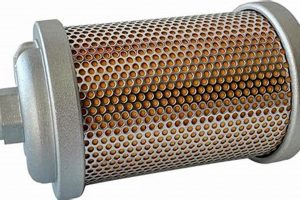

A device used in exhaust systems features multiple internal compartments designed to reduce noise generated by an internal combustion engine. This component, characterized by its series of chambers, strategically redirects and attenuates sound waves as they travel through the exhaust flow. The internal baffling and resonance tuning contribute to its effectiveness in minimizing unwanted engine noise.

The benefits of this multi-chambered design include enhanced noise reduction compared to simpler muffler types, while also offering a balance between sound dampening and exhaust flow restriction. Historically, such components have been favored in applications where a quieter operation is desired, such as passenger vehicles and residential areas. They represent a compromise between performance and noise abatement.

The construction and design specifics of these noise-reducing elements influence their overall performance and suitability for various engine types and applications. Factors such as chamber size, baffle configuration, and material selection all play a critical role in determining the final sound characteristics and backpressure generated within the exhaust system.

Optimizing Exhaust Systems Using Multi-Chamber Technology

Considerations when integrating advanced noise reduction technology within automotive exhaust systems are outlined below. These points highlight best practices for maintaining optimal performance and sound characteristics.

Tip 1: Material Selection: Employ corrosion-resistant materials, such as stainless steel, to prolong the lifespan of the component, particularly in environments exposed to road salts or harsh weather conditions. This minimizes degradation and maintains structural integrity.

Tip 2: Chamber Volume Optimization: Precisely calculate internal chamber volumes to target specific frequencies for noise cancellation. Adjusting chamber sizes can fine-tune the overall sound profile of the exhaust system.

Tip 3: Baffle Design and Placement: Strategically position internal baffles to redirect exhaust flow and maximize sound wave attenuation. The angle and perforation patterns of these baffles directly influence noise reduction efficiency.

Tip 4: Weld Integrity: Ensure all welds are robust and leak-proof to prevent exhaust gas escapes and maintain the designed acoustic performance. Poor welds can significantly impact noise levels and system efficiency.

Tip 5: Flow Rate Consideration: Account for engine displacement and operating RPM range when designing the internal flow paths. Insufficient flow can create excessive backpressure, negatively affecting engine performance.

Tip 6: Resonance Tuning: Employ Helmholtz resonance principles within the chambers to target and neutralize specific undesirable frequencies, further refining the exhaust note.

Tip 7: Mounting Considerations: Utilize vibration-dampening mounts to minimize the transmission of vibrations from the exhaust system to the vehicle’s chassis, thereby reducing perceived noise levels within the cabin.

Proper implementation of these strategies allows for enhanced noise suppression without compromising engine performance, leading to a more refined and comfortable driving experience.

Further exploration into specific vehicle applications and engine types will provide more tailored insights into the optimal integration of these exhaust system components.

1. Noise Reduction Capability

The capacity of a four-chambered exhaust component to attenuate sound is a primary factor in its design and application. This capability directly relates to the component’s internal architecture, influencing its effectiveness in minimizing unwanted engine noise.

- Chamber Volume and Frequency Attenuation

The volume of each chamber within the component is strategically engineered to target and attenuate specific frequencies produced by the engine. Larger chambers tend to be more effective at reducing lower frequencies, while smaller chambers influence higher frequency sound waves. This frequency-selective attenuation is a key element in achieving a desirable overall exhaust note. The precise tuning of chamber volumes is often determined through empirical testing and acoustic modeling.

- Baffle Design and Sound Wave Interference

Internal baffles play a crucial role in redirecting and disrupting sound waves as they propagate through the component. The geometry, placement, and perforation patterns of these baffles influence the way sound waves interact, creating destructive interference patterns that reduce overall noise levels. Different baffle designs, such as straight-through, S-shaped, or louvered configurations, offer varying degrees of noise reduction and exhaust flow restriction. The selection of baffle design is contingent on the target sound profile and acceptable backpressure levels.

- Resonance Chamber Effects

The chambers can be designed to act as Helmholtz resonators, targeting specific frequencies for cancellation. This is achieved by carefully tuning the chamber dimensions and connecting neck (if applicable) to match the frequency one wishes to reduce. The resonance frequency is determined by the chamber volume and the neck dimensions (if present). This design approach allows for precise control over the exhaust sound characteristics.

- Material Properties and Sound Absorption

The material used in constructing the exhaust component influences its ability to absorb sound energy. Some materials exhibit inherent damping characteristics that contribute to noise reduction. The thickness and density of the material can also impact sound transmission. Furthermore, the component’s exterior surface can be treated with sound-absorbing materials to further reduce radiated noise.

These interconnected facets of noise reduction capability, realized through strategic chamber design, baffle configuration, resonance tuning, and material selection, define the performance characteristics of the multi-chamber component. The integration of these elements allows for a tailored exhaust note, balancing sound attenuation with engine performance considerations.

2. Backpressure optimization

Backpressure optimization represents a crucial design consideration in exhaust systems, particularly concerning multi-chambered units. Managing backpressure is vital to achieving a balance between noise reduction and engine performance. The internal structure of these components significantly impacts exhaust gas flow and, consequently, engine efficiency. Excessive backpressure can impede exhaust gas scavenging, reducing engine power, while insufficient backpressure might compromise noise attenuation.

- Chamber Volume and Exhaust Flow Restriction

The aggregate volume of the chambers within a multi-chamber component directly influences exhaust flow restriction. Smaller chamber volumes tend to increase backpressure, while larger volumes reduce it. Design engineers must carefully calculate chamber sizes to minimize flow impedance without sacrificing noise-reduction capabilities. Simulations and empirical testing are routinely employed to determine optimal chamber dimensions for various engine types and applications. A common trade-off is observed: minimizing chamber volume to maximize scavenging versus enlarging volume to meet noise regulations.

- Baffle Design and Backpressure Generation

The configuration of internal baffles significantly contributes to backpressure. Baffles redirect exhaust flow, creating turbulence and pressure drop. Straight-through designs generally offer minimal backpressure, whereas convoluted or restrictive baffle patterns increase backpressure. The choice of baffle design involves a compromise between flow restriction and sound attenuation. For example, perforated baffles permit a more direct flow path, reducing backpressure compared to solid baffles, but at the expense of diminished noise reduction.

- Exhaust Gas Velocity and Pressure Drop

Exhaust gas velocity through the component influences the pressure drop and, consequently, backpressure. Constricting the flow path increases velocity, which leads to a greater pressure drop. Conversely, expanding the flow path reduces velocity and pressure drop. Optimizing the internal geometry of the component to maintain an appropriate exhaust gas velocity is critical for minimizing backpressure. Computational fluid dynamics (CFD) can be used to model exhaust flow and identify potential bottlenecks that contribute to excessive backpressure.

- Engine Tuning and Backpressure Requirements

The engine’s operating characteristics dictate the optimal backpressure requirements. Naturally aspirated engines often benefit from lower backpressure to maximize exhaust scavenging. Conversely, turbocharged engines can tolerate higher backpressure due to the presence of the turbocharger, which actively forces exhaust gases out of the cylinders. Engine tuning parameters, such as ignition timing and fuel delivery, can be adjusted to compensate for variations in backpressure. A mismatch between the component’s backpressure characteristics and the engine’s requirements can result in reduced power output and increased fuel consumption.

These interconnected elements collectively define the relationship between backpressure optimization and multi-chamber components. By strategically managing chamber volumes, baffle designs, exhaust gas velocity, and engine tuning, engineers can minimize backpressure while maintaining acceptable noise levels. This balanced approach is essential for optimizing engine performance and ensuring compliance with noise regulations.

3. Chamber Volume Ratio

The proportional relationship between the volumes of individual chambers within a four-chambered exhaust component is a crucial design parameter affecting its acoustic performance and overall functionality. This ratio directly influences the component’s ability to attenuate specific frequencies and manage exhaust gas flow dynamics.

- Frequency Targeting and Volume Distribution

Unequal chamber volumes enable selective attenuation of different frequency ranges. A larger first chamber, for example, might be designed to dampen low-frequency noise, while smaller subsequent chambers target higher frequencies. The precise volume distribution is determined through acoustic modeling and experimental testing to achieve a desired exhaust note profile. This deliberate manipulation of chamber size allows for a tailored frequency response, addressing specific noise concerns associated with engine operation. A common application involves minimizing drone at cruising speeds through strategic chamber volume allocation.

- Exhaust Gas Velocity and Chamber Sequencing

The sequence of chamber volumes affects exhaust gas velocity as it progresses through the component. A gradual reduction in chamber size can maintain or even increase exhaust gas velocity, potentially mitigating backpressure. Conversely, an abrupt change in volume can induce turbulence and pressure drop. Optimizing chamber sequencing is essential for balancing noise reduction with exhaust flow efficiency. For instance, a larger initial chamber followed by progressively smaller chambers can help to dampen low-frequency noise while maintaining adequate flow characteristics.

- Resonance Effects and Volume Ratios

The chamber volume ratio can be exploited to create specific resonance effects within the component. By carefully tuning the volumes and interconnecting passages, engineers can create Helmholtz resonators that target specific frequencies for cancellation. The frequency at which resonance occurs is directly related to the chamber volumes and neck dimensions (if present). This approach allows for precise control over the exhaust sound, enabling the attenuation of undesirable frequencies while enhancing others. This design is particularly useful in applications where a specific exhaust tone is desired, such as in performance vehicles.

- Manufacturing Constraints and Volume Limitations

Practical manufacturing limitations can influence the achievable chamber volume ratio. The overall size and shape of the component are often constrained by the vehicle’s undercarriage, limiting the available space for chambers. Material properties and manufacturing processes also impose restrictions on the minimum and maximum achievable chamber volumes. Consequently, design engineers must consider these limitations when determining the optimal volume ratio for a given application. Packaging constraints often necessitate compromises in chamber volume ratios, balancing acoustic performance with manufacturability.

These interconnected facets highlight the complex role of chamber volume ratio in the design and function of a four-chambered exhaust component. Understanding and carefully managing this parameter is crucial for achieving the desired balance between noise reduction, exhaust flow efficiency, and manufacturing feasibility. The specific application dictates the ideal chamber volume ratio, requiring a tailored approach to design and optimization.

4. Baffle configuration impact

Baffle configuration within a four-chambered muffler significantly influences its noise reduction capabilities and overall performance. The arrangement, shape, and perforation patterns of baffles directly affect sound wave propagation, reflection, and absorption within the muffler chambers. These internal structures are not merely passive elements; they actively manipulate the acoustic environment to achieve a desired exhaust note and reduce unwanted noise. The configuration determines the path exhaust gases take and the level of turbulence they experience, impacting backpressure and, consequently, engine efficiency. The absence or improper design of baffles results in diminished noise attenuation and a less refined sound profile, negating the benefits of a multi-chambered design.

Specific baffle designs yield distinct acoustic effects. Straight-through perforated baffles, for example, offer minimal flow restriction and reduced backpressure, making them suitable for performance-oriented applications where noise reduction is secondary. Conversely, offset or louvered baffles create more complex flow paths, increasing turbulence and sound wave interference, thereby enhancing noise attenuation. The placement of baffles within each chamber, and the interrelation between baffle configurations in different chambers, is also crucial. Optimizing baffle configuration typically involves a compromise between noise reduction, backpressure, and durability, often necessitating extensive testing and simulation to achieve the desired outcome. For instance, a high-performance vehicle may utilize a combination of straight-through and louvered baffles to balance power output with acceptable noise levels, while a passenger car prioritizes noise reduction with more restrictive baffle configurations.

In summary, baffle configuration is an integral element of the four-chambered muffler’s functionality, directly determining its noise reduction effectiveness and impact on engine performance. The selection and arrangement of baffles represent a critical engineering decision, requiring a careful balance between acoustic objectives, flow characteristics, and practical constraints. An informed understanding of baffle configuration is therefore essential for designing and optimizing multi-chambered mufflers for diverse automotive applications.

5. Material durability selection

The selection of materials for a four-chambered muffler is paramount to its longevity and performance within the harsh environment of an exhaust system. Exposure to high temperatures, corrosive exhaust gases, road salts, and physical stresses necessitates the use of robust materials capable of withstanding these conditions. Inadequate material selection leads to premature failure, increased noise levels due to corrosion-induced leaks, and potential damage to other exhaust system components. For example, using standard carbon steel in regions with heavy road salt application inevitably leads to rapid rust and eventual muffler disintegration, requiring costly replacements and increased vehicle downtime. Therefore, material selection must consider both the immediate operating environment and the long-term performance expectations.

Stainless steel alloys, such as 304 or 409, represent a common and effective choice for multi-chambered muffler construction due to their superior corrosion resistance and high-temperature strength. These alloys form a protective oxide layer that prevents further corrosion, even when exposed to harsh chemicals and extreme temperatures. Titanium alloys, while offering even greater strength-to-weight ratios and corrosion resistance, are often reserved for high-performance or specialized applications due to their higher cost. The thickness of the material also plays a critical role; thicker gauges provide greater resistance to physical damage from road debris and internal pressure fluctuations. The impact of poor material choice is evident in aftermarket mufflers that utilize aluminized steel rather than stainless steel, often resulting in a significantly shorter lifespan, particularly in regions with severe winters. This underscores the critical role that specific material properties play in determining a component’s long-term reliability.

In conclusion, material durability selection is an inextricable element of four-chambered muffler design and performance. The cost savings associated with using lower-quality materials are often offset by the increased frequency of replacements and potential damage to other vehicle systems. By prioritizing corrosion resistance, high-temperature strength, and appropriate gauge thickness, manufacturers can ensure that the muffler provides reliable noise reduction and exhaust gas management throughout the vehicle’s lifespan. The challenges lie in balancing material cost with long-term performance requirements, demanding a thorough understanding of material properties and operating conditions.

6. Resonance frequency tuning

Resonance frequency tuning, as it pertains to four-chambered mufflers, is a strategic design approach that leverages acoustic principles to attenuate specific undesirable frequencies generated by an internal combustion engine. This process involves manipulating the physical characteristics of the muffler’s internal chambers to create acoustic resonators that counteract targeted sound waves, resulting in a more refined and controlled exhaust note.

- Helmholtz Resonance Application

Helmholtz resonators, formed by the chambers and connecting passages within the muffler, are tuned to specific frequencies by adjusting chamber volume and neck dimensions. When the frequency of an exhaust pulse matches the resonance frequency of a chamber, the chamber acts as a damper, reducing the amplitude of that frequency in the overall exhaust sound. This is achieved through destructive interference, where the resonator cancels out the targeted frequency. For instance, if an engine exhibits a prominent drone at 120 Hz, a chamber can be tuned to resonate at that frequency, effectively minimizing its presence in the exhaust note.

- Chamber Geometry and Frequency Response

The shape and dimensions of each chamber within the muffler influence its frequency response characteristics. Circular or rectangular chambers may exhibit different resonant frequencies, and the overall geometry can be optimized to broaden or narrow the bandwidth of frequency attenuation. Simulation software and empirical testing are often employed to determine the ideal chamber geometry for a given engine and desired exhaust sound profile. Altering the length of an internal pipe within a chamber can effectively change the frequency that is dampened, proving beneficial in targeting specific resonant peaks.

- Interference and Cancellation

By carefully positioning chambers and connecting passages, engineers can create constructive and destructive interference patterns among sound waves. When sound waves of the same frequency are out of phase, they cancel each other out, resulting in noise reduction. Multi-chamber mufflers utilize this principle to attenuate a wider range of frequencies than single-chamber designs. The configuration of the chambers, including their relative placement and connecting pathways, influences the specific frequencies that are effectively cancelled, providing a nuanced level of control over the muffler’s acoustic performance.

- Material Properties and Damping Effects

The materials used in the construction of a four-chambered muffler also play a role in resonance frequency tuning. Materials with inherent damping properties can absorb sound energy and reduce resonance amplification. The thickness and density of the muffler’s walls influence its ability to dampen vibrations and minimize radiated noise. In some cases, sound-absorbing materials are strategically placed within or around the chambers to further enhance noise reduction and control resonant frequencies. Careful consideration of material properties is vital for optimizing the muffler’s overall acoustic performance.

These facets of resonance frequency tuning, when applied to four-chambered mufflers, demonstrate the sophistication involved in managing exhaust system acoustics. By precisely controlling chamber geometry, harnessing Helmholtz resonance principles, manipulating interference patterns, and considering material properties, engineers can craft mufflers that effectively attenuate unwanted frequencies, resulting in a more pleasing and refined exhaust note that complements engine performance.

7. Exhaust flow dynamics

Exhaust flow dynamics are intrinsically linked to the performance characteristics of a four-chambered muffler. The efficient management of exhaust gases as they traverse the muffler’s internal architecture directly impacts engine efficiency, noise attenuation, and overall system longevity. Understanding the principles governing these dynamics is essential for optimizing muffler design and functionality.

- Pressure Wave Propagation and Interference

The propagation of pressure waves within the muffler’s chambers is influenced by the exhaust gas velocity and temperature. These pressure waves interact with the internal baffles and chamber walls, creating interference patterns that contribute to noise reduction. The effectiveness of these interference patterns is directly related to the precise configuration of the chambers and baffles, requiring careful consideration of exhaust flow dynamics to achieve optimal noise attenuation. For instance, improper baffle placement can disrupt the desired wave interference, leading to increased noise levels and reduced muffler efficiency. The tuning of these chambers for specific frequencies relies heavily on the predictable behavior of exhaust flow.

- Turbulence and Flow Resistance

The design of a four-chambered muffler inherently introduces turbulence into the exhaust flow. While this turbulence is essential for noise reduction by disrupting laminar flow and promoting sound wave dissipation, excessive turbulence can increase flow resistance, leading to backpressure. Balancing the need for turbulence to attenuate noise with the desire to minimize backpressure is a key challenge in muffler design. Simulations using computational fluid dynamics (CFD) are routinely used to model exhaust flow and identify areas of excessive turbulence, allowing engineers to optimize baffle designs and chamber geometries to minimize flow resistance while maintaining effective noise reduction. This balance dictates the overall engine performance of the vehicle.

- Temperature Gradients and Thermal Stress

Exhaust gases entering the muffler can exhibit significant temperature gradients, creating thermal stress on the muffler’s internal components. Uneven temperature distribution can lead to warping, cracking, and eventual failure of the muffler. The design of the muffler’s internal structure and the selection of appropriate materials are critical for managing these thermal stresses. For example, the placement of baffles can influence temperature distribution, with areas of high turbulence potentially experiencing elevated temperatures. Furthermore, the use of high-quality stainless steel alloys helps to mitigate corrosion and thermal fatigue, ensuring the muffler’s longevity under harsh operating conditions. Efficient exhaust flow reduces the potential for hot spots and prolongs the lifespan of the muffler.

- Scavenging Effects and Engine Performance

The efficiency with which exhaust gases are evacuated from the engine cylinders, known as scavenging, is influenced by the muffler’s backpressure. Excessive backpressure can impede scavenging, reducing engine power and fuel efficiency. The four-chambered muffler’s internal design must be optimized to minimize backpressure without compromising noise attenuation. This requires careful consideration of chamber volumes, baffle designs, and exhaust flow paths. A well-designed muffler promotes efficient scavenging, allowing the engine to operate at peak performance. In contrast, a poorly designed muffler can restrict exhaust flow, negatively impacting engine performance and fuel economy. Therefore, understanding exhaust flow dynamics is critical for maximizing both noise reduction and engine efficiency.

These facets of exhaust flow dynamics underscore the intricate relationship between muffler design and engine performance. By carefully considering pressure wave propagation, turbulence generation, temperature gradients, and scavenging effects, engineers can optimize four-chambered mufflers to achieve a balance between noise reduction, engine efficiency, and system longevity. The design considerations are always a compromise between conflicting factors and require precise calculations and thorough testing.

Frequently Asked Questions

This section addresses common inquiries regarding the function, benefits, and application of multi-chambered exhaust components.

Question 1: What is the primary function of a four-chambered muffler?

The primary function is to reduce noise generated by an internal combustion engine. It achieves this through a series of internal chambers and baffles that attenuate sound waves before they exit the exhaust system.

Question 2: How does a four-chambered muffler differ from other muffler designs?

Compared to single-chamber or dual-chamber mufflers, a four-chambered design typically offers enhanced noise reduction capabilities due to its more complex internal structure and increased opportunities for sound wave interference.

Question 3: Does a four-chambered muffler impact engine performance?

A properly designed four-chambered muffler seeks to minimize backpressure, which can negatively affect engine performance. The chamber volumes and baffle configurations are carefully calibrated to strike a balance between noise reduction and exhaust flow efficiency.

Question 4: What materials are commonly used in the construction of four-chambered mufflers?

Stainless steel alloys, such as 304 and 409, are frequently employed due to their corrosion resistance and ability to withstand high temperatures. Aluminized steel is sometimes used, though it offers less corrosion protection.

Question 5: How does the baffle configuration affect the sound characteristics of a four-chambered muffler?

The baffle configuration dictates the path exhaust gases take and the degree of sound wave reflection and absorption. Straight-through baffles tend to produce a louder, more aggressive sound, while offset or louvered baffles offer greater noise reduction.

Question 6: What factors should be considered when selecting a four-chambered muffler?

Key considerations include the vehicle’s engine type, intended use (e.g., street, track), desired sound level, and the need to comply with local noise regulations. Material durability and overall build quality are also important factors.

The design and selection of a multi-chambered exhaust component is dictated by a trade-off between multiple design factors with no single best answer.

The next section will examine relevant technologies applicable to four-chambered muffler systems.

Conclusion

The preceding exploration has illuminated the multifaceted nature of the 4 chambered muffler, detailing its design intricacies, performance characteristics, and crucial role in mitigating engine noise. Its effectiveness stems from a carefully engineered interplay of chamber volumes, baffle configurations, material properties, and acoustic resonance, all contributing to a delicate balance between noise reduction and engine efficiency. The 4 chambered muffler represents more than a simple component; it embodies a sophisticated application of acoustic principles within automotive engineering.

As noise regulations continue to tighten and consumer demand for quieter vehicles persists, the importance of effective noise reduction technologies will only increase. The 4 chambered muffler, through ongoing refinement and adaptation, will likely remain a vital element in achieving those objectives. Further research and development in materials science, computational fluid dynamics, and acoustic modeling hold the potential to unlock even greater performance and efficiency gains in this essential automotive component, reinforcing its enduring significance in the pursuit of quieter and more refined transportation.