The exhaust component attached to a specific model of motorcycle, known for its displacement, serves the crucial functions of channeling exhaust gases away from the engine, reducing noise levels, and influencing engine performance characteristics. This component’s design directly impacts back pressure, which subsequently affects the engine’s power output and fuel efficiency. Aftermarket options provide avenues for riders to customize sound and performance.

Upgrading this particular part can yield benefits such as improved exhaust flow, resulting in increased horsepower and torque. Historically, modifications to this component have been popular among motorcycle enthusiasts seeking a more aggressive sound profile and enhanced performance. The evolution of its design has mirrored advancements in engine technology and noise reduction strategies.

The subsequent sections will delve into various aspects including types available, factors to consider when selecting a replacement, installation procedures, and maintenance tips related to this critical motorcycle part. Different performance and sound characteristics will be explored in detail, along with factors influencing longevity.

Maintenance and Optimization Strategies

Effective maintenance and strategic optimization are crucial for ensuring the continued performance and longevity of the exhaust system component designed for the 883 model. Implementing these tips will contribute to maximizing its efficiency and minimizing potential issues.

Tip 1: Regular Inspection: Conduct frequent visual inspections for signs of rust, corrosion, or physical damage. Addressing minor issues promptly prevents escalation into more significant problems.

Tip 2: Proper Mounting Hardware: Ensure all mounting bolts and clamps are securely fastened. Loose hardware can lead to vibrations and potential exhaust leaks, negatively impacting performance.

Tip 3: Cleaning and Polishing: Use appropriate cleaning agents and polishing compounds to remove road grime and surface oxidation. This practice preserves the finish and prevents corrosion.

Tip 4: Exhaust Leak Detection: Regularly check for exhaust leaks, particularly at the header connections and muffler joints. Leaks can diminish performance and alter the sound profile.

Tip 5: Avoid Prolonged Idling: Minimize extended periods of idling, as this can lead to carbon buildup within the exhaust system, potentially reducing efficiency.

Tip 6: Check Baffle Integrity: Inspect the internal baffle for damage or deterioration. A compromised baffle can affect sound attenuation and exhaust flow.

Tip 7: Consider Heat Shields: Utilizing heat shields can mitigate heat exposure to adjacent components, preventing damage and improving rider comfort.

Adherence to these maintenance and optimization strategies extends the lifespan of the exhaust system component and preserves its intended performance characteristics. Regular attention and proactive care are key to maximizing its effectiveness.

The following sections will provide guidance on the selection process, performance considerations, and compatibility factors related to this specific motorcycle part.

1. Sound Attenuation

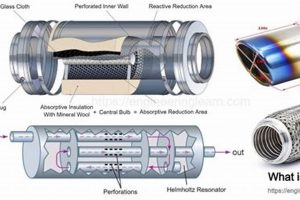

The characteristic sound emanating from a motorcycle is significantly shaped by the exhaust system. The ability of a specific component within that system, commonly found on an 883 model, to reduce noise, or sound attenuation, is critical. This component serves as a primary means of controlling the volume and tonal quality of the exhaust note. The component’s design, incorporating internal baffles and sound-absorbing materials, directly impacts the degree of sound reduction. For example, a model with multiple baffles and dense packing material will generally produce a quieter exhaust note than one with a straight-through design and minimal packing. Understanding this relationship is paramount for achieving a balance between desired auditory experience and regulatory compliance.

The effectiveness of the sound attenuation is not solely dependent on the component’s construction. Factors such as the engine’s inherent sound characteristics and the overall exhaust system design also play a significant role. Furthermore, alterations or modifications to the component, such as baffle removal or packing material degradation, can drastically alter the sound output. In practical applications, riders often seek aftermarket options to achieve a specific sound profile, carefully considering the impact on sound attenuation and potential legal ramifications. Measuring decibel levels before and after alterations offers a quantifiable means of assessing the component’s impact on sound reduction.

In summary, sound attenuation is a fundamental function of this exhaust system component, influencing both the rider’s experience and the vehicle’s compliance with noise regulations. Design attributes, engine characteristics, and maintenance practices all contribute to the effectiveness of sound attenuation. A comprehensive understanding of this interplay is essential for making informed decisions regarding exhaust system modifications and ensuring responsible operation.

2. Exhaust Flow

Exhaust flow, the measure of how readily exhaust gases exit the engine, significantly correlates with the performance characteristics of an 883 model’s exhaust component. A less restrictive system facilitates a more efficient removal of spent gases from the combustion chamber. This, in turn, allows the engine to operate more freely and produce greater power. For instance, replacing a stock system with an aftermarket option designed for enhanced flow may result in a noticeable increase in horsepower and torque, particularly in the mid-range RPMs. However, excessively free-flowing systems may reduce back pressure to a point where low-end torque is negatively affected. This emphasizes the need for a balanced approach to exhaust flow modification.

The internal design of the component directly impacts exhaust flow. Straight-through designs, devoid of significant obstructions, generally offer superior flow compared to baffled systems. The diameter of the piping also plays a role; larger diameter pipes facilitate greater flow, albeit potentially at the expense of exhaust gas velocity. Real-world examples include comparisons between different aftermarket options for the 883 model, where dyno testing often reveals performance variations directly attributable to differences in exhaust flow characteristics. Furthermore, proper maintenance, such as the removal of carbon deposits, is essential for preserving optimal exhaust flow over time.

In conclusion, exhaust flow is a critical parameter influencing the performance of the 883 exhaust component. Its optimization requires a nuanced understanding of its relationship with engine characteristics and careful consideration of the design attributes. While modifications to enhance flow can yield performance benefits, a balanced approach is necessary to avoid unintended consequences. The practical significance of this understanding lies in the ability to select and maintain systems that maximize engine efficiency and deliver the desired riding experience.

3. Back Pressure

Back pressure, the resistance encountered by exhaust gases as they exit the engine, is a critical factor in the performance of the exhaust component designed for the 883 model. Its influence on torque production, fuel efficiency, and overall engine operation necessitates careful consideration.

- Engine Torque and Low-End Power

Excessive reduction of back pressure can negatively impact low-end torque. The controlled resistance created by the component helps maintain exhaust gas velocity, scavenging the cylinders more effectively at lower engine speeds. A reduction of back pressure below optimal levels can result in a decrease in the engine’s ability to generate power at lower RPMs, leading to a less responsive throttle.

- Exhaust Gas Scavenging

Back pressure contributes to exhaust gas scavenging, the process of efficiently removing spent gases from the combustion chamber. The slight pressure created by the system helps draw out remaining exhaust gases, creating a vacuum effect that aids in drawing in the fresh air-fuel mixture. The correct amount of back pressure improves the efficiency of the scavenging process, ultimately optimizing combustion and engine output.

- Fuel Efficiency and Combustion

Alterations to back pressure can directly affect fuel efficiency and combustion. An exhaust system with inadequate back pressure may lead to incomplete combustion, resulting in a loss of fuel economy and an increase in emissions. The careful design of the component ensures that back pressure is maintained within a range that promotes optimal combustion, reducing fuel consumption and minimizing pollutants.

- Exhaust Valve Overlap and Engine Tuning

Back pressure interacts with exhaust valve overlap, a characteristic of the engine’s valve timing. The design should complement the engine’s valve timing to maximize performance. Alterations to the exhaust system without proper engine tuning may disrupt this balance, leading to performance degradation. Tuning modifications, such as fuel injection adjustments, can be necessary to optimize performance after changes to the system.

The interplay between back pressure and engine performance highlights the necessity of selecting and maintaining an exhaust system that is appropriately matched to the specific needs of the 883 model. Understanding the nuances of back pressure enables informed decisions regarding modifications, ensuring optimal torque, fuel efficiency, and overall engine performance. Maintaining the correct back pressure, often a characteristic of the stock part, results in a longer engine life and proper performance parameters as intended by the manufacturer.

4. Material Durability

The operational lifespan and performance of the 883 exhaust component are intrinsically linked to the durability of its constituent materials. The extreme conditions encountered by this part, including exposure to high temperatures, corrosive exhaust gases, and environmental elements, necessitate the use of materials capable of withstanding significant stress. Inadequate material selection will result in premature failure, necessitating frequent replacements and compromising the motorcycle’s performance. For instance, a system constructed from low-grade steel may exhibit accelerated rusting and degradation, directly impacting its ability to effectively channel exhaust gases and attenuate noise.

Examples of material choices directly impacting the 883 exhaust component’s performance abound. Stainless steel, owing to its inherent resistance to corrosion and high-temperature oxidation, is frequently employed in premium aftermarket systems. This choice results in extended operational life and sustained performance characteristics. Conversely, less expensive systems utilizing mild steel often require protective coatings to mitigate corrosion. However, these coatings are susceptible to chipping, cracking, and eventual failure, exposing the underlying material to the elements and accelerating degradation. Furthermore, the thickness and gauge of the material used directly impact its ability to resist physical damage from road debris and vibrations. A thinner-gauge material is more prone to denting and cracking, compromising the component’s integrity.

In summation, the material’s durability is a paramount consideration in the design and selection of this crucial motorcycle part. The ability to withstand extreme conditions, resist corrosion, and maintain structural integrity directly impacts the component’s lifespan, performance characteristics, and overall value. A comprehensive understanding of the properties and limitations of different materials empowers informed decision-making, ensuring optimal performance and long-term reliability, ultimately minimizing maintenance costs and maximizing the riding experience.

5. Aesthetic Design

The visual presentation of the exhaust component significantly influences a motorcycle’s overall style. The selected finish, shape, and detailing of the component contribute directly to the vehicle’s aesthetic appeal. A harmonious integration of the parts design with the existing visual language of the motorcycle is paramount.

- Finish and Coating

The chosen finish, such as chrome, black ceramic, or raw metal, significantly impacts the overall appearance. A chrome finish often imparts a classic, reflective aesthetic, while black ceramic provides a more modern and understated look. The durability of the finish is equally important, ensuring that the component maintains its visual appeal over time, resisting discoloration and corrosion.

- Shape and Silhouette

The shape and profile of the component, whether cylindrical, tapered, or uniquely contoured, contribute to the motorcycle’s visual character. A sleek, minimalist design complements modern styling, while a more robust and prominent shape may enhance a traditional aesthetic. The component’s silhouette should harmonize with the lines of the motorcycle, creating a cohesive and balanced appearance.

- End Cap Design

The design of the end cap provides a focal point and an opportunity for customization. Options range from simple, clean designs to more elaborate and decorative styles. The selected end cap should complement the overall aesthetic of the component and the motorcycle, enhancing the visual impact of the exhaust system.

- Branding and Embellishments

The presence of branding elements, such as logos or emblems, can add a touch of personalization and reflect the owner’s preferences. The placement and size of these embellishments should be carefully considered to avoid detracting from the component’s overall design. Subtlety and tasteful integration are key to maintaining a refined aesthetic.

The integration of these aesthetic design elements contributes significantly to the overall visual impact of the component. A well-designed component enhances the motorcycle’s appearance, reflecting the owner’s individual style and attention to detail. The aesthetic considerations, when combined with performance attributes, create a holistic and satisfying riding experience.

6. Regulatory Compliance

Adherence to established standards is crucial when considering modifications or replacements to the exhaust component on an 883 model. These regulations govern noise emissions, exhaust emissions, and overall system integrity, impacting legal operation and environmental responsibility.

- Noise Emission Standards

Federal and local regulations mandate specific noise level limits for motorcycles. Replacement components must meet these standards, often measured in decibels (dB). Non-compliant systems can result in fines, vehicle impoundment, or mandatory rectification. The Environmental Protection Agency (EPA) sets national standards, while individual states and municipalities may impose stricter local ordinances. Certification markings and documentation are essential to demonstrate compliance during inspections.

- Exhaust Emission Controls

Emissions standards aim to minimize the release of harmful pollutants. Altering the exhaust system can impact emissions levels, potentially violating environmental regulations. Some aftermarket components may remove or bypass catalytic converters or other emissions control devices, leading to increased emissions. Compliance requires maintaining factory-installed emissions controls or using aftermarket components certified to meet or exceed original equipment standards. Regular emissions testing is often required to ensure ongoing compliance.

- Component Certification and Labeling

Certified components, typically bearing stamps or labels, signify adherence to applicable regulations. These certifications provide documentation for inspections and demonstrate due diligence. The absence of proper certification may raise red flags and lead to scrutiny from law enforcement or regulatory agencies. Ensuring that replacement components are properly certified is essential for legal operation.

- Tampering and Modifications

Regulations prohibit tampering with or disabling emissions control devices. Modifications intended to increase performance or alter the exhaust note may inadvertently violate these regulations. Even seemingly minor alterations can have significant impacts on emissions levels. Riders are responsible for understanding the legal ramifications of any modifications made to their motorcycle’s exhaust system.

These considerations underscore the importance of verifying the compliance of any replacement or modified exhaust component intended for use on an 883 model. Ignorance of relevant regulations is not a valid defense, and non-compliance can result in significant penalties. Selecting certified components and avoiding prohibited modifications ensures legal and responsible operation.

Frequently Asked Questions About Harley 883 Muffler Components

The following addresses common inquiries regarding the exhaust component found on the Harley 883, providing clarity on performance, maintenance, and compatibility issues.

Question 1: What are the primary functions of the 883 exhaust component?

The primary functions are to channel exhaust gases away from the engine, reduce noise levels to comply with regulations, and influence engine performance characteristics by managing back pressure.

Question 2: How does replacing the stock exhaust component affect performance?

Replacing the stock component can alter horsepower, torque, and fuel efficiency. Aftermarket options may improve exhaust flow, potentially increasing power, but can also affect low-end torque if back pressure is significantly reduced. Proper tuning may be necessary to optimize performance.

Question 3: What materials are commonly used in the construction of these components, and how do they impact durability?

Common materials include steel, stainless steel, and titanium. Stainless steel offers superior corrosion resistance and durability compared to steel. Titanium provides a lightweight and high-strength option but is generally more expensive.

Question 4: What factors influence the sound level produced by a specific exhaust component?

The sound level is influenced by the internal design of the component, including the presence and configuration of baffles, the type and amount of sound-absorbing materials, and the overall flow path. Regulations often dictate maximum permissible sound levels.

Question 5: How does the design of the component impact back pressure, and why is back pressure important?

The internal design, including pipe diameter and baffle configuration, affects back pressure. Back pressure influences torque production, exhaust gas scavenging, and fuel efficiency. Too little or too much back pressure can negatively impact engine performance.

Question 6: What maintenance procedures are recommended for preserving the performance and longevity of the part?

Recommended procedures include regular visual inspections for rust or damage, ensuring proper mounting hardware tightness, cleaning to remove road grime, checking for exhaust leaks, and avoiding prolonged idling to prevent carbon buildup.

In summary, understanding the functions, materials, and design characteristics of the exhaust component, as well as adhering to proper maintenance practices, are crucial for optimizing the performance and extending the life of this important component.

The following sections will provide deeper insights into specific considerations, including performance and aftermarket enhancements.

Harley 883 Muffler

This exploration of the exhaust component tailored for a specific motorcycle has revealed its multifaceted role. The component serves not only to attenuate noise and channel exhaust gases, but also to influence engine performance, and contribute to the motorcycles aesthetic. Understanding the interplay between materials, design, and regulatory compliance is vital for responsible modification or replacement.

The selection and maintenance of a Harley 883 muffler requires informed consideration of performance characteristics, material durability, and adherence to legal standards. Neglecting these aspects can lead to diminished performance, increased maintenance costs, and potential legal ramifications. Responsible operation and modification ensures a balance between individual preference and adherence to broader regulatory and environmental considerations.