The exhaust component designed specifically for a particular motorcycle model, the Yamaha V-Star 650, serves to attenuate engine noise and direct exhaust gases away from the rider. This part is an integral element of the motorcycle’s exhaust system, influencing both its sound profile and performance characteristics. It is typically constructed from materials like steel or aluminum and may incorporate baffles or other internal structures to achieve desired sound levels.

Proper functioning of this exhaust component is critical for meeting noise regulations and ensuring optimal engine operation. Replacement or modification can affect the motorcycle’s sound output, backpressure, and potentially, its horsepower and torque. Historically, the design and materials used in these systems have evolved alongside advancements in engine technology and increasing awareness of environmental concerns related to noise pollution.

The following discussion will explore various aspects related to this essential motorcycle component, including aftermarket options, installation procedures, performance considerations, and maintenance practices. Understanding these factors can assist owners in making informed decisions regarding their motorcycle’s exhaust system.

Essential Considerations for Maintaining Exhaust Systems

The following tips offer guidance on maintaining and optimizing the motorcycle’s exhaust system. Diligent attention to these areas can contribute to the longevity and performance of the vehicle.

Tip 1: Inspect Regularly for Corrosion: Routine examination of the exhaust component is crucial for identifying rust or corrosion. Early detection can prevent significant structural damage and costly repairs. Pay close attention to areas exposed to road spray and salt.

Tip 2: Monitor Exhaust Leaks: Listen for unusual hissing or popping sounds originating from the exhaust system. These noises may indicate leaks at the joints or welds. Prompt repair is essential to prevent performance degradation and potential exhaust fume exposure.

Tip 3: Utilize Proper Mounting Hardware: When replacing or reinstalling the exhaust, ensure that the correct mounting hardware is used and tightened to the manufacturer’s specified torque. Improper installation can lead to vibration, premature wear, and eventual failure.

Tip 4: Clean the Exhaust Surface: Regular cleaning of the exhaust surface can help prevent the buildup of grime and road debris. Use appropriate cleaning agents designed for the exhaust’s material to avoid damage or discoloration.

Tip 5: Consider Aftermarket Options Carefully: When exploring aftermarket exhaust components, research reputable brands and ensure that the selected option is compatible with the specific motorcycle model and meets applicable noise regulations. Performance gains should be weighed against potential drawbacks, such as increased noise levels.

Tip 6: Check for Baffle Integrity: If the component incorporates baffles, periodically inspect them for damage or deterioration. Damaged baffles can lead to increased noise levels and reduced exhaust backpressure, potentially affecting engine performance.

Tip 7: Address Any Dents or Damage: Impacts and road debris can cause dents or other damage to the component. While minor cosmetic damage may not affect performance, significant dents can restrict exhaust flow. Consider professional repair or replacement in cases of substantial damage.

Adhering to these maintenance practices will promote the overall health and efficiency of the motorcycle’s exhaust system, ensuring a longer lifespan and consistent performance.

The subsequent sections will delve into topics related to installation, performance tuning, and troubleshooting common issues associated with this component.

1. Sound Attenuation

Sound attenuation, the reduction of noise intensity, is a primary function of the exhaust component fitted to the Yamaha V-Star 650. This component incorporates internal baffling and sound-dampening materials designed to lower the decibel level of the engine’s exhaust output. Without effective sound attenuation, the motorcycle would produce excessive noise, potentially violating local ordinances and negatively impacting rider comfort. The design and construction of the internal components directly affect the degree of sound attenuation achieved.

The design of the V-Star 650 exhaust component demonstrates the practical application of sound attenuation principles. For instance, the inclusion of strategically placed baffles within the exhaust canister disrupts sound waves, reducing their amplitude. Different exhaust designs, whether stock or aftermarket, can exhibit varying levels of sound attenuation. A straight-through design, common in performance-oriented aftermarket systems, typically offers reduced sound attenuation compared to the stock configuration. This tradeoff necessitates a careful consideration of desired performance gains against acceptable noise levels.

Effective sound attenuation is not solely a matter of regulatory compliance; it also contributes to a more enjoyable riding experience. Excessive noise can lead to rider fatigue and potentially damage hearing over prolonged periods. Therefore, maintaining the integrity of the exhaust system and ensuring proper functioning of its sound attenuation features is crucial. Alterations that compromise sound attenuation, while potentially boosting performance, should be approached with awareness of the associated noise implications and potential legal ramifications.

2. Exhaust Flow

Exhaust flow is a critical performance parameter directly influenced by the exhaust component of the Yamaha V-Star 650. The efficiency with which exhaust gases are evacuated from the engine cylinders impacts power output, fuel economy, and overall engine health. The design and condition of the exhaust system, particularly the component in question, play a pivotal role in regulating this flow.

- Backpressure Management

The design of the exhaust component significantly affects backpressure, the resistance to exhaust gas flow. Excessive backpressure hinders the engine’s ability to expel spent gases efficiently, reducing volumetric efficiency and power. Conversely, insufficient backpressure can negatively impact low-end torque. The stock exhaust system is engineered to strike a balance suitable for general riding conditions. Modifications to the exhaust, especially the replacement of the component, can alter backpressure characteristics, requiring careful consideration and potential engine tuning adjustments.

- Diameter and Length Optimization

The diameter and length of the exhaust component’s internal passages influence exhaust gas velocity and scavenging effects. A larger diameter generally facilitates higher flow rates, beneficial at high engine speeds. However, excessively large diameters can reduce gas velocity at lower RPMs, potentially diminishing low-end torque. The length of the exhaust system also affects the timing of pressure waves within the exhaust, which can be tuned to enhance cylinder filling and scavenging. Proper optimization requires careful design and testing, often necessitating specialized equipment.

- Internal Baffle Design

Internal baffles within the component are utilized to control noise levels and influence exhaust flow characteristics. These baffles create controlled restrictions that attenuate sound while also impacting backpressure. The design of these baffles, including their shape, size, and placement, is critical in achieving the desired balance between noise reduction and performance. Aftermarket components may feature different baffle designs that offer alternative sound and performance profiles. Removal or modification of baffles can significantly alter exhaust flow, potentially leading to performance changes and increased noise levels.

- Catalytic Converter Impact

Although not always present on all V-Star 650 models depending on the year and region, catalytic converters, when installed, introduce a significant restriction to exhaust flow. These devices are designed to reduce harmful emissions but inherently increase backpressure. The condition of the catalytic converter also affects exhaust flow; a clogged or damaged converter can severely restrict flow and negatively impact engine performance. Replacement or removal of the catalytic converter (where legally permissible) can improve exhaust flow but also increase emissions.

In summary, the exhaust component’s influence on exhaust flow is multifaceted, involving backpressure management, diameter and length optimization, baffle design, and, where applicable, catalytic converter considerations. Modifications to this component can substantially alter these characteristics, impacting engine performance and noise levels. Therefore, a thorough understanding of these factors is essential when considering alterations to the stock exhaust system.

3. Material Durability

The material durability of the exhaust component designed for the Yamaha V-Star 650 is paramount to its operational lifespan and reliability. This component is subjected to extreme conditions, including high temperatures, corrosive exhaust gases, vibration, and exposure to environmental elements like road salt and moisture. Consequently, the material selected for its construction directly impacts its resistance to degradation and, ultimately, its longevity.

The consequences of inadequate material durability are significant. Premature failure of the exhaust component can result in exhaust leaks, reduced engine performance, increased noise levels, and potential safety hazards. For example, a component constructed from low-grade steel may exhibit rapid corrosion, leading to structural weakness and eventual cracking. This can manifest as a noticeable increase in exhaust noise and a reduction in engine power due to compromised exhaust flow. Conversely, components fabricated from materials like stainless steel or titanium offer superior corrosion resistance and higher strength, extending their service life and reducing the risk of failure. The cost differential between these materials reflects their differing levels of durability and performance.

Understanding the practical significance of material durability allows owners to make informed decisions regarding replacement or upgrade options. Choosing an exhaust component constructed from a durable material ensures a longer lifespan, reduces the frequency of repairs, and maintains optimal engine performance. Challenges include balancing cost considerations with the long-term benefits of increased durability. The choice of material represents a critical engineering trade-off that directly influences the overall value and reliability of the exhaust system.

4. Aftermarket Options

The aftermarket for Yamaha V-Star 650 exhaust components presents a wide array of options that cater to diverse rider preferences and performance objectives. These alternatives to the original equipment component offer possibilities for customization, performance enhancement, and aesthetic modification. However, informed selection requires careful consideration of factors such as sound levels, performance impact, and regulatory compliance.

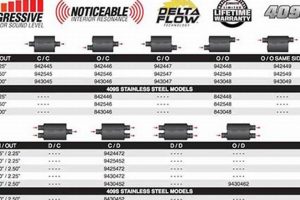

- Performance Enhancement Mufflers

These aftermarket components are designed to optimize exhaust flow, potentially increasing horsepower and torque. They often feature larger diameter piping and less restrictive baffling compared to the stock component. Examples include “slip-on” mufflers that replace only the final section of the exhaust system and complete exhaust systems that replace the entire assembly from the engine to the tailpipe. The performance gains achieved with these components can vary depending on the design and the presence of other engine modifications. Implications include potential increases in noise levels, requiring careful consideration of local noise ordinances.

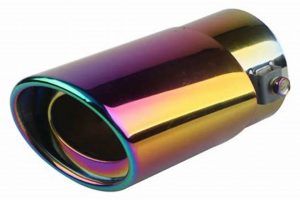

- Aesthetic Customization Mufflers

Aftermarket components offer a wide range of aesthetic styles, from classic chrome finishes to modern blacked-out designs. These components allow riders to personalize the appearance of their motorcycles. Examples include components with unique shapes, end caps, and finishes. The aesthetic appeal of these components is subjective, and selection often depends on personal preference. Implications include the need to ensure that the chosen component complements the overall style of the motorcycle and does not compromise its structural integrity.

- Sound Profile Modification Mufflers

These components are designed to alter the sound characteristics of the exhaust system. They can range from components that produce a deeper, more resonant tone to components that generate a louder, more aggressive sound. Examples include components with adjustable baffles that allow riders to fine-tune the sound level. The sound profile of an exhaust system is a significant factor for many riders, and aftermarket components provide the opportunity to customize this aspect. Implications include the importance of adhering to local noise regulations to avoid potential fines or restrictions.

- Material Upgrade Mufflers

Aftermarket options provide components constructed from alternative materials, such as stainless steel or titanium. These materials offer improved corrosion resistance and potentially reduced weight compared to the stock steel component. Examples include complete stainless-steel exhaust systems that provide enhanced durability in harsh environments. The benefits of material upgrades include increased lifespan and improved aesthetics. Implications include a higher initial cost, which must be weighed against the long-term benefits of increased durability and performance.

The availability of diverse aftermarket exhaust components for the Yamaha V-Star 650 empowers owners to tailor their motorcycles to their individual preferences. However, responsible selection requires careful evaluation of performance, aesthetics, sound, and regulatory considerations. Modifications should be undertaken with a clear understanding of the potential implications and a commitment to maintaining responsible riding practices.

5. Noise Regulation

Noise regulation imposes constraints on the permissible sound levels emitted by motorcycles, directly influencing the design, modification, and operation of the Yamaha V-Star 650’s exhaust component. These regulations, enforced at local, state, and federal levels, aim to mitigate noise pollution and its associated adverse effects on public health and environmental quality. The exhaust component serves as a primary means of controlling engine noise; therefore, its conformity to noise standards is critical for legal operation.

- Legal Compliance Standards

Motorcycle exhaust components must adhere to specific decibel limits established by regulatory bodies. These limits vary depending on the jurisdiction and are often measured using standardized testing procedures. The Yamaha V-Star 650’s original exhaust component is designed to meet these requirements. Alterations, such as installing aftermarket components lacking proper certification, can lead to non-compliance, resulting in fines, vehicle impoundment, or mandatory modifications to restore compliance. Enforcement agencies often conduct roadside inspections to assess noise levels, employing sound meters to verify adherence to legal thresholds.

- Aftermarket Component Certification

Many aftermarket exhaust manufacturers seek certification from regulatory agencies to demonstrate that their components meet applicable noise standards. These certifications, such as those issued by the Environmental Protection Agency (EPA) in the United States, provide assurance that the component has been tested and proven to comply with noise regulations. Consumers should seek out certified components when modifying their Yamaha V-Star 650’s exhaust system to avoid potential legal issues and ensure responsible sound management. The presence of a certification label or marking on the component indicates its compliance status.

- Impact on Exhaust Design

Noise regulations directly influence the design of the Yamaha V-Star 650’s exhaust component. Manufacturers must incorporate noise-reducing technologies, such as baffles, resonators, and sound-absorbing materials, to attenuate engine noise while maintaining acceptable performance levels. These design considerations often involve trade-offs between noise reduction, exhaust flow, and engine power. Aftermarket component designers face similar challenges, striving to create components that offer performance improvements without exceeding legal noise limits. The complexity of exhaust system design is significantly increased by the need to meet stringent noise regulations.

- Enforcement and Penalties

Violations of noise regulations can result in a range of penalties, including fines, citations, and mandatory vehicle inspections. Repeat offenders may face more severe consequences, such as license suspension or vehicle impoundment. Enforcement agencies actively monitor motorcycle noise levels in areas where noise pollution is a concern. The costs associated with non-compliance can be substantial, encompassing fines, repair expenses to restore compliance, and potential legal fees. Awareness of local noise regulations and adherence to established standards are essential for responsible motorcycle ownership and operation.

The interplay between noise regulation and the Yamaha V-Star 650 exhaust component underscores the importance of responsible modification and maintenance. While aftermarket components offer opportunities for customization and performance enhancement, adherence to noise regulations is paramount to ensure legal operation and mitigate the impact of motorcycle noise on the environment. Compliance represents a shared responsibility between manufacturers, aftermarket suppliers, and individual motorcycle owners.

Frequently Asked Questions Regarding Yamaha V-Star 650 Mufflers

This section addresses common inquiries pertaining to the exhaust component, aiming to provide factual information and dispel misconceptions surrounding its function, maintenance, and modification.

Question 1: What is the primary function of the exhaust component on a Yamaha V-Star 650?

The primary function is to attenuate engine noise, directing exhaust gases away from the rider and surrounding environment. It also plays a role in regulating exhaust flow, influencing engine performance.

Question 2: How does the exhaust component affect engine performance?

The component’s design influences exhaust backpressure, which can impact horsepower, torque, and fuel economy. Proper exhaust flow is essential for optimal engine operation. Modifications that alter exhaust flow should be approached with an understanding of their potential effects on performance.

Question 3: What are the signs of a damaged exhaust component?

Indicators of damage include excessive noise, exhaust leaks, rust, corrosion, and physical damage such as dents or cracks. Any of these issues can compromise the component’s functionality and may require repair or replacement.

Question 4: Is it legal to modify the exhaust system of a Yamaha V-Star 650?

Modification is permissible, but alterations must comply with applicable noise regulations. Aftermarket components lacking proper certification may result in legal penalties. Owners should verify compliance with local noise ordinances before making any modifications.

Question 5: What materials are commonly used in the construction of exhaust components?

Common materials include steel, stainless steel, and, less frequently, titanium. Stainless steel offers superior corrosion resistance compared to standard steel. The material selected impacts the component’s durability and lifespan.

Question 6: What maintenance is required for the exhaust component?

Regular inspection for rust, corrosion, and leaks is essential. Cleaning the component’s surface can prevent grime buildup. Damaged sections may require professional repair or complete replacement.

In summary, the exhaust component is a crucial element of the Yamaha V-Star 650, impacting noise levels, engine performance, and environmental compliance. Proper maintenance and informed modification are essential for ensuring optimal operation and legal compliance.

The subsequent section will transition into practical troubleshooting tips for common exhaust-related issues.

Conclusion

This exploration of the Yamaha V-Star 650 muffler has emphasized its multifaceted role. It is not merely a noise suppression device, but a critical component influencing engine performance, environmental compliance, and overall vehicle functionality. The choice of materials, design, and maintenance practices directly impact its lifespan and effectiveness. Aftermarket options offer opportunities for customization, but necessitate a careful consideration of regulatory requirements and performance trade-offs.

The continued responsible operation and maintenance of the Yamaha V-Star 650 muffler remains paramount. Owners should prioritize adherence to noise regulations, conduct regular inspections for damage, and select replacement parts that meet or exceed original equipment specifications. Such diligence ensures both a positive riding experience and the mitigation of adverse environmental impacts. The future will likely see advancements in muffler technology focused on enhanced noise reduction and improved engine efficiency.