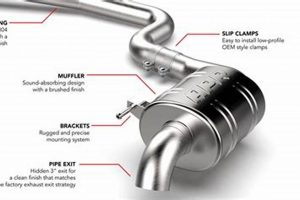

The internal architecture of an aftermarket exhaust component, specifically one manufactured by Magnaflow, significantly affects its performance characteristics. This internal design dictates the flow of exhaust gases, influencing backpressure, sound levels, and overall engine efficiency. Variations in chamber size, baffle placement, and core design contribute to the unique attributes of each muffler model.

Optimizing this internal configuration yields several advantages, including enhanced horsepower and torque, a distinctive exhaust note, and improved fuel economy. Historically, advancements in muffler technology have focused on balancing these performance aspects while minimizing undesirable noise pollution. Effective internal design also contributes to the longevity of the component by managing heat dissipation and reducing the likelihood of corrosion.

Understanding the principles of exhaust gas dynamics within these systems is crucial for appreciating the impact of design choices. The following sections will delve into specific aspects of muffler construction, focusing on materials, core types, and the scientific principles governing their operation. This exploration will provide a detailed perspective on how these elements combine to achieve desired performance outcomes.

Guidance on Internal Muffler Assessment and Maintenance

The following guidance pertains to the examination and upkeep of the internal components influencing exhaust system performance. These considerations are critical for ensuring longevity and optimal function.

Tip 1: Material Compatibility is Paramount: When replacing internal components, ensure compatibility with the existing system’s materials. Dissimilar metals can lead to galvanic corrosion, reducing system lifespan and performance.

Tip 2: Core Design Influences Performance: The internal core design directly affects exhaust flow characteristics. A perforated core promotes smoother flow compared to baffled designs, potentially increasing horsepower while mitigating backpressure.

Tip 3: Chamber Size Affects Sound Profile: Chamber size plays a critical role in modulating the exhaust note. Larger chambers generally produce lower frequencies, resulting in a deeper sound.

Tip 4: Baffle Placement Alters Sound Dynamics: Baffle placement strategically redirects exhaust gases, influencing tone and volume. Modified baffle configurations can alter the system’s sonic signature.

Tip 5: Regular Inspection Prevents Degradation: Periodic inspection of internal components for corrosion, cracks, or obstructions is crucial for maintaining optimal performance and preventing costly repairs.

Tip 6: Proper Welding Techniques are Essential: When welding internal components, employ proper techniques to ensure strong, leak-proof joints. Improper welding can compromise structural integrity and lead to exhaust leaks.

Tip 7: Consider Flow Directionality: Confirm proper flow directionality when installing internal components. Incorrect orientation can significantly impede exhaust flow and diminish performance.

These considerations highlight the importance of meticulous assessment and maintenance. Adherence to these guidelines ensures sustained optimal performance and prolonged system lifespan.

The subsequent sections will delve into specific scenarios and troubleshooting techniques related to internal muffler maintenance, providing practical solutions for common issues.

1. Chamber volume

Chamber volume, within the context of a Magnaflow muffler, directly correlates to its sound-attenuation capabilities and the resultant exhaust note. The internal chambers act as resonators, influencing the frequencies that are dampened or amplified. Larger chamber volumes generally lead to the suppression of higher frequencies, yielding a deeper, lower-pitched exhaust sound. Conversely, smaller chamber volumes are less effective at attenuating higher frequencies, potentially resulting in a raspy or tinny exhaust note. The dimensions of these chambers are engineered to target specific frequency ranges, contributing to the overall acoustic profile of the muffler. Therefore, the careful consideration of chamber volume is crucial in achieving the desired sound characteristic.

The relationship between chamber volume and exhaust note is demonstrable across the Magnaflow product line. For instance, their larger “Magnapack” mufflers, designed for high-performance applications, typically feature larger internal chambers to produce a deep, throaty rumble. Conversely, smaller, more compact mufflers may utilize smaller chambers to achieve a more aggressive, high-pitched sound, often preferred in sport compact vehicles. These design choices are not arbitrary; they are predicated on the principles of acoustics and are tailored to meet the specific needs of different vehicle types and driver preferences. The selection of an appropriate muffler with suitable chamber volume is a key factor in achieving a harmonious blend of performance and sound.

In summary, chamber volume represents a fundamental design parameter within a Magnaflow muffler, exerting significant influence over its sonic signature. Optimizing chamber volume is essential for achieving the desired balance between sound quality and performance characteristics. Challenges in this process include accurately predicting the acoustic behavior of complex chamber geometries and accounting for variations in vehicle exhaust systems. However, a thorough understanding of this relationship remains critical for both muffler manufacturers and consumers seeking to fine-tune their exhaust systems.

2. Perforated core

The perforated core is a critical component of many Magnaflow mufflers, directly influencing exhaust gas flow and sound attenuation. Its design and materials impact performance and durability.

- Flow Optimization

The primary function of a perforated core is to facilitate the smooth passage of exhaust gases. The perforations allow exhaust to flow through the core while also interacting with the surrounding sound-absorbing materials. A well-designed perforated core minimizes backpressure, which can improve engine efficiency and power output. Examples include straight-through designs with consistent hole patterns for minimal restriction.

- Sound Attenuation Mechanics

The perforations in the core enable exhaust gases to enter the muffler’s internal chamber, where sound waves are partially absorbed and cancelled out. The size and density of the perforations affect the range of frequencies that are attenuated. Denser perforation patterns may be employed in areas where higher frequencies need to be dampened. This process converts acoustic energy into thermal energy, reducing exhaust noise.

- Material Properties and Durability

The material used for the perforated core, often stainless steel, must withstand high temperatures, corrosive exhaust gases, and vibrations. Stainless steel cores offer superior durability compared to aluminized steel, extending the lifespan of the muffler. Corrosion resistance is crucial to prevent the core from degrading and obstructing exhaust flow over time. The thickness of the core material also influences its resistance to mechanical failure.

- Impact on Tone Characteristics

The geometry and design of the perforations also influence the quality and character of the exhaust sound. Different perforation patterns can emphasize certain frequencies or create a smoother, more refined exhaust note. Some designs incorporate variations in perforation size or spacing to achieve specific acoustic effects. These subtle differences contribute to the distinct sound profiles associated with different Magnaflow models.

The perforated core is an integral element within the Magnaflow muffler, seamlessly integrating flow optimization, sound dampening, and material robustness. Its design directly impacts the overall performance and acoustic signature, exemplifying the critical engineering considerations involved in effective muffler technology.

3. Sound absorption

Sound absorption within a Magnaflow muffler is a critical factor in determining the exhaust system’s overall noise reduction and tonal characteristics. This process involves the conversion of acoustic energy into other forms of energy, primarily thermal, through interactions with specific materials and structural designs inside the muffler. The effectiveness of this absorption directly affects the levels of undesirable frequencies that are attenuated, thereby shaping the final exhaust note. The interior of a Magnaflow muffler is typically engineered with sound-absorbing materials, such as fiberglass packing or strategically designed chambers, to maximize this energy conversion. The type, density, and placement of these materials are meticulously calculated to target specific frequency ranges, resulting in a controlled and refined sound output.

The design of the perforated core, discussed previously, also plays a significant role in sound absorption. As exhaust gases pass through the perforations, sound waves are directed into the surrounding absorption material. This creates an environment where acoustic energy is dissipated as the waves interact with the fibrous structure of the packing material. Variations in the perforation pattern and the proximity to the absorption material can be tailored to optimize sound absorption for different engine types and desired exhaust tones. For example, high-performance applications often utilize less sound absorption to maximize exhaust flow, resulting in a louder, more aggressive sound. Conversely, street-oriented mufflers employ greater sound absorption to reduce noise levels and comply with local regulations. Real-world applications demonstrate that improper sound absorption can lead to drone, excessive noise, and decreased performance.

Effective sound absorption in a Magnaflow muffler is a complex interplay of material properties, internal design, and exhaust gas dynamics. Optimizing this process requires careful consideration of these factors to achieve the desired balance between noise reduction, performance, and sound quality. The challenge lies in accurately predicting the acoustic behavior within the muffler and adapting the design to meet specific vehicle and driver requirements. Therefore, a thorough understanding of sound absorption principles is essential for both muffler manufacturers and consumers seeking to enhance their exhaust systems. The evolution of sound-absorbing materials and design techniques continues to be a central focus in the ongoing development of more efficient and sophisticated muffler technologies.

4. Baffle design

Baffle design within a Magnaflow muffler directly impacts exhaust gas flow, sound wave manipulation, and overall performance characteristics. Baffles are internal components strategically positioned to redirect exhaust gases, creating interference patterns that attenuate specific frequencies. Variations in baffle shape, size, and placement determine the resulting exhaust note and the level of backpressure generated within the system. A poorly designed baffle configuration can lead to undesirable drone, reduced horsepower, and increased fuel consumption. Conversely, an optimized baffle design effectively manages sound levels while maintaining acceptable performance metrics. Magnaflow utilizes various baffle designs, including chambered baffles, louvered baffles, and perforated baffles, each offering distinct advantages and disadvantages depending on the application.

The practical significance of baffle design is evident in the distinct sound profiles and performance capabilities of different Magnaflow muffler models. For example, mufflers intended for high-performance applications often incorporate minimal baffling to maximize exhaust flow, prioritizing horsepower gains over noise reduction. In contrast, mufflers designed for daily driving scenarios typically feature more extensive baffling to achieve a quieter, more refined exhaust note. The selection of an appropriate baffle design necessitates a careful balance between performance considerations and noise level requirements. Case studies involving vehicle-specific muffler replacements consistently demonstrate the influence of baffle design on both measured horsepower and subjective sound evaluations. A change in baffle configuration can transform a droning, inefficient exhaust system into a smooth, high-performing one.

In summary, baffle design constitutes a crucial element of a Magnaflow muffler, directly impacting its performance and acoustic properties. The strategic placement and configuration of baffles determine the effectiveness of sound wave attenuation and the level of backpressure within the exhaust system. The challenge lies in optimizing baffle design to achieve the desired balance between performance, noise reduction, and vehicle-specific requirements. Further advancements in baffle technology continue to focus on innovative designs that minimize backpressure while maximizing sound control, ultimately enhancing the driving experience.

5. Welding integrity

Welding integrity is paramount to the structural soundness and long-term performance of a Magnaflow muffler. Deficiencies in weld quality can lead to premature failure, compromising exhaust system efficiency and potentially causing safety concerns. The internal components, secured primarily through welding, rely on these bonds to withstand the harsh conditions of exhaust gas flow, extreme temperatures, and constant vibration.

- Structural Stability

Welding provides the primary means of connecting the internal components within a Magnaflow muffler, such as the core, baffles, and end caps. Sound welds ensure that these components remain securely in place, preventing rattling, shifting, or detachment. For example, a failure in the weld securing a baffle can cause it to break loose and obstruct exhaust flow, significantly reducing engine performance. The implications extend to noise levels; a loose baffle will generate unwanted rattling sounds.

- Leak Prevention

A critical function of welding in muffler construction is to create a gas-tight seal. Imperfect welds can result in exhaust leaks, leading to reduced engine efficiency, increased noise pollution, and the potential introduction of harmful gases into the vehicle’s cabin. Instances of pinhole leaks or incomplete welds can be detected through visual inspection or the application of soapy water, revealing bubbles indicating escaping exhaust gases. Real-world examples often highlight the necessity of consistent, high-quality welds to maintain the integrity of the exhaust system.

- Corrosion Resistance

The type of welding process and the filler material used directly impact the corrosion resistance of the welded joints. Incompatible welding materials can create galvanic corrosion, accelerating the deterioration of the joint and weakening its structural integrity. Magnaflow typically utilizes stainless steel welding techniques to ensure compatibility with the muffler’s stainless steel components. The implementation of proper welding procedures minimizes the risk of corrosion and extends the lifespan of the muffler. Case studies demonstrate that substandard welding practices can significantly reduce the service life of exhaust systems.

- Vibration Fatigue Mitigation

Exhaust systems are subjected to constant vibrations from the engine, which can induce fatigue cracking in poorly executed welds. Proper welding techniques, including adequate penetration and fusion, are essential to create strong, durable joints capable of withstanding these vibrational stresses. Examples of vibration-induced weld failures are common in exhaust systems that have been subjected to prolonged use under demanding conditions. Reinforcement welds or strategically placed support brackets can further mitigate the risk of fatigue cracking, ensuring the long-term reliability of the muffler.

The connection between welding integrity and the longevity and performance of a Magnaflow muffler is undeniable. Proper welding techniques, compatible materials, and stringent quality control measures are vital for ensuring that the internal components remain securely in place, preventing leaks, resisting corrosion, and withstanding vibrational stresses. Substandard welding compromises these factors, leading to premature failure and diminishing the value of the aftermarket exhaust component.

6. Material durability

The correlation between material durability and the performance longevity of a Magnaflow muffler is direct and consequential. The internal components, subjected to extreme thermal cycling, corrosive exhaust gases, and constant vibration, require robust materials capable of withstanding these demanding conditions. Premature material failure directly impacts the muffler’s ability to maintain its designed performance characteristics, including sound attenuation and exhaust flow. The use of high-quality materials, such as austenitic stainless steel, is therefore critical to ensuring extended service life and consistent operation. Instances of utilizing less durable materials, like aluminized steel, demonstrate a significantly reduced lifespan, particularly in regions with harsh climates or high road salt usage.

The choice of materials for the perforated core, baffles, and internal chambers dictates the muffler’s resistance to corrosion, erosion, and mechanical fatigue. Stainless steel, for example, exhibits superior corrosion resistance compared to carbon steel, mitigating the risk of rust and subsequent structural weakening. Similarly, the thickness and grade of the steel employed influence its ability to withstand vibrational stresses and thermal expansion without cracking or warping. The practical application of this understanding is evident in the varying warranty periods offered by Magnaflow for different muffler models, reflecting the anticipated service life based on the materials used in their construction. Mufflers constructed with higher-grade stainless steel typically carry longer warranties, reflecting the manufacturer’s confidence in their durability.

In conclusion, material durability is not merely a desirable attribute but a fundamental requirement for a Magnaflow muffler to deliver consistent performance over an extended period. The selection of appropriate materials, carefully considering their resistance to heat, corrosion, and mechanical stress, directly translates to the muffler’s lifespan and its ability to maintain its intended acoustic and performance characteristics. The challenge lies in balancing material costs with the need for long-term durability, a consideration that informs Magnaflow’s product design and manufacturing decisions. Recognizing the practical significance of this connection enables informed purchasing decisions, ensuring the selected muffler aligns with the vehicle’s usage and the owner’s expectations for long-term reliability.

Frequently Asked Questions

The following addresses common inquiries regarding the internal components and functionality that determine the performance characteristics of Magnaflow mufflers.

Question 1: What constitutes the primary function of the internal perforations within a Magnaflow muffler?

The internal perforations facilitate the controlled passage of exhaust gases, minimizing backpressure while simultaneously directing sound waves towards the sound-absorbing materials. This dual-function design is critical for balancing performance and noise reduction.

Question 2: How does the volume of internal chambers influence the sound characteristics of a Magnaflow muffler?

The volume of the internal chambers directly correlates with the frequencies attenuated by the muffler. Larger chambers typically suppress higher frequencies, resulting in a deeper, lower-pitched exhaust note. Smaller chambers have less impact on high frequencies and may produce a raspy tone.

Question 3: What materials are commonly used for the internal components of a Magnaflow muffler, and why?

Austenitic stainless steel is commonly employed due to its superior resistance to corrosion from exhaust gases and its ability to withstand high temperatures. This material choice ensures longevity and consistent performance under demanding operating conditions.

Question 4: How does the baffle design contribute to the overall performance of a Magnaflow muffler?

Baffles are strategically placed to redirect exhaust gases and create interference patterns that attenuate specific frequencies. The shape, size, and placement of baffles influence the exhaust note and the level of backpressure, requiring a careful balance to optimize performance and noise reduction.

Question 5: What are the potential consequences of compromised welding integrity within a Magnaflow muffler?

Compromised welding integrity can lead to exhaust leaks, component detachment, and structural failure. These issues can result in reduced engine efficiency, increased noise pollution, and potential safety hazards. Regular inspection and proper welding techniques are vital for maintaining the muffler’s integrity.

Question 6: How does the sound absorption material contribute to the performance and longevity of the exhaust system?

Sound absorption materials reduce unwanted noise by converting sound waves into thermal energy. The effectiveness of these materials, along with proper maintenance and inspection, prevents excessive noise, reduces wear on other exhaust components, and maintains optimal vehicle efficiency.

Understanding these internal aspects is essential for appreciating the engineering behind Magnaflow mufflers and for making informed decisions regarding exhaust system upgrades.

The subsequent sections will provide detailed information on specific Magnaflow muffler models and their applications.

Conclusion

This exploration of “inside magnaflow muffler” reveals the intricate engineering that governs its performance. The strategic configuration of chambers, cores, baffles, and sound-absorbing materials directly impacts exhaust gas flow, sound attenuation, and overall system durability. Material selection and welding integrity are paramount in ensuring long-term reliability under demanding operating conditions. Optimizing these internal elements allows for achieving a balance between performance enhancement and noise mitigation.

Continued research and development in muffler technology will undoubtedly yield further refinements in internal design. Understanding these principles allows for a greater appreciation of exhaust system engineering and enables informed decisions regarding system selection and maintenance. Therefore, the internal dynamics dictate not only the sound but also the functional lifespan of the after-market exhaust components.