Automotive sound reduction devices, integral components of exhaust systems, are categorized based on their internal construction and acoustic properties. These components, designed to mitigate engine noise, employ various methods of sound wave cancellation and absorption. Examples include chambered designs, which utilize strategically placed baffles to reflect and cancel sound waves, and absorption designs, which incorporate fiberglass or other sound-dampening materials.

The selection of a specific sound reduction device impacts vehicle sound levels, performance characteristics, and emissions compliance. Their utilization contributes to reduced noise pollution in urban environments and enhances the comfort of vehicle occupants. Historically, advancements in their design have focused on optimizing the balance between noise reduction, exhaust flow efficiency, and durability.

The subsequent sections will detail the operational principles, performance attributes, and typical applications of several distinct categories of these sound-dampening devices. Factors such as vehicle type, engine configuration, and desired sound profile influence the optimal selection for a given application.

Guidance on Automotive Sound Reduction Devices

The following guidelines provide essential considerations for selecting and maintaining exhaust sound reduction components, crucial for vehicle performance and environmental compliance.

Tip 1: Understand Vehicle Requirements: Consider the vehicle’s intended use. Performance vehicles may benefit from designs prioritizing exhaust flow, while daily drivers often require maximum noise reduction. Consult vehicle specifications and local noise regulations.

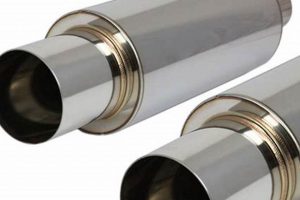

Tip 2: Evaluate Material Quality: Opt for components constructed from corrosion-resistant materials such as stainless steel. This extends the lifespan of the device, particularly in regions with harsh road conditions.

Tip 3: Assess Noise Reduction Levels: Different internal designs yield varying degrees of sound attenuation. Research decibel reduction capabilities and select a model that aligns with desired sound levels and legal limits.

Tip 4: Consider Backpressure Effects: Designs impacting exhaust flow can affect engine performance. Low backpressure models are often favored for performance applications, whereas others may offer greater noise reduction at the expense of flow.

Tip 5: Professional Installation Recommended: Proper installation is crucial for optimal performance and longevity. Incorrect installation can lead to leaks, reduced effectiveness, and potential damage to the exhaust system.

Tip 6: Regular Inspection for Damage: Periodically inspect the sound reduction device for signs of corrosion, cracks, or other damage. Addressing minor issues promptly can prevent more significant and costly repairs.

Tip 7: Comply with Local Regulations: Ensure the selected component complies with all applicable noise regulations in your area. Failure to do so can result in fines or vehicle inspection failures.

Implementing these guidelines facilitates informed decision-making when selecting and maintaining automotive sound reduction components, contributing to vehicle performance, environmental responsibility, and legal compliance.

The next section concludes this exploration with a summary of key features and a broader perspective on future trends in automotive sound management.

1. Chambered Sound Reduction

Chambered sound reduction represents a fundamental design principle employed in a significant proportion of exhaust silencers. This approach involves strategically partitioning the interior volume of the device into a series of interconnected chambers. The geometric arrangement of these chambers, along with the size and placement of connecting tubes or orifices, dictates the reflection and interference patterns of sound waves propagating through the exhaust system. The objective is to attenuate specific frequencies generated by the engine, thereby reducing overall noise emissions. For example, a chambered silencer in a passenger vehicle exhaust system typically targets frequencies associated with engine firing, intake, and exhaust valve operation, contributing to a quieter cabin environment. Effective design hinges on precise acoustic modeling to achieve optimal noise cancellation within the targeted frequency range.

The effectiveness of chambered sound reduction is directly correlated to the accuracy of the design parameters and the quality of the materials used in construction. Variations in chamber dimensions, baffle angles, and internal tube lengths can significantly alter the device’s performance characteristics. Furthermore, the presence of corrosion or mechanical damage can compromise the integrity of the chambers, leading to reduced noise attenuation and potential exhaust leaks. In industrial applications, such as power generation facilities, large-scale chambered silencers are employed to mitigate noise generated by turbines and other rotating equipment, demonstrating the scalability of this technology. The design of these large-scale systems necessitates sophisticated computational fluid dynamics analysis to ensure optimal performance under varying operating conditions.

In conclusion, chambered sound reduction constitutes a critical component of numerous exhaust silencer configurations. Its effectiveness depends on precise engineering and careful execution, taking into account vehicle-specific noise characteristics and operational requirements. While offering a robust and relatively simple solution for noise attenuation, its performance can be compromised by design flaws, material degradation, or improper installation. Ongoing research continues to explore novel chamber geometries and advanced materials to further enhance the performance and durability of these sound reduction devices. This understanding of chambered sound reduction’s cause and effect on muffler types enhances the practical effectiveness of noise management strategies across diverse applications.

2. Absorption Efficiency

Absorption efficiency, a critical parameter in exhaust silencer design, quantifies the capacity of a given device to dissipate acoustic energy as it propagates through the exhaust system. This efficiency is inextricably linked to the internal structure and materials comprising the silencer, directly influencing its noise reduction capabilities. Various types of silencers rely on distinct absorption mechanisms to achieve targeted sound attenuation.

- Material Composition

The selection of sound-absorbing materials is paramount in determining absorption efficiency. Fiberglass, steel wool, and specialized acoustic packing materials are commonly employed within silencers to convert sound energy into heat through frictional losses. The density, porosity, and fiber orientation of these materials significantly impact their acoustic performance. For example, high-performance silencers often utilize tightly packed, high-density materials to maximize sound absorption across a broad frequency spectrum. In contrast, less expensive silencers may employ lower-density materials, resulting in reduced absorption efficiency and a narrower effective frequency range.

- Internal Geometry

The internal configuration of a silencer plays a crucial role in maximizing the interaction between sound waves and the absorbing material. Straight-through designs, commonly found in performance applications, typically incorporate a perforated core surrounded by a layer of sound-absorbing material. This allows exhaust gases to flow directly through the silencer while maximizing exposure to the absorbing medium. Chambered designs, while primarily relying on reflective cancellation, may also incorporate strategically placed absorption elements to further attenuate specific frequencies. The overall surface area and distribution of the absorbing material within the silencer directly influence its absorption efficiency.

- Frequency Dependence

Absorption efficiency is inherently frequency-dependent, with different materials and designs exhibiting varying degrees of effectiveness at different frequencies. Low-frequency sounds, characterized by longer wavelengths, are generally more difficult to absorb than high-frequency sounds. Consequently, silencers designed for low-frequency attenuation often require larger volumes of absorbing material and specialized internal geometries. Some silencer designs incorporate Helmholtz resonators or tuned cavities to specifically target and absorb specific low-frequency tones, enhancing overall absorption efficiency across the relevant frequency range. This frequency dependence is a critical consideration in matching a silencer’s characteristics to a vehicle’s engine and exhaust system.

- Service Life and Degradation

The absorption efficiency of a silencer can degrade over time due to exposure to high temperatures, exhaust gases, and moisture. Sound-absorbing materials can compress, decompose, or become saturated with contaminants, reducing their ability to dissipate acoustic energy. Regular inspection and maintenance are crucial to ensuring continued performance. Some silencer designs incorporate replaceable absorption cartridges to facilitate maintenance and extend the overall service life. The rate of degradation is influenced by the quality of the materials used and the operating conditions of the exhaust system.

In summary, absorption efficiency is a multifaceted characteristic of exhaust silencers, dependent on material composition, internal geometry, frequency, and service conditions. A comprehensive understanding of these factors is essential for selecting a silencer that effectively reduces noise emissions while meeting the specific performance requirements of a given application. The design and material selection must carefully balance acoustic performance with durability and cost considerations to ensure long-term effectiveness.

3. Baffle Configuration

Baffle configuration within exhaust silencers constitutes a critical determinant of acoustic performance and exhaust flow characteristics. The arrangement, shape, and number of baffles directly influence the sound attenuation properties and backpressure generated within different silencer designs, thereby defining distinct categories of these components.

- Chambered Baffle Systems

Chambered silencers utilize a series of baffles to create interconnected chambers. Sound waves are reflected and interfered within these chambers, leading to noise reduction through destructive interference. The specific baffle arrangement including baffle angles, chamber volumes, and connecting tube diameters dictates the frequencies targeted for attenuation. For instance, a performance-oriented chambered silencer might prioritize high-frequency noise reduction while minimizing backpressure, employing a less restrictive baffle configuration compared to a silencer designed for maximum overall sound attenuation. An example includes the use of Helmholtz resonators within specific chambers to target and eliminate narrow bands of frequencies. The design complexity depends on the required level of sound reduction and target frequency range.

- Straight-Through Baffle Designs

Straight-through silencers employ perforated baffles surrounding a central core. Exhaust gases flow directly through the core, while sound waves are directed through the perforations into an absorption material surrounding the core. The number, size, and pattern of the perforations influence the degree of sound attenuation and the backpressure generated. Higher perforation densities typically result in greater sound reduction but also increase backpressure. Some designs utilize angled or louvered perforations to optimize both sound attenuation and flow characteristics. An example is seen in many aftermarket performance silencers, striking a balance between noise reduction and minimal exhaust restriction.

- Louvered Baffle Systems

Louvered baffles redirect the flow of exhaust gases and sound waves in a controlled manner. This type of baffle is often used in combination with other noise reduction techniques, such as absorption materials or chambered designs. Louvers are angled plates that deflect sound waves, causing them to reflect and interfere with each other. An example of this approach includes silencers employed in heavy-duty applications and some motorcycle silencers where the balance of noise reduction and performance is optimized.

- Variable Baffle Designs

Emerging silencer technologies incorporate variable baffle configurations, allowing for dynamic adjustment of sound attenuation characteristics based on engine operating conditions or driver preferences. These systems may employ electronically controlled valves or movable baffles to alter the internal flow path and acoustic properties of the silencer. An example includes active exhaust systems found in some performance vehicles, where the silencer’s noise reduction level can be adjusted to enhance the driving experience. These designs can offer the benefit of both sound reduction and performance depending on the driving situation.

The diversity in baffle configurations highlights the varied approaches to sound management in automotive exhaust systems. The choice of a specific baffle arrangement depends on a multitude of factors, including vehicle type, engine characteristics, desired sound level, and performance requirements. The baffle configuration dictates a substantial portion of the sound reduction capabilities within all silencer types. Therefore, understanding these configurations is crucial for effective design selection and ensuring regulatory compliance.

4. Exhaust Flow Impact

Exhaust flow dynamics are significantly influenced by the internal design of silencer types, directly affecting engine performance characteristics. The design dictates the degree of restriction placed on the expulsion of exhaust gases. This restriction, known as backpressure, affects engine volumetric efficiency, power output, and fuel consumption. Silencers with complex internal chambers and restrictive baffles tend to generate higher backpressure levels. As an example, in a turbocharged engine, excessive backpressure impedes turbine spin-up, negatively impacting boost response and overall power delivery. The effect is a reduction of the amount of new air and fuel entering the combustion chamber, which is necessary to generate power.

Different silencer types offer varying trade-offs between noise reduction and exhaust flow optimization. Straight-through designs, characterized by minimal internal obstructions, generally provide the least restrictive exhaust path and are favored in performance applications where maximizing power output is a priority. Chambered designs, while offering superior noise attenuation, often introduce greater backpressure due to the tortuous flow paths within the silencer. Examples can be found in different automotive racing categories: some allow less restrictive types of mufflers while others dictate specific noise requirements, leading to more complex muffler designs that may trade off performance for noise reduction. Selecting the appropriate silencer type involves carefully balancing noise reduction requirements with acceptable levels of performance impact.

In summary, the exhaust flow impact of silencer types constitutes a crucial consideration in vehicle design and modification. The internal design of the silencer has a direct impact on backpressure, which directly effects engine performance, fuel economy, and noise reduction. A thorough understanding of these interrelationships is essential for selecting an silencer that meets both regulatory requirements and performance objectives. Future designs may focus on active systems that dynamically adjust internal flow paths to optimize both noise reduction and engine performance across varying operating conditions.

5. Resonator Integration

Resonator integration within exhaust systems, particularly as a component of various silencer types, serves to attenuate specific frequencies that are not effectively addressed by the primary silencing mechanism. A resonator, in this context, is a tuned acoustic chamber designed to counteract undesirable frequencies by creating destructive interference. When integrated with different silencer configurations, resonators target and neutralize specific “droning” or harmonic frequencies that may otherwise persist, resulting in a more refined and pleasing exhaust note. For example, a Helmholtz resonator can be added to a chambered silencer to eliminate a prominent low-frequency resonance that the chambered design alone cannot adequately suppress. This addition enhances the silencer’s overall performance by broadening the range of frequencies effectively attenuated.

Resonator integration can influence the exhaust system’s overall efficiency and performance characteristics. Incorrectly sized or tuned resonators can introduce additional backpressure, negatively affecting engine performance. Therefore, careful acoustic modeling and testing are essential to ensure that the resonator effectively cancels the target frequencies without compromising exhaust flow. In some high-performance applications, adjustable resonators are used to dynamically tune the exhaust system’s sound characteristics based on engine operating conditions. This allows for a balance between noise reduction and maximizing engine power output. Such systems require sophisticated control algorithms and sensors to maintain optimal performance.

In conclusion, resonator integration is a valuable technique for enhancing the performance of exhaust systems, particularly concerning sound quality. By targeting specific frequencies that are not adequately addressed by the primary noise reduction elements of a silencer, resonators contribute to a more refined and less intrusive exhaust note. Effective integration necessitates precise acoustic design and careful consideration of the potential impact on exhaust flow and engine performance. The ongoing development of tunable resonator systems promises to further optimize the balance between sound management and engine efficiency.

6. Material Durability

Material durability directly impacts the longevity and performance consistency of various sound reduction devices. Exposure to high temperatures, corrosive exhaust gases, road salts, and mechanical stresses causes material degradation. Different types of sound reduction devices employ diverse materials with varying resistance to these factors, directly affecting their lifespan and acoustic properties. An example includes the use of aluminized steel versus stainless steel in the construction of chambered sound reduction devices; the former exhibits lower initial cost but is more susceptible to rust and corrosion, leading to premature failure and increased noise emissions. This highlights the importance of material selection for ensuring long-term performance and regulatory compliance.

The practical significance of material durability extends beyond component longevity. As materials degrade, the device’s internal structure may be compromised, altering its acoustic characteristics and potentially increasing backpressure. This can negatively impact engine performance and fuel efficiency. Consider the degradation of fiberglass packing in absorption silencers; as the material compresses and deteriorates, its ability to absorb sound energy diminishes, resulting in increased noise levels and reduced silencing effectiveness. The selection of appropriate materials, coupled with proper maintenance practices, is crucial for preserving the intended performance characteristics of sound reduction devices and minimizing their environmental impact.

The relationship between material durability and sound reduction device types necessitates a balanced approach considering cost, performance requirements, and environmental conditions. While high-grade materials like titanium offer exceptional durability and weight savings, their high cost may limit their application to specialized performance vehicles. Conversely, lower-cost materials may be suitable for applications where extended service life is not a primary concern. Ultimately, the selection of materials and the design of sound reduction devices must account for the specific operating environment and the desired trade-offs between durability, performance, and cost. Continuous advancements in materials science and manufacturing processes are driving the development of more durable and efficient sound reduction technologies, contributing to reduced noise pollution and improved vehicle performance.

Frequently Asked Questions

The following questions address common inquiries regarding automotive exhaust sound reduction devices, providing clarity on selection, operation, and maintenance.

Question 1: What are the primary categories of automotive exhaust sound reduction devices?

The primary categories include chambered, absorption, and combination designs. Chambered devices utilize internal chambers to reflect and cancel sound waves. Absorption devices employ sound-absorbing materials. Combination designs incorporate both techniques.

Question 2: How does the design of an exhaust sound reduction device affect engine performance?

The design directly impacts exhaust flow and backpressure. Restrictive designs increase backpressure, potentially reducing engine power. Straight-through designs minimize backpressure, favoring performance.

Question 3: What materials are commonly used in the construction of exhaust sound reduction devices, and how do these materials affect durability?

Common materials include aluminized steel, stainless steel, and titanium. Stainless steel offers superior corrosion resistance and durability compared to aluminized steel. Titanium provides exceptional strength and weight savings but is more expensive.

Question 4: How does resonator integration enhance the performance of exhaust sound reduction devices?

Resonators target and attenuate specific frequencies, such as drone, that are not effectively addressed by the primary silencing mechanism. This results in a more refined and less intrusive exhaust note.

Question 5: What factors contribute to the degradation of exhaust sound reduction devices, and how can this be mitigated?

Degradation factors include high temperatures, corrosive exhaust gases, and mechanical stresses. Mitigation strategies include selecting durable materials, ensuring proper installation, and performing regular inspections.

Question 6: How does one ensure compliance with noise regulations when selecting and installing an exhaust sound reduction device?

Consult local noise regulations and select a device certified to meet the applicable standards. Professional installation is recommended to ensure proper fitment and compliance with regulatory requirements.

In summary, informed selection and proper maintenance of exhaust sound reduction devices are critical for balancing performance, noise reduction, and regulatory compliance.

The subsequent article will explore advanced technologies and future trends in automotive exhaust sound management.

Conclusion

This exploration of muffler types has delineated critical aspects pertaining to their design, functionality, and influence on vehicle performance and noise emissions. The characteristics of chambered, absorption, and hybrid designs were examined, alongside considerations for exhaust flow dynamics, material durability, and the integration of resonators. Understanding these elements is paramount for selecting appropriate components that satisfy both regulatory requirements and desired vehicle performance characteristics.

Continued advancements in material science and acoustic engineering will likely lead to further refinements in muffler designs, enabling greater efficiency in noise reduction without compromising engine performance. It is incumbent upon vehicle manufacturers and aftermarket suppliers to prioritize research and development efforts aimed at optimizing these crucial components for the benefit of both environmental responsibility and vehicle operability.