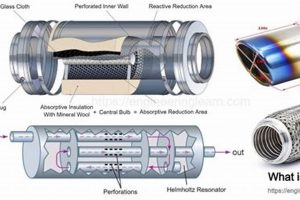

This component, typically found in exhaust systems, is designed to reduce noise generated by an internal combustion engine. Functioning through a series of chambers and baffles, it redirects and diffuses sound waves, decreasing their amplitude before they exit the tailpipe. An example would be its application in minimizing the auditory disturbance created by high-performance vehicles.

The significance of this device lies in its contribution to noise pollution control and regulatory compliance. By effectively dampening exhaust sounds, it enhances the overall driving experience and mitigates environmental impact. Historically, its development has been closely tied to evolving noise regulations and public demand for quieter vehicles, leading to continuous advancements in its design and materials.

The subsequent sections will delve into the specific types available, their impact on engine performance, and best practices for their maintenance and selection. Further discussion will explore the technological innovations driving their future development and integration with advanced vehicle systems.

Guidance on Muffler Systems

This section provides essential guidelines for understanding, maintaining, and selecting exhaust noise reduction systems to ensure optimal performance and longevity.

Tip 1: Select the Appropriate System. Prioritize selection based on vehicle type, engine specifications, and intended use. Systems designed for high-performance applications may differ significantly from those suitable for standard vehicles. Misapplication can lead to inefficiencies or damage.

Tip 2: Conduct Regular Inspections. Routine visual checks for corrosion, physical damage, and exhaust leaks are essential. Early detection of issues can prevent more extensive and costly repairs.

Tip 3: Address Unusual Noises Promptly. A change in exhaust sound, such as rattling or hissing, may indicate internal damage or leaks. Investigate and resolve these issues without delay to avoid further degradation.

Tip 4: Ensure Proper Installation. Improper installation can compromise the effectiveness of the system and potentially damage other vehicle components. Adhere strictly to manufacturer guidelines or seek professional assistance.

Tip 5: Consider Material Composition. The materials used in its construction impact its durability and resistance to corrosion. Stainless steel and aluminized steel offer superior protection compared to standard steel, particularly in harsh environments.

Tip 6: Prioritize OEM or Reputable Aftermarket Brands. Opt for original equipment manufacturer (OEM) parts or established aftermarket brands known for their quality and performance. Avoid generic or unverified components that may not meet required standards.

Consistent adherence to these guidelines will ensure the prolonged effectiveness and optimal performance of the exhaust noise reduction system. Proper maintenance and informed selection are critical for maximizing benefits.

The next section will address common misconceptions about these systems and offer clarification based on current research and engineering practices.

1. Noise Reduction Effectiveness

Noise Reduction Effectiveness, as it pertains to exhaust systems, is a measurable parameter indicating the degree to which a component diminishes sound pressure levels. This effectiveness is intrinsically linked to the design and functionality of exhaust noise reduction devices, influencing vehicle acoustics and regulatory compliance.

- Internal Baffle Design

The configuration of internal baffles within a device significantly influences its noise reduction capabilities. Baffles strategically redirect sound waves, causing destructive interference and energy dissipation. Effective designs maximize surface area for sound absorption and minimize direct pathways for noise propagation, thereby enhancing noise reduction.

- Chamber Resonance and Helmholtz Effect

Resonance chambers utilize the Helmholtz effect to selectively attenuate specific frequencies. The dimensions and shapes of these chambers are engineered to counteract prominent exhaust frequencies, creating a dampening effect. The precision of chamber tuning directly impacts its ability to reduce targeted noise levels.

- Sound Absorption Materials

The utilization of sound-absorbing materials, such as fiberglass or mineral wool, within exhaust noise reduction devices contributes to noise reduction. These materials convert sound energy into heat through frictional losses, effectively reducing the amplitude of sound waves traveling through the system. The density and composition of these materials influence their absorption coefficient across different frequencies.

- Perforation Patterns and Gas Flow Dynamics

Perforated tubes and plates within a component manage gas flow and facilitate sound wave interaction with absorption materials. The size, density, and arrangement of perforations optimize the balance between exhaust gas flow and sound attenuation. Inefficient perforation patterns can impede gas flow, leading to increased backpressure, while inadequate perforation can compromise noise reduction.

The interplay of these design elements dictates the overall Noise Reduction Effectiveness. Maximizing this effectiveness requires a holistic approach, considering the specific acoustic characteristics of the engine, regulatory requirements, and the desired auditory experience within the vehicle cabin.

2. Backpressure Impact

The installation of an exhaust noise reduction device introduces a degree of backpressure within the exhaust system. Backpressure, defined as the resistance to exhaust gas flow, is intrinsically linked to the internal design of the device. The complex network of chambers, baffles, and perforations, designed to attenuate sound waves, inherently restricts the free flow of exhaust gases, causing an increase in pressure upstream. Excessive backpressure can negatively affect engine performance, specifically volumetric efficiency and power output. An example is observed in turbocharged engines, where excessive backpressure can impede turbine function, reducing boost pressure and overall engine responsiveness. Therefore, careful consideration of backpressure is paramount in system design.

The relationship between the design and backpressure is often a trade-off. Effective noise reduction typically necessitates a more complex internal structure, leading to increased resistance. However, advancements in computational fluid dynamics (CFD) and material science have enabled the development of optimized designs that minimize backpressure while maintaining acceptable noise attenuation levels. For instance, the utilization of larger diameter tubing and strategically placed perforations can reduce flow restriction without compromising noise reduction capabilities. The choice of material, specifically its smoothness and thermal conductivity, can also play a role in minimizing backpressure by reducing friction and promoting efficient heat dissipation.

Minimizing backpressure impact is crucial for maintaining optimal engine performance and fuel efficiency. The selection of an exhaust noise reduction device requires a balanced approach, considering both its noise reduction effectiveness and its impact on backpressure. Regular monitoring of engine performance parameters, such as manifold pressure and exhaust gas temperature, can provide insights into potential backpressure issues. In summary, understanding the interrelationship between exhaust noise reduction technology and backpressure is essential for informed decision-making in vehicle design and modification, ensuring compliance with noise regulations without sacrificing engine performance.

3. Material Durability

Material durability, within the context of exhaust noise reduction systems, dictates the service life and long-term performance of these components. The materials employed must withstand a combination of high temperatures, corrosive exhaust gases, and environmental factors to ensure consistent noise attenuation and structural integrity.

- Corrosion Resistance

The exhaust stream contains corrosive byproducts of combustion, including acids and water vapor. Materials with inherent corrosion resistance, such as stainless steel, prolong the component’s lifespan. Premature failure due to corrosion leads to exhaust leaks and diminished noise reduction effectiveness. An example includes the degradation of standard steel systems in regions with heavy road salt usage, resulting in rapid rust and eventual structural failure.

- Thermal Stability

Exhaust systems experience significant temperature fluctuations. Materials must maintain their mechanical properties and resist deformation at elevated temperatures. Inadequate thermal stability can lead to cracking, warping, and weakening of structural welds, reducing noise reduction efficiency and potentially causing system failure. High-performance vehicles, which generate higher exhaust temperatures, necessitate materials with superior thermal stability.

- Vibration Fatigue Resistance

The constant vibration generated by the engine and road conditions induces fatigue stress on the system. Materials with high fatigue strength resist crack propagation and structural failure over extended periods. Systems constructed from low-grade materials are susceptible to premature failure due to vibration-induced fatigue, particularly at weld points and mounting locations. Proper design and material selection mitigate the risk of fatigue failure.

- Abrasion Resistance

Road debris and particulate matter can impact the exterior of the system, causing abrasion and erosion. Materials with high abrasion resistance maintain their structural integrity and resist thinning due to external wear. Systems exposed to harsh environmental conditions, such as off-road vehicles, require materials with enhanced abrasion resistance to prevent premature failure.

The synergistic effect of these durability characteristics directly influences the lifespan and effectiveness of exhaust noise reduction components. Selecting materials optimized for these specific conditions ensures consistent performance and minimizes the need for frequent replacements. The trade-offs between material cost, performance, and lifespan must be carefully considered to achieve an optimal balance.

4. Regulatory Compliance

The design and implementation of exhaust noise reduction technology are inextricably linked to regulatory compliance. Stringent noise emission standards, mandated by governmental bodies, directly dictate the acceptable levels of sound emitted by vehicles. The device functions as a critical component in achieving these mandated limits, serving as a primary means to mitigate exhaust noise pollution. Non-compliance with these regulations can result in substantial penalties for vehicle manufacturers, importers, and even individual vehicle owners. For instance, the European Union’s noise emission standards (UNECE R51) place stringent limits on vehicle noise, forcing manufacturers to develop sophisticated exhaust systems incorporating advanced noise reduction technologies. Similarly, the United States Environmental Protection Agency (EPA) regulates vehicle noise emissions through its noise standards, impacting the design and implementation of these systems in vehicles sold within the US market.

The effectiveness of a noise reduction system in meeting regulatory requirements is evaluated through standardized testing procedures. These tests involve measuring the sound pressure levels emitted by a vehicle under various operating conditions, such as acceleration, constant speed, and idling. The system must consistently demonstrate adherence to the prescribed noise limits throughout these tests to achieve certification. The performance of the device also dictates its marketability and consumer acceptance. Vehicles equipped with systems that fail to meet regulatory standards face significant restrictions on their sale and use. In practical terms, achieving regulatory compliance often requires a delicate balance between noise reduction effectiveness, engine performance, and system cost.

In summary, regulatory compliance is not merely an external constraint but an intrinsic design consideration for exhaust noise reduction. The success of such a system hinges on its ability to meet or exceed prevailing noise emission standards while maintaining acceptable levels of engine performance and vehicle drivability. Continued advancements in material science, acoustic engineering, and manufacturing techniques are essential to navigating the evolving regulatory landscape and ensuring that vehicles operate within legally mandated noise limits.

5. Service Life

The service life of an exhaust noise reduction device is a critical parameter determining its economic value and environmental impact. The duration of effective operation is governed by a complex interplay of material properties, operating conditions, and maintenance practices.

- Material Degradation Mechanisms

Corrosion, thermal fatigue, and mechanical stress are primary drivers of material degradation in these systems. The rate of degradation is influenced by the composition of the exhaust gases, operating temperatures, and exposure to road salts or other corrosive agents. Systems fabricated from lower-grade materials exhibit accelerated degradation, leading to diminished noise reduction and potential structural failure. For example, standard steel systems in northern climates often succumb to rust within a few years, necessitating replacement.

- Impact of Engine Operating Conditions

Aggressive driving styles, frequent short trips, and inadequate engine maintenance exacerbate degradation. Prolonged exposure to high exhaust temperatures and incomplete combustion byproducts accelerates corrosion and thermal stress. Vehicles subjected to severe operating conditions typically exhibit reduced service life compared to those used for moderate driving. Diesel engines, which often produce higher levels of soot and particulate matter, can contribute to clogging and reduced effectiveness over time.

- Influence of Design and Manufacturing Processes

Design features that minimize stress concentrations and promote efficient heat dissipation contribute to extended service life. Manufacturing processes that ensure proper weld integrity and consistent material thickness enhance resistance to fatigue and corrosion. Poorly designed or manufactured systems are prone to premature failure, regardless of the materials used. Systems with inadequate drainage mechanisms may accumulate moisture, accelerating corrosion from within.

- Role of Regular Inspection and Maintenance

Routine visual inspections can identify early signs of corrosion, damage, or leaks, allowing for timely repairs or replacements. Proper maintenance, such as addressing engine issues that contribute to excessive exhaust emissions, can also prolong its service life. Neglecting regular inspections and maintenance accelerates the degradation process and increases the likelihood of catastrophic failure. For example, ignoring a small exhaust leak can lead to more extensive corrosion damage and eventual system replacement.

In conclusion, maximizing the service life of an exhaust noise reduction device requires a holistic approach, encompassing material selection, optimized design, conscientious operation, and diligent maintenance practices. Extending its lifespan reduces replacement costs, minimizes environmental impact, and ensures continued compliance with noise regulations. The correlation between extended service life and reduced environmental burden highlights the importance of responsible system management.

Frequently Asked Questions about Exhaust Noise Reduction

This section addresses common inquiries regarding exhaust noise reduction devices. The information provided aims to clarify misconceptions and offer technical insights for optimal system understanding and management.

Question 1: What is the primary function of an exhaust noise reduction component?

Its primary function is to attenuate noise generated by an internal combustion engine. This is achieved through a combination of sound wave redirection, interference, and absorption within its internal structure. This component is crucial for meeting noise pollution regulations.

Question 2: How does the design of an exhaust noise reduction impact engine performance?

The internal design, including baffle configuration and chamber dimensions, can influence backpressure. Excessive backpressure can negatively impact engine efficiency and power output. Therefore, design optimization is necessary to minimize this effect.

Question 3: What materials are commonly used in their construction, and why?

Common materials include steel, aluminized steel, and stainless steel. Stainless steel offers superior corrosion resistance and durability, extending the component’s service life, while steel is more economic.

Question 4: How frequently should this component be inspected, and what should be looked for?

Regular visual inspections, ideally during routine vehicle maintenance, are recommended. Inspections should focus on identifying signs of corrosion, physical damage, leaks, and unusual noises emanating from the exhaust system.

Question 5: What are the consequences of neglecting a damaged noise reduction device?

Neglecting a damaged component can lead to increased noise pollution, reduced engine performance, and potential regulatory violations. Additionally, exhaust leaks can pose safety hazards and damage other vehicle components.

Question 6: Can the installation of an aftermarket noise reduction system void a vehicle’s warranty?

The installation of an aftermarket component may void the warranty on related exhaust system components if the aftermarket device is determined to be the direct cause of the failure. However, the Magnuson-Moss Warranty Act protects consumers, preventing manufacturers from voiding warranties solely based on the use of aftermarket parts unless a direct causal link is established.

These FAQs offer a foundational understanding of the operational aspects and essential considerations. Ongoing advancements in technology continue to refine the design and performance characteristics.

The subsequent section will provide a detailed glossary of terms commonly associated with this technology, further enhancing comprehension.

Concluding Remarks on Exhaust Noise Reduction

The preceding exploration has elucidated the multifaceted nature of exhaust noise reduction technology. From the intricacies of internal design and material science to the imperative of regulatory compliance and the importance of diligent maintenance, each facet contributes to the overall effectiveness and longevity of this critical component. The significance of backpressure management and the understanding of potential performance trade-offs have been underscored, highlighting the need for informed decision-making in vehicle design and modification.

Continued advancements in acoustic engineering and materials science promise further refinements in exhaust noise management. As regulatory demands evolve and public awareness of noise pollution increases, ongoing research and development are essential to ensure vehicles operate within acceptable acoustic boundaries while maximizing performance and efficiency. The responsible application of this technology is paramount in fostering a quieter, more sustainable transportation ecosystem.