The exhaust component designed for Ford F-150 models manufactured in 2005 plays a crucial role in managing engine noise and emissions. It is a key part of the vehicle’s exhaust system, situated downstream from the catalytic converter, and works by attenuating sound waves generated by the combustion process within the engine. A typical example is an aftermarket performance version of this component, often constructed from stainless steel for increased durability and a more aggressive sound profile.

Proper functionality of this component is essential for maintaining acceptable noise levels, as mandated by regulations, and can contribute to overall vehicle performance. Historically, designs have evolved to optimize both sound reduction and exhaust flow. Upgrading or replacing a worn or damaged unit can result in a noticeable improvement in sound quality, and, depending on the design, a minor increase in horsepower.

The following sections will delve into the various types available for this specific vehicle, factors influencing their performance, common issues that may arise, and considerations for selecting a suitable replacement or upgrade.

Essential Considerations for F-150 (2005) Exhaust Components

Maximizing the lifespan and performance of an exhaust system for a 2005 Ford F-150 requires diligent attention to several key factors. The following points provide critical guidance.

Tip 1: Material Selection: Consider stainless steel construction for enhanced longevity, particularly in regions with high road salt usage. Stainless steel resists corrosion significantly better than aluminized steel, extending the component’s service life.

Tip 2: Welding Integrity: Inspect welds carefully. Poorly executed welds are a primary source of failure in exhaust systems, leading to leaks and reduced performance. Ensure welds are smooth, complete, and free of porosity.

Tip 3: Proper Installation: Ensure correct alignment and secure mounting. Misalignment can introduce stress points, accelerating wear and potentially causing damage to other exhaust components. Use new hardware where appropriate.

Tip 4: Regular Inspection: Conduct routine visual inspections for rust, damage, and leaks. Early detection of problems can prevent more costly repairs down the line and maintain optimal engine performance.

Tip 5: Hanger Condition: Check rubber hangers for deterioration. Worn or broken hangers contribute to excessive movement and vibration, shortening the lifespan of the exhaust system and potentially causing damage to surrounding components.

Tip 6: Torque Specifications: Adhere to specified torque values during installation. Over-tightening can damage components, while under-tightening can result in leaks and loosening over time. Consult the vehicle’s service manual.

Tip 7: Sound Level Compliance: Ensure the selected unit meets local noise regulations. Exceeding permitted sound levels can result in fines and necessitate corrective action.

Adhering to these considerations will contribute significantly to the long-term reliability and optimal performance of the exhaust system, ensuring compliance and minimizing potential issues.

The subsequent sections will address troubleshooting common issues and exploring performance upgrade options.

1. Sound attenuation capabilities

Sound attenuation capabilities are a primary design consideration for the exhaust silencing device installed on a 2005 Ford F-150. The effectiveness of this component directly impacts the vehicle’s compliance with noise regulations and the overall driving experience. Understanding the facets contributing to sound attenuation is crucial for selecting and maintaining the appropriate component.

- Internal Baffle Design

The internal structure, often employing baffles and resonating chambers, is engineered to disrupt and reduce sound waves generated by the engine’s combustion process. Different baffle designs offer varying degrees of sound reduction. A design with multiple chambers and strategically placed baffles can effectively cancel out a wider range of frequencies. Aftermarket performance units may prioritize exhaust flow over maximal sound reduction, resulting in a louder exhaust note.

- Sound Absorption Materials

Some designs incorporate sound-absorbing materials, such as fiberglass packing, to further dampen noise. These materials absorb sound energy, converting it into heat. The type and amount of packing material used significantly affect the attenuation level and the tonal quality of the exhaust sound. Over time, the packing material can degrade, leading to increased exhaust noise.

- Chamber Resonance Tuning

The dimensions and shapes of the internal chambers are carefully tuned to create resonant frequencies that cancel out specific unwanted sound frequencies. This process, known as Helmholtz resonance, allows engineers to target particular noise issues common in the 2005 F-150 engine’s exhaust. Precise tuning ensures optimal noise reduction without significantly restricting exhaust flow.

- Exhaust System Backpressure

The level of backpressure generated by the design impacts both sound attenuation and engine performance. A design with excessive backpressure can reduce engine efficiency and horsepower, while a design with insufficient backpressure might not adequately dampen sound. Balancing backpressure and sound attenuation is a key engineering challenge in developing effective components.

These interconnected facets highlight the complexity involved in designing an effective exhaust silencing device for the 2005 F-150. The interplay between internal baffling, sound absorption, resonance tuning, and backpressure dictates the component’s overall sound attenuation capabilities and its impact on vehicle performance and regulatory compliance.

2. Material corrosion resistance

The selection of materials with high corrosion resistance is paramount in the design and longevity of the exhaust silencing device installed on a 2005 Ford F-150. This component is subjected to a harsh operating environment, enduring extreme temperature fluctuations and exposure to corrosive elements such as road salt, water, and exhaust byproducts. Inadequate corrosion resistance directly leads to premature failure, necessitating costly repairs or replacements.

For example, units constructed from aluminized steel exhibit limited corrosion resistance compared to those made from stainless steel. In regions where road salt is heavily used during winter months, aluminized steel components often succumb to rust within a few years, developing leaks and compromising their sound attenuation capabilities. Conversely, a stainless-steel component, while initially more expensive, provides significantly extended service life under the same conditions, demonstrating the practical benefits of superior material selection. The internal design can also impact corrosion; condensation can accumulate within the component, accelerating corrosion from the inside out if the materials are not resistant.

In conclusion, the material’s ability to withstand corrosive environments directly determines the lifespan and effectiveness of the exhaust silencing device in a 2005 F-150. Choosing components with robust corrosion resistance represents a strategic investment, mitigating future maintenance costs and ensuring sustained performance of the vehicle’s exhaust system, addressing a critical aspect of vehicle ownership and maintenance.

3. Exhaust flow optimization

Exhaust flow optimization, concerning a silencing device designed for 2005 Ford F-150 models, directly influences engine performance and fuel efficiency. The internal design of the component affects the ease with which exhaust gases exit the engine’s combustion chambers. A less restrictive design reduces backpressure, potentially improving horsepower and torque. Conversely, an overly restrictive design increases backpressure, hindering engine performance and potentially decreasing fuel economy. This relationship underscores the importance of selecting a design that balances sound attenuation with efficient exhaust flow.

For instance, consider two distinct aftermarket options for the 2005 F-150. One unit, emphasizing sound reduction, might employ intricate baffling that significantly reduces noise but also impedes exhaust flow, resulting in a negligible, or even negative, impact on performance. Another unit, engineered for performance gains, might utilize a straight-through design with minimal baffling, optimizing exhaust flow but producing a louder exhaust note. The specific trade-off between sound attenuation and exhaust flow characteristics must align with the vehicle operator’s preferences and performance goals. Improper flow can also affect catalytic converter function and overall emissions.

In summary, exhaust flow optimization is a critical design parameter for the 2005 F-150 exhaust component. The interplay between exhaust flow, sound attenuation, and engine performance necessitates careful consideration when selecting a replacement or upgrade. Achieving an optimal balance ensures both a comfortable driving experience and efficient engine operation, while also meeting emission standards and maintaining the vehicle’s overall mechanical integrity.

4. Mounting point integrity

Mounting point integrity is a critical factor affecting the longevity and performance of the exhaust component installed on a 2005 Ford F-150. The robustness of these attachment points directly influences the system’s ability to withstand vibrations, thermal stress, and physical impacts encountered during vehicle operation. Degradation or failure of these mounting points can lead to exhaust leaks, component damage, and potential safety hazards.

- Hanger Bracket Strength

Hanger brackets are metal components welded to the component’s body, providing attachment points for rubber isolators. The strength of these brackets is crucial, as they bear the weight of the component and absorb vibrations. Weak or poorly welded brackets are prone to cracking and eventual failure, leading to excessive movement and potential damage to other exhaust components. A common example is a fractured hanger bracket caused by corrosion or metal fatigue, resulting in a rattling noise and potential exhaust leaks.

- Rubber Isolator Condition

Rubber isolators, or hangers, dampen vibrations and prevent the transmission of noise to the vehicle’s chassis. Deteriorated or broken rubber isolators compromise their ability to absorb vibrations, placing increased stress on the hanger brackets and the component itself. Regular inspection and replacement of worn rubber isolators are essential for maintaining the integrity of the mounting system and preventing premature failure of the component.

- Attachment Hardware Security

Secure attachment hardware, including bolts, nuts, and clamps, is vital for maintaining the integrity of the mounting points. Corroded or loose hardware can compromise the stability of the exhaust system, leading to leaks and potential disconnections. Using appropriate torque specifications during installation and regularly inspecting hardware for tightness are crucial preventative measures.

- Weld Quality and Placement

The quality and placement of welds connecting the mounting brackets to the body directly affect the strength and durability of the mounting system. Poorly executed welds can create stress concentration points, leading to premature failure. Proper weld penetration and strategic placement of the welds are essential for distributing stress evenly and ensuring long-term reliability. A visual inspection of the welds for cracks, porosity, or incomplete fusion is a necessary maintenance step.

These interconnected factors highlight the importance of maintaining mounting point integrity for the exhaust component in a 2005 Ford F-150. Regular inspection, timely replacement of worn components, and adherence to proper installation procedures are crucial for ensuring the long-term reliability, safety, and performance of the exhaust system.

5. Regulatory noise compliance

The exhaust silencing device installed on a 2005 Ford F-150 is directly linked to regulatory noise compliance. Governments at various levels establish noise limits for vehicles operating within their jurisdictions. The effectiveness of the component in attenuating engine noise determines whether the vehicle meets these legal requirements. Non-compliance can result in fines, mandatory repairs, and restrictions on vehicle operation. The specific noise limits vary by location and are often measured in decibels (dB) at a specified distance from the vehicle. A malfunctioning or improperly modified exhaust system can significantly increase noise emissions, leading to violations.

For example, many municipalities have ordinances prohibiting excessive vehicle noise during nighttime hours. A 2005 F-150 equipped with an aftermarket exhaust system lacking adequate sound dampening may exceed these limits, resulting in a noise violation. In contrast, a vehicle with a well-maintained, factory-specified exhaust component is more likely to comply with noise regulations. Moreover, state-level vehicle inspections often include a visual and auditory assessment of the exhaust system to ensure it conforms to established standards. These inspections serve as a practical mechanism for enforcing noise compliance and identifying vehicles with problematic exhaust systems.

Therefore, maintaining the exhaust silencing device on a 2005 F-150 in proper working order is not only a matter of vehicle performance but also a legal obligation. Understanding the connection between exhaust system components and regulatory noise limits is crucial for responsible vehicle ownership. Failure to comply with these regulations can have tangible consequences, underscoring the importance of regular exhaust system inspections and adherence to established noise standards. The challenges lie in balancing performance modifications with legal requirements and ensuring that the selected exhaust components provide adequate sound attenuation without compromising engine efficiency.

Frequently Asked Questions

This section addresses common inquiries regarding the exhaust silencing device, often referred to as a muffler, specific to the 2005 Ford F-150, providing factual information to assist in understanding its function, maintenance, and replacement.

Question 1: What is the expected lifespan of a factory-installed component on a 2005 F-150?

The typical service life ranges from 5 to 7 years, depending on environmental factors such as road salt exposure and driving conditions. Coastal regions and areas with harsh winters tend to shorten the lifespan due to accelerated corrosion.

Question 2: Does an aftermarket performance component void the vehicle’s warranty?

The installation of an aftermarket component generally does not automatically void the entire vehicle warranty. However, any damage directly attributable to the aftermarket part may not be covered under the original manufacturer’s warranty. Refer to the specific warranty terms for clarification.

Question 3: What are the key indicators that a replacement is necessary?

Common signs include excessive exhaust noise, visible rust or damage, a decrease in fuel efficiency, and a failed state vehicle inspection. These symptoms suggest a compromised exhaust system requiring prompt attention.

Question 4: Can a damaged component negatively impact engine performance?

Yes, a compromised component can increase backpressure, reducing engine efficiency and potentially decreasing horsepower and torque. Furthermore, exhaust leaks can disrupt oxygen sensor readings, leading to improper fuel mixture and reduced fuel economy.

Question 5: Are there specific tools required for replacing this component on a 2005 F-150?

Basic tools include a socket set, wrenches, penetrating oil, and potentially an exhaust pipe cutter or saw. The use of a vehicle lift or jack stands is also recommended for safe access to the exhaust system. Adherence to safety precautions is essential.

Question 6: How does the choice of material affect the component’s performance and longevity?

Stainless steel construction offers superior corrosion resistance compared to aluminized steel, extending the component’s lifespan, particularly in environments with high road salt exposure. However, stainless-steel components typically have a higher initial cost.

Understanding these frequently asked questions provides a foundation for informed decision-making regarding maintenance and repair of the exhaust system on a 2005 Ford F-150.

The next section will cover a guide on how to properly install a unit.

Concluding Remarks on the 2005 F-150 Muffler

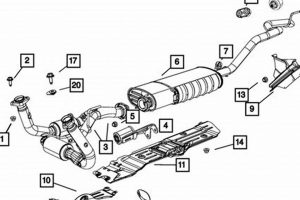

The preceding discussion has comprehensively explored the function, maintenance, and selection criteria for the 05 f150 muffler. The components role in noise reduction, its susceptibility to corrosion, the importance of exhaust flow optimization, and the necessity of secure mounting points have been addressed. Regulatory compliance has also been emphasized as a vital consideration for responsible vehicle operation. The information presented serves to equip owners and technicians with a solid understanding of this essential exhaust system element.

Proper attention to the exhaust components condition and performance is crucial for maintaining the vehicles operational integrity, regulatory compliance, and overall driving experience. Consistent inspection and timely replacement, when warranted, will contribute to the vehicles longevity and minimize potential issues. Prioritizing quality materials and professional installation practices are also advisable. The exhaust system, though often overlooked, plays a significant role in the vehicle’s overall health and must be addressed with informed diligence.