An exhaust system component offered by a national automotive service chain redirects engine emissions away from the vehicle’s occupants. These parts play a role in reducing noise pollution and ensuring efficient engine performance.

Properly functioning units of this type are critical for maintaining vehicle compliance with environmental regulations and ensuring a comfortable driving experience. Historically, the brand associated with these components has been a well-known name in automotive repair, building a reputation for providing accessible and reliable service.

The following discussion will delve into related aspects of vehicle maintenance, exhaust system design, and the broader context of the automotive service industry.

Maintenance and Longevity Tips

Maintaining the vehicle’s exhaust system is crucial for optimal performance and regulatory compliance. The following tips can contribute to extending the lifespan of exhaust components and preventing costly repairs.

Tip 1: Routine Inspections: Schedule regular inspections of the exhaust system, including the muffler, tailpipe, and connecting pipes. Look for signs of rust, corrosion, or physical damage. Early detection can prevent minor issues from escalating.

Tip 2: Address Unusual Noises Promptly: Be attentive to any changes in exhaust noise. Rattling, hissing, or roaring sounds may indicate a leak or damaged component requiring immediate attention.

Tip 3: Avoid Short Trips When Possible: Short trips can lead to moisture accumulation within the exhaust system, accelerating corrosion. Longer drives allow the system to heat up and evaporate moisture, extending component life.

Tip 4: Consider Protective Coatings: Applying a high-temperature protective coating to the exhaust system can help protect against rust and corrosion, particularly in regions with harsh weather conditions or road salt use.

Tip 5: Promptly Replace Worn Rubber Hangers: Inspect and replace rubber hangers that secure the exhaust system. Deteriorated hangers can cause excessive movement and stress on exhaust components, leading to premature failure.

Tip 6: Ensure Proper Engine Function: A properly tuned engine reduces stress on the exhaust system. Address any engine issues, such as misfires or excessive oil consumption, promptly.

Implementing these measures can help ensure the exhaust system operates efficiently, minimizing environmental impact and reducing the likelihood of unexpected repairs.

The subsequent sections will discuss the importance of selecting appropriate replacement parts and understanding warranty information.

1. Exhaust Noise Reduction

Exhaust noise reduction is a primary function of mufflers, and the performance of these components directly impacts the vehicle’s acoustic signature and compliance with noise regulations. The following points outline critical aspects of exhaust noise reduction in the context of an exhaust system.

- Acoustic Dampening

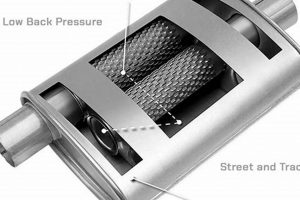

Acoustic dampening involves the use of internal chambers and baffles within the muffler to dissipate sound waves generated by the engine’s combustion process. For example, a straight-through muffler design reduces backpressure but may provide less noise reduction compared to a chambered design that reflects and cancels sound waves. The internal design directly correlates with the decibel level of the exhaust.

- Resonance Cancellation

Resonance cancellation employs specific chamber dimensions to create destructive interference of sound waves, effectively reducing noise at particular frequencies. Different engine designs produce varying frequency profiles, and the mufflers must be tuned to target the most prominent noise frequencies. This concept ensures a quieter exhaust note, meeting regulatory standards.

- Material Absorption

Material absorption utilizes sound-absorbing materials like fiberglass packing within the muffler to convert acoustic energy into heat, reducing the amplitude of sound waves. Over time, this packing can degrade, leading to increased exhaust noise. This degradation often necessitates the replacement of the unit to restore its sound-dampening properties.

- Backpressure Management

Backpressure management requires a balance between noise reduction and engine performance. Excessive backpressure can reduce engine power, while insufficient backpressure may result in unacceptable noise levels. The challenge lies in designing a muffler that effectively reduces noise without significantly hindering exhaust flow, optimizing both sound and performance.

The integration of these facets within the design and functionality of components like those provided by the subject brand demonstrates the intricate engineering involved in achieving effective exhaust noise reduction while maintaining overall vehicle performance and regulatory compliance. Properly functioning exhaust noise reduction systems contribute to both a more pleasant driving experience and environmental responsibility.

2. Emissions Compliance

Adherence to emissions standards is a fundamental aspect of modern vehicle operation, directly influencing the design and functionality of exhaust system components. The connection between such components, particularly mufflers, and emissions compliance stems from the role of the exhaust system in managing and treating engine emissions. Improperly functioning or non-compliant exhaust components can lead to increased emissions of pollutants, such as hydrocarbons, carbon monoxide, and nitrogen oxides, exceeding regulatory limits. This connection is seen when a vehicle fails an emissions test due to a deteriorated or incorrect muffler, resulting in a required repair or replacement to meet legal standards. The importance of emissions compliance as a component of such components reflects the overarching legal and environmental imperatives driving automotive engineering.

Specific examples further illustrate this interplay. Many jurisdictions mandate periodic vehicle inspections, focusing heavily on exhaust emissions. These tests often involve measuring the concentration of pollutants in the exhaust stream. Using aftermarket components, including mufflers, that lack proper certification or are not designed for the specific vehicle can lead to emissions failures. Conversely, the proper installation and maintenance of certified components contribute to reducing harmful emissions, aligning with governmental regulations. This consideration extends to selecting replacement parts that maintain the original equipment manufacturer’s (OEM) emissions control strategy.

In conclusion, the effective alignment between mufflers and emissions compliance is essential for environmental protection and legal adherence. Challenges remain in ensuring the availability and affordability of compliant components, particularly for older vehicles. Continued research and development of advanced exhaust technologies and robust testing protocols are critical for sustaining and improving vehicle emissions performance. This integrated approach addresses both immediate environmental concerns and fosters long-term sustainability within the automotive industry.

3. Vehicle Performance Impact

The operational state of an exhaust system component directly influences the vehicle’s overall performance. Restrictions in exhaust flow, often caused by a deteriorated or improperly designed muffler, can increase backpressure. Elevated backpressure impedes the engine’s ability to expel exhaust gases efficiently, resulting in decreased horsepower and torque output. This effect is noticeable during acceleration and at higher engine speeds, where the engine’s demand for efficient exhaust flow is greatest. Conversely, an inappropriately designed muffler with insufficient backpressure can also negatively affect performance, potentially leading to reduced low-end torque and compromised fuel efficiency.

A practical example lies in comparing a vehicle equipped with a standard factory-installed component to one with an aftermarket, high-flow alternative. While a high-flow muffler might offer improved top-end power, it could also compromise low-end responsiveness, particularly in smaller displacement engines. The optimal choice depends on the vehicle’s intended use and the driver’s performance priorities. The brand name of exhaust component mentioned is often associated with offering standard replacement components designed to maintain original equipment manufacturer (OEM) performance levels. Selecting a replacement from such a brand provides assurance of compatibility and adherence to the vehicle manufacturer’s specifications.

In summary, the selection and maintenance of such mufflers hold tangible implications for vehicle performance. Balancing exhaust flow, backpressure, and noise reduction is crucial. Understanding these dynamics enables informed decisions that ensure optimal engine operation and driving experience, and helps avoid potential performance degradation due to unsuitable exhaust system modifications. Proper maintenance and timely replacement of deteriorated mufflers are key to upholding both performance and fuel efficiency.

4. Material Durability

The service life of an exhaust component is inextricably linked to the materials used in its construction. Exposure to extreme temperatures, corrosive road salts, and constant vibration necessitates the use of robust materials resistant to degradation. Premature failure caused by inferior materials leads to increased replacement frequency and higher long-term operating costs. The brand’s reputation hinges, in part, on the perceived durability of the components it offers. Examples of material failures include rust-through of the muffler casing, disintegration of internal baffles, and cracking of welds, all impacting noise levels and emissions control.

Specific material choices impact longevity. Aluminized steel, stainless steel, and specialized coatings offer varying degrees of corrosion resistance. Higher grades of stainless steel provide superior protection but come at a greater cost. The design of internal components also plays a role; for instance, the use of thicker gauge steel in critical areas enhances resistance to fatigue and vibration-induced cracking. Furthermore, quality control measures during manufacturing are paramount in ensuring consistent material properties and weld integrity, both of which directly influence overall durability. The practical implication of this material science is that consumers must balance initial cost with expected lifespan when selecting an exhaust component.

Ultimately, the relationship between material durability and the longevity of an exhaust component, particularly the offering provided by the service chain, dictates its overall value proposition. Challenges remain in providing cost-effective solutions that withstand demanding environmental conditions. Ongoing material research and development are vital in extending the service life of such components, minimizing environmental impact, and reducing the financial burden on vehicle owners. Understanding the material composition and construction techniques is therefore essential for making informed purchasing decisions and ensuring long-term vehicle reliability.

5. Installation Procedures

Proper installation is critical to the intended performance and longevity of an exhaust system component. Deviations from established procedures can compromise its effectiveness, void warranties, and potentially damage the vehicle. An improper installation might cause exhaust leaks, increased noise levels, or mechanical stress on the component itself, ultimately leading to premature failure. For example, overtightening clamps can deform the pipe, creating leaks. Similarly, using incorrect hangers or failing to align the exhaust system properly can induce stress on welds and joints, significantly reducing the lifespan of the component.

The established automotive service chain relies on standardized installation procedures to ensure consistent service quality. Technicians adhere to manufacturer-specified torque values, use appropriate tools, and perform leak checks after installation. Neglecting these steps can lead to customer dissatisfaction and potential liability issues. A real-world example involves the improper welding of a muffler, which can result in exhaust leaks and compromised noise reduction, prompting a return visit and corrective action. The availability of detailed installation manuals and ongoing training programs is vital for maintaining quality control.

In summary, adherence to correct installation procedures is essential for realizing the full benefits and avoiding potential pitfalls associated with exhaust system components. Challenges remain in ensuring consistent application of best practices across all service locations. Continuous training, rigorous quality control measures, and readily available technical support are vital to maintaining a high standard of installation quality and fostering customer confidence. The practical significance of this understanding lies in minimizing warranty claims, enhancing customer satisfaction, and ensuring long-term vehicle reliability.

6. Warranty Coverage

Warranty coverage associated with exhaust system components, particularly those installed by established automotive service chains, represents a critical element of the overall value proposition. It provides consumers with a degree of financial protection against premature failure or defects in materials and workmanship. The specific terms and conditions of these warranties vary and understanding them is essential for making informed purchasing decisions.

- Scope of Coverage

The scope defines precisely what the warranty covers. Typical coverage encompasses defects in materials or workmanship under normal operating conditions. Damage resulting from accidents, misuse, or modifications is generally excluded. For components installed by the service chain, the warranty may also cover labor costs associated with repair or replacement, provided the work is performed by an authorized installer. An example of real-world application would be a muffler that rusts through within the warranty period due to a manufacturing flaw, entitling the consumer to a free replacement.

- Duration of Coverage

The duration specifies the length of time the warranty remains in effect. Warranty periods for exhaust components typically range from one year to the lifetime of the product. Lifetime warranties may be subject to limitations, such as requiring the consumer to retain ownership of the vehicle. Extended warranties are often available for purchase, providing coverage beyond the standard warranty period. A practical example would be a warranty that covers the component for two years or 24,000 miles, whichever comes first.

- Claim Procedures

Claim procedures outline the steps a consumer must take to initiate a warranty claim. Typically, this involves presenting proof of purchase and a description of the issue to the service chain or manufacturer. An inspection of the component may be required to determine the cause of the failure. The claim may be denied if the failure is deemed to be outside the scope of the warranty. For example, if a muffler is damaged by impact with a road hazard, the warranty claim would likely be rejected.

- Limitations and Exclusions

Limitations and exclusions define specific circumstances under which the warranty does not apply. Common exclusions include damage caused by improper installation, off-road use, or the use of non-approved parts. Some warranties may also exclude coverage for consequential damages, such as lost income or towing charges. Understanding these limitations is essential for managing expectations and avoiding potential disputes. A typical limitation could be a requirement that all maintenance and repairs be performed by authorized service providers.

The warranty coverage associated with exhaust components offered and installed by a service chain represents a valuable assurance to consumers. It reflects a commitment to product quality and provides recourse in the event of unforeseen issues. However, it is crucial to carefully review the terms and conditions of the warranty to fully understand the scope of coverage, claim procedures, and any applicable limitations. Such careful review will allow a consumer to make a well-informed purchase, and protect their investment.

Frequently Asked Questions Regarding Meineke Mufflers

The following section addresses common inquiries and misconceptions regarding exhaust system components provided by the automotive service chain.

Question 1: What is the typical lifespan of such a component?

The longevity of these parts is influenced by factors such as driving conditions, climate, and the material composition of the unit. Under average conditions, it could last between 5 to 7 years. Regular inspections and preventative maintenance can extend its service life.

Question 2: How can one determine if this specific component requires replacement?

Indications of required replacement include excessive exhaust noise, visible rust or physical damage, and a failed emissions test. A professional inspection is recommended to accurately assess the component’s condition.

Question 3: Do these specific exhaust system components affect fuel efficiency?

A properly functioning exhaust system optimizes engine performance and fuel efficiency. A restricted or damaged part can increase backpressure, leading to reduced fuel economy.

Question 4: Are the specific mufflers compatible with all vehicle makes and models?

Compatibility varies depending on the vehicle’s specifications. The service chain offers a range of components designed for specific makes and models. Consulting with a qualified technician is essential to ensure proper fitment.

Question 5: What are the potential consequences of driving with a faulty exhaust component?

Operating a vehicle with a defective exhaust component can result in increased emissions, reduced engine performance, and potential safety hazards. It may also lead to legal penalties for violating emissions regulations.

Question 6: Does the service chain offer a warranty on its exhaust components?

Warranty coverage varies. Specific details regarding warranty terms, duration, and exclusions should be obtained from the service chain at the time of purchase.

Understanding these frequently asked questions can assist in making informed decisions regarding exhaust system maintenance and repair.

The subsequent section will discuss the broader context of automotive exhaust systems and their role in environmental protection.

Conclusion

This exploration has examined various facets of “meineke muffler,” including their role in noise reduction, emissions compliance, vehicle performance, material durability, proper installation, and warranty coverage. The multifaceted nature of these components underscores their importance in maintaining vehicle functionality and regulatory adherence. Understanding these aspects enables vehicle owners to make informed decisions regarding maintenance and replacement.

Considering the increasing focus on environmental sustainability and vehicle longevity, a proactive approach to exhaust system maintenance is essential. By prioritizing regular inspections and timely replacements, individuals can contribute to both enhanced vehicle performance and reduced environmental impact. Continued advancements in material science and exhaust system design will further refine the capabilities and durability of these critical components, shaping the future of automotive exhaust technology.