The component under consideration is a specific type of exhaust system element designed to reduce noise output from an internal combustion engine. It’s a component commonly found in automobiles and other vehicles that utilize such engines, playing a crucial role in emissions control and sound modulation. Examples include aftermarket modifications intended to alter a vehicle’s auditory profile and performance characteristics.

This particular item offers potential advantages such as enhanced exhaust flow, which may lead to improved engine efficiency and power output. Its design often prioritizes durability and resistance to corrosion, extending its lifespan and reducing maintenance requirements. The product’s development reflects a growing demand for vehicle customization and a desire to personalize the driving experience, while adhering to noise regulations and performance expectations.

Further discussion will delve into specific design features, material composition, performance characteristics, and installation considerations related to this crucial automotive part. Subsequent sections will explore the impact of this component on overall vehicle performance and the factors influencing its selection and maintenance.

Guidance on Selection and Maintenance

The following recommendations are intended to facilitate informed decision-making and optimize the operational lifespan of the specified exhaust component.

Tip 1: Verify Compatibility: Prior to procurement, ensure that the unit is specifically designed for the target vehicle make, model, and year. Incompatible components may result in suboptimal performance or installation difficulties.

Tip 2: Material Consideration: Evaluate the material composition based on environmental conditions and usage patterns. Stainless steel offers superior corrosion resistance compared to aluminized steel, particularly in regions with high salt exposure.

Tip 3: Professional Installation: While self-installation may be tempting, engaging a qualified technician ensures proper fitment, alignment, and sealing, preventing exhaust leaks and potential damage to surrounding components.

Tip 4: Regular Inspection: Periodically inspect the component for signs of damage, such as dents, cracks, or excessive rust. Early detection allows for timely repairs and prevents catastrophic failures.

Tip 5: Proper Cleaning: Remove road debris, salt, and other contaminants regularly to prevent corrosion and maintain optimal performance. Mild soap and water are generally sufficient for cleaning.

Tip 6: Torque Specifications: Adhere to manufacturer-specified torque settings during installation or re-tightening of fasteners. Overtightening can lead to thread stripping or component damage.

Tip 7: Exhaust Leak Detection: Periodically check for exhaust leaks, indicated by unusual noises or a burning smell. Leaks can reduce engine efficiency, increase emissions, and pose a safety hazard.

Adherence to these guidelines contributes to the longevity, efficiency, and safe operation of the exhaust system. Neglecting these recommendations may result in premature failure and associated expenses.

The subsequent section will address frequently asked questions and provide additional resources for further information.

1. Sound Characteristics

The sonic attributes represent a key differentiator in aftermarket exhaust components. The specific design and construction of an exhaust affect the auditory experience, ranging from subtle alterations to pronounced changes in the vehicle’s sound signature.

- Frequency Modulation

This aspect refers to the alteration of sound frequencies produced by the engine. Aftermarket exhaust systems, including the series under consideration, can amplify or attenuate specific frequencies. For example, some designs emphasize lower frequencies, resulting in a deeper, more resonant sound profile, while others focus on higher frequencies, producing a sharper, more aggressive tone. This modulation impacts perceived loudness and overall auditory quality.

- Decibel Level Adjustment

Exhaust modifications directly influence the sound pressure level, measured in decibels (dB). Regulations often impose limits on vehicle noise emissions. Components that significantly increase decibel levels may violate these regulations, potentially leading to fines or restrictions. Conversely, some modifications aim to reduce noise output while maintaining acceptable performance. It is crucial to consider legal compliance when altering exhaust systems.

- Resonance Chamber Tuning

Many exhaust designs incorporate resonance chambers or Helmholtz resonators. These elements are tuned to specific frequencies to cancel out unwanted noise or enhance desired tones. Proper tuning is essential for achieving a balanced and pleasing sound profile. Incorrectly tuned resonance chambers can result in droning or other undesirable auditory artifacts. The strategic placement and dimensions of these chambers directly impact the overall sound quality.

- Material and Construction Influence

The materials used in the construction of an exhaust system significantly impact its sonic characteristics. Thicker-gauge metals tend to produce deeper, more resonant tones, while thinner-gauge metals may result in a brighter, more metallic sound. Weld quality and exhaust system geometry also contribute to the overall auditory experience. The choice of materials and construction techniques represents a critical factor in shaping the desired sound profile.

Sound characteristic selection involves balancing personal preferences with legal and performance considerations. Modifying these components must be done responsibly, considering the impact on both the vehicle and the surrounding environment. Understanding the principles of frequency modulation, decibel level adjustment, resonance chamber tuning, and material influence facilitates informed decision-making and ensures a satisfying outcome.

2. Material Composition

Material selection is a crucial determinant of the performance, durability, and longevity of an exhaust component. The composition of the materials used directly impacts its resistance to corrosion, ability to withstand high temperatures, and overall structural integrity, which subsequently affects its sound characteristics and flow dynamics.

- Stainless Steel Grades

Different grades of stainless steel, such as 304 and 409, offer varying levels of corrosion resistance. 304 stainless steel, with its higher chromium and nickel content, provides superior protection against rust and oxidation, particularly in environments with high salt exposure. While more expensive, its extended lifespan often justifies the initial investment. 409 stainless steel, being more economical, may suffice in less corrosive environments but offers reduced longevity.

- Aluminized Steel Properties

Aluminized steel, coated with a layer of aluminum, provides a cost-effective alternative to stainless steel. The aluminum coating offers a degree of corrosion protection, but it is generally less durable than stainless steel, especially when exposed to prolonged high temperatures or abrasive conditions. Aluminized steel is often selected for applications where cost considerations outweigh the need for maximum durability.

- Welding Techniques and Materials

The quality of the welds and the materials used in the welding process significantly impact the structural integrity of the exhaust component. TIG (Tungsten Inert Gas) welding, known for its precision and clean welds, is often preferred for stainless steel applications. MIG (Metal Inert Gas) welding may be used for aluminized steel. The selection of appropriate filler metals ensures compatibility with the base materials and prevents premature weld failure.

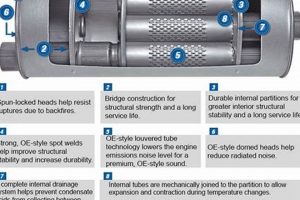

- Internal Packing Materials

The internal packing materials, such as fiberglass or ceramic wool, play a critical role in sound absorption and attenuation. These materials reduce noise levels by converting sound energy into heat. Over time, these materials can degrade due to exposure to high temperatures and exhaust gases, leading to increased noise and decreased performance. The selection of high-quality, heat-resistant packing materials ensures long-term sound control.

The choice of materials for the exhaust system component is a complex decision involving trade-offs between cost, durability, and performance. Understanding the properties and limitations of each material allows for informed selection, ensuring optimal performance and longevity in specific operating conditions. Selecting the correct material increases product performance.

3. Flow Dynamics

Flow dynamics, concerning the movement of exhaust gases through an exhaust system, are paramount to the performance of any aftermarket exhaust component. In relation to the aforementioned performance part, optimized flow characteristics contribute significantly to enhanced engine efficiency and power output.

- Backpressure Reduction

A primary goal of aftermarket exhaust systems is to reduce backpressure, the resistance to exhaust gas flow within the system. Excessive backpressure hinders the engine’s ability to expel exhaust gases efficiently, reducing volumetric efficiency and potentially limiting power output. A well-designed unit minimizes backpressure through optimized pipe diameter, smooth bends, and efficient internal baffling. Reduced backpressure translates directly to improved engine responsiveness and horsepower gains.

- Scavenging Enhancement

Scavenging refers to the process of using exhaust pulses to help draw spent gases out of the cylinders during the valve overlap period. Optimized flow dynamics can enhance scavenging by creating a vacuum effect that accelerates exhaust gas removal. This improved scavenging leads to a more complete combustion cycle, resulting in increased power and reduced emissions. The internal design of the component, including the placement and configuration of baffles, plays a crucial role in promoting effective scavenging.

- Velocity Management

Maintaining appropriate exhaust gas velocity is essential for optimal performance. High velocity ensures efficient exhaust gas removal, while excessively high velocity can create turbulence and increase backpressure. The unit’s design aims to balance velocity and pressure to maximize flow efficiency. Variances in pipe diameter and internal structure can be employed to manage exhaust gas velocity effectively.

- Turbulence Minimization

Turbulence disrupts smooth exhaust gas flow, increasing backpressure and reducing overall efficiency. The internal design of the exhaust system component should minimize turbulence through smooth transitions, gradual bends, and strategically placed baffles. A streamlined internal structure promotes laminar flow, where the exhaust gases move in parallel layers with minimal mixing or disruption. By minimizing turbulence, the exhaust system enhances engine performance and reduces exhaust noise.

These factors contribute to the overall performance characteristics of the exhaust product. The design seeks to balance backpressure reduction, scavenging enhancement, velocity management, and turbulence minimization to achieve optimal engine performance. Performance characteristics and vehicle dynamics are also impacted.

4. Vehicle Compatibility

The assurance of proper fitment and functionality constitutes a critical aspect of selecting an exhaust component. Specifically, verifying vehicle compatibility ensures the selected unit integrates seamlessly with the target vehicle’s existing exhaust system and structural architecture.

- Exhaust Port Alignment

The exhaust ports on the manifold or header must align precisely with the inlet of the aftermarket component. Misalignment leads to exhaust leaks, reduced engine performance, and potential damage to the exhaust manifold or cylinder head. Manufacturers typically provide compatibility charts specifying the vehicle makes, models, and years for which the part is designed. Confirming port alignment prevents installation complications and ensures optimal performance.

- Chassis Clearance Requirements

The selected unit must provide adequate clearance with the vehicle’s chassis, suspension components, and fuel lines. Insufficient clearance may result in rattling, vibration, and potential damage to the exhaust system or surrounding components. Careful measurement of available space and comparison with the component’s dimensions are necessary to guarantee proper fitment. Interference issues can compromise safety and longevity.

- Hanger Placement and Mounting Points

The location and orientation of exhaust hangers and mounting points must correspond with the vehicle’s existing support structure. Mismatched hangers necessitate modifications or fabrication of new mounting points, increasing installation complexity and potentially compromising structural integrity. Compatibility charts and detailed product specifications outline the hanger placement and mounting configurations, facilitating a straightforward installation process.

- Emissions Control System Integration

The aftermarket exhaust component must integrate seamlessly with the vehicle’s emissions control system, including catalytic converters and oxygen sensors. Alterations to the exhaust system can affect sensor readings and potentially trigger check engine lights or emissions failures. Compliance with local emissions regulations is paramount. Selecting components certified to meet or exceed emissions standards ensures legal compliance and minimizes environmental impact.

These aforementioned considerations underscore the importance of diligent verification prior to purchase and installation. Thoroughly confirming compatibility ensures the component performs as intended, without compromising vehicle safety, performance, or emissions compliance. Modifications and customizations should prioritize adherence to established compatibility guidelines.

5. Installation Complexity

The degree of effort and expertise required to install an exhaust system element, specifically the focus of our informative discussion is a direct consequence of its design and the vehicle it’s intended for. Several factors contribute to the difficulty, including the need for specialized tools, the accessibility of existing exhaust system components, and the precision required for a leak-free seal. Improper installation can lead to reduced performance, exhaust leaks, and potential damage to the vehicle.

For instance, a direct-fit replacement may involve simply unbolting the old component and bolting in the new one, a task achievable by a moderately skilled DIY mechanic. However, more complex installations may necessitate cutting, welding, or modifying existing exhaust hangers. The presence of seized bolts, corroded components, or limited workspace further increases the complexity and demands greater expertise. Incorrectly torqued bolts, improper alignment, or failure to use appropriate sealant can result in exhaust leaks, leading to reduced engine efficiency, increased noise, and potentially dangerous carbon monoxide exposure.

Understanding the degree of effort involved is crucial for both the installer and the end user. It helps determine whether professional installation is required, allowing for informed decision-making and budgeting. It also ensures the correct tools and materials are available, minimizing delays and potential complications. Properly installed exhaust system enhancements deliver the intended performance benefits and contribute to the vehicle’s longevity and safety.

Frequently Asked Questions

The following section addresses common inquiries and clarifies prevalent misconceptions regarding the performance, installation, and maintenance of the exhaust system component under discussion.

Question 1: What specific performance gains can be expected from installing an R Series muffler on a stock vehicle?

Performance gains vary depending on the vehicle’s engine configuration and existing exhaust system. However, typical improvements range from 5 to 15 horsepower, accompanied by enhanced throttle response. Dyno testing is recommended to quantify specific gains for individual applications.

Question 2: Does the R Series muffler require any modifications to the vehicle’s ECU or other engine control systems?

In most applications, no ECU recalibration is necessary. The design is intended to function within the parameters of the stock engine management system. However, vehicles with heavily modified engines may benefit from a custom tune to optimize performance with the aftermarket exhaust.

Question 3: Is the R Series muffler compatible with vehicles equipped with active exhaust systems?

Compatibility with active exhaust systems varies depending on the specific vehicle model. Some R Series mufflers are designed to integrate with active exhaust valves, while others require bypassing or disabling the system. Refer to the product specifications for compatibility information.

Question 4: What is the expected lifespan of an R Series muffler under normal operating conditions?

The lifespan of an R Series muffler depends on factors such as climate, driving conditions, and maintenance practices. Stainless steel models typically last 5 to 10 years, while aluminized steel models may have a shorter lifespan in corrosive environments. Regular inspection and cleaning can extend the lifespan.

Question 5: Does installing an R Series muffler void the vehicle’s factory warranty?

The impact on the factory warranty depends on the manufacturer and the specific terms of the warranty agreement. In some cases, aftermarket modifications may void portions of the warranty if they are determined to be the direct cause of a failure. Consult the vehicle’s warranty documentation for details.

Question 6: What are the legal requirements regarding noise emissions when installing an R Series muffler?

Noise emission regulations vary by locality. It is the vehicle owner’s responsibility to ensure compliance with applicable noise ordinances. The R Series muffler is designed to provide an enhanced sound profile while remaining within acceptable noise levels, but local regulations should be verified prior to installation.

In summary, proper installation, vehicle compatibility, and adherence to maintenance recommendations will optimize the benefits derived from the performance component under consideration.

The next section will provide resources for further investigation.

Conclusion

This exploration has dissected the design, function, selection, and maintenance of the Carven R Series muffler. Its impact on sound characteristics, the importance of material composition, flow dynamics optimization, vehicle compatibility verification, and the subtleties of installation complexity have been examined. This analysis provided a framework for understanding the performance potential and the factors governing its real-world application.

Ultimately, the acquisition and integration of a Carven R Series muffler necessitates a discerning evaluation of individual requirements and a commitment to informed decision-making. Proper application ensures not only enhanced vehicle dynamics but also responsible stewardship of both performance and regulatory compliance, fostering a synergy between driving experience and community standards. Future advancements should focus on sustainable materials and enhanced sound management technologies.