This component serves as an integral part of the exhaust system, specifically designed for a particular make and model of vehicle. It functions primarily to reduce noise emissions generated by the engine’s combustion process. Aftermarket options often provide alterations to the exhaust note and flow characteristics when compared to the original equipment. For example, owners might choose to replace the factory-installed part with a performance-oriented version to achieve a deeper, more aggressive sound.

The implementation of this element can yield several advantages, including a potentially enhanced driving experience and modified aesthetics. Historically, enthusiasts have modified exhaust systems to improve engine performance and personalize their vehicles. Selecting an appropriate aftermarket solution should consider factors such as sound level, emissions compliance, and potential impact on engine performance. Incorrect installation or selection can negatively impact vehicle operation or legality.

The subsequent sections will delve into the selection process, performance implications, installation considerations, and maintenance requirements associated with this specific type of exhaust component. This information is crucial for making informed decisions regarding upgrades or replacements.

Selecting the Optimal Exhaust Silencer

This section provides essential guidance for individuals seeking to replace or upgrade an exhaust silencer specifically designed for the Impreza WRX platform. Careful consideration of these points will ensure optimal performance and satisfaction.

Tip 1: Research Compatibility. Verify precise fitment with the vehicle’s year, model, and engine configuration. Incorrect specification can lead to installation difficulties and performance degradation. Consult manufacturer specifications or a qualified mechanic.

Tip 2: Evaluate Material Quality. Stainless steel construction offers superior corrosion resistance compared to aluminized steel, resulting in extended product lifespan, particularly in regions with harsh weather conditions.

Tip 3: Assess Noise Level. Understand local noise ordinances and select a component that complies with legal sound limits. Excessive noise may result in fines or vehicle inspection failures. Decibel ratings are often provided by manufacturers.

Tip 4: Consider Backpressure Effects. Modifications to exhaust systems can influence engine backpressure. Insufficient backpressure may reduce low-end torque, while excessive backpressure can hinder overall engine performance. Consult with a performance specialist.

Tip 5: Investigate Installation Complexity. Determine the level of skill and tools required for installation. Professional installation may be necessary if specialized equipment or extensive vehicle knowledge is needed.

Tip 6: Prioritize Reputable Brands. Opt for brands known for quality craftsmanship, reliable performance, and comprehensive warranty support. Review customer feedback and independent product evaluations.

Tip 7: Confirm Emissions Compliance. Ensure the chosen component meets local and national emissions standards. Non-compliant parts may result in failed emissions tests and potential legal repercussions.

These guidelines emphasize the importance of thorough research and informed decision-making when selecting an aftermarket exhaust silencer. Proper selection ensures performance enhancement while mitigating potential risks.

The subsequent article segments will address performance characteristics, installation procedures, and long-term maintenance considerations related to exhaust systems.

1. Noise Reduction

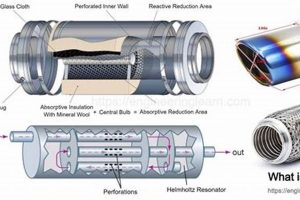

The primary function of an exhaust silencer on a WRX, as with any vehicle, is noise reduction. The internal combustion process generates significant sound energy, which, if left unabated, would result in excessive noise pollution. The silencer, through a series of chambers and baffles, attenuates these sound waves, reducing the overall decibel level emitted by the vehicle. This attenuation is crucial for compliance with local and national noise regulations. For example, many municipalities have specific limits on vehicle exhaust noise, and a malfunctioning or improperly modified silencer can lead to citations and fines. The effectiveness of a silencer in reducing noise depends on its design, materials, and condition; a larger silencer with more intricate baffling generally provides greater noise reduction than a smaller, simpler design.

The relationship between noise reduction and silencer design presents inherent trade-offs. Performance-oriented silencers often prioritize exhaust flow over maximum noise attenuation, resulting in a louder exhaust note compared to stock or quieter aftermarket options. Owners seeking increased performance may accept a slight increase in noise, while those prioritizing quiet operation will opt for silencers with greater noise reduction capabilities. Furthermore, the material composition of the silencer influences its sound characteristics. Certain materials, such as stainless steel, can produce a sharper, more resonant exhaust note, while others, like aluminized steel, may offer a more subdued sound profile. Aftermarket silencers commonly advertise their noise reduction capabilities, often specifying decibel levels achieved under various operating conditions. Understanding these specifications is essential for selecting a silencer that meets both performance and noise compliance requirements.

In summary, noise reduction is a fundamental attribute of a WRX’s exhaust silencer, directly impacting the vehicle’s compliance with noise regulations and its overall operational suitability. The design and material composition of the silencer significantly influence its noise reduction capabilities, and understanding these factors is essential for informed decision-making. Challenges arise from the inherent trade-offs between noise reduction and performance, requiring owners to carefully balance their desired sound characteristics with regulatory compliance. The importance of effective noise reduction extends beyond legal compliance, contributing to a more comfortable and considerate driving experience for both the vehicle operator and the surrounding community.

2. Performance Impact

The selection and modification of an exhaust silencer on a Subaru Impreza WRX directly influences engine performance. Changes to exhaust flow characteristics can alter horsepower, torque, and fuel efficiency. A factory-installed silencer is designed to balance noise reduction with acceptable backpressure levels for optimal engine operation in its stock configuration. Replacement with an aftermarket component, particularly one designed for enhanced flow, can modify this balance. Increased exhaust flow can potentially reduce backpressure, allowing the engine to expel exhaust gases more efficiently. This can lead to gains in horsepower, especially at higher engine speeds. However, excessive reduction in backpressure can negatively impact low-end torque, making the vehicle feel less responsive at lower RPMs. A real-world example includes instances where WRX owners installing large-diameter, straight-through silencers report improved top-end power but a noticeable decrease in low-end responsiveness for daily driving.

Conversely, a restrictive silencer can impede exhaust flow, increasing backpressure. This can limit the engine’s ability to expel exhaust gases effectively, reducing horsepower and fuel efficiency. While excessive backpressure is generally detrimental, a certain level is necessary for proper engine operation. The optimal balance between exhaust flow and backpressure is specific to each engine and its tuning. Furthermore, the impact on performance can be influenced by other modifications made to the vehicle, such as aftermarket intakes or engine management systems. A properly tuned engine management system can compensate for changes in exhaust flow, optimizing performance across the RPM range. For example, installing an aftermarket silencer and retuning the engine can yield more significant performance gains than simply installing the silencer alone. Practical significance lies in the ability to tailor the vehicle’s performance characteristics to suit individual driving preferences and needs. Understanding the potential impact of silencer modifications allows owners to make informed decisions and avoid unintended consequences.

In summary, the performance impact of a WRX’s exhaust silencer is a multifaceted consideration. Modifications can lead to tangible gains in horsepower and torque, but also require careful attention to backpressure levels and overall engine tuning. The challenge lies in achieving the optimal balance between exhaust flow and backpressure, which varies depending on the specific engine configuration and desired performance characteristics. Ignoring these factors can result in reduced performance, increased fuel consumption, or even engine damage. The overarching understanding contributes to enhanced vehicle performance and a more optimized driving experience.

3. Material Durability

The longevity and reliable operation of an exhaust silencer on a WRX are intrinsically linked to the materials used in its construction. Premature failure of this component due to corrosion, fatigue, or physical damage can lead to increased noise emissions, reduced performance, and costly repairs. The operating environment of an exhaust system exposes the silencer to extreme temperatures, corrosive exhaust gases, road salts, and physical impacts from debris. Therefore, selecting a silencer constructed from durable materials is paramount to ensuring long-term performance and minimizing maintenance requirements. For example, a silencer manufactured from low-grade steel is susceptible to rapid corrosion, particularly in regions with harsh winters where road salts are prevalent. This corrosion can weaken the structural integrity of the silencer, leading to leaks, increased noise, and eventual failure.

Stainless steel is commonly employed in higher-quality aftermarket silencers due to its superior corrosion resistance compared to aluminized or mild steel. Different grades of stainless steel, such as 304 or 409, offer varying levels of resistance, with 304 typically providing better protection against corrosion but at a higher cost. Thicker gauge materials also enhance durability, providing greater resistance to physical damage from road debris or accidental impacts. Consider the real-world scenario of a WRX used for rallycross or off-road driving; a silencer constructed from thin-gauge, low-grade steel is far more likely to sustain damage and require replacement than one constructed from thick-gauge stainless steel. The practical significance of this understanding lies in the ability to make informed decisions regarding silencer selection, balancing cost considerations with the need for long-term reliability and performance.

In summary, material durability is a critical determinant of the lifespan and performance of a WRX’s exhaust silencer. The corrosive and physically demanding operating environment necessitates the use of high-quality, corrosion-resistant materials such as stainless steel. While cost may be a factor, prioritizing durability ensures long-term reliability, reduces maintenance costs, and maintains optimal vehicle performance. The challenge lies in discerning the quality and material composition of different aftermarket options, emphasizing the importance of researching reputable brands and consulting with experienced mechanics. The material composition of a “muffler wrx” is key for its function.

4. Emissions Compliance

The relationship between a WRX exhaust silencer and emissions compliance is critical due to stringent environmental regulations governing vehicle exhaust emissions. A properly functioning silencer, particularly one equipped with catalytic converters or other emissions control devices, plays a vital role in reducing harmful pollutants such as hydrocarbons, carbon monoxide, and nitrogen oxides. Non-compliance with emissions standards can result in fines, failed vehicle inspections, and legal repercussions for vehicle owners. The silencer’s design directly influences its ability to effectively facilitate the catalytic conversion of these pollutants. For example, a silencer with insufficient internal volume or improper catalyst placement may not provide adequate residence time for the chemical reactions necessary to reduce emissions to acceptable levels.

Aftermarket exhaust silencers designed for performance enhancements often face scrutiny regarding emissions compliance. Some modifications, such as removing catalytic converters or installing “cat-back” systems that alter the silencer’s design, can significantly increase emissions output. Real-world examples demonstrate instances where WRX owners installing aftermarket exhaust systems failed emissions tests, necessitating costly modifications or replacement with compliant components. In some jurisdictions, modifications that tamper with or remove emissions control devices are strictly prohibited, regardless of the performance benefits gained. Therefore, selecting an aftermarket silencer requires careful consideration of its impact on emissions levels and adherence to local and national regulations. Many manufacturers offer “CARB-compliant” silencers, indicating that the component has been tested and approved by the California Air Resources Board, a recognized standard for emissions control. This certification provides assurance that the silencer meets specific emissions standards.

In summary, the connection between a WRX exhaust silencer and emissions compliance is a complex but essential consideration. While performance enhancements may be desirable, they must be balanced with the need to adhere to environmental regulations. The challenge lies in selecting aftermarket components that provide both performance gains and emissions compliance, requiring thorough research and careful evaluation of product specifications. Neglecting this aspect can lead to legal penalties, environmental damage, and ultimately, a compromised driving experience. A properly designed and maintained silencer is essential for minimizing harmful emissions and ensuring the responsible operation of the vehicle.

5. Installation Complexity

The degree of difficulty associated with installing an exhaust silencer on a Subaru Impreza WRX constitutes a crucial factor for vehicle owners considering either a replacement or an upgrade. Installation complexity impacts both the time required for the procedure and the skills and tools necessary for its successful completion, directly influencing project feasibility and cost considerations.

- Required Skill Level

The installation process may range from a straightforward bolt-on procedure achievable with basic hand tools to a more intricate operation demanding specialized knowledge and equipment. A simple replacement of an original equipment silencer with a compatible aftermarket component often requires minimal mechanical aptitude. Conversely, modifications involving welding, cutting, or custom fabrication necessitate expertise in metalworking and exhaust system dynamics. For instance, adapting a silencer designed for a different vehicle may involve complex modifications to ensure proper fitment and exhaust flow. Failure to possess the requisite skills can lead to improper installation, resulting in exhaust leaks, reduced performance, or even damage to the vehicle’s exhaust system.

- Necessary Tools and Equipment

The tools required for installation vary based on the complexity of the project. Basic replacements may only necessitate wrenches, sockets, and a jack to elevate the vehicle. More complex installations, however, may demand specialized equipment such as a welding machine, cutting tools (e.g., a reciprocating saw or angle grinder), and exhaust pipe bending tools. Inadequate access to the appropriate tools can significantly hinder the installation process and compromise the quality of the final result. For example, attempting to cut exhaust pipes with improper tools can result in jagged edges and poor fitment, increasing the risk of leaks and performance degradation.

- Potential for Complications

Unforeseen complications can arise during the installation process, regardless of the apparent simplicity of the task. These complications may include corroded bolts, seized exhaust hangers, or incompatible mounting hardware. Removing a rusted bolt, for instance, may require the use of penetrating oil, heat, or specialized bolt extraction tools. Similarly, aligning and securing the new silencer may present challenges if the mounting points are misaligned or if the exhaust system has been previously damaged. Addressing these complications often requires ingenuity and problem-solving skills, potentially extending the installation time and increasing the overall cost.

- Impact on Vehicle Performance and Safety

Improper installation of an exhaust silencer can have detrimental effects on vehicle performance and safety. An exhaust leak resulting from a poorly sealed connection can reduce engine power, decrease fuel efficiency, and introduce harmful exhaust fumes into the vehicle’s cabin. In extreme cases, a dislodged silencer can pose a safety hazard to other drivers. Therefore, meticulous attention to detail and adherence to proper installation techniques are crucial to ensuring both optimal performance and safe vehicle operation. Professional installation by a qualified mechanic is often recommended for individuals lacking the necessary skills or experience.

The factors outlined above underscore the importance of carefully evaluating the installation complexity before undertaking a “muffler wrx” replacement or upgrade. Assessing one’s mechanical aptitude, access to necessary tools, and potential for encountering complications is essential for making an informed decision regarding whether to perform the installation independently or seek professional assistance. A well-executed installation ensures optimal performance, long-term reliability, and adherence to safety standards.

6. Vehicle Compatibility

Vehicle compatibility is a foundational element in the successful integration and function of any aftermarket or replacement exhaust silencer designed for a Subaru Impreza WRX. The “muffler wrx” must be specifically engineered to match the vehicle’s chassis, exhaust system configuration, and engine specifications. Mismatched components can lead to a cascade of adverse effects, ranging from installation difficulties to compromised performance and potential engine damage. Real-life instances frequently illustrate the consequences of neglecting this critical factor, with owners encountering issues such as incompatible flange sizes, incorrect hanger placements, and interference with other vehicle components. The practical significance of understanding vehicle compatibility lies in preventing these complications and ensuring that the chosen silencer operates as intended within the vehicle’s overall system.

Further elaboration reveals the importance of considering factors such as the vehicle’s model year, trim level, and any existing modifications when selecting a “muffler wrx”. Subtle variations in exhaust system design across different model years can render a silencer incompatible, even within the same vehicle generation. For example, a silencer designed for a 2002 WRX may not properly fit a 2007 model due to changes in exhaust routing or hanger locations. Moreover, the presence of aftermarket modifications, such as a different downpipe or exhaust manifold, can further complicate the selection process, necessitating careful measurements and potentially requiring custom fabrication to ensure proper fitment. Practical applications of this understanding extend to consulting with reputable exhaust system manufacturers or experienced mechanics who possess the knowledge and expertise to guide vehicle owners toward compatible solutions.

In summary, vehicle compatibility is not merely a desirable attribute but a non-negotiable prerequisite for the successful implementation of a “muffler wrx”. The challenge lies in navigating the complexities of vehicle-specific exhaust system designs and ensuring that the selected silencer is precisely matched to the vehicle’s unique requirements. By prioritizing vehicle compatibility, owners can mitigate the risk of installation difficulties, performance degradation, and potential damage, ultimately maximizing the benefits of their exhaust system modification. This understanding underscores the broader theme of informed decision-making and responsible vehicle modification practices.

Frequently Asked Questions

This section addresses common inquiries concerning exhaust silencers designed for the Subaru Impreza WRX, aiming to clarify misconceptions and provide pertinent information.

Question 1: What is the primary function of a “muffler wrx”?

The primary function is to reduce the noise generated by the engine’s exhaust gases. It accomplishes this through internal baffling and sound-absorbing materials, ensuring compliance with noise regulations and enhancing driving comfort.

Question 2: How does an aftermarket “muffler wrx” affect vehicle performance?

Aftermarket components can alter exhaust flow, potentially impacting horsepower and torque. A less restrictive design may increase top-end power but could diminish low-end responsiveness. Careful consideration of backpressure characteristics is essential.

Question 3: What materials are commonly used in “muffler wrx” construction, and how do they differ?

Common materials include aluminized steel and stainless steel. Stainless steel offers superior corrosion resistance, extending the component’s lifespan, particularly in regions with harsh environmental conditions. Aluminized steel provides a more economical alternative but is less durable.

Question 4: Are aftermarket “muffler wrx” options legal for street use?

Legality depends on local and national regulations regarding noise emissions and tampering with emissions control devices. Certain aftermarket components may not comply with these regulations, potentially resulting in fines or failed vehicle inspections. Confirm compliance before installation.

Question 5: Can I install a “muffler wrx” myself, or is professional installation required?

The installation complexity varies depending on the specific component and the individual’s mechanical aptitude. Simple bolt-on replacements may be manageable for experienced individuals, while more complex modifications necessitate professional installation to ensure proper fitment and avoid potential damage.

Question 6: How do I ensure that a “muffler wrx” is compatible with my specific WRX model?

Confirm the component’s compatibility with the vehicle’s year, model, and engine configuration. Consult manufacturer specifications, cross-reference part numbers, and seek advice from qualified mechanics to ensure proper fitment and functionality.

In summation, understanding the function, performance implications, material properties, legality, installation complexity, and compatibility factors associated with exhaust silencers for the Subaru Impreza WRX is crucial for making informed decisions and ensuring optimal vehicle performance and compliance.

The following section will explore the long-term maintenance considerations for exhaust systems.

Conclusion

This exploration of the “muffler wrx” has illuminated its critical role within the Subaru Impreza WRX’s exhaust system. The analysis encompasses noise reduction, performance implications, material durability, emissions compliance, installation complexities, and vehicle compatibility. Successful implementation requires a holistic understanding of these interwoven factors to achieve both desired performance enhancements and adherence to regulatory standards. A compromised approach in any area can yield detrimental consequences.

The information presented underscores the importance of meticulous research and informed decision-making when selecting and installing an exhaust silencer. Prudence is advised; proper diligence ensures both optimal vehicle operation and responsible environmental stewardship. Continued advancements in exhaust system technology necessitate ongoing awareness and adaptation within the automotive community.

![Best Kinney Muffler: Reviews & Alternatives [Year] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Best Kinney Muffler: Reviews & Alternatives [Year] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/03/th-52-300x200.jpg)