A visual representation providing specifications for a manufacturer’s exhaust components facilitates the selection of the correct part for a given vehicle application. This tool typically organizes data related to muffler dimensions, inlet/outlet configurations, casing styles, and performance characteristics. Users refer to this organized information to determine compatible muffler models based on their vehicle’s requirements and desired sound profile.

Access to accurate product data benefits both installers and consumers by streamlining the selection process, reducing the likelihood of ordering incompatible parts, and improving the overall efficiency of exhaust system modifications. Historically, accessing such information required consulting paper catalogs or contacting customer support. The evolution towards digital formats has provided readily accessible and easily searchable resources, greatly improving customer experience.

The following sections will explore key aspects of muffler selection, performance considerations, and installation procedures, providing a detailed guide to optimizing your vehicle’s exhaust system.

Dynomax Muffler Chart

This section offers essential advice for effectively utilizing manufacturer-provided exhaust component specifications.

Tip 1: Verify Vehicle Compatibility: Cross-reference the vehicle’s year, make, and model with the data to ensure accurate muffler fitment and avoid installation issues.

Tip 2: Analyze Dimensions Carefully: Pay close attention to inlet/outlet diameters and muffler casing length. Discrepancies can lead to exhaust leaks or the inability to physically install the muffler.

Tip 3: Consider Muffler Style: Different casing styles (e.g., round, oval, rectangular) affect ground clearance and overall appearance. Choose a style that aligns with the vehicle’s design and usage.

Tip 4: Review Performance Ratings: Evaluate noise reduction levels and flow rates. Select a muffler that balances desired sound characteristics with optimal engine performance.

Tip 5: Consult Technical Specifications: Examine construction materials and internal design. These factors influence durability, sound quality, and resistance to corrosion.

Tip 6: Identify Relevant Notes: Scan additional notes or caveats associated with specific models. These may include installation requirements, emissions compliance, or application limitations.

Tip 7: Prioritize Professional Installation: While self-installation is possible, consulting a qualified mechanic is highly recommended to ensure proper fitment, secure connections, and compliance with local regulations.

Careful attention to these details enhances the likelihood of selecting the correct muffler, resulting in improved performance, optimized sound, and a long-lasting exhaust system upgrade.

The subsequent section will delve into troubleshooting common exhaust system problems, providing solutions for maintaining optimal vehicle performance.

1. Vehicle Compatibility

Vehicle compatibility serves as the foundational element when interpreting manufacturer exhaust specifications. The accuracy of exhaust component selection hinges on precisely matching the part to the intended vehicle, thereby preventing fitment issues and ensuring optimal performance. In the context of exhaust system upgrades, meticulous verification of vehicle-specific data becomes paramount.

- Year, Make, and Model Specification

The primary step involves confirming that the manufacturer’s specifications explicitly list the vehicle’s year, make, and model. For example, a muffler designated for a “2015 Ford F-150” will likely exhibit dimensional and performance characteristics distinct from one intended for a “2020 Toyota Tacoma.” Erroneously selecting a part based on superficial similarities can lead to significant installation challenges and compromised exhaust flow.

- Engine Size and Configuration

Engine size and configuration significantly influence exhaust flow requirements. A V8 engine will necessitate a muffler with a higher flow capacity than a four-cylinder engine. Manufacturer data often specifies the engine displacement (e.g., 5.0L, 2.0L) for which a particular muffler is designed. Neglecting this parameter can result in backpressure issues, reduced engine efficiency, and potential damage to exhaust components.

- Chassis Type and Drivetrain

Chassis type (e.g., sedan, SUV, truck) and drivetrain (e.g., 2WD, 4WD) can affect muffler placement and exhaust routing. A muffler designed for a rear-wheel-drive vehicle may not physically fit in a front-wheel-drive application due to space constraints or interference with suspension components. Exhaust specifications frequently include notes regarding chassis compatibility to avoid these complications.

- Emissions Compliance

Mufflers are often subject to specific emissions regulations depending on the vehicle’s model year and geographic location. Manufacturer specifications will indicate whether a particular muffler is compliant with relevant emissions standards, such as those mandated by the Environmental Protection Agency (EPA). Installing a non-compliant muffler may result in failed emissions tests and potential legal penalties.

The meticulous assessment of these compatibility facets, as detailed within manufacturer exhaust specifications, mitigates the risk of improper part selection. This rigorous approach ensures that the chosen muffler aligns with the vehicle’s specific requirements, thereby maximizing performance gains and minimizing installation difficulties.

2. Dimensional Accuracy

Dimensional accuracy represents a critical aspect when interpreting exhaust component specifications. Discrepancies between manufacturer-provided dimensions and actual vehicle measurements can lead to significant fitment challenges, installation complications, and compromised exhaust system performance. A thorough understanding of these dimensional factors is therefore essential for selecting a compatible muffler.

- Inlet and Outlet Diameter Matching

The inlet and outlet diameters of the muffler must precisely match the corresponding dimensions of the existing exhaust piping. A mismatch, even by a small margin, can result in exhaust leaks, reduced flow efficiency, and potential damage to connecting components. For example, if the specification indicates a 2.5-inch inlet, the connecting pipe must also measure 2.5 inches in diameter. Adapters can sometimes be used to bridge minor differences, but they introduce additional points of failure and can restrict exhaust flow.

- Muffler Body Length and Width Considerations

The overall length and width of the muffler body are crucial for ensuring adequate clearance within the vehicle’s undercarriage. Insufficient space can lead to contact with other components, such as the frame, suspension, or fuel tank, causing noise, vibration, and potential damage. Specifications typically provide the muffler’s overall dimensions, allowing installers to verify compatibility with available space.

- Offset and Configuration of Inlet/Outlet

The relative position and orientation of the inlet and outlet (e.g., center/offset, single/dual) directly impact installation feasibility. An incorrectly configured muffler may require extensive modifications to the exhaust piping, increasing installation time and cost. Specifications clearly indicate the inlet/outlet configuration, enabling installers to select a muffler that aligns with the existing exhaust system layout.

- Hanger Placement and Mounting Points

Muffler hanger placement and the type of mounting points (e.g., welded brackets, clamps) are essential for secure installation and vibration isolation. Mismatched hanger locations can necessitate custom fabrication or compromise the stability of the exhaust system. Specifications detail the location and type of hanger points, allowing installers to ensure proper support and minimize noise transmission.

These dimensional considerations are integral to the accurate interpretation of exhaust specifications. Failure to account for these factors can result in significant installation challenges, reduced performance, and potential damage to the vehicle. Therefore, a meticulous examination of all dimensional data is paramount when selecting an exhaust component. This information is an important aspect of the selection process.

3. Casing Configuration

Casing configuration, as documented within a manufacturer’s exhaust component specification, directly influences muffler performance, sound characteristics, and installation constraints. The external shape and internal design of the muffler casing dictate exhaust gas flow patterns, affecting backpressure and noise attenuation. Selection based on casing configuration should align with vehicle-specific requirements and desired acoustic outcomes.

- Shape and Size Influence

The shape and overall size of the muffler casing (e.g., round, oval, rectangular) impact available space within the vehicle’s undercarriage and influence exhaust flow dynamics. A compact, oval design might be preferred for vehicles with limited ground clearance, while a larger, round casing could provide greater noise reduction capabilities. For example, a high-performance vehicle may benefit from a cylindrical casing optimized for straight-through flow.

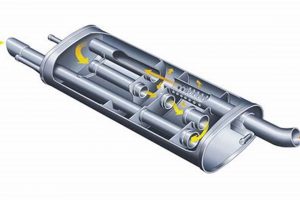

- Internal Chamber Design and Impact

The internal chamber design of the muffler casing (e.g., baffled, straight-through, multi-chambered) dictates how exhaust gases are directed and attenuated. Baffled designs typically offer greater noise reduction but can restrict flow, while straight-through designs prioritize flow but may produce a louder exhaust note. A multi-chambered muffler combines both approaches to balance performance and sound. Choosing the appropriate internal design, based on detailed diagrams often found within manufacturer documentation, is critical for achieving the desired outcome.

- Material Composition and Acoustic Properties

The material composition of the muffler casing (e.g., aluminized steel, stainless steel) influences its durability, corrosion resistance, and acoustic properties. Stainless steel casings offer superior corrosion resistance but may be more expensive. Aluminized steel provides a cost-effective alternative with adequate corrosion protection in moderate climates. Material thickness can affect the muffler’s ability to dampen vibrations and reduce noise. Reviewing material specifications within the manufacturer provided information is vital for application specific compatibility.

- Inlet/Outlet Placement and Configuration

The location and orientation of the inlet and outlet pipes on the muffler casing directly affect installation ease and exhaust system routing. Incorrect inlet/outlet placement can necessitate modifications to the existing exhaust system. Manufacturer documentation provides precise diagrams detailing inlet/outlet positions, enabling installers to select a muffler that minimizes installation complexity. Specific attention to offset considerations is necessary. This information assists in a seamless integration within the existing infrastructure.

In conclusion, casing configuration, as detailed within a manufacturer’s exhaust component data, is a critical factor influencing muffler selection. This information dictates performance characteristics and installation parameters. Understanding these design nuances is essential for achieving the desired balance of performance, sound, and ease of installation when modifying a vehicle’s exhaust system.

4. Performance Metrics

Performance metrics within exhaust component specifications, specifically as they relate to a manufacturer’s data, provide quantifiable measures of a muffler’s capabilities. These metrics serve as critical indicators for assessing the impact of the exhaust system on engine performance, sound characteristics, and overall vehicle efficiency. Disregarding these metrics can result in suboptimal component selection, leading to compromised performance or undesirable sound profiles. Metrics typically detail flow rate, backpressure, and sound level reduction.

Exhaust flow rate, measured in cubic feet per minute (CFM), indicates the volume of exhaust gases the muffler can efficiently handle. Higher flow rates are generally desirable for performance applications, as they minimize backpressure and allow the engine to breathe more freely. Backpressure, conversely, represents the resistance to exhaust gas flow within the muffler. Excessive backpressure can reduce engine power and fuel economy. Sound level reduction, often measured in decibels (dB), quantifies the muffler’s ability to attenuate exhaust noise. Muffler specification charts detail these performance values to allow for an informed selection process. For instance, selecting a high-flow muffler with minimal backpressure is critical for a modified engine where power is the main consideration. A high-restriction muffler, while achieving greater sound dampening, may hinder overall performance. Charts are an essential reference for consumers looking to maximize performance and those looking to quiet their engine.

A comprehensive understanding of exhaust component performance metrics is vital for optimizing vehicle performance, and achieving the desired sound profile. These metrics act as definitive benchmarks against which to gauge the appropriateness of a chosen component, thereby mitigating the likelihood of installation failures or sub-optimal system behavior. The integration of such detail ensures both efficiency of choice and that the results match the vehicle’s intended use and the consumer’s expectations.

5. Construction Material

Construction material is a fundamental element within a Dynomax muffler chart, directly impacting the muffler’s durability, performance characteristics, and suitability for specific environmental conditions. The material composition dictates the muffler’s resistance to corrosion, its ability to withstand high temperatures, and its influence on sound attenuation. Understanding these material properties is therefore crucial for informed muffler selection.

- Steel Grade and Composition

The specific steel grade used in a Dynomax muffler, such as aluminized steel or stainless steel (e.g., 304 or 409), dictates its resistance to corrosion. Aluminized steel offers a cost-effective solution with adequate protection in moderate climates, while stainless steel provides superior resistance in harsh environments exposed to road salt or extreme temperatures. The chart often specifies the steel grade used in each model, enabling users to assess its suitability for their local climate. For instance, coastal regions benefit from stainless steel due to its higher salinity resilience.

- Material Thickness and Gauge

Material thickness, typically measured in gauge, influences the muffler’s ability to withstand mechanical stress and dampen vibrations. A thicker gauge steel generally provides greater durability and reduces the likelihood of damage from road debris or impacts. The chart may specify the gauge of steel used in different sections of the muffler, such as the casing or internal baffles, allowing users to assess its overall robustness. Trucks driven off road may require higher gauge material.

- Welding Techniques and Quality

Welding techniques used during muffler construction impact its structural integrity and resistance to leaks. High-quality welds, such as those achieved through TIG or MIG welding, ensure a strong and durable bond between muffler components. The chart may provide information about the welding processes used, indirectly indicating the overall quality of construction. Improper welding can lead to premature failure and a compromised performance. Many brands offer information about the weld-quality certification available.

- Internal Coating and Corrosion Protection

Internal coatings, such as ceramic or aluminized coatings, enhance the muffler’s resistance to corrosion from within, protecting it from exhaust gases and condensation. These coatings extend the muffler’s lifespan and maintain its performance over time. The chart may specify whether a muffler features an internal coating and, if so, the type of coating used. Components used with turbochargers often receive these internal coatings.

In summary, construction material, as detailed within a Dynomax muffler chart, serves as a key indicator of a muffler’s durability, performance, and suitability for specific operating conditions. Careful consideration of steel grade, material thickness, welding quality, and internal coatings ensures informed muffler selection and long-term performance. Charts help consumers make educated purchases by presenting these metrics transparently. The material information is essential for purchase decisions.

6. Installation Notes

Installation Notes within a Dynomax muffler chart serve as a critical adjunct to the core performance and dimensional data. These notes provide essential, often overlooked, details that directly impact the success and safety of the installation process. Ignoring these specifications can lead to improper fitment, compromised performance, and potential damage to the vehicle or the muffler itself. The chart provides explicit details that would otherwise be left to the discretion of a novice installer. For example, a note might specify the need for specific exhaust hangers or the requirement to use heat shields in close proximity to fuel lines. Failure to heed these guidelines could result in exhaust leaks, rattling noises, or, in extreme cases, fuel system damage.

Furthermore, Installation Notes frequently address vehicle-specific considerations that are not readily apparent from the general dimensional data. This could include warnings about known clearance issues with certain models, specific torque specifications for exhaust clamps, or recommended procedures for disconnecting oxygen sensors. Consider an instance where a Dynomax muffler chart stipulates the use of anti-seize compound on exhaust bolts for vehicles in regions with high road salt usage. Neglecting this recommendation could lead to seized bolts, making future exhaust system maintenance significantly more difficult. Without the guidance of these notes, the install becomes considerably more difficult.

In conclusion, Installation Notes within a Dynomax muffler chart represent a vital component of the overall product information. They mitigate installation risks, address vehicle-specific nuances, and promote long-term reliability. While performance metrics and dimensional data offer insight into the muffler’s capabilities, Installation Notes provide the practical guidance necessary for a successful and safe installation. As such, they should be regarded as an indispensable resource, not an afterthought, when selecting and installing a Dynomax muffler.

Frequently Asked Questions Regarding Dynomax Muffler Charts

The following section addresses common inquiries related to the interpretation and utilization of manufacturer-provided exhaust specifications. This information is intended to provide clarity and promote informed decision-making in muffler selection.

Question 1: What is the primary purpose of a Dynomax muffler chart?

The principal function is to furnish detailed technical data pertaining to various muffler models, enabling users to identify components compatible with specific vehicle applications and performance requirements.

Question 2: Where can a Dynomax muffler chart be accessed?

These charts are typically available on the manufacturer’s official website, through authorized dealers, or within product catalogs. Access may require navigating to the specific product line or downloading a PDF document.

Question 3: What key information is commonly found within a Dynomax muffler chart?

Essential data includes muffler dimensions, inlet/outlet diameters, casing style, construction material, performance metrics (e.g., flow rate, noise reduction), and installation notes. These details facilitate accurate component selection and proper installation.

Question 4: How does a Dynomax muffler chart assist in determining vehicle compatibility?

Charts delineate the vehicle year, make, and model applicability for each muffler, along with engine size and configuration. Cross-referencing these specifications ensures proper fitment and avoids installation issues.

Question 5: What should be done if the provided specifications appear ambiguous or incomplete?

In cases of uncertainty, contacting the manufacturer’s customer support or consulting a qualified mechanic is recommended. Seeking expert guidance clarifies ambiguities and ensures accurate component selection.

Question 6: Are Dynomax muffler charts regularly updated?

Manufacturers periodically revise these charts to reflect new product releases, specification changes, or improvements in data accuracy. Verifying the chart’s publication date ensures access to the most current information.

Accurate interpretation and diligent application of information found within product data enhance the likelihood of a successful exhaust system modification.

The following section will explore troubleshooting common exhaust system problems, providing solutions for maintaining optimal vehicle performance.

Dynomax Muffler Chart

The preceding analysis has underscored the critical role of the Dynomax muffler chart as a comprehensive resource for exhaust system component selection. From dimensional accuracy and casing configuration to performance metrics and installation notes, the chart serves as an indispensable tool for ensuring compatibility, optimizing performance, and facilitating proper installation. Its effective utilization demands meticulous attention to detail and a thorough understanding of the technical specifications provided.

The Dynomax muffler chart, therefore, represents more than a mere listing of product attributes; it embodies a commitment to precision, performance, and informed decision-making. Its continued use as a primary reference will remain essential for those seeking to enhance their vehicles’ exhaust systems with confidence and achieve lasting results. Automotive professionals and informed consumers will benefit from the data within.