An automotive exhaust component designed to reduce noise levels typically incorporates internal partitions to create multiple resonating cavities. This design forces exhaust gases to pass through these chambers, causing sound waves to cancel each other out through destructive interference. The number and size of these chambers directly influence the resulting sound characteristics. For instance, vehicles utilizing this design often exhibit a distinct exhaust note compared to those employing alternative methods of sound suppression.

This approach to exhaust system design offers a balance between noise reduction and performance. By carefully tuning the internal chamber dimensions, engineers can minimize backpressure while achieving desirable sound dampening. This balance has made it a popular choice for both original equipment manufacturers and aftermarket performance enthusiasts seeking an enhanced driving experience without excessive noise. Historically, advancements in materials and computational fluid dynamics have enabled further refinement of these designs, resulting in improved efficiency and durability.

The effectiveness of this particular silencing solution can be assessed through various metrics, including sound pressure levels at different engine speeds and the overall impact on engine performance. These factors will be addressed in greater detail in subsequent sections, along with a comparative analysis against other noise reduction techniques used in exhaust systems.

Optimizing Performance with Multi-Cavity Silencers

The following guidelines are presented to assist in the selection, installation, and maintenance of exhaust systems incorporating internal resonance chambers for optimal performance and longevity.

Tip 1: Material Selection: Consider the vehicle’s operating environment when choosing a muffler. Stainless steel provides superior corrosion resistance in regions with salted roads or high humidity, extending the lifespan of the component.

Tip 2: Chamber Volume and Engine Displacement: The internal volumes of the chambers should be proportional to the engine’s displacement. An improperly sized muffler can negatively impact exhaust flow and engine performance. Consult manufacturer specifications for recommended sizing.

Tip 3: Installation Precautions: Ensure proper alignment during installation to prevent stress on the exhaust system. Misalignment can lead to premature failure of welds and other components.

Tip 4: Regular Inspections: Periodically inspect the muffler for signs of corrosion, leaks, or damage. Early detection of these issues can prevent more significant problems and costly repairs.

Tip 5: Mounting Hardware: Utilize high-quality mounting hardware and hangers designed to withstand the vibrations and thermal stresses of the exhaust system. Worn or damaged hangers can contribute to premature muffler failure.

Tip 6: Exhaust Backpressure Monitoring: Monitor exhaust backpressure to ensure it remains within acceptable limits. Excessive backpressure can indicate a clogged muffler or other exhaust system restriction, negatively impacting engine performance and fuel economy.

Tip 7: Welding Integrity: If welding is required during installation or repair, ensure that welds are performed by a qualified professional using appropriate techniques and materials. Poor welds can create weak points prone to failure.

Adherence to these recommendations will contribute to the enhanced performance, increased longevity, and optimized sound characteristics of vehicles utilizing multi-chamber silencing technology.

The subsequent section will explore comparative analysis with alternative exhaust system designs.

1. Sound Wave Cancellation in Dual-Chamber Exhaust Systems

Sound wave cancellation is the fundamental principle behind the operation of a dual-chamber exhaust system’s ability to reduce noise. This process relies on destructive interference to mitigate unwanted sound produced by the engine. The design strategically manipulates sound waves within the muffler’s chambers to achieve this effect.

- Phase Inversion:

Exhaust gases enter the first chamber, generating sound waves. A portion of these waves then travel through a connecting passage into the second chamber. The path length and internal geometry are engineered so that the sound waves arriving in the second chamber are approximately 180 degrees out of phase with the waves propagating directly from the engine. This phase inversion is crucial for effective cancellation.

- Frequency-Specific Attenuation:

The effectiveness of sound wave cancellation varies depending on the frequency of the sound. Dual-chamber systems are typically designed to target specific frequency ranges that contribute most significantly to perceived exhaust noise. By tuning the chamber dimensions, engineers can optimize the system’s performance within these critical frequency bands. However, it’s crucial to note that not all frequencies will be equally attenuated.

- Chamber Geometry Influence:

The physical dimensions and shapes of the chambers play a pivotal role. The size and shape of each chamber, along with the connecting pipe’s length and diameter, dictate the resonant frequencies within the system. These parameters are carefully calculated and adjusted to create the desired phase relationships and optimize cancellation across the targeted frequency range.

- Backpressure Considerations:

While sound wave cancellation reduces noise, it’s essential to consider its impact on exhaust backpressure. Excessive backpressure can negatively affect engine performance. Therefore, a well-designed exhaust system incorporating this technology must strike a balance between noise reduction and maintaining optimal exhaust flow. This often involves trade-offs and careful consideration of chamber design and flow path.

In summary, sound wave cancellation within dual-chamber exhaust systems is a complex process involving precise manipulation of sound waves through phase inversion and frequency-specific attenuation. Chamber geometry, along with backpressure considerations, are significant in optimizing performance and acoustic properties. The principles of sound wave cancellation are consistently applied for noise reduction in various engineering contexts.

2. Engine Performance Impact

The integration of an exhaust silencing system, particularly one employing a dual-chamber design, has a discernible effect on engine performance. The nature and extent of this influence are primarily governed by the design characteristics of the muffler and its impact on exhaust backpressure. An exhaust system, irrespective of its complexity, introduces a degree of flow restriction. The dual-chamber configuration, by directing exhaust gases through multiple expansion and contraction cycles, inevitably contributes to this resistance. Elevated backpressure can impede the expulsion of exhaust gases from the engine cylinders, leading to reduced volumetric efficiency and a commensurate decrease in power output. However, the magnitude of this effect depends critically on the specific design parameters of the two chamber muffler and the engine’s operating characteristics. For instance, in high-performance applications, an improperly designed dual-chamber unit can demonstrably restrict exhaust flow, measurably diminishing horsepower and torque, especially at higher engine speeds. Conversely, a carefully engineered design can minimize backpressure while still achieving effective noise reduction, thereby mitigating any substantial compromise in engine performance.

Furthermore, the impact extends beyond peak power figures. Changes in exhaust backpressure can also influence the engine’s torque curve. A dual-chamber design that generates a moderate level of backpressure can, in certain engine configurations, enhance low-end torque at the expense of high-end power. This is because the increased backpressure can improve cylinder filling during the intake stroke at lower engine speeds. Conversely, minimizing backpressure tends to favor high-end power by facilitating more efficient exhaust scavenging at higher RPMs. The selection of a dual-chamber muffler should therefore be predicated on a thorough understanding of the engine’s intended operating range and the desired performance characteristics.

In summary, while a dual-chamber exhaust system contributes to exhaust backpressure and can potentially reduce engine performance, the actual impact varies significantly based on the design, engine characteristics, and intended application. A well-designed system will minimize backpressure while providing adequate noise reduction. Comprehensive testing and careful consideration of engine performance goals are essential for selecting an appropriate two chamber muffler.

3. Material Durability Options

The longevity and operational effectiveness of a two chamber muffler are intrinsically linked to the materials from which it is constructed. Material selection directly influences the component’s resistance to corrosion, thermal stress, and mechanical degradation, thereby determining its service life. The internal environment of an exhaust system is inherently hostile, characterized by high temperatures, corrosive combustion byproducts, and constant vibration. Therefore, the choice of materials is a critical engineering consideration.

Common materials employed in muffler construction include aluminized steel, stainless steel, and, in some cost-sensitive applications, mild steel with protective coatings. Aluminized steel offers a reasonable balance between cost and corrosion resistance, achieved by applying a thin layer of aluminum to the steel substrate. Stainless steel, particularly grades such as 304 and 409, provides superior corrosion resistance due to its inherent chromium content, which forms a passive oxide layer on the surface, preventing rust. However, stainless steel options generally command a higher price point. Mild steel, while economical, is significantly more susceptible to corrosion and is typically limited to applications where cost is the primary constraint and component lifespan is not a paramount concern. The choice of material directly impacts the frequency of replacement and associated maintenance costs. For example, a muffler constructed from stainless steel in a region with harsh winter conditions and road salt application is likely to outlast an aluminized steel counterpart by several years. Similarly, in high-performance applications where exhaust gas temperatures are elevated, stainless steel’s superior heat resistance becomes a crucial factor in preventing premature failure.

In summary, material durability options are paramount to the effective long-term function of a two chamber muffler. Selecting the appropriate material, based on environmental conditions, operational demands, and budget constraints, is essential for maximizing the component’s lifespan and minimizing maintenance requirements. Although initial cost considerations often play a role in material selection, a long-term cost-benefit analysis typically favors more durable materials like stainless steel in demanding applications. The ultimate choice represents a compromise between performance, longevity, and economic factors.

4. Chamber Volume Influence

The acoustic performance of a two chamber muffler is critically dependent on the volume of each chamber. The chamber dimensions dictate the resonant frequencies within the system. These resonant frequencies, in turn, determine the muffler’s ability to attenuate specific sound frequencies generated by the engine. Increasing chamber volume generally lowers the resonant frequency, potentially shifting the noise reduction profile towards lower frequencies. Conversely, decreasing chamber volume raises the resonant frequency, targeting higher-pitched sounds. The effective management of exhaust noise necessitates a precise calibration of chamber volumes to address the dominant frequencies produced by a given engine. An improperly sized chamber can lead to either ineffective noise reduction or the amplification of undesirable frequencies. For instance, a two chamber muffler designed for a four-cylinder engine might prove unsuitable for a V8 engine due to differences in exhaust pulse frequency and volume.

The ratio between the volumes of the two chambers is also a crucial parameter. This ratio influences the degree of destructive interference achieved within the muffler. An optimal ratio maximizes the cancellation of sound waves within the targeted frequency range. Altering this ratio can shift the frequency at which maximum noise reduction occurs. Furthermore, chamber volume affects backpressure. Smaller volumes can increase backpressure, which may negatively impact engine performance, while excessively large volumes might reduce noise reduction effectiveness. Engine manufacturers often specify exhaust system backpressure limits to ensure optimal performance and fuel efficiency. These limits guide the selection or design of a two chamber muffler with appropriate chamber volumes.

In conclusion, chamber volume influence is a central determinant of the acoustic and performance characteristics of a two chamber muffler. The precise calibration of each chamber volume and their volume ratio is essential for achieving optimal noise reduction without compromising engine efficiency. A thorough understanding of these relationships, coupled with accurate acoustic modeling and engine performance testing, is paramount for effective muffler design and application. Challenges remain in developing adaptable designs that can accommodate a broader range of engine types and operating conditions while maintaining optimal performance, warranting further research and innovation in this area.

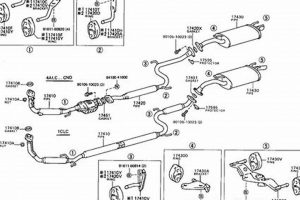

5. Exhaust Gas Flow Path in a Two Chamber Muffler

The exhaust gas flow path within a two chamber muffler is a critical determinant of its performance characteristics. The design of this path dictates the muffler’s ability to attenuate noise, manage backpressure, and influence overall engine efficiency. Optimization of the flow path is, therefore, a central consideration in the design and application of these mufflers.

- Inlet Configuration and Initial Expansion

The point at which exhaust gases enter the muffler and the initial expansion area significantly affect flow distribution and pressure dynamics. A well-designed inlet promotes uniform flow into the first chamber, minimizing turbulence and promoting efficient sound wave interaction. Conversely, a poorly designed inlet can create localized pressure gradients and increase backpressure.

- Inter-Chamber Connection Geometry

The geometry of the connection between the two chambers, including its size, shape, and position, dictates the proportion of exhaust gas that is directed into the second chamber. This geometry directly impacts the phase relationship of sound waves in the two chambers, influencing the effectiveness of noise cancellation. A restrictive connection can increase backpressure, while an overly large opening may reduce noise attenuation.

- Internal Baffle and Perforation Patterns

Baffles and perforated tubes strategically placed within the chambers control the direction and velocity of the exhaust gas flow. Baffles create longer flow paths, increasing sound wave interaction and attenuation. Perforations allow for controlled expansion and contraction of gases, influencing both noise reduction and backpressure. The patterns and configurations of these elements are crucial for tuning the muffler’s performance characteristics.

- Outlet Configuration and Final Exhaust Velocity

The design of the muffler outlet influences the final exhaust gas velocity and the overall backpressure of the system. A smooth, gradually expanding outlet minimizes flow restriction and promotes efficient evacuation of exhaust gases. The size and shape of the outlet are carefully calculated to optimize performance based on the engine’s specific requirements.

The intricacies of the exhaust gas flow path within a two chamber muffler are crucial for realizing its intended functionality. These features serve to highlight the degree of complexity in even a seemingly straightforward component. Balancing noise reduction, backpressure, and flow dynamics requires a rigorous engineering approach and an acute awareness of the interplay between these key parameters.

6. Specific Acoustic Properties

The acoustic signature of a two chamber muffler is not merely a function of noise reduction, but a complex interplay of various acoustic properties that define its overall sound characteristics. These properties are carefully engineered to achieve a desired sound profile, balancing noise attenuation with specific audible qualities.

- Insertion Loss

Insertion loss quantifies the muffler’s ability to reduce sound pressure levels across a range of frequencies. It is a critical metric for assessing the muffler’s effectiveness in attenuating engine exhaust noise. A higher insertion loss generally indicates greater noise reduction. However, the frequency distribution of insertion loss is equally important. A muffler optimized for low-frequency attenuation may not be effective at reducing high-frequency noise components, and vice-versa. Real-world applications require a balanced insertion loss profile that addresses the dominant frequencies produced by the engine. For example, a diesel engine, with its characteristic low-frequency rumble, necessitates a muffler with high insertion loss in the lower frequency range.

- Transmission Loss

Transmission loss refers to the amount of sound energy prevented from passing through the muffler. It is expressed in decibels (dB) and varies with frequency. Engineers manipulate the internal structure of the two chamber muffler to maximize transmission loss within specific frequency ranges, effectively blocking unwanted sound. Higher transmission loss values at targeted frequencies correlate with better noise suppression. This principle is applied in applications requiring adherence to stringent noise regulations, such as residential areas or environments with heightened noise sensitivity.

- Backpressure Influence

While not strictly an acoustic property, backpressure significantly influences the acoustic behavior of the muffler and the engine’s sound signature. Higher backpressure can alter the exhaust note and potentially amplify certain frequencies. A balance must be struck between noise reduction and minimizing backpressure to maintain optimal engine performance and avoid undesirable sound characteristics. This trade-off is particularly evident in performance-oriented applications, where achieving a specific exhaust note is often prioritized alongside power output.

- Resonance Frequencies

The internal chambers of the muffler act as resonators, amplifying certain frequencies while attenuating others. The locations and magnitudes of these resonance frequencies directly influence the overall sound quality. By carefully tuning the chamber dimensions and internal geometry, engineers can shape the muffler’s frequency response, creating a distinctive exhaust note. Some manufacturers intentionally design mufflers with specific resonance frequencies to produce a “sporty” or “aggressive” sound, while others aim for a more subdued and refined acoustic profile.

These acoustic properties, when considered in concert, define the subjective and objective sound characteristics of a two chamber muffler. Through careful design and engineering, these properties can be tailored to meet specific noise reduction targets and achieve a desired acoustic signature, influencing the overall driving experience and environmental impact.

Frequently Asked Questions

This section addresses common inquiries concerning two chamber muffler systems, offering clarity on their functionality, performance aspects, and application considerations.

Question 1: What defines the primary function?

The fundamental purpose is to attenuate noise generated by an internal combustion engine. This is achieved through destructive interference of sound waves within the muffler’s internal chambers, thereby reducing overall exhaust noise levels.

Question 2: Does this design negatively impact engine performance?

A properly designed two chamber muffler minimizes backpressure, thereby mitigating any significant reduction in engine power output. However, an improperly sized or designed unit can impede exhaust flow, resulting in a performance decrease.

Question 3: What materials are typically employed in the construction of these devices?

Common materials include aluminized steel, stainless steel (typically 304 or 409 grades), and, less frequently, coated mild steel. Stainless steel offers superior corrosion resistance and longevity, while aluminized steel provides a balance between cost and durability.

Question 4: How do chamber volumes affect performance and sound?

Chamber volumes influence the resonant frequencies within the muffler, which in turn dictates its ability to attenuate specific sound frequencies. The ratio between chamber volumes impacts the degree of destructive interference and the overall noise reduction profile.

Question 5: Are such mufflers suitable for all vehicle types?

Suitability depends on factors such as engine displacement, exhaust gas flow rate, and desired sound characteristics. A muffler designed for a small engine may not be appropriate for a larger, more powerful engine.

Question 6: What maintenance is required to ensure optimal performance and longevity?

Regular inspections for corrosion, leaks, and damage are essential. Ensuring secure mounting and addressing any exhaust system leaks promptly will prolong the muffler’s lifespan.

Understanding these aspects contributes to informed decision-making regarding the selection and application of a two chamber muffler.

The following section will offer a comparison of this design against alternative muffler technologies.

Conclusion

The preceding sections have provided a comprehensive examination of the two chamber muffler, detailing its operational principles, performance characteristics, material considerations, and acoustic properties. The analysis underscores the delicate balance between noise reduction and engine performance that engineers strive to achieve with this design. Optimal application necessitates a thorough understanding of engine specifications, desired sound profiles, and environmental factors. The interplay between chamber volumes, exhaust gas flow paths, and material selection collectively determines the muffler’s effectiveness and longevity.

The two chamber muffler remains a relevant technology in exhaust system design. As automotive engineering continues to evolve, further research into advanced materials, innovative chamber geometries, and active noise cancellation techniques may yield improvements in performance, durability, and acoustic control. The ongoing pursuit of optimized exhaust systems is paramount for meeting increasingly stringent noise regulations and enhancing the overall driving experience. Further investigation and application are critical for the continued success of two chamber muffler design.