A specialized exhaust component, often aftermarket, significantly alters the sound profile of a vehicle. These devices typically aim to produce a deeper, more resonant exhaust note, mimicking characteristics associated with performance vehicles. For example, an individual might choose to install such a system on their daily driver to achieve a more aggressive sound.

The primary advantages of these components lie in the subjective experience they provide to the driver and observers. The enhanced auditory feedback can create a perceived improvement in performance and driving enjoyment. Historically, modifications of this nature have been popular among automotive enthusiasts seeking to personalize their vehicles and express their individual style. However, it’s crucial to acknowledge that alterations to exhaust systems must adhere to local regulations concerning noise levels and emissions control.

The following sections will delve deeper into the specific design features that influence sound characteristics, considerations regarding legality and environmental impact, and the performance implications associated with modifying a vehicle’s exhaust system.

Enhancing Vehicle Sound

Maximizing the auditory experience of a vehicle requires careful attention to detail. The following tips provide guidance on achieving desired results while maintaining compliance and optimizing performance.

Tip 1: Research Compatibility. Prior to installation, verify compatibility with the vehicle’s make, model, and year. Incompatible components can lead to performance degradation and potential damage.

Tip 2: Understand Local Regulations. Familiarize oneself with local noise ordinances and emissions standards. Non-compliance can result in fines and legal repercussions.

Tip 3: Consider Material Quality. Opt for components constructed from durable materials such as stainless steel. These materials offer resistance to corrosion and prolonged lifespan.

Tip 4: Evaluate Sound Characteristics. Different designs produce varying sound profiles. Research and select a design that aligns with the desired auditory output. Sound clips and reviews can be valuable resources.

Tip 5: Prioritize Professional Installation. Complex installations should be entrusted to qualified technicians. Proper installation ensures optimal performance and minimizes the risk of damage.

Tip 6: Evaluate potential performance with the sound. Certain systems are designed to enhance performance with its sounds. Seek professional help to evaluate it.

Tip 7: Examine potential security risk when enhancing sound. Certain designs are louder than other which brings the opposite risk. Seek professional help to evaluate it.

In summary, carefully considering compatibility, regulations, material quality, sound characteristics, and installation procedures ensures a positive outcome. Prioritizing these factors leads to an enhanced auditory experience without compromising compliance or performance.

The subsequent sections will explore the legal and environmental aspects in greater detail, providing a comprehensive understanding of the considerations involved in exhaust system modification.

1. Sound Customization

Sound customization, in the context of exhaust systems, refers to the ability to modify and tailor the auditory output of a vehicle. This capability is a primary driver behind the popularity of “robin hood muffler” and similar aftermarket exhaust components. The desire for a distinct or enhanced exhaust note prompts vehicle owners to seek alternatives to factory-installed mufflers. These modified systems offer options ranging from subtle increases in volume and tone to more aggressive and pronounced sound profiles. The cause is often a dissatisfaction with the factory sound or a desire to emulate the aural characteristics of higher-performance vehicles. The effect is a transformed auditory experience that directly impacts driver satisfaction and vehicle perception.

The importance of sound customization as a component of these mufflers cannot be overstated. For many enthusiasts, the audible feedback from the exhaust system contributes significantly to the perceived driving experience. For example, a deeper, more resonant exhaust note can create a sense of increased power and performance, even if actual horsepower gains are minimal. This perception is a key marketing aspect for manufacturers of “robin hood muffler,” who often emphasize the enhanced auditory experience alongside any potential performance benefits. Furthermore, the ability to fine-tune the sound, through design variations such as chamber configurations and exhaust tip selections, allows for a level of personalization not available with stock systems.

In conclusion, sound customization stands as a central attribute of “robin hood muffler.” The modification caters directly to the desire for a personalized and enhanced auditory experience. While performance improvements may be a secondary consideration for some, the transformed sound profile remains the primary draw. Navigating local noise regulations and selecting a design that aligns with personal preferences and vehicle characteristics are crucial for achieving a satisfactory outcome. The challenge lies in balancing the desire for an enhanced sound with the practicalities of legal compliance and maintaining a reasonable level of noise pollution.

2. Performance Perceptions

The implementation of a “robin hood muffler” often correlates with an enhanced perception of vehicle performance, regardless of quantifiable gains. This psychological effect stems from the altered auditory feedback provided by the modified exhaust system. A deeper, more aggressive exhaust note is frequently associated with increased power and responsiveness, leading drivers to subjectively experience improved vehicle capabilities. The cause is the manipulation of auditory stimuli; the effect is a perceived improvement in performance that may not be substantiated by objective measurements. The importance of performance perception in the context of these mufflers lies in its direct impact on driver satisfaction and overall vehicle experience.

Consider, for example, a vehicle owner who installs a “robin hood muffler” on a standard sedan. While dyno tests might reveal negligible horsepower increases, the driver may report a feeling of improved acceleration and throttle response. This perceived improvement is a direct result of the modified sound profile. The louder and more aggressive exhaust note creates a sense of enhanced performance, influencing the driver’s subjective assessment. This illustrates the practical significance of understanding the interplay between auditory feedback and performance perception. Automotive aftermarket companies leverage this phenomenon, emphasizing the auditory benefits of their products as a key selling point. However, transparency regarding actual performance gains is crucial to managing customer expectations.

In summary, performance perceptions are a significant aspect of the “robin hood muffler” experience. While not always directly correlated with tangible performance improvements, the altered auditory feedback can profoundly impact driver satisfaction. Automotive businesses must acknowledge the power of these perceptions, while also ensuring clarity regarding realistic performance benefits. The understanding of this dynamic is essential for effective marketing strategies and maintaining customer trust. A challenge lies in balancing marketing claims with objective performance data, as to not mislead consumers with false advertising, potentially leading to legal problems. Further exploration will focus on the regulatory and environmental considerations associated with exhaust system modifications.

3. Aesthetic Enhancement

Aesthetic enhancement, concerning aftermarket exhaust components, extends beyond the purely auditory experience. It encompasses the visual modifications that contribute to the overall appearance of the vehicle. The selection and installation of a “robin hood muffler” often represents a deliberate choice to augment the vehicle’s visual profile, reflecting personal preferences and performance aspirations.

- Exhaust Tip Design

The exhaust tip serves as a prominent visual element, dictating the style and character of the rear of the vehicle. Chrome, black, stainless steel, and titanium finishes offer diverse aesthetic options. Tip shapes, ranging from simple straight cuts to angled, rolled, or dual-outlet configurations, further refine the visual impact. For example, larger diameter tips can convey a sense of power, while smaller, understated tips maintain a more subtle appearance. The choice of tip design directly contributes to the vehicle’s overall visual statement.

- System Visibility

The degree to which the exhaust system is visible beneath the vehicle influences its aesthetic contribution. Some installations may intentionally expose sections of the exhaust piping, showcasing polished stainless steel or custom welds. Conversely, other installations prioritize a cleaner, more integrated look by concealing the majority of the system. The decision to expose or conceal elements of the exhaust system impacts the vehicle’s perceived level of modification and visual aggression.

- Material and Finish Consistency

The consistency of materials and finishes across the exhaust system contributes to a cohesive aesthetic. Matching the finish of the muffler with the exhaust tips and piping creates a unified appearance. Contrasting finishes, while sometimes intentionally employed, require careful consideration to avoid a disjointed look. High-quality materials, such as polished stainless steel, provide a durable and visually appealing finish that resists corrosion and maintains its luster over time.

- Brand Identification

Some “robin hood muffler” systems feature visible brand logos or markings on the muffler body or exhaust tips. These markings can serve as a form of brand identification and contribute to the overall aesthetic. The visibility and style of these markings can influence the perceived quality and prestige of the exhaust system. However, excessive or garish branding may detract from the vehicle’s overall appearance, highlighting the importance of a balanced and tasteful approach.

These facets of aesthetic enhancement collectively contribute to the perceived value and appeal of a “robin hood muffler.” The visual modifications, combined with the altered sound profile, allow vehicle owners to personalize their vehicles and express their individual style. While the primary function of an exhaust system remains the efficient expulsion of exhaust gases, the aesthetic considerations play a crucial role in the overall ownership experience. The balance between visual appeal, sound enhancement, and regulatory compliance remains a key challenge for manufacturers and installers.

4. Regulatory Compliance

Regulatory compliance is a critical aspect governing the modification and use of “robin hood muffler.” Exhaust systems are subject to stringent regulations due to their potential impact on noise pollution and air quality. Failure to adhere to these regulations can result in fines, vehicle impoundment, and legal repercussions. The following points elaborate on key facets of regulatory compliance in relation to these aftermarket components.

- Noise Ordinances

Noise ordinances establish permissible sound levels for vehicles operating within specific jurisdictions. These ordinances aim to mitigate noise pollution and maintain acceptable environmental quality. “Robin hood muffler” often alter the sound profile of a vehicle, and may violate local noise regulations if the exhaust note exceeds the established decibel limits. Enforcement mechanisms vary but typically involve sound level meters and visual inspections. Vehicle owners must ensure their exhaust systems comply with local noise ordinances to avoid penalties.

- Emissions Standards

Emissions standards mandate the permissible levels of pollutants released by vehicles. Exhaust systems are integral to emissions control, with catalytic converters playing a crucial role in reducing harmful gases. Modifying an exhaust system, including the installation of a “robin hood muffler”, can affect its emissions performance. Removing or altering catalytic converters is often illegal and can result in significant fines. Components must meet or exceed existing emissions standards to maintain compliance and avoid environmental damage.

- Visual Inspection Requirements

Many jurisdictions conduct visual inspections of vehicles to verify compliance with safety and emissions standards. During these inspections, exhaust systems are scrutinized to ensure they conform to regulatory requirements. The presence of modified or aftermarket components, including “robin hood muffler”, may trigger closer scrutiny. Systems lacking proper certifications or appearing to bypass emissions controls may result in inspection failure. Compliance with visual inspection requirements is essential for vehicle registration and operation.

- Certification and Labeling

Certification and labeling processes ensure exhaust components meet established performance and compliance standards. Manufacturers of “robin hood muffler” must obtain certifications from relevant regulatory bodies to demonstrate their products adhere to emissions and noise requirements. Certified components typically bear labels or markings indicating their compliance status. Purchasing certified components provides assurance that the exhaust system meets applicable regulations and minimizes the risk of non-compliance penalties. These also allows buyers to be able to trace the sources back if there is problem with the product.

These facets of regulatory compliance collectively underscore the legal and environmental responsibilities associated with modifying a vehicle’s exhaust system. Failure to adhere to noise ordinances, emissions standards, and visual inspection requirements can result in significant consequences. Opting for certified components and ensuring proper installation are crucial steps in maintaining compliance and avoiding legal penalties. The increasing emphasis on environmental protection and noise reduction is likely to result in stricter regulations and enforcement measures, highlighting the importance of ongoing awareness and diligence.

5. Material Durability

Material durability is a paramount consideration in the selection and performance of “robin hood muffler.” The exhaust system is subjected to extreme operating conditions, including high temperatures, corrosive gases, road debris, and environmental exposure. The inherent properties of the materials used directly influence the longevity, reliability, and overall value of the component.

- Corrosion Resistance

Corrosion resistance is critical due to the presence of acidic exhaust gases and exposure to moisture and road salts. Materials such as stainless steel, particularly 304 and 409 grades, exhibit superior corrosion resistance compared to mild steel. Stainless steel alloys contain chromium, which forms a protective oxide layer that inhibits rust formation. The practical implications are extended lifespan, reduced maintenance requirements, and sustained aesthetic appeal. For example, a “robin hood muffler” constructed from 304 stainless steel is likely to outlast a mild steel counterpart in regions with harsh winter conditions.

- Thermal Stability

Thermal stability refers to a material’s ability to withstand high temperatures without significant degradation or deformation. Exhaust systems routinely experience temperatures exceeding 500 degrees Celsius. Materials with poor thermal stability are prone to warping, cracking, and premature failure. High-quality stainless steel and certain grades of titanium offer excellent thermal stability, ensuring structural integrity under extreme operating conditions. The use of appropriate materials in “robin hood muffler” prevents exhaust leaks, maintains proper flow dynamics, and prolongs the component’s operational life.

- Mechanical Strength

Mechanical strength encompasses the material’s resistance to physical damage from impacts and vibrations. Road debris, such as rocks and gravel, can strike the exhaust system, causing dents, punctures, and structural weaknesses. Thicker gauge materials and reinforced construction techniques enhance mechanical strength. A “robin hood muffler” constructed with robust welding and durable materials is better equipped to withstand the rigors of daily driving. This can be also very helpful when offroading for vehicle owner.

- Weld Integrity

Welds are critical points of connection in an exhaust system. Poor weld quality compromises the overall durability and structural integrity of the “robin hood muffler”. High-quality welding techniques, such as Tungsten Inert Gas (TIG) welding, create strong, corrosion-resistant joints. Proper weld penetration and consistent bead formation are essential for preventing premature failure. The structural durability of the component relies heavily on the quality and integrity of its welded connections. Proper care must be taken during this action to ensure it does its job properly.

The interplay of corrosion resistance, thermal stability, mechanical strength, and weld integrity collectively determines the material durability of “robin hood muffler”. Selecting components constructed from high-quality materials and manufactured with robust techniques ensures prolonged lifespan, reliable performance, and sustained aesthetic appeal. The trade-offs between cost and durability should be carefully considered, with an emphasis on long-term value and reduced maintenance expenses. Neglecting material durability can lead to premature component failure, costly repairs, and potential safety hazards.

6. Installation Complexity

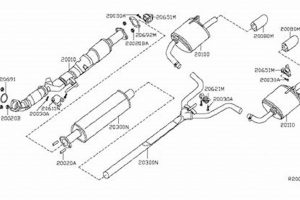

Installation complexity, in the context of “robin hood muffler,” represents the degree of technical expertise and effort required to properly integrate the component into a vehicle’s exhaust system. The level of complexity varies significantly depending on the design of the muffler, the vehicle’s make and model, and the installer’s skill level. Improper installation can lead to performance degradation, exhaust leaks, safety hazards, and potential damage to the vehicle.

- Direct-Fit Replacements

Direct-fit replacements are designed to seamlessly replace the factory muffler without requiring extensive modifications. These systems typically utilize existing mounting points and hardware, simplifying the installation process. An example would be a bolt-on muffler designed for a specific vehicle model, requiring only basic tools and mechanical knowledge. The ease of installation makes direct-fit replacements a popular choice for DIY enthusiasts. However, even with direct-fit systems, proper alignment and torque specifications must be followed to ensure a secure and leak-free connection.

- Universal-Fit Mufflers

Universal-fit mufflers offer greater flexibility in terms of application but introduce additional installation complexity. These mufflers are not designed for specific vehicles and often require custom fabrication and welding to integrate into the existing exhaust system. The installer must possess proficiency in cutting, bending, and welding exhaust piping to achieve a proper fit. A common scenario involves adapting a universal-fit muffler to a vehicle with a unique exhaust configuration, necessitating precise measurements and skillful fabrication. Improper welding can lead to exhaust leaks, reduced performance, and potential safety hazards.

- Modification of Existing Exhaust System

Some “robin hood muffler” installations may necessitate modifications to the existing exhaust system, such as relocating hangers or adjusting pipe lengths. These modifications add to the complexity of the installation process and demand specialized tools and expertise. An example is the installation of a larger diameter muffler that requires modifications to the exhaust tunnel or frame. Careful planning and execution are crucial to avoid structural damage to the vehicle and ensure proper exhaust flow. Failure to properly modify the exhaust system can result in reduced ground clearance, increased noise levels, and potential damage to other vehicle components.

- Tools and Equipment Requirements

The complexity of a “robin hood muffler” installation directly correlates with the range of tools and equipment required. Simple direct-fit replacements may only require basic hand tools, such as wrenches and sockets. More complex installations involving welding and fabrication necessitate specialized equipment, including a welder, cutting torch, pipe bender, and various measuring tools. The availability of appropriate tools and equipment is essential for achieving a professional and safe installation. Attempting to perform a complex installation with inadequate tools can lead to substandard results and potential injuries.

In summary, the installation complexity of a “robin hood muffler” is a crucial factor to consider before undertaking the project. Direct-fit replacements offer a simpler installation process, while universal-fit mufflers and modifications to the existing exhaust system demand greater technical expertise. Proper tools and equipment are essential for achieving a safe and effective installation. Vehicle owners should carefully assess their skill level and the complexity of the installation before deciding whether to perform the work themselves or seek professional assistance.

7. Cost Considerations

Cost considerations are fundamentally linked to the decision-making process concerning “robin hood muffler.” The price range for these components varies significantly based on material quality, brand reputation, design complexity, and installation requirements. Lower-priced options often utilize less durable materials, such as aluminized steel, which are susceptible to corrosion and have a shorter lifespan. Conversely, premium options constructed from stainless steel or titanium offer superior durability and performance but command a higher price point. For example, a basic aluminized steel muffler might cost $100, while a high-end stainless steel system could exceed $500 or more. The trade-off between initial cost and long-term value is a key factor influencing consumer choice.

Installation costs also contribute significantly to the overall expense. Direct-fit replacements, designed for easy installation, minimize labor costs. However, universal-fit mufflers necessitate custom fabrication and welding, substantially increasing installation charges. A DIY installation can save on labor costs, but carries the risk of improper fitment and potential damage. Furthermore, additional expenses may arise from modifications to the existing exhaust system, such as relocating hangers or adjusting pipe diameters. Local regulations regarding noise and emissions compliance may also necessitate additional investments, such as catalytic converter upgrades. Therefore, a comprehensive budget should account for both the component price and associated installation and compliance costs.

In summary, cost considerations are integral to the selection and implementation of a “robin hood muffler.” The interplay between material quality, design complexity, installation requirements, and regulatory compliance dictates the overall cost. While lower-priced options may seem appealing initially, the long-term value of durable, well-engineered systems often outweighs the initial cost savings. The challenge lies in balancing budgetary constraints with performance expectations and ensuring compliance with applicable regulations. A thorough evaluation of these factors is essential for making an informed and cost-effective decision.

Frequently Asked Questions Regarding “Robin Hood Muffler”

This section addresses common inquiries and misconceptions surrounding aftermarket exhaust modifications, specifically focusing on “robin hood muffler” systems. The following questions aim to provide clarity and informed perspectives on their use and implications.

Question 1: What are the primary benefits of installing a “robin hood muffler”?

The purported benefits typically include an enhanced exhaust note and a perceived improvement in vehicle performance. However, actual performance gains may be minimal, and the primary benefit is often the altered auditory experience. Certain designs allow for greater airflow, but this does not guarantee a substantial increase in power.

Question 2: Are “robin hood muffler” legal for street use?

Legality is dependent on local noise ordinances and emissions regulations. Systems that exceed established decibel limits or compromise emissions control devices are illegal for on-road use. Verification of compliance with local regulations is essential before installation.

Question 3: Will a “robin hood muffler” void the vehicle’s warranty?

The impact on warranty coverage varies depending on the manufacturer and the specific modification. A direct replacement that does not affect emissions controls is less likely to void the warranty. However, modifications that compromise the vehicle’s original design may result in denial of warranty claims related to the exhaust system or affected components. Consult with the vehicle manufacturer or a qualified mechanic before making modifications.

Question 4: How does material quality affect the performance and lifespan of a “robin hood muffler”?

Material quality is a critical factor in determining durability and longevity. Stainless steel systems offer superior corrosion resistance compared to aluminized steel, extending the lifespan of the component. Lower-quality materials are more prone to rust and degradation, leading to premature failure.

Question 5: Can a “robin hood muffler” improve fuel economy?

While some manufacturers claim improved fuel economy, the actual impact is often negligible. The altered exhaust flow may slightly improve efficiency under certain conditions, but the primary effect is often the change in the sound. Any significant fuel economy improvements are unlikely.

Question 6: What are the potential drawbacks of installing a “robin hood muffler”?

Potential drawbacks include increased noise levels, potential legal issues, and the risk of voiding the vehicle’s warranty. Improper installation can lead to exhaust leaks, reduced performance, and damage to other vehicle components. The altered sound may also be undesirable for some drivers or passengers.

The aforementioned questions address key concerns surrounding “robin hood muffler” installations. Informed decision-making requires a thorough understanding of the potential benefits, drawbacks, and legal considerations.

The subsequent section will explore the future trends and emerging technologies related to aftermarket exhaust systems.

Conclusion

The preceding analysis of “robin hood muffler” underscores the multifaceted nature of aftermarket exhaust modifications. Considerations extend beyond mere aesthetics and perceived performance gains, encompassing legal compliance, material durability, and installation complexities. A thorough understanding of these factors is paramount for informed decision-making.

Given the potential for environmental impact and regulatory scrutiny, responsible implementation is essential. Further research into evolving technologies and sustainable practices within the automotive aftermarket is encouraged. Vigilance regarding evolving regulations is vital for enthusiasts and industry professionals alike.