A device installed in an exhaust system allows the redirection of exhaust gases, bypassing the muffler. This mechanism, typically valve-controlled, provides a means to alter the sound and performance characteristics of a vehicle. For example, a driver might activate this feature to increase horsepower during a race or generate a louder exhaust note.

The utility stems from its capacity to reduce backpressure, potentially enhancing engine output. Historically, these devices were more prevalent in racing applications, where maximizing performance was paramount. Modern applications extend to enthusiasts seeking customization of their vehicle’s auditory profile and a temporary boost in power.

The subsequent sections will elaborate on the different types of these exhaust modifications, their installation procedures, and the legal considerations surrounding their use.

Muffler Cutout

Optimizing the integration and operation of exhaust bypass systems requires careful attention to several critical factors. Adherence to these guidelines will promote safe and efficient functionality.

Tip 1: Verify Legal Compliance: Prior to installation, confirm local and national regulations pertaining to exhaust modification. Many jurisdictions have noise restrictions and emissions standards that exhaust bypass systems may violate, resulting in fines or vehicle impoundment.

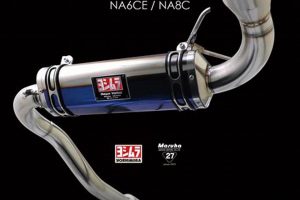

Tip 2: Select a Reputable Brand: Choose a product from a well-known manufacturer with a proven track record of quality and reliability. Inferior components are prone to failure, leading to exhaust leaks and potential engine damage.

Tip 3: Employ Professional Installation: Unless possessing advanced automotive mechanical skills, engage a qualified technician to install the bypass system. Improper installation can compromise exhaust system integrity and create safety hazards.

Tip 4: Monitor Engine Performance: After installation, carefully observe engine parameters such as temperature, fuel consumption, and exhaust gas composition. Deviations from normal ranges may indicate issues requiring immediate attention.

Tip 5: Implement Regular Maintenance: Periodically inspect the bypass valve and associated hardware for signs of corrosion, wear, or damage. Lubricate moving parts as recommended by the manufacturer to ensure proper operation and prevent seizing.

Tip 6: Consider Electronic Control: Opt for an electronically controlled bypass system that allows for precise and automated valve actuation based on engine load and speed. This provides greater control and optimizes performance.

Tip 7: Ensure Proper Sealing: During installation, utilize high-quality gaskets and sealants to prevent exhaust leaks. Even small leaks can degrade performance and introduce harmful gases into the passenger compartment.

By adhering to these guidelines, individuals can maximize the benefits of exhaust bypass systems while minimizing potential risks and ensuring compliance with applicable regulations.

The concluding section will address potential drawbacks and environmental impact considerations.

1. Exhaust Flow Diversion

Exhaust flow diversion, a core function achieved through exhaust modification, significantly impacts engine performance and sound characteristics. Its implementation, particularly within the context of a bypass mechanism, warrants careful examination of its operational facets and their implications.

- Bypass Activation Effects

Activating a bypass system directly alters the path of exhaust gases, diverting them away from the standard muffler. This redirection reduces backpressure on the engine, potentially increasing horsepower and torque, especially at higher engine speeds. The immediate consequence is a change in the exhaust note, typically resulting in a louder and more aggressive sound profile.

- Valve Mechanism Operation

The valve mechanism, whether electronically or manually controlled, governs the diversion of exhaust gases. Electronic systems allow for automated valve actuation based on engine parameters such as RPM or throttle position, optimizing performance and sound according to driving conditions. Manual systems offer direct driver control, enabling on-demand adjustments to the exhaust profile.

- Impact on Fuel Efficiency

While performance gains are often the primary objective, exhaust flow diversion can influence fuel efficiency. Reducing backpressure may improve fuel economy under certain driving conditions, such as highway cruising. However, aggressive use of the bypass system, leading to frequent high-RPM operation, can negate these benefits, resulting in increased fuel consumption.

- System Design Variability

Bypass systems exhibit significant design variability, ranging from simple Y-pipe configurations to more complex setups with integrated resonators or secondary mufflers. These design choices directly influence the sound characteristics and performance gains achieved through exhaust flow diversion. The specific design should be selected based on the desired outcome and the vehicle’s intended use.

The preceding facets highlight the intricate relationship between exhaust flow diversion and exhaust modification. By understanding these elements, individuals can make informed decisions regarding the implementation and operation of a bypass system, balancing performance gains with considerations for sound, fuel efficiency, and regulatory compliance.

2. Performance Enhancement Potential

The performance enhancement potential realized through the utilization of an exhaust bypass device is predicated on the reduction of exhaust backpressure. An engine’s ability to expel exhaust gases more efficiently directly correlates to its capacity for increased power output. By bypassing the muffler, resistance to exhaust flow is diminished, allowing the engine to operate with less restriction. This effect is most pronounced at higher engine speeds where exhaust volume is greatest. For instance, in motorsport applications, the use of such a device can translate to measurable gains in horsepower, leading to improved acceleration and top-end speed. The magnitude of these gains depends on factors such as engine displacement, exhaust system design, and the efficiency of the bypass mechanism itself.

However, the implementation of this modification is not without consideration. While the removal of exhaust backpressure offers potential advantages, it can also alter the engine’s torque curve, potentially shifting the peak torque output to a higher RPM range. This may affect drivability in everyday situations where low-end torque is desired. Furthermore, an unrestrained exhaust can create significant noise pollution, leading to legal ramifications and reduced vehicle usability in residential areas. A balance must therefore be struck between performance augmentation and practical operational considerations. Real-world applications range from track-focused vehicles prioritizing outright power to street cars seeking a more aggressive exhaust note and a modest increase in performance.

In summary, the performance enhancement potential associated with bypassing the muffler is a tangible benefit rooted in the principles of exhaust gas dynamics. The degree of enhancement varies across different engine configurations and driving scenarios. The challenges lie in mitigating the adverse effects of increased noise and potential alterations to the engine’s torque characteristics. A thorough understanding of these factors is crucial for achieving the desired performance gains without compromising vehicle usability or regulatory compliance.

3. Auditory Profile Alteration

The manipulation of a vehicle’s sound signature, or auditory profile alteration, is a primary motivator for employing exhaust bypass mechanisms. The inherent design of such a system directly influences the resulting sound characteristics, offering users a spectrum of options ranging from subtle modifications to dramatic transformations of the exhaust note.

- Volume Amplification

The most immediate effect of bypassing the muffler is an increase in exhaust volume. Removing the muffling element allows the raw engine sound to propagate with less obstruction, leading to a significantly louder auditory experience. This is particularly desirable in performance applications where the sound serves as an indicator of engine load and performance. The extent of volume amplification is dependent on the size and design of the bypass valve and the presence (or absence) of any secondary resonators.

- Frequency Spectrum Shift

In addition to increased volume, bypassing the muffler alters the frequency spectrum of the exhaust sound. Mufflers are designed to attenuate specific frequencies, typically those associated with harshness or unwanted noise. Removing this attenuation allows a broader range of frequencies to be present, resulting in a richer and more complex sound profile. This may manifest as a deeper, more resonant tone, or a sharper, more aggressive note, depending on the engine and exhaust system configuration.

- Resonance Modification

Exhaust bypass systems can also influence resonance within the exhaust system. The length and diameter of the exhaust piping, combined with the presence of the bypass valve, can create specific resonant frequencies that are amplified or attenuated. This effect can be used to fine-tune the exhaust sound, accentuating certain frequencies while suppressing others. Some systems incorporate adjustable resonators to allow for precise control over the resonant characteristics.

- Character Enhancement

Ultimately, exhaust bypass systems provide a means to enhance the overall character of the exhaust sound. Whether the goal is to create a more aggressive and intimidating roar, a refined and sophisticated rumble, or a unique and distinctive tone, these systems offer a level of customization that is not possible with a standard muffler. The specific character of the sound is influenced by a combination of factors, including the engine type, exhaust system design, and the individual preferences of the user.

The multifaceted nature of auditory profile alteration highlights the importance of careful consideration when selecting and implementing an exhaust bypass system. The resulting sound is not merely a matter of volume, but a complex interplay of frequencies, resonances, and tonal characteristics that contribute to the overall driving experience. Balancing the desired sound with considerations for noise regulations and personal preferences is crucial for achieving a satisfactory outcome.

4. Installation Complexity Varies

The range of difficulty associated with installing an exhaust bypass mechanism is substantial. This variability stems from factors including vehicle model, exhaust system design, and the specific bypass kit selected. Accurate assessment of installation complexity is crucial prior to commencing any modification to prevent complications and ensure proper functionality.

- Welding Requirements

Certain bypass installations necessitate welding to integrate the bypass valve into the existing exhaust system. This is particularly common when retrofitting a universal bypass kit to a vehicle not specifically designed for such a modification. Welding requires specialized equipment and expertise, potentially adding significant cost and complexity to the installation process. Incorrect welds can lead to exhaust leaks and compromised system performance.

- Electrical Integration

Electronically controlled bypass systems often demand integration with the vehicle’s electrical system for valve actuation. This may involve tapping into existing wiring harnesses, running new wires, and programming control modules. Improper electrical connections can result in malfunction of the bypass valve or damage to the vehicle’s electrical system. Understanding the vehicle’s wiring diagrams and utilizing proper wiring techniques is essential for a successful installation.

- Mechanical Fitment Issues

Physical fitment challenges can arise due to limited space within the vehicle’s undercarriage or incompatibilities between the bypass kit and the existing exhaust system components. Modifications to the vehicle’s frame or exhaust system may be required to achieve proper clearance. Careful measurement and planning are necessary to anticipate and address potential fitment issues.

- Software Calibration Needs

Advanced bypass systems may incorporate software calibration features that require specialized diagnostic tools and expertise. Adjusting parameters such as valve actuation points and exhaust gas recirculation rates can optimize performance and ensure compliance with emissions regulations. Incorrect calibration can lead to reduced performance or even engine damage.

The multifaceted nature of installation complexity underscores the importance of thorough preparation and expertise when modifying an exhaust system with a bypass mechanism. Proper assessment of these factors, combined with adherence to best practices, is crucial for achieving a successful installation and maximizing the benefits of the modification.

5. Regulatory Compliance Scrutiny

The utilization of exhaust bypass systems elicits significant regulatory compliance scrutiny due to the potential for exceeding established noise emission standards. Governmental bodies worldwide have enacted legislation that dictates acceptable decibel levels for motor vehicles, particularly in residential areas. Bypassing the muffler, the component specifically designed to attenuate exhaust noise, often results in levels that contravene these regulations. This discrepancy is a direct cause-and-effect relationship: the removal of noise dampening leads to increased noise output, triggering enforcement actions. The importance of understanding regulatory compliance stems from the legal ramifications, including fines, vehicle impoundment, and mandatory system modifications to restore compliance. A practical example is the California Vehicle Code, which prohibits modifications that amplify or increase vehicle noise above specified limits. The prevalence of these devices among automotive enthusiasts necessitates vigilance to avoid legal penalties.

Furthermore, exhaust modifications can impact vehicle emissions, raising concerns about compliance with environmental regulations. Some jurisdictions mandate periodic emissions testing to ensure vehicles meet established standards for pollutants such as hydrocarbons, nitrogen oxides, and carbon monoxide. While a bypass system may not directly increase emissions when closed, its use can affect engine performance and combustion efficiency, potentially leading to elevated pollutant levels when the bypass is activated. A case in point is the European Union’s Euro emissions standards, which impose stringent limits on vehicle emissions. Any modification affecting these limits, including exhaust alterations, is subject to rigorous scrutiny and potential penalties. The practical application of this understanding lies in evaluating the environmental impact of such devices and adhering to legal requirements concerning emissions control.

In summary, exhaust bypass mechanisms are subject to intense regulatory compliance scrutiny owing to their potential to breach noise and emissions standards. This scrutiny is a critical component to the installation and use of such systems, ensuring that both individuals and automotive businesses operate within the bounds of applicable laws. Challenges arise in accurately measuring and controlling noise and emissions levels, requiring precise system design and responsible operation. This understanding is significant because it links directly to broader themes of environmental protection and societal well-being, promoting adherence to legal standards and mitigating potential harm to public health and safety.

6. Materials, Durability Concerns

The longevity and operational effectiveness of an exhaust bypass system are intrinsically linked to the materials employed in its construction and their resistance to the harsh operating environment. Considerations of durability are paramount, given the exposure to high temperatures, corrosive exhaust gases, and mechanical stresses. The selection of appropriate materials directly dictates the system’s lifespan and its ability to maintain performance integrity over time.

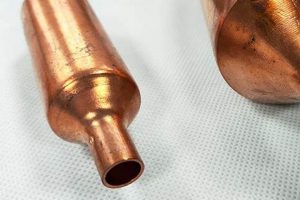

- Stainless Steel Grade Selection

The choice of stainless steel grade is a critical determinant of durability. While 304 stainless steel offers adequate corrosion resistance for many applications, more demanding environments may necessitate the use of 316 stainless steel, which exhibits superior resistance to chloride-induced pitting and crevice corrosion. In marine environments, or in regions where road salts are prevalent, the use of 316 stainless steel is particularly advisable. An example of inadequate material selection would be the premature failure of a bypass valve constructed from low-grade steel in a northern climate due to road salt exposure.

- Valve Mechanism Design and Tolerances

The design and manufacturing tolerances of the bypass valve mechanism are crucial for ensuring reliable operation. Tight tolerances minimize play and prevent exhaust leaks, while robust construction materials withstand the repeated thermal cycling and mechanical stresses associated with valve actuation. Insufficient tolerances or weak materials can lead to valve seizing, rattling, or complete failure. A common example is the failure of a butterfly valve due to excessive wear on the pivot points, resulting in exhaust leakage and reduced performance.

- Welding Quality and Techniques

The quality of the welds used to fabricate the exhaust bypass system is a critical factor in its overall durability. Poorly executed welds are prone to cracking, fatigue, and corrosion, leading to exhaust leaks and structural failure. The use of appropriate welding techniques, such as TIG welding, and the selection of compatible filler metals are essential for ensuring strong and durable joints. An example of poor welding practice would be the cracking of a bypass valve flange due to insufficient weld penetration, resulting in exhaust leaks and potential safety hazards.

- Corrosion Protection Measures

In addition to material selection, corrosion protection measures can significantly extend the lifespan of an exhaust bypass system. These measures may include the application of protective coatings, such as ceramic coatings or high-temperature paints, to shield the metal surfaces from corrosion. Regular cleaning and maintenance can also help to remove corrosive contaminants and prevent the onset of corrosion. An example of effective corrosion protection would be the application of a ceramic coating to the exhaust piping to reduce surface temperatures and prevent oxidation, thereby prolonging the system’s lifespan.

In summation, the selection of appropriate materials, coupled with robust design and manufacturing practices, is paramount for ensuring the durability and longevity of an exhaust bypass system. The long-term performance and reliability of the system are directly dependent on these factors, making careful consideration of materials and durability concerns essential for maximizing the value and minimizing the risk of premature failure.

Frequently Asked Questions

This section addresses common inquiries regarding the implementation and operation of exhaust bypass systems. These answers are intended to provide clarity and inform responsible decision-making.

Question 1: What is the primary purpose of a muffler cutout?

The primary purpose is to provide a means to bypass the vehicle’s muffler, thereby reducing exhaust backpressure and potentially increasing engine power output. This feature is often utilized for performance enhancement or to alter the vehicle’s exhaust sound.

Question 2: Are muffler cutouts legal for street use?

The legality of utilizing a muffler cutout on public roadways varies significantly depending on local and national regulations. Many jurisdictions have noise restrictions that prohibit the operation of vehicles exceeding specified decibel limits. Employing a muffler cutout can easily violate these regulations, leading to potential fines or vehicle impoundment.

Question 3: Will installing a muffler cutout automatically increase engine horsepower?

While reducing exhaust backpressure can potentially increase horsepower, the actual gains realized are dependent on factors such as engine displacement, exhaust system design, and the overall efficiency of the bypass mechanism. Measurable horsepower gains are typically more pronounced at higher engine speeds.

Question 4: What are the potential drawbacks of using a muffler cutout?

Potential drawbacks include increased noise levels, which may be objectionable to others or violate noise ordinances; potential alterations to the engine’s torque curve; and the possibility of increased exhaust emissions when the bypass is activated.

Question 5: How difficult is it to install a muffler cutout?

Installation complexity varies depending on the vehicle model, exhaust system design, and the specific bypass kit selected. Some installations may require welding, electrical integration, and modifications to the vehicle’s exhaust system. Professional installation is recommended unless the individual possesses advanced automotive mechanical skills.

Question 6: What materials are commonly used in the construction of muffler cutouts?

Stainless steel is a commonly used material due to its corrosion resistance and ability to withstand high temperatures. The specific grade of stainless steel, as well as the quality of the welding and valve mechanism, will affect the system’s overall durability.

These answers provide a foundation for understanding the key aspects of exhaust bypass systems. Prior to making any modifications, it is crucial to conduct thorough research and adhere to all applicable regulations.

The subsequent section will delve into the maintenance requirements associated with these systems.

Muffler Cutout

This exploration of the exhaust bypass system has illuminated its multifaceted nature, encompassing performance implications, auditory profile modifications, installation complexities, regulatory compliance concerns, and materials-related durability factors. Each aspect demands careful consideration to ensure responsible implementation and operational adherence to legal standards.

The decision to employ an exhaust modification necessitates a comprehensive understanding of its potential impact on both vehicle performance and the surrounding environment. Responsible implementation, in accordance with legal and ethical considerations, is paramount. Further research and due diligence are strongly encouraged before undertaking such modifications, promoting a balanced approach to automotive customization.