An exhaust system component, typically constructed from durable materials like steel, significantly reduces engine noise. It’s designed to channel exhaust gases away from the engine, minimizing sound pollution and improving vehicle emissions. A common example is a component attached to the exhaust system of automobiles, motorcycles, and other internal combustion engine vehicles.

Proper functionality of this noise-reduction part is vital for regulatory compliance and maintaining acceptable noise levels in urban and residential areas. Historically, this type of automotive part has evolved from simple metal chambers to complex multi-chambered and baffled designs, enhancing their acoustic dampening capabilities and contributing to improved fuel efficiency in some models.

The remainder of this article will discuss the selection, maintenance, and potential issues related to this kind of component, and delve into topics like performance optimization, aftermarket options, and relevant environmental considerations.

Tips for Maximizing Exhaust System Performance

Proper maintenance and understanding of exhaust system components can significantly extend lifespan and optimize vehicle performance.

Tip 1: Regular Inspection: Conduct visual checks for rust, leaks, or physical damage, especially at connection points and welds. Early detection prevents larger issues.

Tip 2: Address Unusual Noises: Investigate any rattling, hissing, or changes in exhaust tone promptly. These can indicate leaks or component failure.

Tip 3: Proper Installation: Ensure correct mounting and alignment during installation. Misalignment can cause stress and premature wear.

Tip 4: Manage Condensation: Allow the exhaust system to fully heat up during operation. Short trips encourage condensation build-up, leading to corrosion.

Tip 5: Select Quality Replacements: When replacements are necessary, choose parts manufactured from durable materials for optimal longevity.

Tip 6: Professional Servicing: Entrust complex repairs or modifications to qualified technicians to ensure proper functioning and avoid compromising vehicle safety.

Adhering to these guidelines helps to maintain exhaust system efficiency, reduce noise pollution, and extend the components operational life, ultimately benefiting vehicle performance and longevity.

The final section will summarize the core concepts discussed and provide resources for further exploration of exhaust system technology.

1. Sound Dampening Performance

Sound dampening performance represents a core functional attribute of an exhaust system component designed to minimize engine noise. This performance metric, measured in decibels (dB), directly correlates with the effectiveness of the system in attenuating the high-frequency and low-frequency sounds generated by the combustion process. Ineffective sound dampening can result in noise pollution exceeding regulatory limits, leading to legal repercussions and diminished driver and community comfort. For example, a properly engineered system will drastically reduce the sound pressure level compared to a straight-pipe exhaust, contributing to a more subdued acoustic environment.

The internal structure of a component significantly influences its sound dampening capabilities. Baffles, resonating chambers, and sound-absorbing materials (like fiberglass or steel wool) manipulate sound waves, causing destructive interference and dissipating energy. The arrangement, dimensions, and properties of these internal elements are critical to achieving targeted noise reduction across the frequency spectrum. Furthermore, the material composition and thickness of the outer shell impact the transmission of sound vibrations, influencing the overall acoustic performance.

Ultimately, effective sound dampening depends on a holistic design approach encompassing material selection, internal architecture, and precise manufacturing. A well-designed system not only reduces noise levels but also contributes to improved vehicle driveability by minimizing backpressure, a crucial factor for engine performance. Continual advancements in materials science and acoustic engineering drive the development of more efficient and durable systems, thereby balancing environmental considerations with performance demands.

2. Material Durability Standards

Material durability standards are intrinsically linked to the longevity and reliable performance of exhaust system components. These standards dictate the material properties, manufacturing processes, and testing protocols necessary to ensure these parts withstand harsh operating conditions, including extreme temperatures, corrosive exhaust gases, and physical stress. Adherence to these standards is paramount for ensuring vehicle safety, minimizing environmental impact, and reducing the frequency of component replacements.

- Corrosion Resistance

The ability of materials to resist degradation from exposure to corrosive substances, like water, road salts, and acidic exhaust byproducts, is essential. Stainless steel, aluminized steel, and specialized coatings are commonly employed to enhance corrosion resistance. Failure to meet corrosion resistance standards leads to premature rusting and structural failure, necessitating costly repairs and potentially compromising vehicle safety.

- Thermal Stability

Exhaust system components experience significant temperature fluctuations, ranging from ambient to several hundred degrees Celsius. Materials must maintain their mechanical properties and structural integrity across this temperature range. Thermal cycling can induce stress and cracking if materials with inadequate thermal stability are used. Standards dictate the allowable levels of thermal expansion and contraction to prevent failure.

- Fatigue Strength

Vibrations from the engine and road induce cyclic stress on exhaust system components, potentially leading to fatigue failure over time. Materials must possess adequate fatigue strength to withstand these repeated stresses without cracking or fracturing. Standards specify fatigue testing procedures to assess a material’s ability to endure cyclic loading under simulated operating conditions.

- Weld Integrity

Welded joints are often the weakest points in an exhaust system. Standards dictate the welding procedures, filler materials, and inspection methods required to ensure strong and durable welds. Poor weld integrity can result in leaks, structural failure, and compromised system performance. Non-destructive testing methods, such as radiographic inspection, are often employed to verify weld quality.

These facets of material durability standards are critical to the reliable operation and long lifespan of exhaust system components. By adhering to these standards, manufacturers can produce parts that withstand the rigors of automotive use, ensuring vehicle safety, reducing environmental impact, and minimizing the need for frequent replacements, therefore increasing “romana muffler” performance

3. Exhaust Gas Flow

Exhaust gas flow represents a fundamental performance characteristic inextricably linked to the functionality of noise-reduction components within vehicle exhaust systems. Restriction of exhaust gas flow directly influences engine efficiency and power output. A properly designed system, including the sound-attenuating features, minimizes backpressure while effectively reducing noise emissions. Excessive backpressure impedes the expulsion of exhaust gases from the engine cylinders, resulting in reduced volumetric efficiency, increased fuel consumption, and diminished overall engine performance. For example, a severely clogged sound-reduction component will demonstrably restrict exhaust gas flow, leading to a noticeable decrease in engine power and fuel economy.

The internal geometry and materials selection of sound-attenuating devices play critical roles in determining exhaust gas flow characteristics. Baffles, perforations, and chamber designs are carefully engineered to balance sound attenuation with minimal flow restriction. The size, shape, and placement of these internal elements are optimized to promote laminar flow and minimize turbulence, reducing pressure drop across the component. Materials with smooth internal surfaces and minimal flow obstructions are preferred to further enhance gas flow efficiency. Consider a scenario where a sound-reduction part designed with improperly sized or positioned baffles creates significant turbulence, resulting in a substantial increase in backpressure and decreased engine performance. Conversely, a well-designed component facilitates smooth exhaust gas flow while effectively reducing noise levels.

Effective management of exhaust gas flow is paramount for achieving optimal engine performance and minimizing emissions. A well-designed system minimizes backpressure, promotes efficient combustion, and reduces fuel consumption. By understanding the relationship between exhaust gas flow and sound-attenuating components, engineers can develop systems that effectively balance noise reduction with performance demands. Addressing flow restriction is essential for optimizing engine efficiency, reducing emissions, and maintaining the overall performance and lifespan of a vehicle’s exhaust system.

4. Vehicle Compatibility

Vehicle compatibility represents a critical determinant in the effective application and performance of exhaust noise-reduction components. Incompatibility can lead to compromised vehicle performance, potential damage to other systems, and failure to meet regulatory standards. Accurate assessment of vehicle-specific requirements is paramount for selecting appropriate parts.

- Engine Size and Configuration

Engine displacement and cylinder configuration influence the required flow rate and backpressure characteristics of the exhaust system. A component designed for a small inline-four engine will likely be unsuitable for a large V8, potentially causing excessive backpressure and reduced performance. Conversely, an overly large component may not provide sufficient sound attenuation on a smaller engine.

- Vehicle Model and Year

Exhaust system designs often vary significantly across different vehicle models and model years, even within the same manufacturer’s lineup. Differences in chassis design, engine placement, and emissions control systems necessitate specific component geometries and mounting configurations. Installing a component intended for an incompatible vehicle model may require extensive modifications, potentially compromising structural integrity and emissions compliance.

- Emissions Standards Compliance

Vehicles certified to different emissions standards (e.g., Euro 6, EPA Tier 3) may require specific exhaust system components to meet regulatory requirements. Installing a non-compliant component can result in failed emissions tests and legal penalties. Some components may incorporate catalytic converters or other emissions control devices that are tailored to specific engine families and emissions standards.

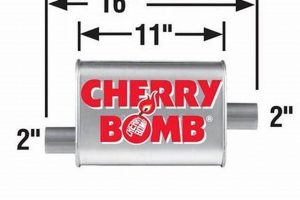

- Mounting and Dimensional Constraints

Physical space limitations within the vehicle chassis impose constraints on the size, shape, and orientation of exhaust system components. A component that is physically too large or has an incompatible mounting configuration cannot be properly installed. Accurate measurements and consideration of available space are crucial for selecting a compatible component.

These considerations underscore the importance of verifying vehicle compatibility before selecting or installing any exhaust system component. Failure to do so can result in performance degradation, damage to other vehicle systems, and non-compliance with emissions regulations. Careful attention to these factors is essential for ensuring the proper function and longevity of the entire exhaust system.

5. Installation Requirements

Proper installation is crucial for realizing the intended performance and longevity of an exhaust noise-reduction component. Adherence to specified procedures and the use of appropriate hardware are essential for ensuring a secure, leak-free, and functional exhaust system. Deviations from recommended practices can lead to compromised performance, premature component failure, and potential safety hazards.

- Component Alignment and Support

Correct alignment of the component with the exhaust piping is essential to prevent stress on the joints and ensure proper exhaust flow. Adequate support, using hangers and brackets, is necessary to minimize vibration and prevent premature wear. Misalignment can lead to leaks, while inadequate support can cause fatigue failure due to excessive stress.

- Sealing and Gasket Integrity

Proper sealing at all connection points is critical for preventing exhaust leaks. The use of new gaskets and sealants, specified for high-temperature exhaust applications, is recommended. Worn or damaged gaskets should be replaced to ensure a leak-free seal. Exhaust leaks can result in reduced engine performance, increased noise levels, and potentially harmful emissions.

- Torque Specifications and Fastener Selection

Proper tightening of fasteners to the manufacturer’s specified torque is essential for ensuring a secure and leak-free connection. Over-tightening can damage the component or fasteners, while under-tightening can result in leaks and loosening over time. The use of correct fastener types, compatible with high-temperature environments, is also important to prevent corrosion and failure.

- Clearance and Heat Shielding

Adequate clearance between the component and surrounding vehicle components is necessary to prevent overheating and potential fire hazards. Heat shields should be installed where necessary to protect sensitive components from excessive heat exposure. Insufficient clearance can lead to damage to nearby components, while inadequate heat shielding can increase the risk of fire.

Ignoring these installation requirements can undermine the functionality and lifespan of the noise-reduction component, potentially negating its intended benefits. Proper installation ensures that the component performs as designed, contributing to reduced noise pollution, optimal engine performance, and long-term reliability of the exhaust system. Consistent adherence to recommended installation practices is vital for maximizing the effectiveness and durability.

6. Regulatory Compliance

Regulatory compliance forms a cornerstone of the design, manufacturing, and utilization of exhaust system components, particularly concerning noise reduction. Governmental bodies establish noise emission standards for vehicles to mitigate noise pollution in urban and residential areas. Failure to meet these standards can result in significant penalties for manufacturers and vehicle operators alike. Noise-reduction mufflers are therefore engineered to ensure vehicles operate within legally mandated decibel limits. For example, many European countries enforce strict noise level regulations, requiring vehicles to undergo testing to demonstrate compliance before being permitted on public roads. The implementation of these components directly addresses the legal obligation to minimize environmental noise impact.

The design and materials used in the construction of a muffler are often influenced by regulatory requirements concerning both noise and emissions. Stringent regulations often necessitate complex internal baffling and the use of specialized sound-absorbing materials. Additionally, regulations concerning material content, such as restrictions on lead or asbestos, may impact material selection. As regulations evolve to address emerging environmental concerns, manufacturers must adapt their designs and materials to maintain compliance. The real-world impact can be seen in the evolution of muffler designs, incorporating increasingly sophisticated technologies to achieve noise reduction targets while also meeting emissions standards.

Ultimately, regulatory compliance ensures that vehicles operate within acceptable noise levels, promoting public health and minimizing environmental disturbance. While the challenge of meeting increasingly stringent regulations pushes technological advancements, it also presents economic considerations for manufacturers. A thorough understanding of regulatory requirements is thus essential for all stakeholders involved in the design, production, and operation of vehicles, including designers, engineers, and policy makers, ensuring the benefits are received while meeting the performance of romana muffler.

7. Corrosion Resistance

Corrosion resistance is a critical attribute of exhaust system components, especially for those designed to reduce noise. The operating environment of an exhaust system exposes it to a wide range of corrosive agents, including water, road salts, and acidic byproducts of combustion. Premature degradation of components due to corrosion compromises their structural integrity and acoustic performance, directly impacting the effectiveness of the noise-reduction system. For example, rust-through in a muffler can create holes and gaps, allowing exhaust gases to escape without proper attenuation, increasing noise emissions and violating regulatory standards. The selection of materials with high corrosion resistance is, therefore, paramount in the design and manufacturing of these components.

The use of materials such as stainless steel or aluminized steel significantly enhances the resistance to corrosion. Stainless steel alloys contain chromium, which forms a passive oxide layer that protects the underlying metal from further degradation. Aluminized steel is coated with a layer of aluminum that provides a sacrificial barrier, corroding in preference to the steel substrate. These materials not only extend the lifespan of the exhaust system but also maintain its noise-reduction performance over time. Without adequate corrosion resistance, components require more frequent replacements, increasing vehicle maintenance costs and environmental impact. The automotive industry standard reflects that exhaust systems must endure many years and miles of driving in diverse environments without significant corrosion-related failure.

The connection between corrosion resistance and the lifespan and performance of noise-reducing mufflers is direct and undeniable. Adequate corrosion resistance is essential to ensure continued compliance with noise regulations, maintaining vehicle efficiency, and minimizing long-term ownership expenses. Choosing quality, corrosion-resistant components represents a sound investment in the longevity and reliable operation of the vehicle.

Frequently Asked Questions About Noise Reduction Components

This section addresses common inquiries regarding noise reduction exhaust components, clarifying their function, maintenance, and regulatory considerations.

Question 1: What is the primary function of a noise-reduction component in an exhaust system?

The primary function is to attenuate engine noise, reducing the sound pressure level emitted by a vehicle and ensuring compliance with local noise regulations. It achieves this by employing internal structures that manipulate and dissipate sound waves.

Question 2: How often should a noise-reduction exhaust component be inspected?

A visual inspection should be conducted at least annually, or more frequently in regions with harsh environmental conditions, to check for signs of corrosion, leaks, or physical damage. Early detection of problems prevents more costly repairs.

Question 3: What are the common signs of a failing noise reduction device?

Common indicators include increased exhaust noise, rattling sounds, hissing noises, reduced engine performance, and visible signs of rust or physical damage. Any of these symptoms warrant further investigation.

Question 4: Can a high-performance exhaust system still comply with noise regulations?

Yes, if the system is designed with effective sound-attenuation technologies and meets the noise emission standards established by the relevant regulatory agencies. Performance and compliance are not mutually exclusive.

Question 5: What materials are commonly used in the construction of noise reduction exhaust parts?

Common materials include stainless steel, aluminized steel, and coated steel, chosen for their durability, corrosion resistance, and ability to withstand high temperatures. The specific material depends on the application and budget.

Question 6: Does the size of an engine affect the type of component required?

Yes, engine size and configuration significantly influence the type of device needed. Larger engines require larger components with greater flow capacity and more effective sound attenuation capabilities.

Regular inspections and prompt attention to any signs of failure are essential for maintaining optimal noise reduction performance and compliance with regulations.

The next section will focus on advancements in exhaust system technology and future trends in noise reduction.

Conclusion

This exploration of the noise-reduction muffler has underscored its pivotal role in mitigating vehicular noise pollution, enabling regulatory compliance, and optimizing engine performance. Key aspects examined included material durability, exhaust gas flow dynamics, vehicle compatibility considerations, and the imperative of adherence to established installation protocols.

The sustained importance of this component mandates ongoing research and development to further enhance acoustic dampening capabilities while simultaneously minimizing backpressure. Continued innovation is essential to meet increasingly stringent environmental standards and secure a more sustainable future for automotive technology. The long-term effectiveness requires diligent maintenance and informed decision-making regarding replacements, ensuring consistent noise reduction and responsible vehicle operation.