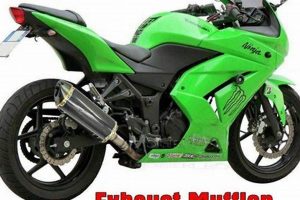

The exhaust system component responsible for mitigating engine noise typically connects to an outlet that can be enhanced for aesthetic and performance reasons. This combination influences both the sound emitted from a vehicle and its visual appeal.

Such equipment plays a critical role in reducing noise pollution from internal combustion engines, contributing to a quieter environment. Furthermore, customized options can allow vehicle owners to personalize their vehicle’s appearance, adding a touch of style and even slightly affecting exhaust flow characteristics.

Therefore, understanding the function and available modifications of these elements is essential for vehicle maintenance, customization, and adherence to noise regulations. The following sections will delve into specific aspects of its selection, installation, and maintenance.

Guidance on Exhaust System Outlets and Noise Reduction Components

The following recommendations aim to provide individuals with insights into optimal selection, maintenance, and potential upgrades for these crucial vehicular components.

Tip 1: Select Based on Vehicle Compatibility: Ensure the chosen component is designed specifically for the make, model, and year of the vehicle. Incompatible components may lead to decreased performance, potential damage, and/or failure to meet emissions standards.

Tip 2: Consider Material Quality: Opt for those constructed from durable materials such as stainless steel or aluminized steel. These materials offer enhanced resistance to corrosion and the elements, extending the lifespan of the component.

Tip 3: Evaluate Noise Level Requirements: Research local noise regulations and select a noise-reduction component that complies with these standards. Exceeding permitted noise levels can result in fines and legal ramifications.

Tip 4: Inspect Regularly for Damage: Conduct periodic visual inspections for signs of rust, leaks, or physical damage. Addressing issues promptly can prevent more significant and costly repairs.

Tip 5: Ensure Proper Installation: Follow the manufacturer’s installation instructions meticulously or seek professional installation services. Improper installation can compromise performance and safety.

Tip 6: Consider Performance Objectives: While primarily focused on noise reduction, some aftermarket options can offer slight performance gains. Research potential performance benefits associated with specific models before purchasing.

Tip 7: Account for Aesthetic Preferences: Choose an outlet design that complements the vehicle’s overall appearance. A visually appealing outlet can enhance the vehicle’s style.

By adhering to these guidelines, individuals can make informed decisions regarding the selection, maintenance, and potential upgrades of exhaust system components, ensuring optimal performance, compliance, and aesthetic appeal.

The subsequent sections will further expand upon specific areas of concern and opportunities for optimization related to the exhaust system and its associated components.

1. Noise Reduction Effectiveness

Noise reduction effectiveness represents a primary function of the combination of an exhaust system’s noise-dampening component and its terminal section. The capacity to minimize engine exhaust sounds directly correlates with design and materials of these components.

- Internal Baffle Design

The internal configuration of baffles within the main noise-reducing component significantly impacts sound wave attenuation. Complex baffle systems, often utilizing multiple chambers and varying flow paths, can more effectively reduce noise levels. For example, S-flow or multi-chamber designs are frequently employed to maximize sound wave cancellation, leading to quieter operation. The effectiveness is quantifiable in decibel reduction, a measure of how much the noise level is lowered.

- Material Density and Composition

The density and composition of materials used in construction influence sound absorption and vibration damping. Denser materials, such as certain types of steel alloys, exhibit superior noise-dampening capabilities. The integration of sound-absorbing packing materials, such as fiberglass or ceramic wool, further enhances noise reduction. Inefficient materials result in greater noise transmission, negating the component’s intended function.

- Acoustic Resonance Tuning

The noise-reducing component can be designed to target and attenuate specific sound frequencies generated by the engine. By carefully tuning the internal dimensions and chamber sizes, engineers can create resonators that cancel out dominant frequencies, resulting in a more pleasant sound profile. Ineffective tuning leads to uneven noise reduction, potentially emphasizing undesirable frequencies.

- Exhaust System Backpressure

The design of the noise-reducing component influences exhaust backpressure, which in turn affects engine performance and noise levels. A highly restrictive design can increase backpressure, potentially reducing engine power and altering the sound characteristics. Conversely, a less restrictive design may improve performance but compromise noise reduction effectiveness. Balancing backpressure and noise reduction is a key design consideration.

These interconnected factors define the ultimate noise reduction effectiveness achievable by an exhaust system’s noise-reduction and terminal components. Understanding their respective roles is crucial for selecting components that meet both performance and sound level requirements. The cumulative effect of these design choices shapes the overall auditory experience, influencing both driver comfort and compliance with noise regulations.

2. Exhaust Flow Modification

The design characteristics of an exhaust system’s terminal segment and noise-reduction components directly influence exhaust flow dynamics. Alterations to either component impact exhaust velocity, backpressure, and scavenging efficiency, subsequently affecting engine performance. A primary function of these parts is to manage the flow of exhaust gases away from the engine, and the effectiveness of this management dictates power output, fuel efficiency, and emissions levels. Aftermarket options often prioritize increased flow, although this may necessitate compromises in noise reduction or emission compliance.

For instance, the shape and diameter of the outlet play a crucial role in regulating exhaust gas velocity. A wider diameter outlet generally reduces backpressure, allowing exhaust gases to exit the system more freely. Similarly, the internal structure of the noise-reducing component, including the baffle design and chamber size, significantly affects flow restriction. Straighter, less restrictive designs promote smoother exhaust flow, potentially increasing horsepower. However, excessively unrestricted flow can lead to reduced scavenging efficiency, negatively affecting low-end torque. These alterations can be beneficial in high-performance applications but must be carefully balanced against street legality and noise considerations. Real-world examples include vehicles modified for racing, where enhanced components prioritize exhaust flow for increased horsepower, and daily-driven vehicles where aftermarket options offer a balance between performance and street legality.

Understanding the interrelation between the exhaust system’s terminal and noise-reduction components and exhaust flow modification is paramount for optimizing engine performance and minimizing adverse effects. Careful consideration must be given to the desired balance between power gains, noise levels, and environmental compliance. This understanding is crucial for both vehicle owners seeking performance upgrades and automotive engineers designing efficient and effective exhaust systems. Challenges exist in simultaneously optimizing for all these parameters, and the optimal configuration often involves tradeoffs tailored to specific vehicle applications and performance goals.

3. Material Durability

Material durability represents a critical factor influencing the lifespan and performance of an exhaust system’s noise reduction and terminal components. The harsh operating environment, characterized by high temperatures, corrosive gases, and exposure to road debris, necessitates the use of robust materials capable of withstanding degradation over extended periods.

- Corrosion Resistance

The primary threat to exhaust system components is corrosion caused by exposure to moisture, road salts, and acidic combustion byproducts. Materials such as stainless steel and aluminized steel offer superior corrosion resistance compared to mild steel, prolonging the component’s lifespan. The presence of even minor corrosion can weaken the structure, leading to leaks, reduced noise reduction effectiveness, and eventual failure. For example, systems constructed from T304 stainless steel exhibit exceptional resistance to rust, making them suitable for vehicles operating in harsh climates.

- Thermal Stability

Exhaust systems operate at elevated temperatures, often exceeding 500 degrees Celsius. Materials must possess high thermal stability to prevent warping, cracking, or other forms of heat-induced damage. Certain grades of stainless steel, along with specialized alloys, maintain their structural integrity at these temperatures, ensuring consistent performance. Conversely, materials with poor thermal stability can experience premature failure, leading to costly repairs. An example is the use of Inconel in high-performance applications, valued for its extreme thermal resistance.

- Mechanical Strength

Exhaust systems are subjected to mechanical stresses from engine vibrations, road impacts, and thermal expansion. Materials with sufficient mechanical strength are essential to resist fatigue cracking, dents, and other forms of physical damage. Thicker gauge metals and reinforced designs enhance the component’s ability to withstand these stresses, contributing to long-term durability. An example is the use of reinforced welds in high-stress areas, preventing premature failure at these critical junctures.

- Resistance to Erosion

The abrasive action of exhaust gases and particulate matter can erode the internal surfaces of exhaust system components over time. Materials with high erosion resistance, such as certain types of ceramic coatings, minimize wear and tear, extending the component’s service life. This is particularly important in high-performance engines with high exhaust gas velocities. The application of ceramic coatings to internal surfaces is one strategy to mitigate this erosive effect.

The interplay of these factors dictates the overall durability of noise reduction and terminal exhaust system components. Selecting components constructed from materials exhibiting high corrosion resistance, thermal stability, mechanical strength, and erosion resistance is crucial for ensuring long-term performance and minimizing maintenance costs. These attributes directly correlate to the overall lifespan and reliability of the system, influencing vehicle performance and environmental impact. The selection process should prioritize materials aligned with the specific operating conditions and performance expectations of the vehicle.

4. Corrosion Resistance

Corrosion resistance is a paramount attribute in the context of exhaust system components, specifically noise reduction elements and terminal outlets. Given the harsh operating environment characterized by high temperatures, exposure to moisture, road salts, and corrosive combustion byproducts, the material’s inherent ability to resist degradation is crucial for longevity and sustained performance.

- Material Composition and Alloys

The specific alloy composition directly dictates the resistance to corrosive elements. Stainless steel variants, particularly those containing chromium and nickel, exhibit superior corrosion resistance compared to carbon steel. The formation of a passive chromium oxide layer on the surface prevents further oxidation, protecting the underlying metal. For instance, T304 stainless steel, commonly used in aftermarket exhaust systems, demonstrates excellent resistance to rust and pitting corrosion. In contrast, aluminized steel offers a more economical alternative, providing a protective aluminum coating that sacrifices some durability for cost-effectiveness. Regular carbon steel, lacking such protective mechanisms, is highly susceptible to corrosion and thus unsuitable for long-term exhaust system applications.

- Surface Treatments and Coatings

Surface treatments, such as ceramic coatings or specialized paint formulations, can enhance the corrosion resistance of exhaust components. These coatings act as a barrier, preventing corrosive substances from directly contacting the underlying metal. Ceramic coatings, in particular, offer high-temperature resistance and excellent protection against chemical attack. These treatments are frequently applied to both internal and external surfaces of the noise reduction element and terminal outlet to maximize protection. Without such surface treatments, even corrosion-resistant alloys can experience localized corrosion in high-stress or high-temperature areas.

- Weld Integrity and Corrosion

The integrity of welds is crucial in maintaining corrosion resistance. Welds are often areas of increased susceptibility to corrosion due to changes in the material’s microstructure during the welding process. Proper welding techniques, such as using inert gas shielding and appropriate filler metals, are essential to minimize corrosion at weld joints. Post-weld treatments, such as passivation, can further enhance corrosion resistance. Poorly executed welds can create crevices where corrosive substances accumulate, leading to accelerated corrosion and premature failure of the component.

- Environmental Factors and Road Conditions

The severity of the operating environment significantly influences the rate of corrosion. Vehicles operating in regions with heavy road salt usage during winter months are exposed to highly corrosive conditions. Similarly, exposure to coastal environments with high salt concentrations accelerates corrosion. Regular cleaning and maintenance can help mitigate the effects of these environmental factors, but the inherent corrosion resistance of the material remains a primary determinant of longevity. The correlation between geographic location and component lifespan underscores the importance of selecting materials appropriate for the intended operating environment.

The interplay of material composition, surface treatments, weld integrity, and environmental factors collectively determines the corrosion resistance and service life of noise reduction elements and terminal outlets. Selecting components constructed from materials exhibiting superior corrosion resistance and employing appropriate manufacturing techniques is critical for ensuring long-term performance and minimizing maintenance costs. The cumulative effect of these considerations impacts vehicle reliability, environmental impact, and overall ownership expenses.

5. Aesthetic Design

Aesthetic design, in the context of exhaust systems, specifically the noise reduction and terminal components, represents a deliberate effort to enhance the visual appeal of these functional parts. While the primary purpose remains the reduction of noise and efficient exhaust flow, the aesthetic design contributes significantly to the overall appearance and perceived value of the vehicle.

- Shape and Form Factor

The physical shape and form of the terminal exhaust segment exert a considerable influence on the vehicle’s visual profile. Designs range from simple, straight outlets to complex, multi-angled forms. Angled outlets can create a more aggressive appearance, while rounded forms project a more subtle, refined aesthetic. The choice of shape is often dictated by the vehicle’s overall design language and the owner’s personal preferences. For example, a performance-oriented vehicle might utilize dual, rectangular outlets to convey power and speed.

- Material Finish and Coating

The surface finish and coating applied to the exterior significantly affect its visual characteristics. Polished stainless steel provides a bright, reflective surface, while black ceramic coatings offer a stealthier, more aggressive look. Brushed finishes create a subtle, understated appearance. The selection of finish should complement the vehicle’s paint color and trim details. In certain instances, colored anodization may be employed to add a unique visual element, although durability can be a concern in harsh environments.

- Size and Proportion

The dimensions relative to the vehicle’s rear fascia impact the perceived aesthetic balance. An overly large outlet can appear disproportionate and detract from the overall design, while an undersized outlet may appear insignificant. Careful consideration must be given to the diameter and length to ensure visual harmony. The size is often determined by the exhaust system’s performance characteristics, but the aesthetic impact must also be factored into the design process.

- Branding and Logo Integration

Some manufacturers incorporate branding elements, such as logos or engraved markings, onto the terminal segment. These branding elements can enhance the perceived value and authenticity of the product. However, excessive or poorly executed branding can detract from the overall aesthetic. The placement and size of branding elements should be carefully considered to maintain a clean and sophisticated appearance. Subtle branding, such as a laser-etched logo, can be a more effective approach than large, prominent markings.

These aesthetic design considerations, while secondary to functional performance, play a crucial role in the overall perception and value of exhaust system components. The careful selection of shape, finish, size, and branding elements can significantly enhance the vehicle’s visual appeal, contributing to a sense of quality and personalization.

6. Vehicle Compatibility

Ensuring vehicle compatibility is a critical prerequisite for the proper functioning and integration of exhaust system noise reduction elements and terminal outlets. Selecting components specifically designed for the intended vehicle make, model, and year is essential to guarantee correct fitment and optimal performance.

- Exhaust System Geometry and Dimensions

Vehicle-specific design dictates the precise geometry and dimensions of the exhaust system. The length, diameter, and routing of exhaust pipes, as well as the mounting locations for noise reduction components, vary significantly between different vehicle models. Attempting to install components designed for a different vehicle can result in fitment issues, such as misalignment, interference with other vehicle components, or the inability to properly secure the parts. These issues can compromise exhaust flow, increase noise levels, and potentially damage the vehicle.

- Engine Specifications and Performance Requirements

Engine characteristics, such as displacement, cylinder configuration, and power output, influence the exhaust system’s design requirements. The noise reduction element must be sized appropriately to handle the exhaust gas volume and flow rate produced by the engine. Similarly, the terminal outlet’s diameter must be optimized to minimize backpressure without compromising noise reduction. Incompatible components can negatively impact engine performance, fuel efficiency, and emissions levels. An undersized component can restrict exhaust flow, reducing power, while an oversized component may not provide adequate noise reduction.

- Emissions Control System Integration

Modern vehicles incorporate complex emissions control systems, including catalytic converters and oxygen sensors. The exhaust system must be compatible with these systems to ensure compliance with emissions regulations. Incorrectly sized or positioned noise reduction elements or terminal outlets can disrupt the operation of these systems, leading to increased emissions and potential legal repercussions. The location of oxygen sensor ports, for example, must be precisely matched to the vehicle’s specifications.

- Mounting Points and Hardware Compatibility

The mounting points and hardware used to secure the exhaust system components vary between different vehicle models. Attempting to install components designed for a different vehicle can result in the inability to properly secure the parts, leading to vibration, leaks, and potential damage. The use of incorrect mounting hardware can also compromise the integrity of the exhaust system. The diameter and thread pitch of bolts and nuts must be matched to the vehicle’s specifications to ensure a secure and reliable connection.

The ramifications of neglecting vehicle compatibility extend beyond mere fitment issues. Mismatched components can degrade engine performance, compromise emissions control, and potentially damage other vehicle systems. Therefore, verifying compatibility before purchase and installation is essential to ensure optimal functionality and prevent costly repairs.

7. Installation Complexity

The ease or difficulty of installing noise reduction and terminal components directly impacts both the cost of the procedure and the likelihood of successful integration within the vehicle’s exhaust system. Complex installations may necessitate specialized tools, extensive mechanical knowledge, and/or professional assistance, thereby increasing the overall expense. Conversely, simpler designs facilitate do-it-yourself installation, reducing labor costs and providing an opportunity for vehicle owners to personalize their vehicles. The installation process involves connecting the components to the existing exhaust system, ensuring proper alignment, and securing all connections to prevent leaks or vibrations. Difficulty arises from tight clearances, the need for welding or cutting, or the presence of rusted or corroded fasteners. Improper installation, regardless of complexity, can lead to reduced performance, increased noise, and potential damage to other vehicle components.

Several factors contribute to the level of complexity encountered during installation. These include the design of the vehicle’s exhaust system, the specific design of the component being installed, and the skill level of the installer. For instance, universal-fit noise reduction elements may require modification to properly fit a particular vehicle, adding complexity and potentially compromising performance. Similarly, terminal segments with intricate designs or requiring specialized welding techniques demand a higher level of expertise. Real-world examples include instances where vehicle owners attempt to install aftermarket components without proper knowledge or tools, resulting in damaged parts or improperly functioning exhaust systems. The practical significance lies in understanding the potential challenges before initiating the installation process, allowing for informed decisions regarding professional assistance or the acquisition of necessary tools and knowledge.

In summary, installation complexity is a crucial consideration when selecting noise reduction and terminal components. A thorough assessment of the required skills, tools, and potential challenges is essential for ensuring a successful and cost-effective installation. Recognizing the inherent complexities allows for proactive planning, minimizing the risk of damage, performance degradation, and increased overall expenses. Proper installation contributes to the overall functionality, longevity, and aesthetic appeal of the exhaust system.

Frequently Asked Questions

The following provides responses to common inquiries concerning exhaust system noise reduction elements and terminal outlets, offering clarity on their function, selection, and maintenance.

Question 1: What is the primary function of a noise reduction component in an exhaust system?

The primary function is to attenuate engine exhaust noise, mitigating the sound pressure levels emitted by the vehicle. These components utilize internal baffles and sound-absorbing materials to reduce the amplitude of sound waves, thereby complying with noise regulations and enhancing driver and passenger comfort.

Question 2: Does the design of the terminal outlet affect vehicle performance?

Yes, the design and diameter of the terminal outlet influence exhaust flow and backpressure. A less restrictive design can improve exhaust flow, potentially increasing horsepower. However, excessively unrestricted flow may reduce low-end torque. Therefore, the outlet design must be carefully matched to the engine’s characteristics and performance goals.

Question 3: What materials offer the best corrosion resistance for exhaust system components?

Stainless steel alloys, particularly those containing chromium and nickel, offer superior corrosion resistance compared to carbon steel. Aluminized steel provides a more economical alternative, offering a protective aluminum coating. Regular carbon steel is highly susceptible to corrosion and generally unsuitable for exhaust system applications.

Question 4: How can the aesthetic appearance of the terminal outlet be enhanced?

The aesthetic appearance can be enhanced through various design choices, including the shape, finish, and material of the outlet. Polished stainless steel provides a bright, reflective surface, while black ceramic coatings offer a stealthier look. The size and shape should be proportional to the vehicle’s design for visual harmony.

Question 5: What factors should be considered when ensuring vehicle compatibility?

Ensuring vehicle compatibility requires careful consideration of exhaust system geometry, engine specifications, emissions control system integration, and mounting point compatibility. Components must be specifically designed for the vehicle make, model, and year to guarantee correct fitment and optimal performance.

Question 6: How does installation complexity impact the overall cost of replacing these components?

Installation complexity directly influences the cost. Complex installations may necessitate specialized tools and professional assistance, increasing labor costs. Simpler designs facilitate do-it-yourself installation, reducing expenses. Improper installation, regardless of complexity, can lead to reduced performance and potential damage.

The information provided above offers a concise overview of critical aspects related to exhaust system noise reduction and terminal outlets. Understanding these facets facilitates informed decision-making regarding component selection, maintenance, and potential upgrades.

The following sections will explore advanced topics related to exhaust system optimization and performance enhancement.

Conclusion

The preceding analysis has illuminated the multifaceted considerations surrounding the selection, maintenance, and modification of the exhaust system’s noise-reducing element and terminal outlet. Key aspects, including material durability, corrosion resistance, aesthetic design, and vehicle compatibility, critically influence performance, longevity, and regulatory compliance.

Therefore, informed decision-making based on a comprehensive understanding of these interconnected factors is paramount. Further research and adherence to established guidelines will ensure optimal system functionality and mitigate potential adverse effects, contributing to both vehicle performance and environmental responsibility.