This aftermarket automotive component, frequently associated with enhanced exhaust systems, is a performance upgrade designed to optimize exhaust gas flow from an engine. One application might involve its installation on a Honda Civic to improve its horsepower and torque output.

Its significance lies in its potential to contribute to improved engine efficiency and a more aggressive exhaust note. Historically, such components have been favored by automotive enthusiasts seeking to enhance their vehicle’s performance beyond factory specifications. They often represent a trade-off between performance gains and potentially increased noise levels.

The following discussion will delve into the specifics of exhaust system modifications, including considerations for material selection, installation procedures, and the potential impact on vehicle emissions compliance.

Installation and Maintenance Guidance

The following guidelines provide essential information for the proper installation and upkeep of this specialized exhaust system component. Adherence to these recommendations will help ensure optimal performance and longevity.

Tip 1: Proper Welding Technique: Employ appropriate welding methods when attaching the exhaust component. Inadequate welds can lead to leaks, reduced performance, and premature failure. Consider TIG welding for optimal strength and precision.

Tip 2: Professional Installation Recommended: Due to the complexities involved, engaging a qualified automotive technician for installation is highly advised. This helps to mitigate potential errors and ensure correct fitment.

Tip 3: Regular Inspection for Corrosion: Periodically inspect the component for signs of rust or corrosion, especially in environments with high salt exposure. Prompt treatment of corrosion will prevent structural weakening.

Tip 4: Torque Specification Adherence: When tightening fasteners, strictly adhere to the manufacturer’s torque specifications. Over-tightening can damage the component or surrounding parts; under-tightening can lead to leaks or loosening.

Tip 5: Exhaust Leak Detection: Regularly check for exhaust leaks by listening for unusual noises or feeling for escaping gases. Address any leaks immediately to maintain optimal performance and prevent potential safety hazards.

Tip 6: Heat Shielding Considerations: Ensure adequate heat shielding is in place to protect nearby components from excessive heat. Improper shielding can lead to damage to wiring, hoses, or other heat-sensitive parts.

Proper execution of these steps is critical for realizing the full potential of the exhaust enhancement and maintaining its integrity over time.

The subsequent section will address common troubleshooting scenarios and potential solutions related to exhaust system modifications.

1. Material Composition

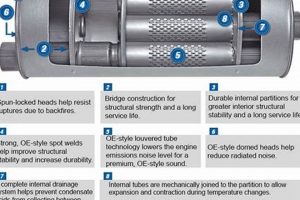

The performance and longevity of an aftermarket automotive exhaust component are inextricably linked to its material composition. The selected material dictates the component’s resistance to corrosion, its ability to withstand high temperatures and pressures, and its overall weight. Different materials offer varying degrees of these properties, thus influencing the exhaust component’s suitability for specific applications and environments. For instance, a stainless steel construction offers a balance of durability and affordability, making it a common choice for street vehicles, while titanium may be preferred in racing applications where weight reduction is paramount.

The choice of material directly affects several key aspects of exhaust component performance. Lower-grade steel may corrode rapidly in regions with road salt, leading to premature failure. In contrast, higher grades of stainless steel or titanium exhibit superior resistance to corrosion, extending the lifespan of the exhaust system. Furthermore, the material’s density impacts the overall weight of the vehicle. Lighter materials, like titanium, can contribute to improved handling and acceleration, albeit at a higher cost. Heat dissipation properties of the material also play a crucial role in preventing thermal damage to surrounding components and ensuring efficient exhaust gas scavenging.

In conclusion, the selection of material is a critical factor in determining the overall effectiveness of an aftermarket automotive exhaust component. Understanding the trade-offs between different materials allows for a more informed decision, ensuring that the selected component meets the specific performance requirements and environmental conditions of the vehicle. The material directly impacts durability, weight, corrosion resistance, and ultimately, the component’s contribution to the overall exhaust system performance. The material composition determines its reliability and effectiveness.

2. Exhaust flow dynamics

Exhaust flow dynamics, referring to the characteristics of exhaust gases moving through a system, is intrinsically linked to the performance of aftermarket exhaust components. These components are engineered to influence exhaust flow, thereby affecting engine efficiency and power output. The degree to which exhaust gases are efficiently evacuated from the cylinders directly impacts the subsequent combustion cycle, and thus, overall engine performance. Aftermarket components are specifically designed to optimize this process. A key element is the reduction of backpressure, which inhibits the efficient expulsion of exhaust gases. For instance, a component designed with a larger diameter and smoother bends can reduce backpressure, leading to improved engine breathing and increased horsepower. The geometry of the component and the internal flow path are specifically tailored to facilitate unimpeded gas movement.

The design considerations for optimizing exhaust flow dynamics extend beyond simply reducing backpressure. Scavenging effects, which utilize the negative pressure waves created by the exiting exhaust gases to help draw out remaining exhaust from the cylinders, are also strategically employed. Certain exhaust designs can create these scavenging effects more effectively, further enhancing engine performance. In practice, these components are often tested using computational fluid dynamics (CFD) software to simulate exhaust gas flow and optimize the design before physical prototyping. The practical application of understanding exhaust flow dynamics lies in the ability to select or design an exhaust system that complements the specific engine characteristics and performance goals. This often involves considering factors such as engine displacement, camshaft timing, and intended use of the vehicle.

In summary, exhaust flow dynamics forms a critical component of exhaust system design and the subsequent performance gains achieved. The efficient evacuation of exhaust gases, the reduction of backpressure, and the utilization of scavenging effects are all governed by the exhaust system’s geometry and internal flow path. Understanding these principles allows for informed decision-making in the selection and application of aftermarket exhaust components, ultimately contributing to optimized engine performance. Challenges include balancing performance gains with noise levels and ensuring compliance with emissions regulations. Optimizing exhaust flow dynamics requires careful engineering and a thorough understanding of engine characteristics.

3. Sound characteristics

Sound characteristics are an inherent attribute of aftermarket exhaust components and play a critical role in the perceived value and overall driving experience. The design of the exhaust system, including the muffler, directly influences the resulting sound profile. A primary function of an exhaust system is to mitigate noise; however, aftermarket components often modify this sound to enhance the auditory experience for the driver. The degree of noise reduction, the frequencies emphasized, and the overall tone are all affected by the specific design and construction of the muffler. A particular model might produce a deep, resonant tone at low engine speeds, while another might generate a high-pitched, raspy sound at higher RPMs. Consider, for example, two exhaust systems installed on identical vehicles; differences in muffler design will invariably result in distinct sound profiles, influencing the driver’s subjective assessment of performance and overall vehicle character.

The connection between sound characteristics and the “spoon n1 muffler”, for instance, is one of design intent. This component is known for its distinctive, aggressive sound profile. This is achieved through a specific internal design that prioritizes exhaust flow while intentionally altering the sound frequencies. The desired outcome is a pronounced, sporty exhaust note that complements the perceived performance gains. Conversely, an alternative exhaust component could prioritize noise reduction, resulting in a quieter, more subdued sound profile. The practical application of understanding sound characteristics involves selecting an exhaust system that aligns with the driver’s personal preferences and the intended use of the vehicle. Some drivers prioritize a louder, more aggressive sound for a sportier driving experience, while others prefer a quieter system for daily commuting. Regulations exist regarding noise levels, which is a crucial aspect for street-legal vehicles. Understanding these regulations and the sonic output of different components is essential. Furthermore, the perceived sound can impact other drivers and the community, underlining the importance of responsible sound management.

In conclusion, sound characteristics are not merely a byproduct of exhaust system design; they are an integral element contributing to the overall driving experience and aftermarket appeal. The interplay between design choices, sound profile, and personal preferences necessitates careful consideration when selecting or modifying exhaust systems. Challenges arise in balancing desired sound levels with regulatory compliance and social responsibility. The ability to accurately characterize and predict sound output is crucial for both manufacturers and consumers in the automotive aftermarket.

4. Installation precision

Installation precision directly influences the performance and lifespan of aftermarket exhaust components such as the “spoon n1 muffler.” Accurate installation ensures proper fitment, which is critical for optimal exhaust flow and the prevention of leaks. Inadequate installation, characterized by misaligned connections or improperly tightened fasteners, can lead to exhaust leaks. These leaks diminish engine performance, increase noise levels, and pose potential safety hazards due to the release of exhaust gases. The design of the “spoon n1 muffler,” often featuring specific mounting points and flange orientations, necessitates precise alignment to the existing exhaust system. For example, if the muffler is not correctly aligned with the exhaust manifold, it can cause stress on the connecting pipes, potentially leading to premature failure or cracking. The correlation between precise installation and optimal functionality is therefore a key factor to consider.

Beyond leak prevention, installation precision also affects the intended sound characteristics and performance gains associated with the component. A misaligned muffler can alter the exhaust flow path, leading to deviations from the designed sound profile and reduced horsepower gains. For instance, if the muffler’s outlet is obstructed due to improper positioning, it can create backpressure that negates the intended performance benefits. Furthermore, correct installation ensures that the component is properly supported, preventing excessive vibration and stress on the exhaust hangers. The instructions provided by the manufacturer outline specific steps and torque specifications to ensure accuracy. Professional installation, while potentially more costly upfront, mitigates the risk of installation errors and can safeguard the long-term integrity of the exhaust system.

In summary, installation precision is not merely a procedural step but an integral factor in realizing the intended benefits of an aftermarket exhaust component. Improper installation can negate performance gains, create safety hazards, and reduce the lifespan of the component. Adhering to manufacturer specifications, utilizing proper tools, and, if necessary, seeking professional assistance are crucial for ensuring accurate installation. The connection between precise installation and the reliable performance of a “spoon n1 muffler” is undeniable, highlighting the importance of meticulous attention to detail during the installation process. The challenge lies in achieving consistent installation quality across diverse vehicle models and skill levels.

5. Corrosion resistance

Corrosion resistance is a critical performance characteristic of any exhaust component, including the “spoon n1 muffler.” The longevity and reliability of the exhaust system are directly contingent on its ability to withstand corrosive elements present in the environment and within the exhaust stream. The following outlines specific facets of corrosion resistance in relation to this type of component.

- Material Selection and Grade

The type and grade of material used in the construction of the exhaust component are primary determinants of its corrosion resistance. Higher grades of stainless steel, such as 304 or 316, exhibit superior resistance to oxidation and chloride-induced corrosion compared to lower-grade steel or aluminized steel. An exhaust built with high-quality stainless steel will withstand exposure to road salts, moisture, and acidic exhaust gases for a longer period, whereas inferior materials will degrade more rapidly. For instance, a “spoon n1 muffler” fabricated from 304 stainless steel will have a significantly longer lifespan in a coastal environment than one made from carbon steel.

- Welding Integrity

The quality of the welds employed during the fabrication of the exhaust component also significantly impacts its corrosion resistance. Welds are often points of vulnerability because they can be more susceptible to corrosion than the base metal if not properly executed. Improper welding techniques can introduce impurities or create crevices that trap moisture and corrosive agents. A well-executed weld with full penetration and proper passivation will minimize these risks. For example, TIG welding, a process often employed for high-quality exhaust systems, provides a cleaner and more corrosion-resistant weld than MIG welding.

- Protective Coatings

The application of protective coatings can further enhance the corrosion resistance of exhaust components. Coatings such as ceramic coatings or specialized paints create a barrier between the metal and the environment, preventing or slowing down the corrosion process. These coatings can be particularly effective in protecting areas that are exposed to high temperatures or are prone to moisture accumulation. A ceramic coating applied to a “spoon n1 muffler” can significantly extend its lifespan by protecting it from thermal oxidation and chemical attack. However, the effectiveness of the coating depends on its quality and proper application.

- Environmental Factors

External environmental factors play a huge role in corrosion. These factors can significantly impact the rate of corrosion on components. Exposure to road salt in winter, coastal environments with high salinity, and areas with high levels of air pollution will accelerate corrosion. The design of the component, including drainage holes and the avoidance of crevices where moisture can collect, can mitigate some of these effects. A “spoon n1 muffler” used in a northern climate with heavy road salting will require more robust corrosion protection measures than one used in a dry, temperate climate.

In conclusion, the corrosion resistance of an exhaust component like the “spoon n1 muffler” is a multifaceted property influenced by material selection, welding integrity, protective coatings, and environmental factors. A comprehensive approach to corrosion protection, incorporating high-quality materials, proper fabrication techniques, and the consideration of environmental conditions, is essential for ensuring the longevity and performance of the exhaust system.

6. Performance enhancement

Performance enhancement is a primary driver behind the selection and installation of aftermarket exhaust components. These components, designed to optimize engine output, directly affect a vehicle’s horsepower, torque, and overall responsiveness. The “spoon n1 muffler,” specifically engineered for performance gains, serves as a relevant example for understanding these principles.

- Exhaust Gas Flow Optimization

Aftermarket exhaust systems frequently reduce backpressure, enabling more efficient exhaust gas evacuation from the engine cylinders. This optimization of exhaust flow directly contributes to increased horsepower and torque. The “spoon n1 muffler,” designed with a specific internal structure and diameter, facilitates improved gas flow, resulting in measurable performance gains compared to stock systems. Independent dyno tests often quantify these increases, providing tangible evidence of the enhancement. It is of note that gains are achieved via modification.

- Engine Breathing Efficiency

Enhanced exhaust flow allows the engine to “breathe” more effectively, enabling the intake of a greater volume of air and fuel. This improved intake efficiency is a critical factor in achieving increased power output. The “spoon n1 muffler,” when coupled with other exhaust system modifications, optimizes the engine’s breathing capacity, contributing to overall performance improvements. These improvements enable better acceleration and vehicle efficiency.

- Weight Reduction Benefits

Certain aftermarket exhaust components, including the “spoon n1 muffler,” may be constructed from lighter materials such as stainless steel or titanium. This weight reduction contributes to improved vehicle handling, acceleration, and braking performance. The reduction of weight can enhance overall vehicle dynamics.

- Sound Profile Enhancement

While not directly related to quantifiable performance metrics, the enhanced sound profile associated with aftermarket exhaust components contributes to the perceived performance enhancement. The aggressive, sporty exhaust note produced by the “spoon n1 muffler” can enhance the driving experience, providing auditory feedback that reinforces the sensation of increased power and responsiveness. The sound is a psychological factor influencing the overall driving experience.

These facets of performance enhancement, achieved through components such as the “spoon n1 muffler,” highlight the significant role of aftermarket exhaust systems in optimizing engine output and improving the driving experience. The selection of appropriate exhaust components, tailored to the specific vehicle and performance goals, is crucial for maximizing these benefits. These improvements impact measurable vehicle performance.

Frequently Asked Questions

The following addresses common inquiries regarding aftermarket exhaust mufflers and their impact on vehicle performance, sound, and regulatory compliance.

Question 1: What quantifiable performance gains can be expected from installing an aftermarket exhaust muffler, specifically the “spoon n1 muffler”?

Performance gains vary based on engine specifications, vehicle modifications, and muffler design. Dyno testing is recommended to ascertain precise figures. However, gains typically range from 5 to 15 horsepower in naturally aspirated engines when coupled with complementary modifications.

Question 2: How does the “spoon n1 muffler” affect vehicle emissions and compliance with local regulations?

Aftermarket mufflers may or may not alter vehicle emissions. It is imperative to ensure the component complies with all applicable local and federal regulations. Modifying or removing catalytic converters is often illegal and detrimental to air quality. Consult local regulations before installation.

Question 3: What is the expected lifespan of an aftermarket exhaust muffler, such as the “spoon n1 muffler,” and what factors influence its durability?

Lifespan depends on material quality, environmental conditions, and usage patterns. Stainless steel models generally last longer than aluminized steel. Exposure to road salt and harsh driving conditions can accelerate corrosion. Regular inspection and maintenance are advised.

Question 4: Will installing an aftermarket exhaust muffler void the vehicle’s warranty?

Installation of an aftermarket component may affect the vehicle’s warranty, particularly if the component is the direct cause of a failure. The Magnuson-Moss Warranty Act provides some protection; however, the specifics depend on the manufacturer’s warranty terms. Consult the warranty documentation and seek clarification from the dealership.

Question 5: What is the ideal installation method for ensuring proper fitment and performance of the “spoon n1 muffler”?

Professional installation is highly recommended due to the complexities involved. Proper welding techniques, torque specifications, and alignment procedures are crucial for optimal performance and leak prevention. Adherence to manufacturer instructions is paramount. Improper welding techniques can cause component failures.

Question 6: How does the “spoon n1 muffler” affect the vehicle’s sound profile, and what are the implications for noise regulations?

Aftermarket mufflers typically alter the exhaust sound. The “spoon n1 muffler” is known for its aggressive sound. Excessive noise levels may violate local noise ordinances. Consult local regulations to ensure compliance with decibel limits. Maintaining responsible sound levels benefits the community.

These answers provide essential information regarding aftermarket exhaust muffler installation and maintenance. Understanding these points helps ensure compliance, performance, and legality.

The subsequent section explores potential issues encountered during exhaust modifications and their recommended solutions.

Concluding Remarks

This exploration has detailed the “spoon n1 muffler” within the broader context of aftermarket exhaust components. Key considerations include material composition, exhaust flow dynamics, sound characteristics, installation precision, corrosion resistance, and performance enhancement. A thorough understanding of these elements is crucial for informed decision-making and responsible vehicle modification.

The selection and application of any aftermarket component, including the “spoon n1 muffler,” necessitate careful consideration of intended use, regulatory compliance, and potential impacts on vehicle performance and longevity. Responsible modification practices are essential for maximizing benefits while minimizing risks and ensuring sustained vehicle integrity.