A specific type of exhaust system component incorporates two entry points for exhaust gases and converges these into a single exit. This design facilitates the management of exhaust flow from engines with dual exhaust manifolds or systems seeking a consolidated outlet. An example would be found in vehicles where the engine configuration necessitates separate exhaust pathways from each cylinder bank, subsequently merging into a single pipe for noise reduction and emissions control.

The implementation of this configuration offers several advantages, including potential improvements in exhaust scavenging, which can positively influence engine performance. Furthermore, the single outlet simplifies the exhaust system’s routing and reduces the number of components required at the rear of the vehicle. Historically, such designs have been employed to balance performance considerations with space constraints and aesthetic requirements in automotive engineering.

The following sections will delve deeper into the operational characteristics, performance implications, installation considerations, and relevant material selection pertaining to this specific exhaust system design. This will be followed by considerations regarding compatible vehicles, maintenance guidance, and aftermarket product selection.

Muffler Selection and Installation Tips

The subsequent recommendations provide guidance on selecting and installing exhaust components featuring a dual inlet, single outlet configuration. Proper execution is critical for optimal performance and longevity.

Tip 1: Verify Compatibility: Prior to purchase, confirm that the component’s inlet and outlet diameters match the existing exhaust system’s specifications. Mismatched sizes will necessitate adapters or modifications, potentially compromising flow and creating leak points.

Tip 2: Material Considerations: Opt for stainless steel construction when feasible. Stainless steel exhibits superior corrosion resistance compared to aluminized steel, extending the component’s lifespan, particularly in regions with harsh environmental conditions.

Tip 3: Welding Procedures: When welding is required, employ proper techniques such as TIG or MIG welding with appropriate filler material. Ensure complete penetration and fusion to prevent leaks and structural failures.

Tip 4: Hanger Alignment: Precisely align exhaust hangers to support the weight of the component without placing undue stress on the exhaust system or vehicle chassis. Misalignment can lead to premature wear and cracking.

Tip 5: Seal Integrity: Utilize new gaskets and exhaust sealant at all connection points to ensure a gas-tight seal. Leaks not only reduce performance but also pose a safety risk due to the potential for carbon monoxide intrusion.

Tip 6: Torque Specifications: Adhere to the manufacturer’s recommended torque specifications for all fasteners. Over-tightening can damage threads or distort flanges, while under-tightening can result in leaks.

Tip 7: Post-Installation Inspection: After installation, thoroughly inspect the exhaust system for leaks or abnormal noises. Address any issues promptly to prevent further complications.

These tips aim to optimize the selection and installation process, ensuring the correct and reliable operation of the exhaust component. Following these guidelines will contribute to improved performance, reduced noise, and extended service life.

The following sections will discuss troubleshooting potential issues, performance tuning, and modifications that can be made to enhance the system’s capabilities.

1. Flow characteristics

Flow characteristics are paramount in exhaust system design, significantly affecting engine performance and emissions. Within a system incorporating a component with dual inlets and a single outlet, the management of exhaust gas flow becomes a critical design consideration.

- Inlet Flow Distribution

The design must ensure balanced flow distribution across both inlets to prevent uneven cylinder scavenging. Imbalances can lead to performance variations between engine banks, negatively impacting overall efficiency and potentially increasing emissions. Examples include unequal pipe lengths leading into the inlets or variations in internal baffling within the component.

- Merge Collector Design

The geometry of the merge collector where the dual inlets converge is crucial. A poorly designed collector can create turbulence and backpressure, hindering exhaust gas evacuation. Computational Fluid Dynamics (CFD) simulations are often employed to optimize collector design for minimal flow restriction.

- Outlet Flow Capacity

The outlet diameter and internal structure must provide sufficient flow capacity to handle the combined exhaust volume from both inlets. Insufficient outlet capacity will result in increased backpressure, which can reduce engine power and fuel economy. The sizing of the outlet is typically based on engine displacement and expected operating RPM.

- Internal Baffling and Resonance

The internal baffling within the muffler component impacts both noise reduction and flow characteristics. While baffles attenuate sound waves, they also introduce flow resistance. Optimizing baffle design requires balancing acoustic performance with minimizing backpressure. Resonance chambers may be incorporated to cancel out specific frequencies, offering noise reduction with minimal impact on flow.

Ultimately, the design of a component with dual inlets and a single outlet requires a holistic approach that considers the interplay between flow characteristics, noise reduction, and engine performance. A well-designed component will efficiently merge exhaust gases from multiple sources, minimizing backpressure and maximizing engine output while meeting noise emission standards.

2. Noise reduction

Noise reduction is a primary function of exhaust systems, and components with dual inlets and a single outlet are designed to mitigate engine noise effectively. The process of noise reduction in these systems relies on a combination of absorption, reflection, and interference of sound waves generated by the engine’s combustion process. The internal construction of the muffler, with its chambers and baffles, is engineered to disrupt the propagation of sound waves, reducing their amplitude before they exit the exhaust system. This attenuation process is essential for compliance with noise regulations and for enhancing vehicle occupant comfort.

Dual inlet, single outlet designs present unique considerations for noise reduction. The confluence of exhaust gases from two separate sources introduces complexities in managing sound wave interactions. The internal design must ensure that the merging of exhaust streams does not amplify specific frequencies or create undesirable acoustic resonances. Examples of noise reduction strategies in these systems include the use of Helmholtz resonators tuned to specific engine frequencies and the incorporation of strategically placed sound-absorbing materials. Successful implementation of these strategies results in a quieter exhaust note without significantly impeding exhaust flow. The design of these components necessitates a balance between noise reduction effectiveness and the minimization of backpressure, as excessive backpressure can negatively impact engine performance.

In summary, noise reduction is an integral function. Its effectiveness hinges on the precise internal design of the muffler, the careful management of exhaust gas flow, and the strategic application of sound attenuation techniques. Challenges in achieving optimal noise reduction stem from the need to balance acoustic performance with other critical factors, such as engine performance and system durability. Understanding the principles of noise reduction in this context is paramount for designing and maintaining effective and compliant exhaust systems.

3. Engine Compatibility

Engine compatibility is a critical consideration when selecting exhaust components with dual inlets and a single outlet. The proper matching of the exhaust system to the engine’s specifications ensures optimal performance and prevents potential damage. Mismatched components can lead to reduced power output, increased fuel consumption, and premature wear of engine components.

- Engine Displacement and Flow Rate

The engine’s displacement dictates the volume of exhaust gases produced. The exhaust component must be sized to handle this flow rate effectively. Insufficient flow capacity will create backpressure, reducing engine power. Conversely, an excessively large component may not provide adequate scavenging, leading to similar performance issues. Engine specifications typically provide exhaust flow rate data necessary for proper component selection.

- Exhaust Manifold Configuration

Engines with dual exhaust manifolds, such as V-type engines, are prime candidates for exhaust systems featuring a component with dual inlets. The configuration of the exhaust manifolds directly influences the routing of exhaust gases and the connection points to the exhaust system. It is essential to ensure that the component’s inlet locations and diameters align with the exhaust manifold outlets to achieve a secure and leak-free connection.

- Emissions Control System Requirements

The engine’s emissions control system, including catalytic converters and oxygen sensors, must be considered when selecting an exhaust component. Modifications to the exhaust system can affect the performance of these components and potentially lead to non-compliance with emissions regulations. Placement and compatibility with existing sensors are important. Modifying the exhaust system without considering these factors can trigger check engine lights and negatively impact the vehicle’s emissions performance.

- Mounting and Clearance Considerations

Physical fitment within the vehicle’s chassis is a practical aspect of engine compatibility. The exhaust component must have adequate clearance from other vehicle components, such as the fuel tank, suspension components, and drivetrain elements. Contact with these components can cause damage, noise, or even safety hazards. Proper mounting of the exhaust component is also essential to prevent excessive stress on the exhaust system and vehicle chassis.

Effective implementation requires a thorough understanding of engine specifications, exhaust manifold configuration, emissions control system requirements, and mounting considerations. When these factors are appropriately addressed, systems can provide optimal performance, meet emissions standards, and ensure long-term reliability.

4. Material durability

Material durability is a paramount factor in the design and longevity of exhaust components with dual inlets and a single outlet. The operational environment of these components is characterized by high temperatures, corrosive exhaust gases, and exposure to environmental elements such as road salt and moisture. Consequently, the selection of durable materials is essential to ensure structural integrity and prevent premature failure.

Stainless steel alloys, such as 304 and 409, are frequently employed due to their superior resistance to corrosion and high-temperature oxidation. The chromium content in these alloys forms a protective oxide layer, preventing further degradation of the material. Aluminized steel is also utilized, offering a cost-effective alternative with moderate corrosion resistance. However, aluminized steel is susceptible to damage if the aluminum coating is compromised, leading to rapid corrosion. Titanium alloys, while offering exceptional strength-to-weight ratios and corrosion resistance, are less common due to their higher cost and specialized manufacturing requirements. An example of material failure is often seen in colder regions where salt accelerates aluminized steel corrosion, whereas stainless steel counterparts in the same environment exhibit a significantly longer service life. The practical significance of understanding material durability lies in minimizing maintenance costs and ensuring reliable vehicle operation. Selecting an exhaust component constructed from a durable material tailored to the operating environment significantly reduces the risk of costly repairs or replacements.

In conclusion, the material selection directly impacts the lifespan and performance of an exhaust system component with a dual inlet and single outlet. While various materials offer different levels of durability and cost, stainless steel typically provides the best balance for most applications. Addressing material concerns prevents premature degradation and ensures reliable functionality.

5. Installation complexity

Installation complexity for exhaust systems featuring dual inlet, single outlet components stems from several factors. The presence of two inlets necessitates precise alignment with the exhaust manifolds, potentially increasing the difficulty compared to single-inlet systems. Restricted space within the vehicle’s undercarriage further complicates the process. The need for secure and leak-free connections at both inlets introduces additional challenges, requiring careful attention to flange alignment and gasket sealing. An example is the replacement on a tightly packaged sports car, where limited access to the exhaust manifold connections significantly increases labor time. This complexity necessitates specialized tools, technical expertise, and meticulous attention to detail.

Improper installation can lead to various adverse effects. Exhaust leaks can result in reduced engine performance, increased noise levels, and potential safety hazards due to carbon monoxide exposure. Misalignment of the exhaust system can induce stress on the exhaust manifold, leading to cracks or failures. Furthermore, incorrectly installed hangers can cause the exhaust system to rattle or vibrate, resulting in discomfort and potential damage to surrounding components. An example of this is a compromised oxygen sensor reading due to a leak near its location, ultimately causing the engine to run inefficiently. Adherence to manufacturer specifications and utilization of proper installation techniques are critical to mitigate these risks.

In summary, installation complexity represents a significant consideration in the implementation of dual inlet, single outlet exhaust systems. Addressing these challenges requires specialized tools, a high degree of technical expertise, and meticulous attention to detail. Recognizing and mitigating these factors ensures optimal performance, safety, and longevity of the exhaust system. Further research and investment in streamlined installation procedures are key to reducing installation time and minimizing the potential for errors.

6. Backpressure impact

Backpressure is a crucial parameter in exhaust system design, influencing engine performance and efficiency. In systems utilizing dual inlet, single outlet components, the management of backpressure becomes a complex balancing act, requiring careful consideration of various design factors.

- Inlet Configuration and Flow Restriction

The configuration of the dual inlets directly impacts backpressure. Suboptimal inlet design, characterized by sharp bends or restrictive diameters, can impede exhaust gas flow, increasing backpressure. This elevated backpressure can hinder exhaust scavenging, reducing engine power and fuel economy. An example includes systems with mismatched inlet diameters compared to the exhaust manifold outlets, leading to a bottleneck effect.

- Internal Muffler Design and Resistance

The internal structure, encompassing baffles, chambers, and resonators, contributes significantly to backpressure. While these features are essential for noise reduction, they inherently introduce resistance to exhaust gas flow. Overly complex internal designs with excessive baffling can create excessive backpressure, negating the performance benefits of a dual-inlet system. A real-world scenario is observed in aftermarket components prioritizing noise suppression over flow efficiency, leading to diminished engine output.

- Outlet Diameter and Flow Capacity

The diameter of the single outlet is critical in managing backpressure. An undersized outlet restricts exhaust gas flow, increasing backpressure and compromising engine performance. The outlet diameter must be sufficient to accommodate the combined exhaust volume from both inlets without creating a bottleneck. Examples include vehicles where a smaller outlet diameter was chosen for aesthetic reasons, resulting in noticeable performance degradation.

- Catalytic Converter Integration and Restrictions

The presence of catalytic converters within the exhaust system further contributes to backpressure. Catalytic converters inherently introduce flow restrictions due to their internal structure and substrate material. It is essential to select catalytic converters with low restriction characteristics to minimize their impact on backpressure. Examples are seen with high-flow catalytic converters, which are designed to reduce exhaust backpressure to a greater extent than their stock counterparts, particularly in performance vehicles.

The interplay of these factors dictates the overall backpressure profile of a system using dual inlet, single outlet configurations. Balancing inlet and outlet diameters, optimizing internal muffler design, and selecting appropriate catalytic converters are key to minimizing backpressure while achieving desired noise reduction and emissions control. A properly designed system minimizes backpressure while optimizing engine performance and complying with regulatory requirements.

7. Space Optimization

Space optimization is a critical consideration in vehicle design, particularly regarding exhaust system layout. Exhaust components with dual inlets and a single outlet present specific opportunities and challenges in maximizing available space, contributing to overall vehicle efficiency and functionality.

- Consolidation of Exhaust Routing

The dual inlet, single outlet configuration consolidates exhaust flow from two separate sources into a single pathway, reducing the overall volume occupied by the exhaust system. In vehicles with limited undercarriage space, this consolidation simplifies routing and minimizes interference with other components, such as the fuel tank, drivetrain, or suspension elements. Examples include compact vehicles or those with complex all-wheel-drive systems, where space constraints are significant.

- Reduced Component Count

By merging two exhaust streams into one, the dual inlet, single outlet design reduces the number of downstream components required, such as mufflers and tailpipes. This reduction in component count not only saves space but also lowers weight, contributing to improved fuel efficiency and handling. This approach is often seen in performance vehicles where weight reduction is a primary design objective.

- Adaptability to Engine Configuration

The dual inlet design is particularly well-suited for vehicles with V-type engines or other configurations where exhaust gases exit from two separate manifolds. By directly accommodating these dual exhaust streams, the system avoids the need for complex merging pipes or crossover tubes, which can consume valuable space and increase exhaust backpressure. Adaptability results in more effective placement within existing constraints.

- Integration with Chassis Design

The compact nature of the single outlet allows for more flexible integration with the vehicle’s chassis design. This can facilitate the placement of other components, such as the spare tire well or rear suspension components, optimizing the overall packaging of the vehicle. Such integration contributes to a more streamlined and efficient vehicle design.

The implementation of systems requires a careful balance between space constraints, exhaust flow characteristics, and noise reduction requirements. Optimizing these factors is paramount to achieving both efficient space utilization and optimal vehicle performance. Addressing the interplay among space optimization, exhaust efficiency, and acoustic considerations is essential for overall design success.

Frequently Asked Questions

The following questions address common concerns and misconceptions regarding exhaust components featuring dual inlets and a single outlet. The information aims to clarify the design, function, and application of these specialized mufflers.

Question 1: Is a dual inlet, single outlet muffler suitable for all vehicles?

No. These mufflers are specifically designed for vehicles with engines that have dual exhaust manifolds, such as V-engines. Using this muffler type on a single exhaust manifold system is inappropriate and will not yield the intended performance benefits.

Question 2: Does a dual inlet, single outlet muffler improve horsepower?

Potentially, yes. The design can improve exhaust scavenging and reduce backpressure, leading to a potential increase in horsepower. However, the actual power gain depends on other factors, including engine size, exhaust system design, and tuning.

Question 3: Is stainless steel the only suitable material for dual inlet, single outlet mufflers?

Stainless steel is the most durable and corrosion-resistant option but is not the only suitable material. Aluminized steel offers a more cost-effective alternative, albeit with reduced lifespan in harsh environments. Titanium is also utilized, but mostly for high-performance or racing applications where weight reduction is a priority.

Question 4: Can a dual inlet, single outlet muffler be installed by a novice?

Installation complexity varies depending on the vehicle. However, proper installation requires a solid understanding of exhaust system mechanics and access to specialized tools. Professional installation is recommended to ensure correct fitment and prevent exhaust leaks.

Question 5: How does a dual inlet, single outlet muffler affect vehicle sound?

The muffler alters the vehicle’s exhaust note through internal baffling and sound wave cancellation. The specific sound characteristics vary depending on the muffler’s design. Some models aim for a deep, throaty tone, while others focus on reducing noise levels to meet regulatory requirements.

Question 6: Are there any downsides to using a dual inlet, single outlet muffler?

Potential downsides include increased complexity compared to single-inlet systems and potential challenges in achieving balanced exhaust flow from both inlets. Incorrect installation or a poorly designed muffler can result in reduced performance and increased backpressure.

In summary, dual inlet, single outlet mufflers represent a specialized exhaust component designed for specific engine configurations. Selecting the appropriate muffler requires a careful evaluation of engine specifications, material considerations, and installation requirements.

The following section will address troubleshooting common issues and provide guidance on system maintenance.

Conclusion

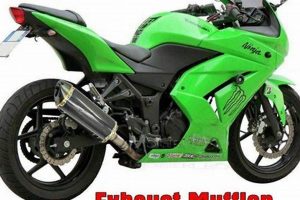

The preceding discussion has explored the various facets of exhaust systems incorporating a muffler dual inlet single outlet. Key aspects include design considerations, performance implications, material selection, installation complexities, and the impact on both noise reduction and engine backpressure. Successfully implementing this exhaust component requires a thorough understanding of these factors and careful attention to detail.

Proper application of the muffler dual inlet single outlet is essential for optimizing exhaust flow and ensuring the longevity of the system. As automotive engineering continues to evolve, further research and development in this area are crucial to maximize performance and address emerging emissions control standards. The informed selection and installation of this component represent a critical step in maintaining vehicle efficiency and environmental responsibility.