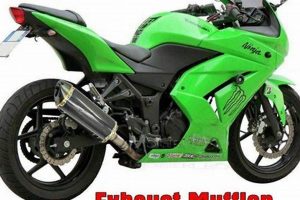

This aftermarket exhaust component significantly alters a vehicle’s sound profile, typically producing a louder, more aggressive tone. It’s frequently constructed from durable materials like aluminized or stainless steel for longevity. For instance, an individual seeking to enhance their truck’s auditory presence might choose this specific component.

The appeal of such a product lies in its potential to improve perceived vehicle performance, although actual gains vary. Historically, modifications to exhaust systems have been a popular way to personalize vehicles and express individuality. The selection criteria often include desired sound level, vehicle compatibility, and material quality for resistance against corrosion.

The following sections will delve into the specific aspects of this type of automotive part, encompassing factors like installation considerations, performance expectations, and long-term maintenance to ensure optimal functionality.

Enhancing Performance and Longevity

Optimizing the performance and lifespan of aftermarket exhaust components requires adherence to several critical guidelines. Neglecting these points can result in diminished effectiveness or premature failure.

Tip 1: Verify Compatibility: Prior to purchase, confirm that the specific component is designed for the target vehicle’s make, model, and year. Incompatible parts can lead to installation difficulties or compromised performance.

Tip 2: Professional Installation Recommended: While some individuals may attempt self-installation, engaging a qualified mechanic is generally advisable. Proper welding, alignment, and securing of the exhaust system are crucial for preventing leaks and ensuring optimal operation.

Tip 3: Regular Inspection for Corrosion: Salt, road debris, and moisture can accelerate corrosion. Periodically inspect the system for signs of rust or damage, particularly in areas exposed to the elements.

Tip 4: Maintain Proper Exhaust Hangers: Damaged or worn exhaust hangers can cause excessive stress on the system, leading to cracks or breaks. Replace worn hangers promptly to maintain structural integrity.

Tip 5: Monitor Sound Levels: Be cognizant of local noise ordinances. Excessive exhaust noise can result in fines or legal complications. Consider installing resonators or mufflers to manage sound output within acceptable limits.

Tip 6: Address Leaks Immediately: Exhaust leaks can compromise fuel efficiency and potentially introduce harmful gases into the vehicle’s cabin. Promptly address any detected leaks to mitigate these risks.

Adhering to these recommendations will maximize the performance, durability, and safety of an aftermarket exhaust system, providing long-term value and satisfaction.

The subsequent sections will explore the nuances of troubleshooting common issues and determining the appropriate time for replacement.

1. Aggressive Sound Profile

The “Aggressive Sound Profile” is a primary characteristic sought by individuals opting for this specific aftermarket exhaust modification. It represents a significant departure from the typically subdued sound of factory-installed mufflers, offering an enhanced auditory experience intended to convey power and performance.

- Frequency Amplification

The design of this particular component often emphasizes the amplification of lower frequencies, resulting in a deeper, more resonant tone. This is achieved through internal baffling and chamber designs that promote sound wave manipulation, resulting in a noticeably louder and more pronounced exhaust note at idle and during acceleration. This amplification differentiates it from quieter, more restrictive stock systems.

- Reduced Backpressure

While not solely responsible for the sound profile, the reduction of backpressure contributes to a louder, more unrestricted exhaust flow. The design minimizes obstructions within the muffler, allowing exhaust gases to exit more freely. This can create a ‘throatier’ or more ‘raw’ sound, especially at higher engine speeds. This contrasts with the deliberately restrictive design of OEM mufflers, which prioritize noise reduction over maximum flow.

- Exterior Material Composition and Thickness

The specific materials employed in construction and their thickness play a crucial role in the overall sound characteristics. Thicker gauge steel, for instance, can contribute to a deeper, less raspy tone compared to thinner materials that may produce a higher-pitched or tinny sound. The choice of stainless steel versus aluminized steel also influences sound, with stainless steel generally being perceived as offering a crisper, more refined tone.

- Resonance Chamber Tuning

Advanced designs may incorporate resonance chambers specifically tuned to particular frequencies. These chambers act as acoustic amplifiers, accentuating certain aspects of the exhaust note and contributing to the desired “Aggressive Sound Profile.” The precise size and shape of these chambers are critical and require careful engineering to achieve the intended sonic effect. This specialized tuning differentiates it from generic aftermarket mufflers.

In conclusion, the “Aggressive Sound Profile” associated with aftermarket exhaust components is not a singular element, but rather a combination of various design features, material selections, and engineering principles. The effectiveness of this automotive part in achieving a desired audible output relies on the careful consideration and integration of these factors.

2. Durable Steel Construction

The term “Durable Steel Construction” directly relates to the longevity and performance of an aftermarket exhaust component. The choice of steel, typically aluminized or stainless steel, significantly impacts the ability of the exhaust system to withstand harsh environmental conditions and the corrosive effects of exhaust gases. In the context of an automotive part such as a high-performance component, this aspect is paramount. A robust build is essential to withstand thermal stress and physical damage from road debris. For instance, a system fabricated from low-grade steel is prone to premature rusting and structural failure, negating any potential performance gains.

Consider a scenario where two vehicles are subjected to similar driving conditions, including exposure to road salt during winter. One vehicle is equipped with an exhaust system constructed from high-quality stainless steel, while the other utilizes a system made from standard aluminized steel. Over time, the aluminized steel system will exhibit signs of corrosion at a faster rate, potentially leading to leaks and reduced efficiency. In contrast, the stainless steel system, due to its inherent resistance to corrosion, will maintain its structural integrity and performance characteristics for a longer duration. This highlights the practical importance of selecting exhaust systems with durable steel construction, especially in regions with harsh climates.

In summary, the selection of durable steel is not merely a superficial consideration; it’s a fundamental factor influencing the lifespan, reliability, and overall value of an aftermarket exhaust. While systems utilizing higher-grade materials may represent a greater initial investment, their long-term durability and resistance to corrosion provide a distinct advantage, ultimately ensuring consistent performance and minimizing the need for frequent replacements. The interplay between material selection, environmental factors, and driving conditions directly determines the real-world benefits of durable steel construction in such systems.

3. Performance Enhancement Potential

The term “Performance Enhancement Potential,” when associated with an aftermarket exhaust component, refers to the theoretical improvements in engine output and efficiency achievable through its installation. Realizing this potential, however, depends on a complex interplay of factors including engine characteristics, vehicle modifications, and proper installation.

- Reduced Backpressure

The primary mechanism through which an aftermarket exhaust system contributes to enhanced performance is the reduction of backpressure. Factory exhaust systems are often designed with restrictive mufflers and piping to minimize noise, which inherently limits the engine’s ability to expel exhaust gases efficiently. A component designed to minimize backpressure allows the engine to “breathe” more freely, potentially resulting in increased horsepower and torque. However, simply reducing backpressure without considering other factors, such as engine tuning and fuel delivery, may not yield significant or even positive results.

- Optimized Exhaust Flow

Beyond simply reducing backpressure, the design of an aftermarket exhaust aims to optimize the flow of exhaust gases. This involves carefully considering pipe diameter, bend radius, and collector design to minimize turbulence and maximize exhaust velocity. A well-designed system promotes efficient scavenging of exhaust gases from the cylinders, which can improve combustion and increase engine output. However, an improperly sized or poorly designed system can actually decrease performance by creating excessive turbulence or disrupting the natural flow of exhaust gases.

- Improved Scavenging Effect

Efficient exhaust systems can improve the scavenging effect. Scavenging is a phenomenon where the exiting exhaust pulse from one cylinder helps to draw out the remaining exhaust gases from another cylinder during the overlap period when both the intake and exhaust valves are partially open. A properly designed aftermarket exhaust can enhance this effect, leading to a more complete and efficient combustion cycle. The effectiveness of scavenging is highly dependent on engine design, cam timing, and exhaust system geometry, necessitating careful matching of components for optimal results.

- Catalytic Converter Efficiency

Some aftermarket exhaust systems may incorporate high-flow catalytic converters, which can further reduce backpressure while still maintaining emissions compliance. These converters utilize a more open substrate design, allowing exhaust gases to flow more freely without sacrificing their ability to filter harmful pollutants. However, the effectiveness of a high-flow catalytic converter depends on its quality and the overall design of the exhaust system. A poorly designed converter can actually increase backpressure or fail to adequately filter emissions, negating any potential performance benefits.

In summary, “Performance Enhancement Potential” relies heavily on the harmonious integration of exhaust design principles with existing engine characteristics. Although a more aggressive sound or improved aesthetics may be achieved through installation, the actual performance gains are often modest and heavily contingent on supporting modifications and proper engine tuning. While theoretically possible, realizing significant performance improvements requires careful planning and a comprehensive understanding of engine dynamics.

4. Vehicle Compatibility Verification

Accurate “Vehicle Compatibility Verification” is a prerequisite for the successful integration of an aftermarket exhaust component. Installing this system on an incompatible vehicle can lead to performance degradation, installation difficulties, and potential damage to related components. A failure to verify compatibility can negate any intended benefits and incur unnecessary costs.

- Engine Displacement and Configuration Matching

Exhaust systems are engineered to suit specific engine displacements and configurations (e.g., inline-four, V6, V8). A muffler designed for a smaller engine may create excessive backpressure on a larger engine, hindering performance. Conversely, a muffler intended for a larger engine may not provide sufficient backpressure for a smaller engine, potentially leading to decreased low-end torque and fuel efficiency. For instance, attempting to fit a component designed for a 5.0L V8 engine onto a 2.0L inline-four engine would create significant performance imbalances. Incompatibility in this area can lead to inefficient engine operation, potentially causing long-term damage.

- Exhaust System Routing and Mounting Point Alignment

The physical dimensions and routing of the exhaust system must align precisely with the undercarriage of the target vehicle. Mounting points, hanger locations, and pipe diameters must be compatible to ensure a secure and leak-free installation. Discrepancies in these areas can result in rattling, vibration, and potential exhaust leaks. For example, if the muffler’s hanger locations do not correspond with the vehicle’s mounting points, the system cannot be properly secured, leading to stress fractures and premature failure. Mismatched routing can also result in interference with other undercarriage components, potentially causing damage to fuel lines or brake lines.

- Emissions Compliance and Regulatory Adherence

Aftermarket exhaust systems must adhere to all applicable emissions regulations in the jurisdiction where the vehicle is operated. Installing a non-compliant system can result in fines, failed emissions tests, and legal penalties. Furthermore, the component must be certified for use on the specific vehicle model to ensure compliance with manufacturer warranties. For instance, tampering with catalytic converters or installing systems that exceed noise level limits are common violations. Compliance with regulations is a critical aspect, as non-compliance can lead to legal consequences and invalidate the vehicle’s warranty.

- Sensor Integration and Interface Compatibility

Modern vehicles often incorporate oxygen sensors and other electronic sensors within the exhaust system. The aftermarket component must be designed to accommodate these sensors and maintain compatibility with the vehicle’s electronic control unit (ECU). Improper sensor placement or incompatibility with the ECU can lead to inaccurate readings, triggering check engine lights and potentially affecting engine performance. For example, if the oxygen sensor bung is located in an incorrect position, the sensor may not accurately measure the exhaust gas composition, leading to incorrect fuel trim adjustments by the ECU. Ensuring proper sensor integration is crucial for maintaining optimal engine performance and avoiding diagnostic issues.

In essence, accurate “Vehicle Compatibility Verification” extends beyond a simple visual inspection. It requires a detailed assessment of engine specifications, physical dimensions, emissions requirements, and electronic system integration to ensure that the aftermarket component functions correctly and without adverse effects on the vehicle. Neglecting any of these aspects can lead to significant complications, highlighting the importance of thorough verification prior to purchase and installation.

5. Optimized Exhaust Flow

Efficient evacuation of exhaust gases from the engine cylinders is paramount for achieving optimal engine performance. The design characteristics of an aftermarket exhaust component such as a system play a significant role in facilitating this process, influencing power output, fuel efficiency, and overall engine health.

- Reduced Backpressure through Internal Design

The internal construction, specifically the baffling and chamber configurations, minimizes resistance to the flow of exhaust gases. Unlike stock systems that often prioritize noise reduction at the expense of flow, these components are engineered with larger internal passages and smoother transitions to reduce backpressure. A practical example involves comparing the internal volume and baffling structure of a stock muffler to that of a high-performance counterpart; the latter typically exhibits a more direct and less restrictive path for exhaust gases, directly correlating with the degree of backpressure reduction. This reduction in backpressure allows the engine to expel exhaust gases more easily, potentially resulting in increased horsepower and torque. However, an excessive reduction in backpressure can, in certain engine configurations, negatively impact low-end torque.

- Strategic Pipe Diameter and Bend Radius

The diameter of the exhaust piping and the sharpness of bends significantly impact exhaust flow. Larger diameter piping can accommodate a greater volume of exhaust gases, while smoother, less abrupt bends minimize turbulence. However, the optimal pipe diameter is dependent on engine displacement and power output; excessively large piping can actually decrease exhaust velocity, negating the benefits of reduced backpressure. For instance, an exhaust system utilizing mandrel-bent tubing, characterized by its consistent diameter throughout the bend, will generally exhibit superior flow characteristics compared to a system employing crush-bent tubing, which constricts the pipe diameter at the bend. Proper sizing and bending techniques are thus crucial for achieving optimized exhaust flow.

- Collector Design and Scavenging Effect

The design of the exhaust manifold collector, where individual exhaust runners converge, plays a critical role in promoting efficient scavenging. A well-designed collector facilitates the creation of negative pressure pulses that help to draw exhaust gases out of the cylinders, particularly during valve overlap. This scavenging effect can improve combustion efficiency and increase engine output. For example, long-tube headers with properly tuned collectors are often used in high-performance applications to maximize scavenging. The precise dimensions and configuration of the collector are dependent on engine firing order and valve timing, requiring careful engineering to achieve optimal performance.

- Material Selection and Surface Finish

The material used in the construction of the exhaust system and the smoothness of its internal surfaces can also influence exhaust flow. Stainless steel, known for its smooth surface and resistance to corrosion, is often preferred over aluminized steel for its superior flow characteristics. Polishing the internal surfaces of the exhaust system can further reduce friction and improve flow, although the gains are typically marginal compared to other design factors. The selection of durable and corrosion-resistant materials, coupled with smooth internal surfaces, helps to maintain consistent exhaust flow over the long term, ensuring sustained performance benefits.

In summation, the achievement of “Optimized Exhaust Flow” represents a multifaceted endeavor, encompassing internal design elements, pipe dimensions, collector configuration, and material selection. While an aftermarket system can contribute to improved exhaust flow, the extent of the performance gains depends on a holistic approach, considering the interplay of these factors and their interaction with the engine’s characteristics. The suitability of a given exhaust system for a specific application therefore warrants careful consideration and expert consultation.

Frequently Asked Questions

The following questions address common inquiries regarding the selection, installation, and performance characteristics of aftermarket exhaust components, specifically those designed for enhanced sound and performance. The answers provided are intended to offer clear and objective information to assist informed decision-making.

Question 1: What is the typical sound characteristic associated with this type of automotive part?

These units generally produce a louder, more aggressive exhaust note compared to stock systems. The specific sound profile can vary depending on the design and construction of the product. Key factors include the internal baffling, chamber size, and material composition. A deeper, more resonant tone is often sought after, though certain models may exhibit a higher-pitched or raspy sound.

Question 2: What level of performance gains can be realistically expected from this component?

Performance gains are often modest and vary depending on the engine configuration, vehicle modifications, and installation quality. While reduced backpressure can potentially increase horsepower and torque, the actual gains may be minimal without supporting modifications such as engine tuning or improved intake systems. Claims of substantial performance increases should be viewed with skepticism.

Question 3: Is professional installation required, or can it be performed by an individual with mechanical experience?

While some mechanically inclined individuals may be capable of performing the installation, professional installation is generally recommended. Proper welding, alignment, and secure mounting are essential for preventing leaks and ensuring optimal performance. Incorrect installation can lead to exhaust leaks, vibration, and potential damage to the system or vehicle.

Question 4: What materials are commonly used in the construction of these systems, and what are the advantages of each?

Aluminized steel and stainless steel are the most prevalent materials. Aluminized steel offers a cost-effective option with moderate corrosion resistance, while stainless steel provides superior durability and resistance to rust. Stainless steel systems typically command a higher price due to their enhanced longevity.

Question 5: What considerations are necessary to ensure compliance with local noise regulations?

Exhaust noise regulations vary by jurisdiction. It is imperative to familiarize oneself with local ordinances prior to installing an aftermarket system. Excessive noise levels can result in fines or legal penalties. The installation of resonators or mufflers can help manage sound output within acceptable limits. Sound level meters can be used to verify compliance.

Question 6: What maintenance is required to prolong the lifespan and performance of this system?

Regular inspection for corrosion, damage, and leaks is essential. Promptly address any detected issues to prevent further deterioration. Maintaining proper exhaust hanger integrity is also crucial to prevent stress fractures and ensure secure mounting. Periodic cleaning can help remove road salt and debris, extending the lifespan of the system.

The information provided in these FAQs is intended for general guidance only and does not constitute professional advice. Specific applications may require expert consultation to ensure optimal results and regulatory compliance.

The subsequent section will delve into the troubleshooting of common issues encountered with aftermarket exhaust components.

Concluding Remarks

The preceding examination of components reveals a landscape where sound, durability, and performance intersect. Each characteristic, from the aggressive sound profile to the optimized exhaust flow, contributes to the overall value and suitability of the automotive part for specific applications. Meticulous attention to vehicle compatibility and adherence to maintenance protocols is essential to realizing the intended benefits.

The decision to incorporate this type of component warrants careful consideration, weighing the potential performance enhancements against factors such as regulatory compliance and noise considerations. Continued advancements in materials and design promise further refinements in the future. Thorough evaluation of individual needs and expert consultation are advised prior to implementation.