting sound aligns with personal preferences and complies with local noise regulations.

Tip 5: Verify Compatibility: Ensure the chosen component is specifically designed for the target vehicle’s make, model, and year. Incompatible systems may lead to installation difficulties, performance issues, or even damage to other vehicle components.

Tip 6: Budget for Professional Installation: While some individuals may opt for self-installation, engaging a qualified mechanic is recommended, particularly for complex installations. Professional installation ensures proper fitment, alignment, and minimizes the risk of future problems.

Tip 7: Understand Legal Implications: Before making any modifications, research local and national laws regarding exhaust modifications. Some jurisdictions have noise restrictions or emissions regulations that may affect the legality of certain aftermarket components.

Adhering to these guidelines will contribute to a well-informed decision, ultimately enhancing vehicle performance and aesthetics while minimizing potential complications.

The subsequent sections will address common issues encountered during installation and troubleshooting, as well as warranty considerations for aftermarket exhaust components.

1. Aesthetics

Aesthetics play a pivotal role in the design and selection of aftermarket exhaust components. Beyond pure functional performance, the visual appeal of these components significantly influences purchasing decisions and the overall perception of a vehicle’s enhanced style.

- Finish and Material Appearance

The surface finish of an exhaust component, such as polished stainless steel or titanium, directly impacts its visual appeal. A high-gloss finish can project a sense of luxury and meticulous attention to detail, while brushed or matte finishes may convey a more aggressive or understated aesthetic. The material itself contributes significantly; for example, the iridescent coloration of heat-treated titanium distinguishes it from standard stainless steel.

- Tip Design and Style

Exhaust tips represent a highly visible element, and their design options are extensive. Choices range from single-wall, double-wall, slant-cut, rolled-edge, and various shapes (round, oval, square). The style of the tip can dramatically alter the perceived character of the vehicle, from subtle elegance to overt sportiness. Tip size, protrusion, and angling also factor into the overall aesthetic impact.

- Integration with Vehicle Design

A well-chosen exhaust component complements the existing design language of the vehicle. Considerations include the vehicle’s body lines, paint color, and overall styling cues. An exhaust system that clashes with these elements can detract from the vehicle’s appearance, while one that harmonizes with them enhances the cohesive aesthetic. Careful matching of materials, finishes, and design features is crucial for achieving a visually integrated outcome.

- Brand Reputation and Perception

The brand associated with the exhaust component can influence its perceived aesthetic value. Some brands are recognized for their commitment to high-quality materials and meticulous craftsmanship, resulting in components that are both visually appealing and durable. Conversely, less reputable brands may prioritize cost over aesthetics, leading to components with inferior finishes or questionable durability. Therefore, brand selection carries aesthetic implications beyond mere functional considerations.

Ultimately, the aesthetic considerations of aftermarket exhaust systems extend beyond superficial appearance. They reflect a deliberate effort to enhance a vehicle’s overall visual identity, contributing to a sense of personalized style and automotive distinction. The interplay between material, design, integration, and brand reputation creates a holistic aesthetic experience that is integral to the perceived value of the component.

2. Performance Enhancement

Aftermarket exhaust systems, frequently incorporating modified mufflers, often advertise performance gains. The underlying principle involves reducing backpressure within the exhaust system. Factory exhaust systems, designed for mass production and noise reduction, may impose restrictions on exhaust gas flow. Aftermarket components, specifically engineered for performance, aim to optimize this flow, potentially leading to increased horsepower and torque. A practical example is the replacement of a factory muffler with a straight-through design, intended to minimize obstructions and facilitate rapid exhaust gas expulsion.

The magnitude of performance enhancement varies considerably, contingent upon several factors. Engine displacement, aspiration method (naturally aspirated versus turbocharged), and the overall exhaust system design exert significant influence. Gains are often more pronounced in turbocharged engines, where reduced backpressure can allow the turbocharger to spool more quickly, resulting in improved throttle response and power output. However, it’s essential to acknowledge that claims of substantial horsepower increases should be viewed with scrutiny, as real-world gains may be less significant than advertised. Dyno testing, conducted under controlled conditions, provides a means of objectively quantifying performance improvements.

Understanding the relationship between exhaust system modifications and engine performance carries practical implications. Informed consumers can make judicious choices based on empirical data rather than solely relying on marketing claims. Furthermore, modifications should be undertaken with a holistic view, considering the potential impact on emissions compliance and overall vehicle reliability. Optimal performance gains are typically achieved through a comprehensive approach, encompassing exhaust modifications in conjunction with other performance enhancements, such as engine tuning and intake system upgrades. The interplay between these factors necessitates a nuanced understanding for maximizing overall vehicle performance while adhering to legal and environmental regulations.

3. Material Composition

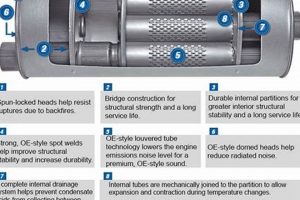

The material composition of an automotive exhaust component directly influences its performance characteristics, durability, and acoustic properties. In the context of a specialized exhaust component, material selection is a critical design consideration that affects heat dissipation, corrosion resistance, and overall lifespan. For instance, utilizing T304 stainless steel in a specialized exhaust system provides substantial resistance to corrosion, making it suitable for environments with high salt exposure. Alternatively, titanium offers significant weight reduction and improved heat dissipation, often preferred in performance-oriented applications where minimizing mass is paramount. The choice between these materials, or others like aluminized steel or Inconel, reflects a balance between cost, performance requirements, and intended application.

The impact of material composition extends beyond physical attributes. The acoustic properties of different materials influence the sound emitted by the exhaust system. Thinner-gauge stainless steel may produce a sharper, more resonant sound, while thicker-gauge materials tend to dampen higher frequencies, resulting in a deeper tone. Design parameters also involve the material’s ability to withstand thermal stress and vibration, especially in high-performance engines. Utilizing inferior materials can lead to premature failure due to cracking or fatigue, negating potential performance benefits. An example of this is the common use of lower grade steel in inexpensive aftermarket systems, which often leads to rust and eventual failure in regions with harsh winters.

Ultimately, the choice of materials in a specialized exhaust component is a multifaceted decision. It necessitates a comprehensive understanding of engineering principles, environmental conditions, and intended performance parameters. A proper selection strategy aligns material properties with functional requirements, ensuring optimal performance, longevity, and acoustic characteristics. Compromises made in material selection frequently translate to compromised performance or reduced lifespan, underscoring the critical importance of this aspect in the design and manufacture of high-quality automotive exhaust components.

4. Sound modulation

The manipulation of exhaust sound constitutes a primary design consideration in aftermarket automotive exhaust systems. A specialized component achieves sound modulation through strategic design elements impacting the frequency, amplitude, and tonal characteristics of the exhaust note. The internal baffling, chamber dimensions, and resonance tuning within the component influence the sound wave propagation, resulting in a customized auditory output. The choice of materials further contributes to sound modulation; for example, stainless steel may produce a sharper tone compared to titanium. A real-world instance involves the utilization of Helmholtz resonators to selectively attenuate specific frequencies, thereby mitigating unwanted drone or resonance within the vehicle cabin. This precise sound modulation offers vehicle owners the ability to personalize their driving experience based on individual preferences and regulatory constraints.

Sound modulation is an integral component in achieving the desired performance characteristics. By strategically engineering the flow path and internal structure, aftermarket exhaust systems can produce a range of auditory profiles, from subdued and refined to aggressive and pronounced. This control over sound output is frequently linked to performance aspirations, where a deeper, more authoritative tone is often associated with enhanced engine power. Manufacturers employ computational fluid dynamics and acoustic modeling to optimize sound modulation parameters, ensuring that the resulting auditory signature complements the vehicle’s overall performance and aesthetic. Such techniques demonstrate the practical application of engineering principles in achieving specific sound modulation objectives.

Effective sound modulation balances subjective aesthetic preferences with objective performance and regulatory requirements. The challenge lies in delivering a desirable auditory experience while remaining compliant with noise regulations and minimizing unwanted cabin resonance. Through careful design and material selection, specialized components can meet these competing demands, providing vehicle owners with a customized exhaust sound that enhances the driving experience without compromising legality or comfort. Understanding the principles and practices of sound modulation is thus essential for achieving a harmonious blend of performance, aesthetics, and regulatory adherence in aftermarket exhaust systems.

5. Regulatory adherence

The design and implementation of aftermarket automotive exhaust components, including customized mufflers, are subject to stringent regulatory oversight at both national and local levels. Adherence to these regulations is not merely an ancillary concern, but an integral component of responsible product development and distribution. Failure to comply with established noise emission standards and air quality mandates can result in significant penalties, including fines, product recalls, and legal liabilities. Therefore, manufacturers of specialized exhaust systems must prioritize regulatory compliance throughout the design, testing, and marketing phases. A pertinent example is the California Air Resources Board (CARB) certification process, which mandates rigorous testing to ensure that aftermarket components do not compromise vehicle emissions control systems. Products lacking CARB certification are deemed illegal for sale and use in California.

The practical significance of regulatory adherence extends beyond mere legal compliance. Components that are designed to meet or exceed established standards often exhibit superior performance and longevity. For instance, mufflers engineered to minimize backpressure while simultaneously attenuating noise to acceptable levels demonstrate a commitment to both performance enhancement and environmental responsibility. Furthermore, adherence to emissions regulations ensures that the vehicle operates within established parameters, preventing potential damage to other engine components and maintaining optimal fuel efficiency. The economic benefits of regulatory compliance, therefore, include reduced warranty claims, enhanced brand reputation, and increased customer satisfaction. The regulatory landscape also influences design innovation, prompting manufacturers to explore novel technologies and materials to achieve performance goals within established limits.

In conclusion, regulatory adherence represents a non-negotiable element in the creation and marketing of specialized exhaust components. Compliance ensures legal viability, promotes product quality and longevity, and fosters environmental responsibility. The challenges associated with navigating complex and evolving regulatory frameworks necessitate a proactive and informed approach. Manufacturers must prioritize continuous monitoring of regulatory changes, investment in testing infrastructure, and transparent communication with consumers regarding product specifications and compliance status. Ultimately, a commitment to regulatory adherence benefits all stakeholders, including manufacturers, consumers, and the broader community.

6. Vehicle Compatibility

The selection and installation of a specific aftermarket automotive exhaust component, particularly a specialized muffler, hinges critically on vehicle compatibility. This compatibility extends beyond mere physical fitment to encompass electronic systems, exhaust manifold flange geometry, and overall vehicle architecture. A mismatch can induce a cascade of adverse consequences, ranging from compromised engine performance to potential damage to associated components. For instance, a muffler designed for a four-cylinder engine, when installed on a six-cylinder engine, may induce excessive backpressure, thereby diminishing horsepower and potentially causing overheating. The initial consideration, therefore, is absolute assurance that the selected component is explicitly designed and validated for the target vehicle’s make, model, and year.

The practical implications of vehicle compatibility necessitate a thorough understanding of engineering specifications and component design. Many modern vehicles incorporate sophisticated electronic control units (ECUs) that monitor and adjust engine parameters based on exhaust system characteristics. An incompatible muffler can disrupt these carefully calibrated settings, leading to diagnostic trouble codes (DTCs), reduced fuel efficiency, and even compromised emissions control. Real-world examples abound: the installation of a universal muffler on a vehicle with a highly sensitive ECU has triggered limp-home mode, severely restricting engine performance. Therefore, adherence to manufacturer-recommended specifications and, where applicable, obtaining professional installation are paramount.

In conclusion, vehicle compatibility constitutes a non-negotiable prerequisite for the successful integration of a specialized muffler. The ramifications of incompatibility extend far beyond simple installation difficulties, potentially encompassing compromised engine performance, electronic system malfunctions, and even vehicle damage. Prioritizing meticulous component selection, adherence to manufacturer specifications, and professional installation, where warranted, serves to mitigate these risks, ensuring optimal performance and longevity. The interconnection between the muffler and the target vehicle is a holistic relationship that must be carefully considered for optimal results.

Frequently Asked Questions Regarding Designer Mufflers

The following questions address common concerns and misconceptions regarding aftermarket automotive exhaust components with emphasis on modified mufflers.

Question 1: What constitutes a “designer muffler” in the context of automotive exhaust systems?

A “designer muffler” refers to an aftermarket automotive component engineered to modify a vehicle’s exhaust sound and potentially enhance performance. These components prioritize aesthetics and performance beyond factory-installed systems.

Question 2: Do aftermarket “designer mufflers” invariably increase horsepower?

While some “designer mufflers” are designed to reduce backpressure, potentially increasing horsepower, the actual gains are contingent on factors such as engine size, aspiration method, and overall exhaust system design. Substantiated performance claims should be verified with dyno testing.

Question 3: What materials are typically employed in the construction of “designer mufflers,” and what are their respective benefits?

“Designer mufflers” are commonly manufactured from stainless steel, aluminized steel, or titanium. Stainless steel offers a balance of durability and corrosion resistance; titanium provides superior weight reduction and heat dissipation, while aluminized steel offers a budget-friendly option with moderate corrosion resistance.

Question 4: How does the design of a “designer muffler” influence its sound characteristics?

The internal baffling, chamber dimensions, and resonance tuning within a “designer muffler” influence sound wave propagation, thereby affecting the frequency, amplitude, and tonal characteristics of the exhaust note. Helmholtz resonators may be incorporated to mitigate unwanted drone or resonance.

Question 5: Are there any legal restrictions pertaining to the use of “designer mufflers”?

Yes, many jurisdictions have noise regulations and emissions standards that may restrict the use of certain aftermarket exhaust components, including “designer mufflers.” Compliance with local laws is essential.

Question 6: Does the installation of a “designer muffler” void a vehicle’s warranty?

The impact on a vehicle’s warranty depends on the manufacturer’s policies and the specific modifications made. Some modifications may void the warranty on related components, while others may have no effect. Consulting the vehicle’s warranty documentation and contacting the manufacturer is advisable.

The prudent selection and installation of a “designer muffler” necessitates a comprehensive understanding of performance claims, material properties, regulatory constraints, and vehicle-specific compatibility.

The subsequent section will address troubleshooting common issues encountered with aftermarket exhaust components.

Designer Muffler

This exploration has illuminated the multi-faceted nature of the designer muffler. It is not simply an aesthetic upgrade, but a component that can significantly influence vehicle performance, sound characteristics, and regulatory compliance. The selection and implementation of such a device necessitates a comprehensive understanding of materials science, acoustic principles, and legal frameworks. Oversimplification of these considerations can lead to suboptimal outcomes, compromised performance, or even legal repercussions.

The pursuit of enhanced automotive performance and personalized aesthetics must be tempered by a commitment to informed decision-making and responsible implementation. Continued advancements in materials technology and design methodologies promise further refinements in the capabilities and applications of the designer muffler. However, the ultimate value of this component rests upon its judicious application, guided by a clear understanding of its capabilities, limitations, and legal implications. The responsibility lies with both manufacturers and consumers to ensure that these components are utilized in a manner that promotes both performance and environmental stewardship.