The exhaust system component responsible for reducing noise generated by the engine of a specific light-duty pickup truck is a critical element for vehicle operation and regulatory compliance. It functions by dampening sound waves produced during the combustion process before they are released into the atmosphere. This component is specifically designed and engineered to fit the exhaust system of the mentioned vehicle, ensuring proper function and compatibility.

Effective sound suppression contributes to driver and passenger comfort, reducing fatigue on long journeys. It also plays a crucial role in meeting noise emission standards set by regulatory bodies, ensuring legal operation. The design and materials used in its construction influence the overall performance, longevity, and acoustic properties. Historically, advancements in muffler technology have focused on improving sound dampening efficiency, reducing backpressure, and increasing durability.

The following sections will detail the types available, factors to consider when selecting one, installation procedures, common issues, and maintenance recommendations for these vehicle-specific components. Understanding these aspects will aid in making informed decisions regarding replacement or upgrades.

Selection and Maintenance Guidance

This section offers guidance on selecting and maintaining the exhaust noise reduction component for the specified vehicle, ensuring optimal performance and longevity.

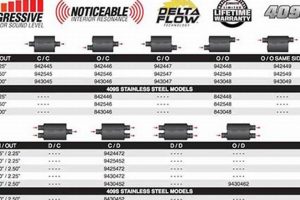

Tip 1: Consider Material Composition: Stainless steel variants offer superior corrosion resistance compared to aluminized steel, extending the lifespan in harsh environments.

Tip 2: Evaluate Internal Design: Chambered designs generally offer a quieter operation, while straight-through designs prioritize performance by minimizing backpressure.

Tip 3: Check for Compatibility: Verify the specific model year and engine configuration of the truck to ensure a proper fit. Mismatched components can lead to performance issues or installation difficulties.

Tip 4: Inspect Welds Regularly: Examine all welds for signs of cracking or corrosion. Weakened welds can lead to exhaust leaks and reduced noise reduction effectiveness.

Tip 5: Address Rust Promptly: Surface rust can compromise structural integrity. Treat rust with a rust converter and protective coating to prevent further deterioration.

Tip 6: Monitor for Exhaust Leaks: Listen for unusual noises emanating from the exhaust system, which may indicate leaks. Address leaks immediately to maintain optimal engine performance and prevent potential safety hazards.

Tip 7: Torque Fasteners to Specification: When installing or replacing, ensure all fasteners are torqued to the manufacturer’s specified values. Over-tightening can damage the components, while under-tightening can lead to leaks.

Adhering to these guidelines will help ensure optimal performance, extended lifespan, and safe operation of this critical exhaust system component.

The following sections will delve into potential issues and troubleshooting techniques.

1. Sound Dampening Efficiency

Sound dampening efficiency, as it pertains to the exhaust component of a light-duty pickup truck, specifically the Dodge Ram 1500, directly affects the vehicle’s noise output and compliance with regulations. A device with high sound dampening capabilities effectively reduces exhaust noise, mitigating sound pollution. Inferior sound dampening results in increased noise levels, potentially leading to violations of local ordinances and diminished driver and passenger comfort. For example, a damaged or improperly designed component will generate excessive noise, negatively impacting the environment and user experience. The component, engineered to meet specified acoustic standards, plays a critical role in controlling the decibel level produced by the engine’s combustion process.

The practical application of understanding the connection between sound dampening and the aforementioned exhaust part lies in making informed purchasing and maintenance decisions. When selecting a replacement, opting for a model with a proven record of noise reduction is important. Moreover, recognizing the signs of a failing unitsuch as increased exhaust noiseallows for timely replacement, preventing further noise pollution and potential legal ramifications. Aftermarket components often advertise varying levels of noise reduction; verification of these claims through independent testing is advised before purchase. Maintaining the exhaust system integrity, including addressing leaks, directly contributes to maintaining optimal sound dampening performance.

In summary, the effectiveness of sound dampening within the specific exhaust system part examined directly impacts both regulatory compliance and the user’s experience. Inadequate sound dampening leads to noise pollution and potential legal issues, emphasizing the importance of selecting and maintaining a device with optimal noise reduction capabilities. The challenge lies in balancing sound dampening with factors like exhaust flow and engine performance, requiring a comprehensive understanding of the design and operation.

2. Material Durability

Material durability directly influences the lifespan and operational effectiveness of the exhaust noise reduction component on the Dodge Ram 1500. The exhaust system is subjected to extreme conditions, including high temperatures, corrosive exhaust gases, road salts, and physical impacts. Consequently, the material composition of the muffler determines its resistance to these factors and its overall longevity. A muffler constructed from low-grade steel is susceptible to premature rust, corrosion, and eventual failure, necessitating frequent replacements. Conversely, employing materials such as stainless steel significantly enhances resistance to corrosion, extending the component’s service life and reducing long-term maintenance costs. For instance, vehicles operating in regions with heavy winter road salting experience accelerated corrosion on exhaust systems made from less durable materials, while those equipped with stainless steel components exhibit significantly improved resistance.

The practical implication of material durability extends beyond merely preventing rust. A compromised muffler can lead to exhaust leaks, reduced engine performance, increased noise levels, and potential safety hazards. For example, a rusted-through muffler may create an exhaust leak that allows harmful gases to enter the vehicle cabin or compromise the catalytic converter’s efficiency. Furthermore, the structural integrity of the muffler is crucial for maintaining its sound-dampening properties. Corrosion can weaken the internal baffles and chambers within the muffler, diminishing its ability to effectively reduce exhaust noise. The selection of durable materials contributes to ensuring regulatory compliance, optimal engine performance, and a safe operating environment.

In conclusion, material durability is a critical determinant of the exhaust noise reduction component’s performance and lifespan on the Dodge Ram 1500. The initial investment in a muffler constructed from corrosion-resistant materials, such as stainless steel, represents a cost-effective strategy in the long run, mitigating the need for frequent replacements and maintaining optimal vehicle performance. The challenge lies in balancing material costs with performance requirements, necessitating a careful evaluation of operating conditions and long-term ownership considerations. Understanding the direct link between material durability and the muffler’s performance is paramount for informed decision-making.

3. Exhaust Backpressure

Exhaust backpressure, the resistance to exhaust gas flow within an engine’s exhaust system, is directly influenced by the design and condition of the Dodge Ram 1500 muffler. The muffler, designed to attenuate engine noise, inherently creates some level of backpressure due to its internal baffling and chamber configurations. Excessive backpressure negatively impacts engine performance by hindering the efficient expulsion of exhaust gases from the cylinders. This, in turn, reduces volumetric efficiency, leading to decreased power output and potentially increased fuel consumption. For example, a clogged or poorly designed muffler significantly elevates backpressure, resulting in noticeable performance degradation, particularly at higher engine speeds.

The selection of an appropriate muffler for the Dodge Ram 1500 necessitates careful consideration of backpressure characteristics. High-performance mufflers often prioritize reduced backpressure to enhance engine output, sacrificing some degree of noise reduction in the process. Conversely, quieter mufflers generally exhibit higher backpressure levels, striking a balance between noise attenuation and performance. The condition of the muffler also plays a crucial role; internal corrosion and debris accumulation can obstruct exhaust flow, leading to increased backpressure and subsequent performance issues. Regular inspection and maintenance are, therefore, essential to ensure optimal exhaust system performance.

In summary, the relationship between exhaust backpressure and the Dodge Ram 1500 muffler is critical for achieving optimal engine performance and fuel efficiency. Excessive backpressure impedes exhaust gas flow, reducing power output and potentially increasing fuel consumption. Selecting a muffler with appropriate backpressure characteristics and maintaining the exhaust system’s integrity are vital for maximizing the vehicle’s performance and minimizing potential operational issues. The challenge lies in finding the right balance between noise reduction and exhaust flow efficiency, requiring an understanding of muffler design principles and the specific needs of the engine.

4. Vehicle Compatibility

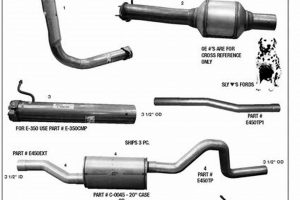

The principle of vehicle compatibility dictates the successful integration and operation of a Dodge Ram 1500 muffler within the vehicle’s exhaust system. A muffler designed for a different vehicle model or engine configuration will likely exhibit dimensional discrepancies, incompatible mounting points, and mismatched exhaust pipe diameters. These incompatibilities prevent proper installation, potentially leading to exhaust leaks, structural instability, and compromised noise reduction. For example, attempting to install a muffler intended for a V6 engine on a V8 Dodge Ram 1500 will likely result in significant fitment issues and inadequate exhaust flow, negating its intended function. Genuine or approved aftermarket mufflers are engineered to specific Dodge Ram 1500 model years and engine types, ensuring precise fit and optimized performance.

The ramifications of neglecting vehicle compatibility extend beyond mere fitment challenges. An incorrectly sized muffler can create excessive backpressure, impeding engine performance and potentially damaging other exhaust system components, such as the catalytic converter. Furthermore, an incompatible muffler may not meet required noise emission standards, resulting in legal non-compliance. Conversely, a properly matched muffler ensures efficient exhaust gas flow, optimal noise reduction, and adherence to regulatory requirements. Parts catalogs and online resources offer compatibility charts to facilitate the selection of the correct muffler for the specific Dodge Ram 1500 variant. Consulting these resources or seeking expert advice minimizes the risk of purchasing and installing an incompatible component.

In summary, vehicle compatibility is paramount to the proper functioning and integration of a Dodge Ram 1500 muffler. Mismatched components can lead to installation difficulties, performance degradation, potential legal non-compliance, and damage to other exhaust system elements. Thorough verification of compatibility using reliable resources and professional guidance mitigates these risks, ensuring optimal exhaust system performance, noise reduction, and adherence to regulatory standards. The challenge lies in navigating the numerous aftermarket options and varying specifications to identify the precisely compatible muffler, underscoring the importance of meticulous research and informed decision-making.

5. Installation Integrity

Installation integrity, regarding the Dodge Ram 1500 muffler, encompasses the correctness and robustness of the installation process, impacting the component’s performance, longevity, and safety. Proper installation is critical to realizing the intended benefits of the muffler and preventing potential issues.

- Proper Alignment and Mounting

Correct alignment of the muffler within the exhaust system ensures seamless integration with existing pipes and hangers. Misalignment can induce stress on the muffler’s welds and connections, leading to premature failure and exhaust leaks. Secure mounting using appropriate hangers and hardware prevents excessive vibration and movement, which can also compromise the muffler’s structural integrity. For example, failing to properly align the inlet and outlet pipes during installation can create a strained connection that is prone to cracking over time.

- Correct Torque Specifications

Adhering to specified torque values for all fasteners is essential. Over-tightening fasteners can damage the muffler’s flanges or mounting brackets, while under-tightening can result in loose connections and exhaust leaks. Using a torque wrench to ensure accurate tightening promotes a secure and leak-free seal between the muffler and the rest of the exhaust system. Ignoring torque specifications can easily damage the component and lead to diminished function.

- Sealing and Leak Prevention

Effective sealing at all connections prevents exhaust leaks, which can compromise engine performance, increase noise levels, and pose safety risks due to the potential for carbon monoxide exposure. The use of appropriate gaskets and sealant ensures a tight seal between the muffler and connecting pipes. Regular inspection of connections for signs of leaks, such as soot deposits or unusual noises, allows for timely corrective action. For example, using exhaust sealant at pipe connections can significantly improve leak prevention over time.

- Avoidance of Stress and Damage

Careless handling during installation can cause dents, bends, or other damage to the muffler, compromising its structural integrity and performance. Avoiding excessive force when fitting the muffler into place prevents unnecessary stress on the component and its connections. Using proper tools and techniques minimizes the risk of accidental damage during the installation process. Even minor dents can affect airflow and reduce noise cancellation effectivness.

In conclusion, installation integrity is indispensable for maximizing the lifespan and effectiveness of the Dodge Ram 1500 muffler. Proper alignment, torque, sealing, and careful handling are essential elements of a successful installation, preventing leaks, damage, and premature failure. A properly installed muffler contributes to optimal engine performance, reduced noise levels, and a safe operating environment. The challenge lies in ensuring adherence to best practices throughout the installation process, requiring both technical competence and meticulous attention to detail.

Frequently Asked Questions

This section addresses common inquiries regarding the exhaust noise reduction device for the specified light-duty pickup truck, aiming to provide clarity and informed decision-making.

Question 1: What is the expected lifespan of a muffler on this vehicle?

The lifespan varies depending on material composition, environmental conditions, and driving habits. Stainless steel components typically last longer than aluminized steel ones. Exposure to road salts and frequent short trips can shorten lifespan. A properly maintained component can last five to ten years or more.

Question 2: How does a failing exhaust noise reduction component affect engine performance?

A failing component, often due to internal corrosion or blockage, can increase backpressure, hindering exhaust flow. This can reduce engine power, fuel efficiency, and potentially damage other exhaust system components.

Question 3: What are the legal implications of operating a vehicle with an excessively loud exhaust system?

Operating a vehicle exceeding established noise emission standards can result in fines and citations. Specific regulations vary by locality, but most jurisdictions have decibel limits for vehicle exhaust systems.

Question 4: Is it possible to replace the exhaust noise reduction device without specialized tools?

While some installations are straightforward, specialized tools, such as a torque wrench and exhaust pipe cutter, are generally recommended for proper and safe installation. Incorrect installation can lead to leaks and other issues.

Question 5: What are the primary differences between aftermarket and original equipment manufacturer (OEM) components?

OEM components are designed and manufactured to meet the vehicle manufacturer’s specifications, ensuring optimal fit and performance. Aftermarket components offer a wider range of options, including performance-oriented designs, but quality and compatibility can vary.

Question 6: How can the likelihood of corrosion on the exhaust system be minimized?

Selecting a stainless steel component is the most effective way to reduce corrosion. Regular washing of the vehicle’s undercarriage, particularly during winter months, can remove road salts and other corrosive elements.

Understanding these points can aid in the maintenance and selection of the correct exhaust component, ensuring performance and legal compliance.

The subsequent section explores common problems and troubleshooting strategies associated with this component.

Conclusion

The Dodge Ram 1500 muffler is a critical element in the vehicle’s exhaust system, impacting noise levels, engine performance, and regulatory compliance. This device’s material composition directly influences its lifespan, and proper installation is essential for preventing leaks and ensuring optimal function. Choosing a compatible component that balances noise reduction with minimal exhaust backpressure contributes to long-term vehicle health.

Careful consideration of the factors outlined is recommended when selecting or maintaining this exhaust system element. Prioritizing durability, compatibility, and proper installation promotes extended component life and sustained performance. The knowledge presented enables informed decisions, resulting in optimized vehicle operation and adherence to applicable standards.